Automatic reloading system

An automatic and material technology, applied in the direction of thin material processing, coiling strips, transportation and packaging, etc., can solve the problems of low production efficiency, short normal working hours of the host, and failure of the host to operate, so as to improve production efficiency and ensure normal operation. Working time and improvement of molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

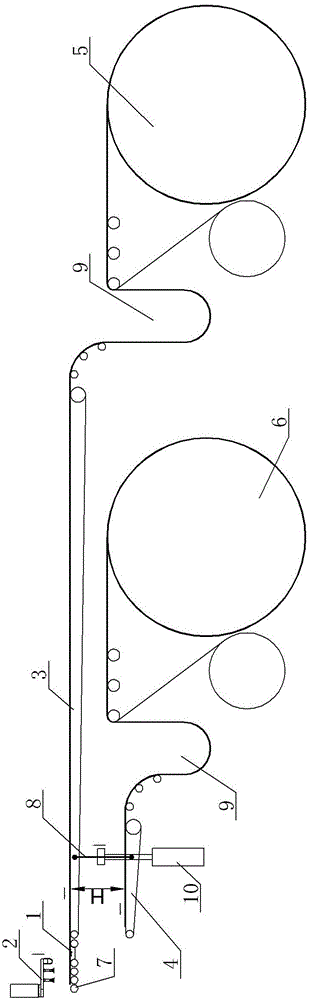

[0018] Specific embodiment one, see figure 1 : the No. 1 material conveyor belt 3 is located directly above the No. 2 material conveyor belt 4, and the height difference is H; the No. 1 guide uncoiling mechanism 5 is located behind the No. 2 guide uncoil mechanism 6; Connecting fasteners 8 are arranged between the output ends of the No. material conveying belt 3, and a cylinder 10 that can be vertically lifted is connected outside the fastening connector 8;

[0019] The driving stroke driven by the vertical lifting cylinder 10 is the height difference H of the two material conveyor belts, ensuring that when the No. 1 material conveyor belt 3 is short of material, the fast position of the No. 2 material conveyor belt 4 reaches the original position of the No. 1 material conveyor belt 3.

specific Embodiment 2

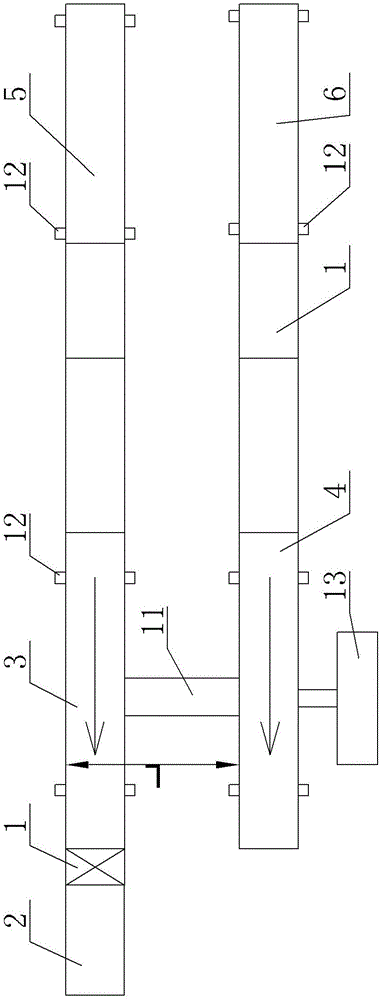

[0020] Specific embodiment two, see figure 2 : No. 1 material conveyor belt 3 and No. 2 material conveyor belt 4 are arranged in parallel on the same horizontal plane, and the horizontal distance between them is L. No. 1 guide uncoiling mechanism 5 is located directly behind the input end of No. 1 material conveyor belt 3. The uncoiling mechanism 6 is located directly behind the input end of the No. 2 material conveyor belt 4, and a connecting rod 11 is arranged between the No. 1 material conveyor belt 3 and the No. 2 material conveyor belt 4. The bottom is provided with a moving structure 12, and one side of the No. 2 material conveyor belt 4 is provided with a horizontal drive cylinder 13. The output end of the horizontal drive cylinder 13 is fixed on the side of the No. 2 material conveyor belt 4. The horizontal drive cylinder 13 The driving stroke is the horizontal distance L between the two material conveyor belts, ensuring that when the No. 1 material conveyor belt 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com