Bearing pedestal surface grinding equipment facilitating chip removal

A technology for surface grinding and bearing housing, which is used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., which can solve the problems of dust, increase labor and time costs, and take a long time for bearing housings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

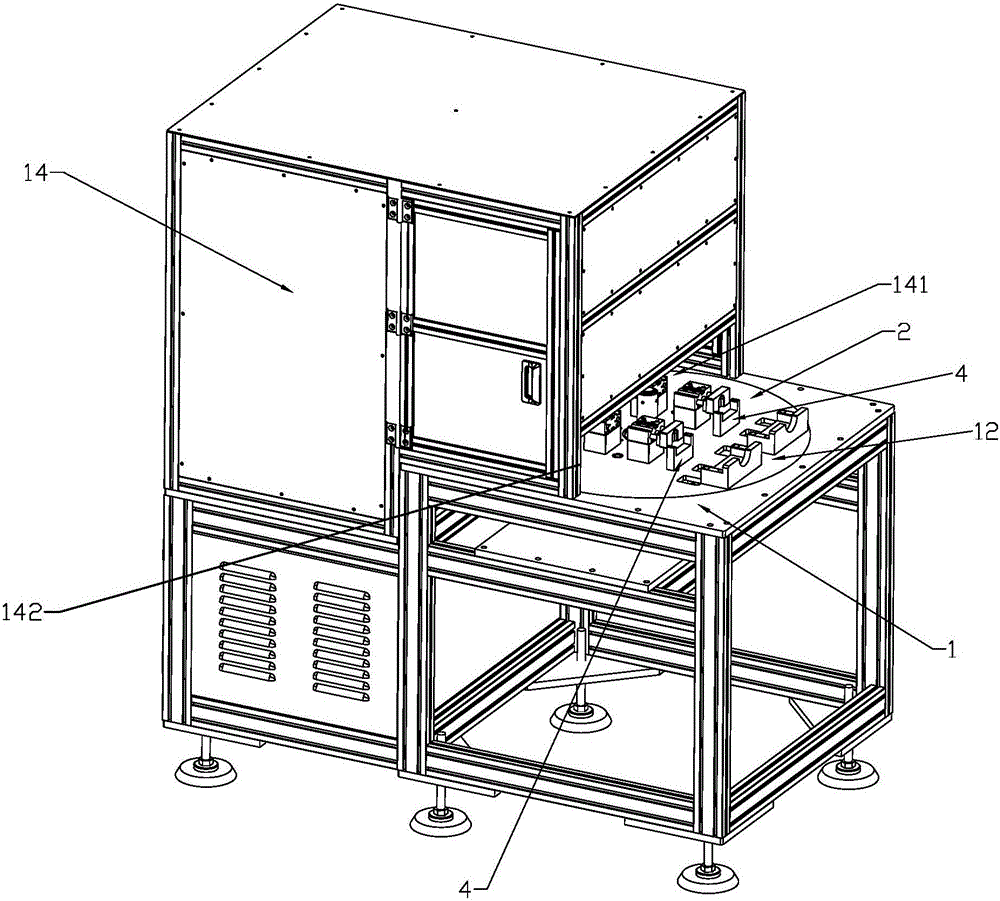

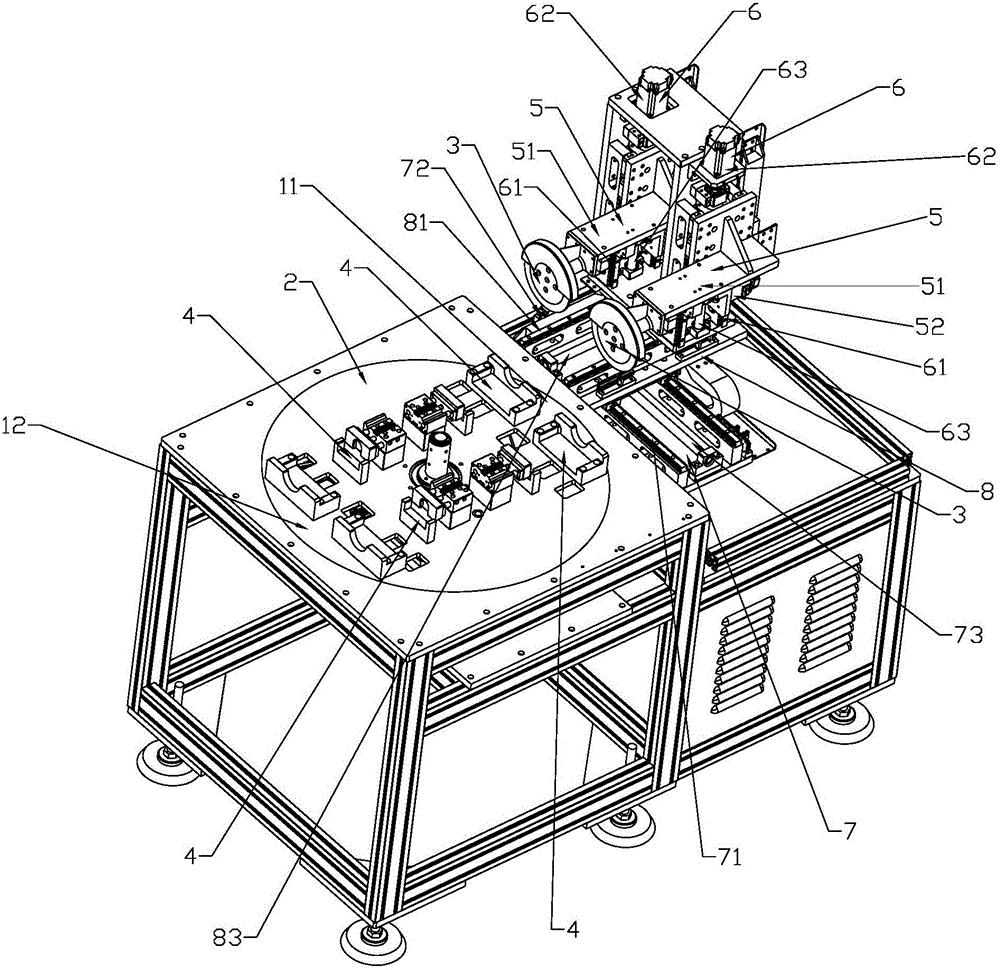

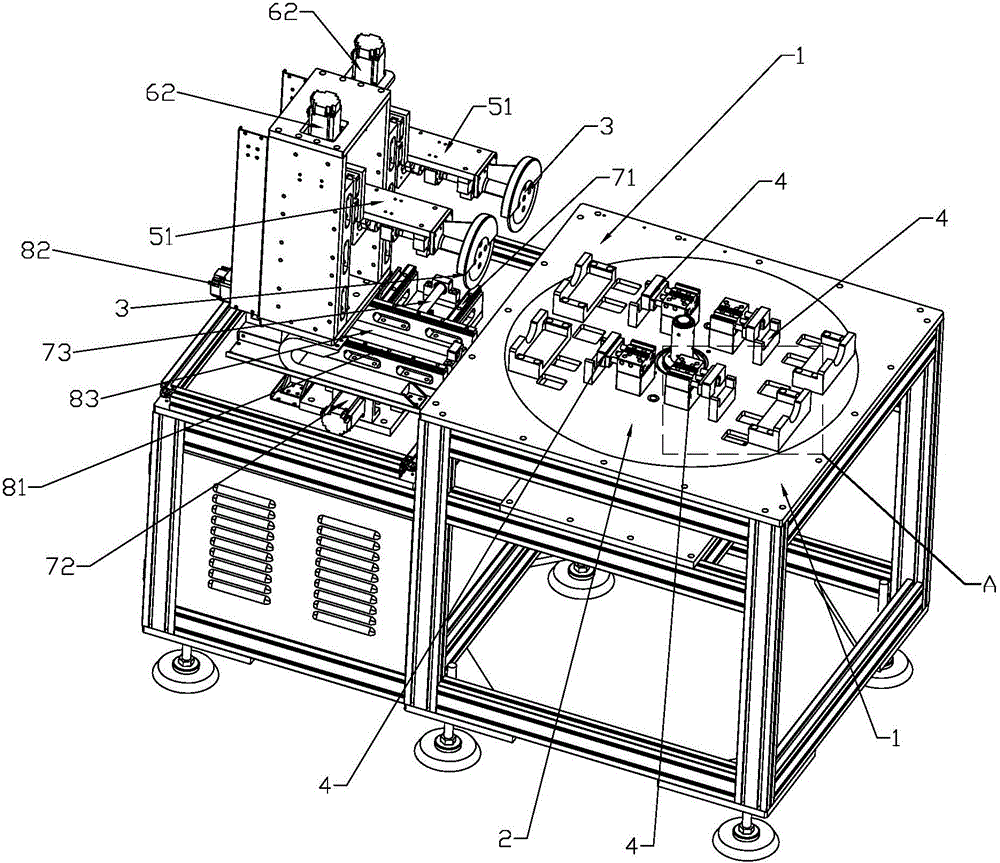

[0025] Such as figure 1 — Figure 6 As shown, the present invention discloses a surface grinding device for chip removal bearing housing, which includes a workbench 1, a main turntable 2, a main turntable rotation mechanism, a bearing seat fixing device, a grinding disc 3, a grinding disc rotation mechanism, and a grinding disc displacement mechanism, the main turntable rotation mechanism is a geared motor 22, the main turntable rotation mechanism is fixed on the workbench 1 and drives the main turntable 2 to rotate horizontally on the workbench 1, and the grinding disc displacement mechanism is fixed on the workbench 1 to drive the grinding disc 3 and grind The disc rotation mechanism is close to and away from the main turntable 2. The worktable 1 is provided with a processing position 11 corresponding to the position of the grinding disc 3 and a refueling position 12 far away from the grinding disc 3 on the moving track of the main turntable. The upper end of the main turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com