Cylinder Safety Lock Device in Single Polishing Machine

A polishing machine and safety lock technology, applied in the mechanical field, can solve problems such as no technical solutions provided, and achieve high practical value, high stability, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

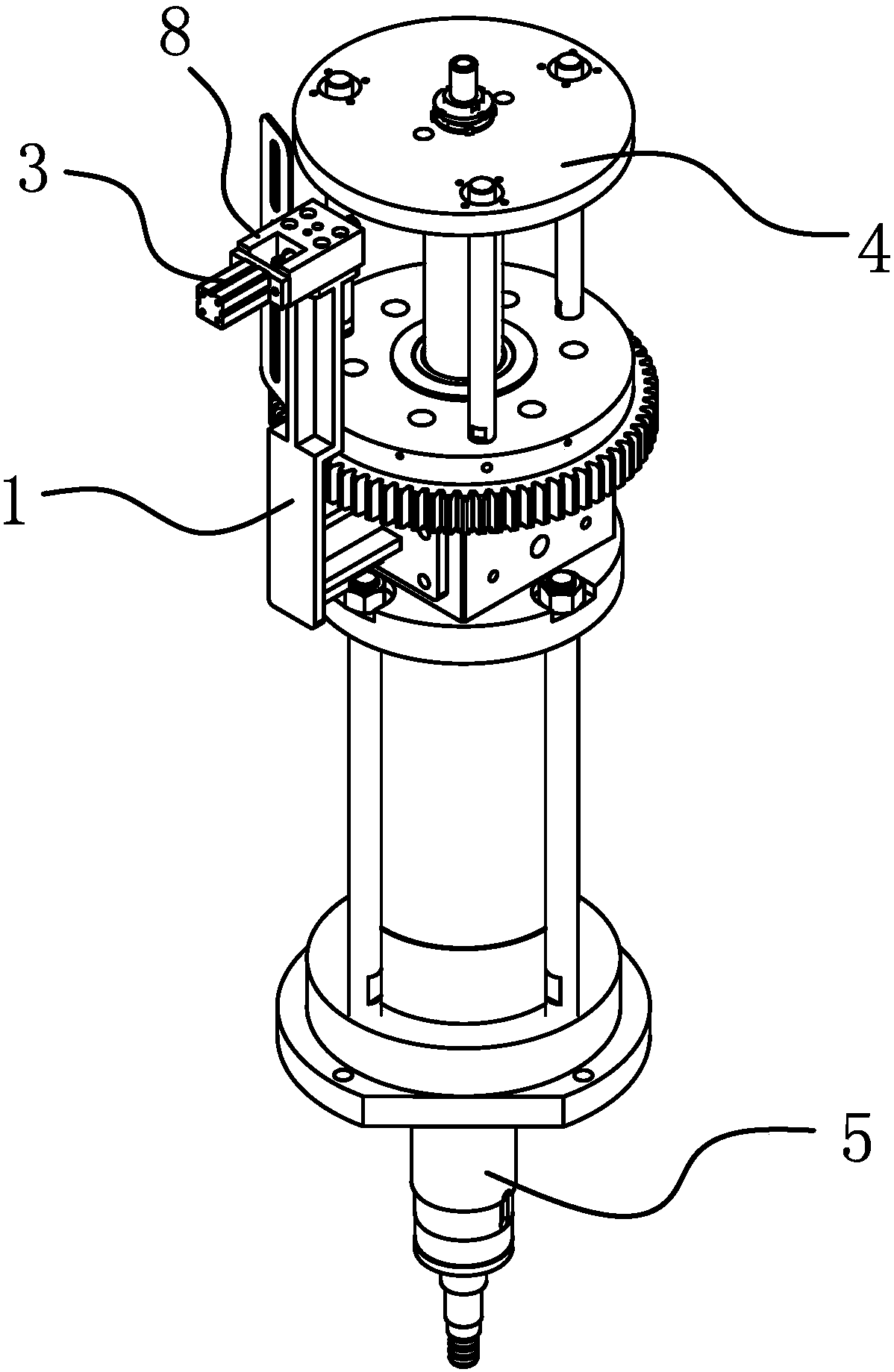

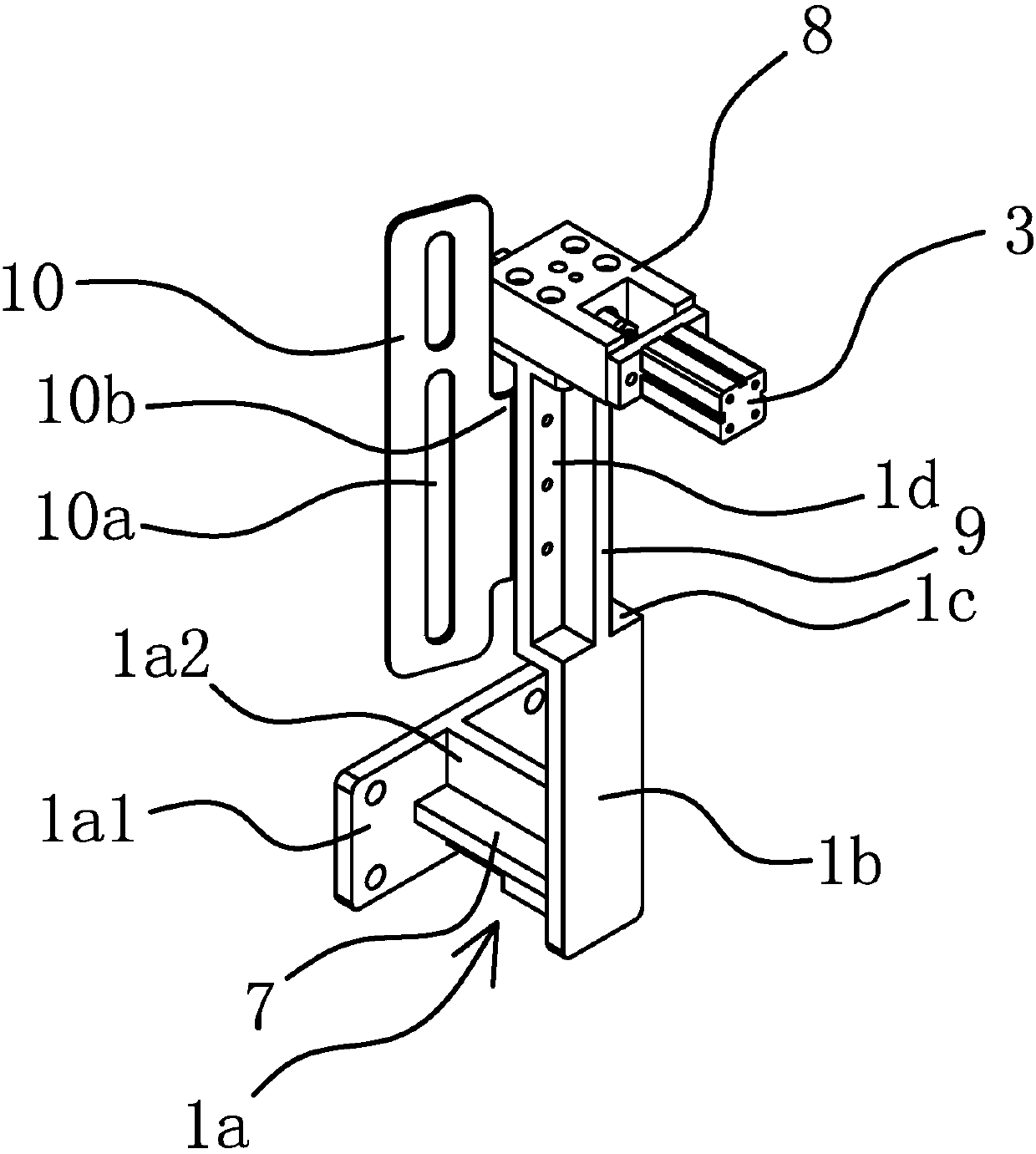

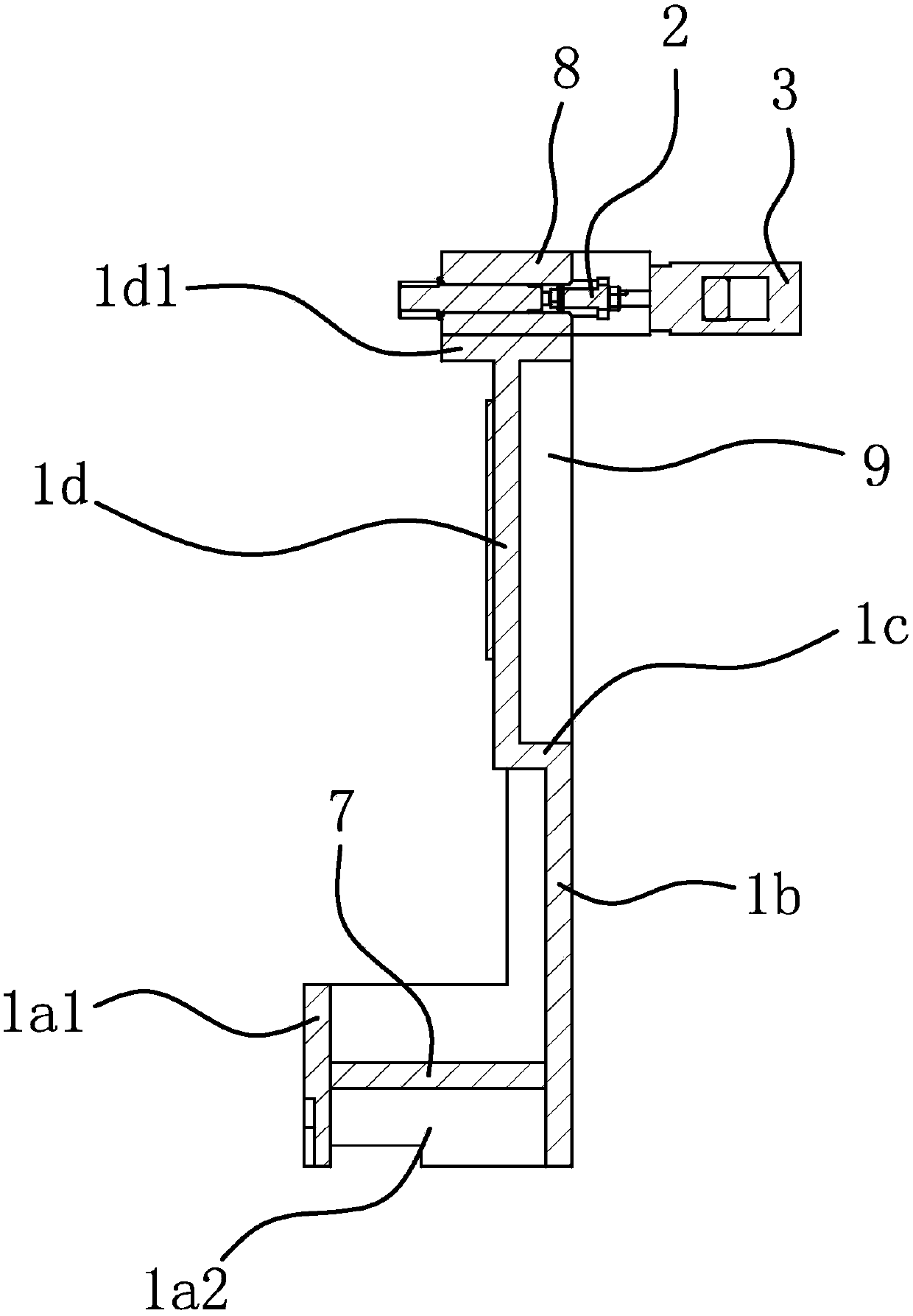

[0042] like figure 1 and figure 2 As shown, the cylinder safety lock device in the single polishing machine is arranged at the cylinder of the single polishing machine, and it includes a bracket 1, a locking rod 2, a driver 3, a pressure plate 4 and an inductor. The above-mentioned bracket 1 is in the shape of a long plate, Described support 1 is arranged in parallel with the cylinder block of cylinder and the bottom of support 1 is the connection part 1a that is used to link with cylinder, and above-mentioned locking bar 2 and driver 3 are all connected on support 1 top, and above-mentioned pressure plate 4 is used for On the cylinder shaft 5 fixedly connected to the cylinder, the inductor 6 is also connected to the support 1 and when the cylinder moves up, the inductor 6 can send a signal to make the driving part 3 act. After the driving part 3 moves, it can Drive the locking rod 2 to stretch out and block the lower part of the pressure plate 4.

[0043] like image 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com