Cone container supporting structure

A technology of support structure and cone, applied in the field of support structure, can solve the problems of high strength requirement of upper wall plate and deformation of lower cone wall plate under pressure, and achieve the effect of reducing force and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail with reference to the accompanying drawings and embodiments:

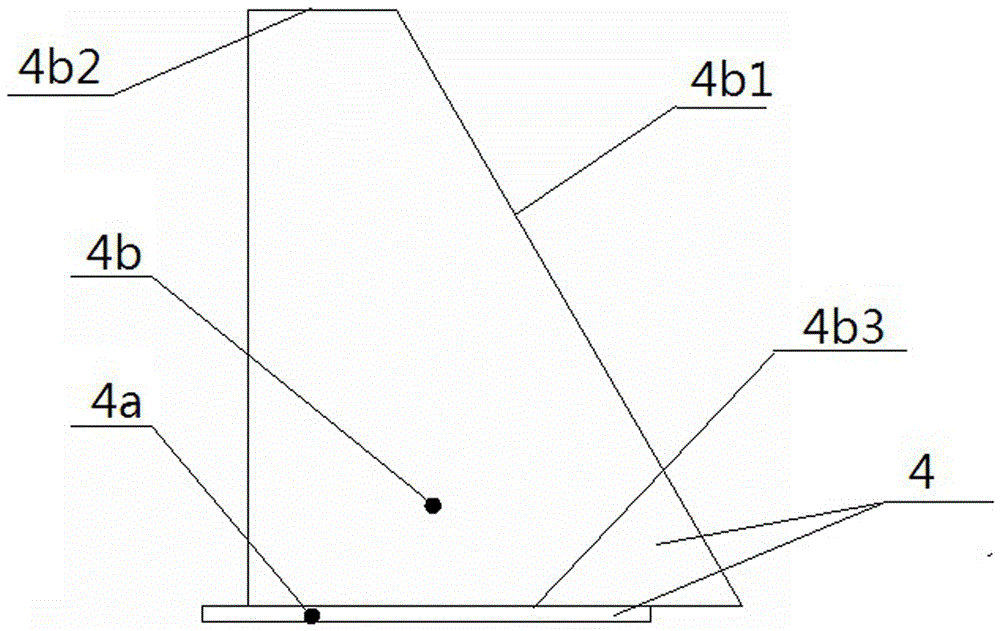

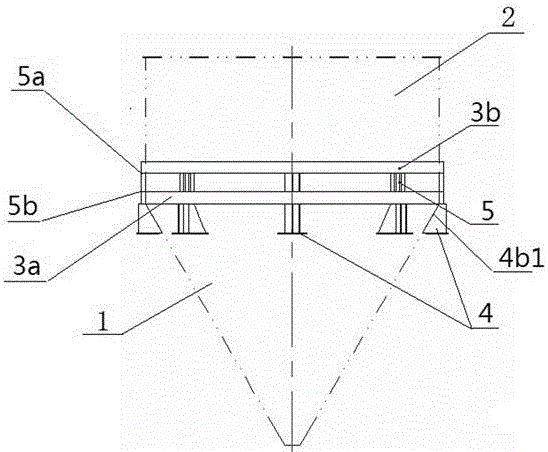

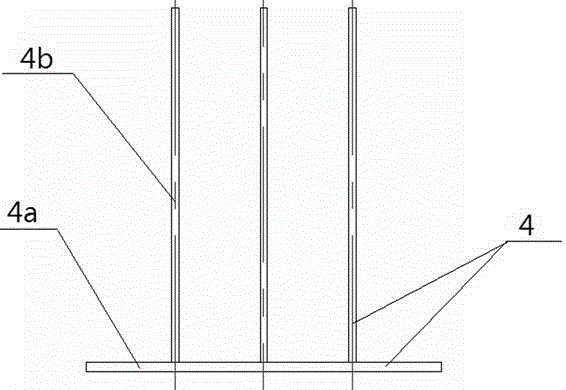

[0010] As shown in the figure, the present invention includes two channel steel rings fixed on the outer side wall of the upper cylindrical container 2 of the cone 1 by welding up and down. The special feature is that a number of support members are provided around the lower side of the next channel steel ring 3a 4. The support 4 includes a bottom steel plate 4a placed horizontally and two or more trapezoidal steel plates 4b fixed side by side and vertically on the bottom steel plate 4a. The hypotenuse 4b1 of the trapezoidal steel plate 4b is welded and fixed to the outer surface of the cone 1, and the trapezoidal steel plate 4b The upper side 4b2 is welded to the bottom of the next channel steel ring 3a, and the lower side 4b3 of the trapezoidal steel plate 4b is welded and fixed to the horizontally placed bottom steel plate 4a. A rectangular steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com