Aircraft panel high-lock bolt pressing-in device

A technology of aircraft wall panel and press-in device, which is applied in aircraft parts, transportation and packaging, metal processing and other directions, can solve problems such as poor assembly accuracy, and achieve the effects of avoiding micro-cracks, uniform force and reducing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

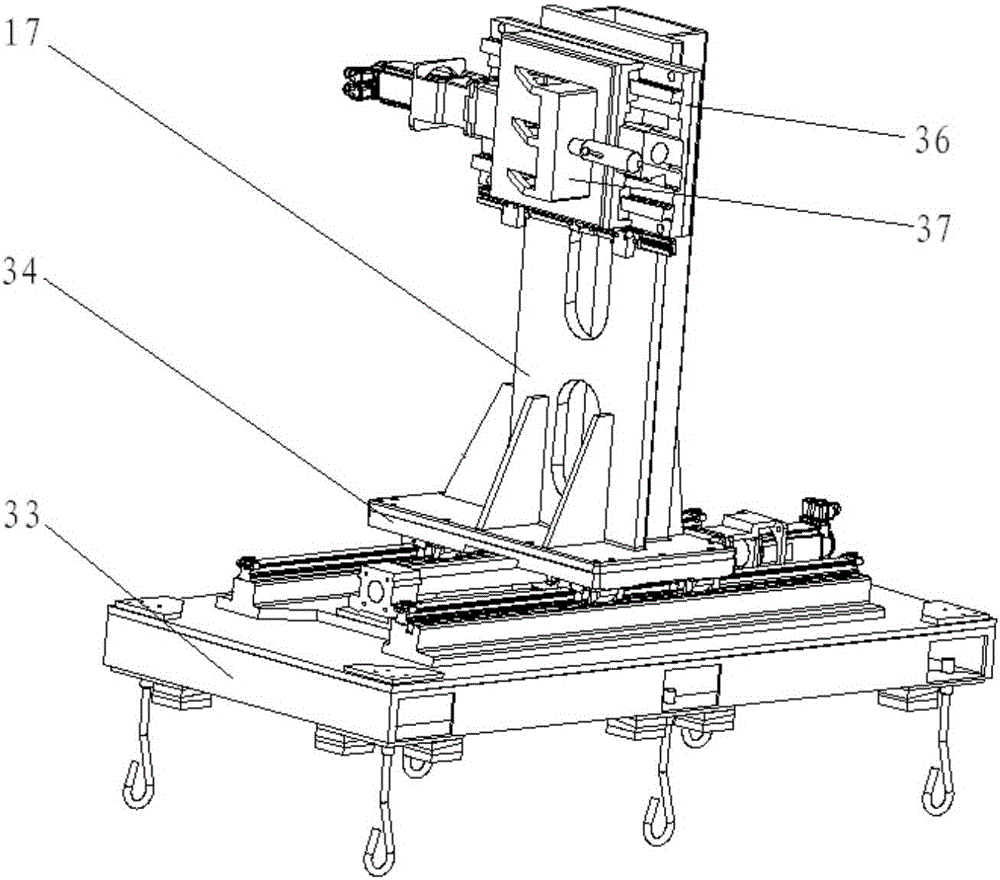

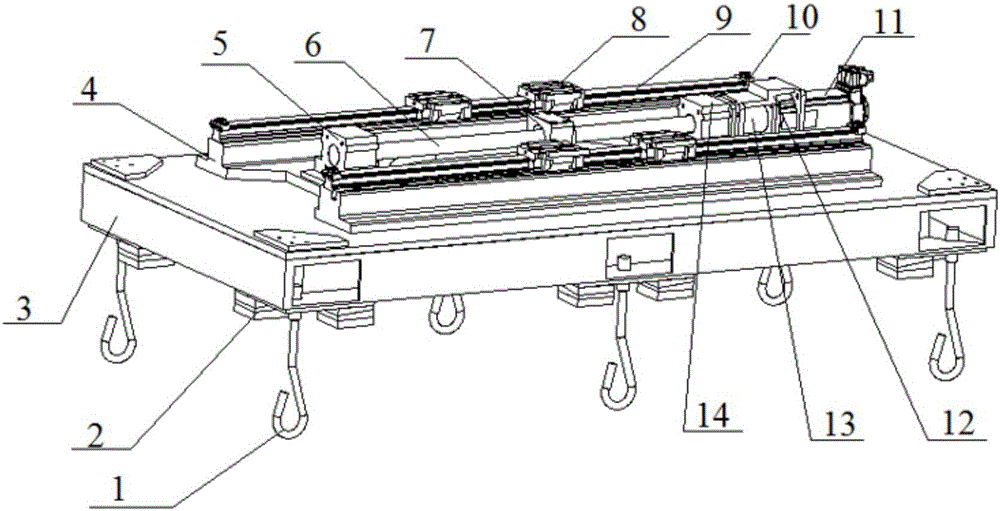

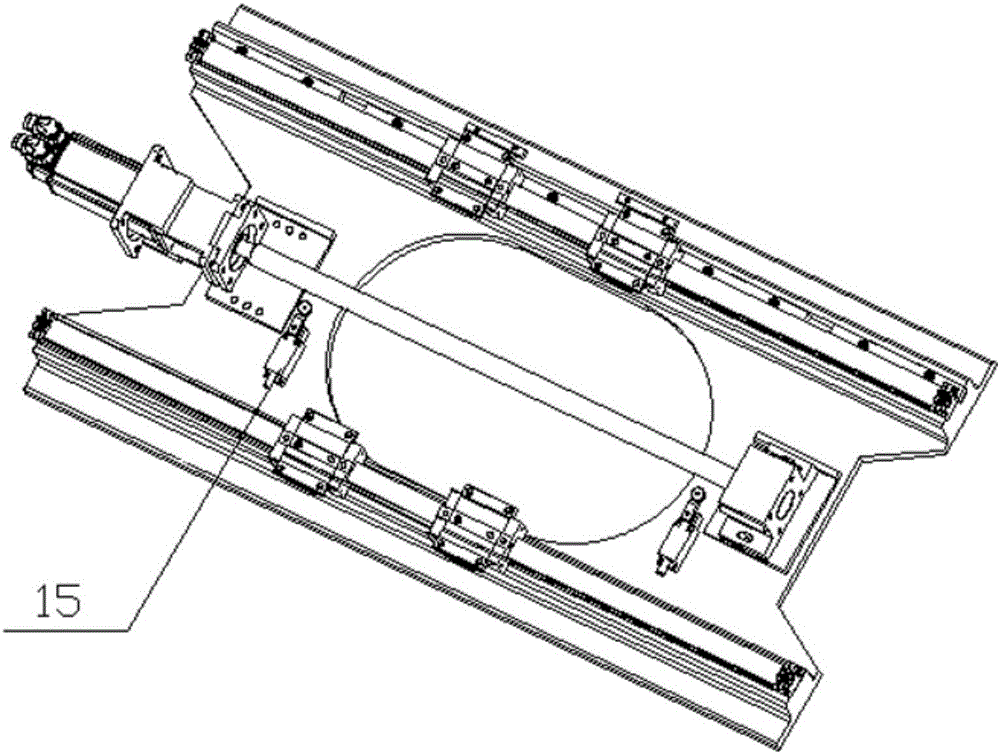

[0025] The following examples refer to Figure 1-8 .

[0026] The high lock bolt press-in device of the aircraft wall plate of the present invention comprises a support base 33 , an X-direction movable workbench 34 , a column 17 , a Y-direction movable structure 36 and an end effector structure 37 .

[0027]The support base 33 includes a cuboid base body 3 , an X-direction mobile platform support 4 , an X-direction mobile platform guide rail 9 , an X-direction mobile motor 11 , an X-direction mobile limit switch 15 and anchor bolts 1 . The base body 3 includes a square steel structure and a rectangular steel plate, and the rectangular steel plate is welded with the square steel to form the base body for supporting the entire installation equipment. The X-direction mobile platform bearing 4 is connected with the base body 3 by ordinary bolts, and is used to support the X-direction movement, and simultaneously connects the X-direction mobile platform guide rail 9 , the X-direct...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap