Fully automatic cardboard box production equipment

A kind of production equipment and fully automatic technology, applied in the direction of papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of inefficient production speed, inability to realize online production, slow carton production speed, etc., and achieve simple structure , Reduce human labor, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

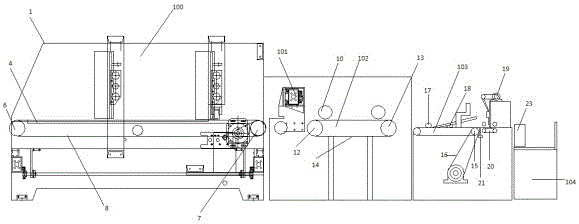

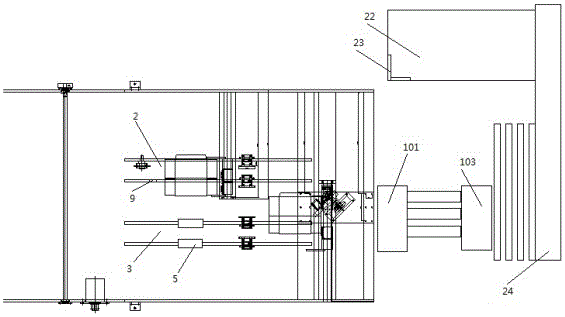

[0015] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0016] Refer to attached figure 1 , the present invention provides a fully automatic carton production equipment, comprising a frame 1, a cardboard conveying device 100, a common carton binding machine 101, a carton conveying mechanism 102, a fully automatic folding nail box mechanism 103 and a carton storage device 104, the cardboard conveying Device, ordinary carton binding machine, carton conveying mechanism, fully automatic folding and nailing mechanism and carton storage device are arranged on the frame from left to right. The cardboard conveying device includes the first conveying platform 2, the second conveying platform 3, The cardboard 4 and the transmission mechanism, the cardboard 4 is placed on the first conveying platform 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com