A Xiwa U-turn machine

A technology of silo and frame, which is applied in the component field of silo production line, can solve problems such as many defective products and scratches, and achieve the effect of simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

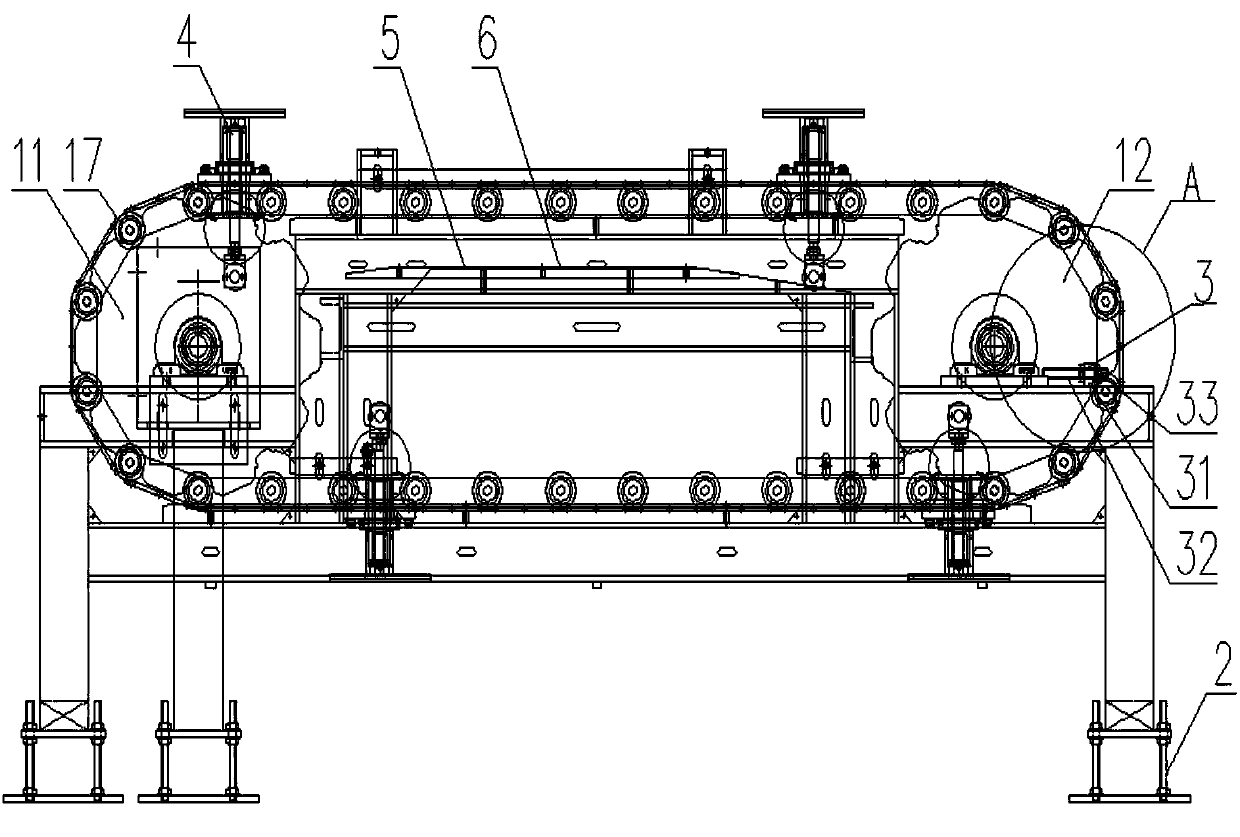

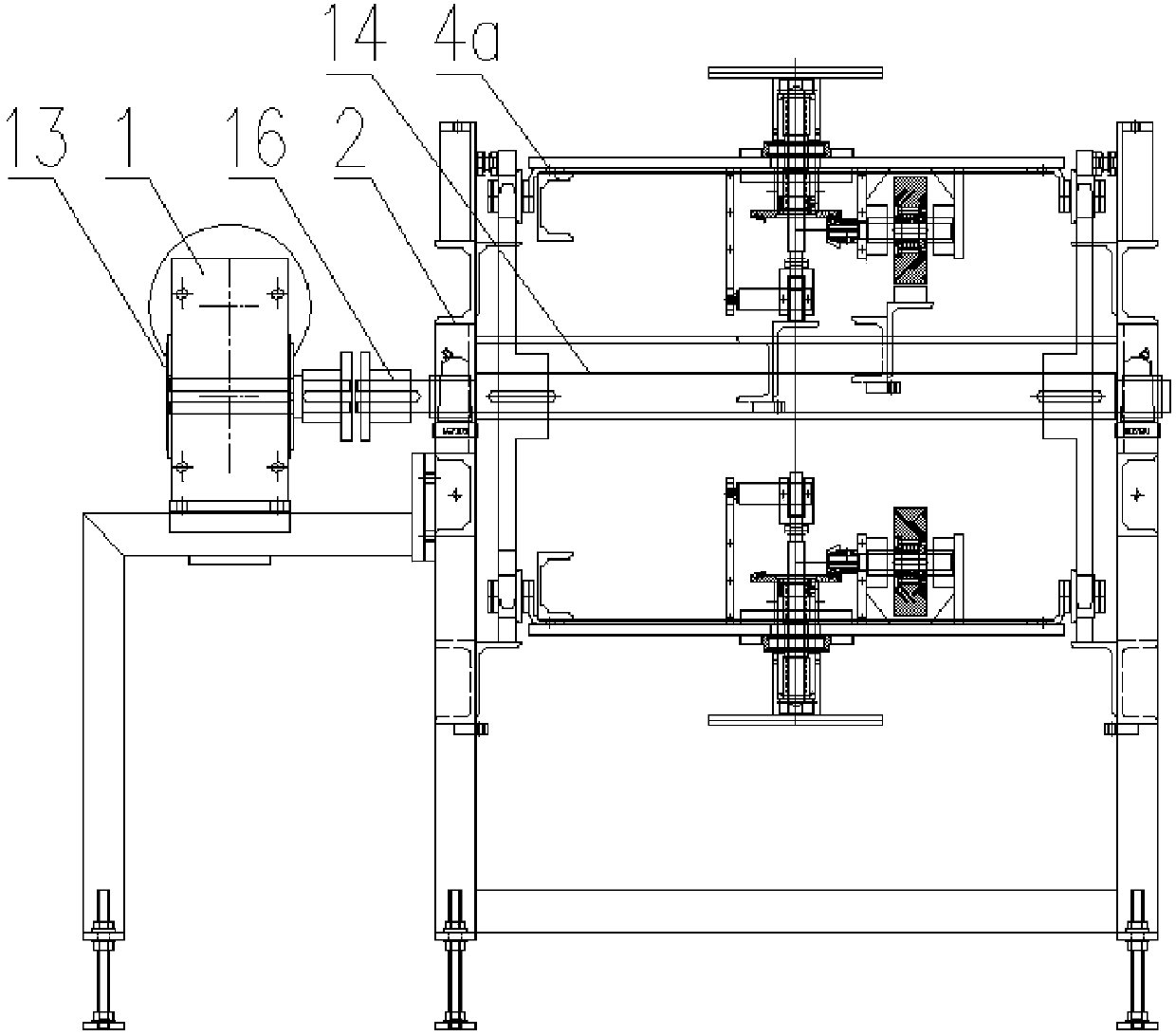

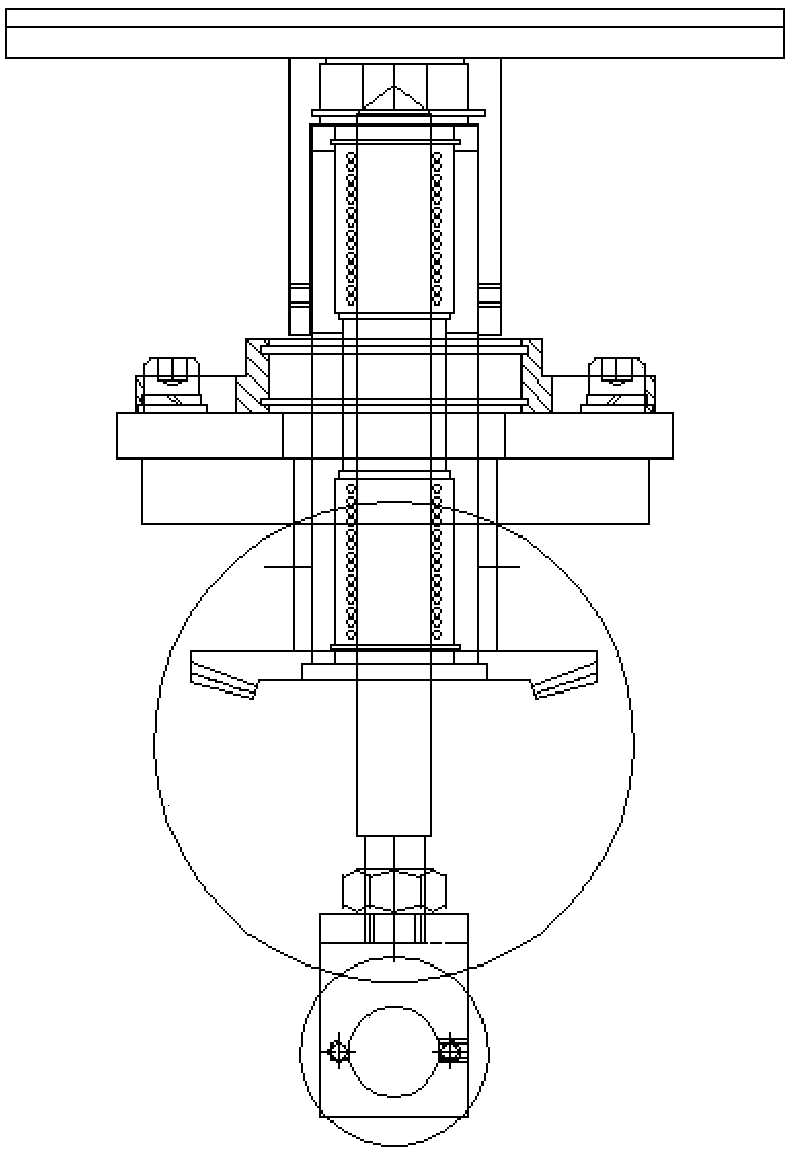

[0029] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, a Xiwa U-turn machine, its structure includes a driving device 1, a frame 2 and a tensioning device 3, the driving device 1 and the tensioning device 3 are respectively fixedly connected with the frame 2, and the driving device 1 includes a drive sprocket 11, from Moving sprocket 12, reduction motor 13, driving shaft 14, driven shaft, shaft coupling 16 and chain 17, driving sprocket 11 is fixed on the driving shaft 14 by the key bar, and through shaft coupling 16 and reduction motor 13 The driven sprocket 12 is fixed on the driven shaft through a key bar, and the driving sprocket 11 and the driven sprocket 12 on the same side are connected by a chain 17 to facilitate synchronous operation, and a tile steering device is also included. 4. The friction wheel transmission key strip 5 and the lifting wheel transmission key strip 6, and the tile steering device 4 are evenly distributed on the chain 17, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com