Full hydraulic rock tunnel drilling device

A fully hydraulic and support device technology, which is applied in the field of drilling devices and fully hydraulic rock tunnel drilling devices, can solve the problems of tree disturbance, waste of resources, and large occupied area, so as to achieve full utilization, improve construction efficiency, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

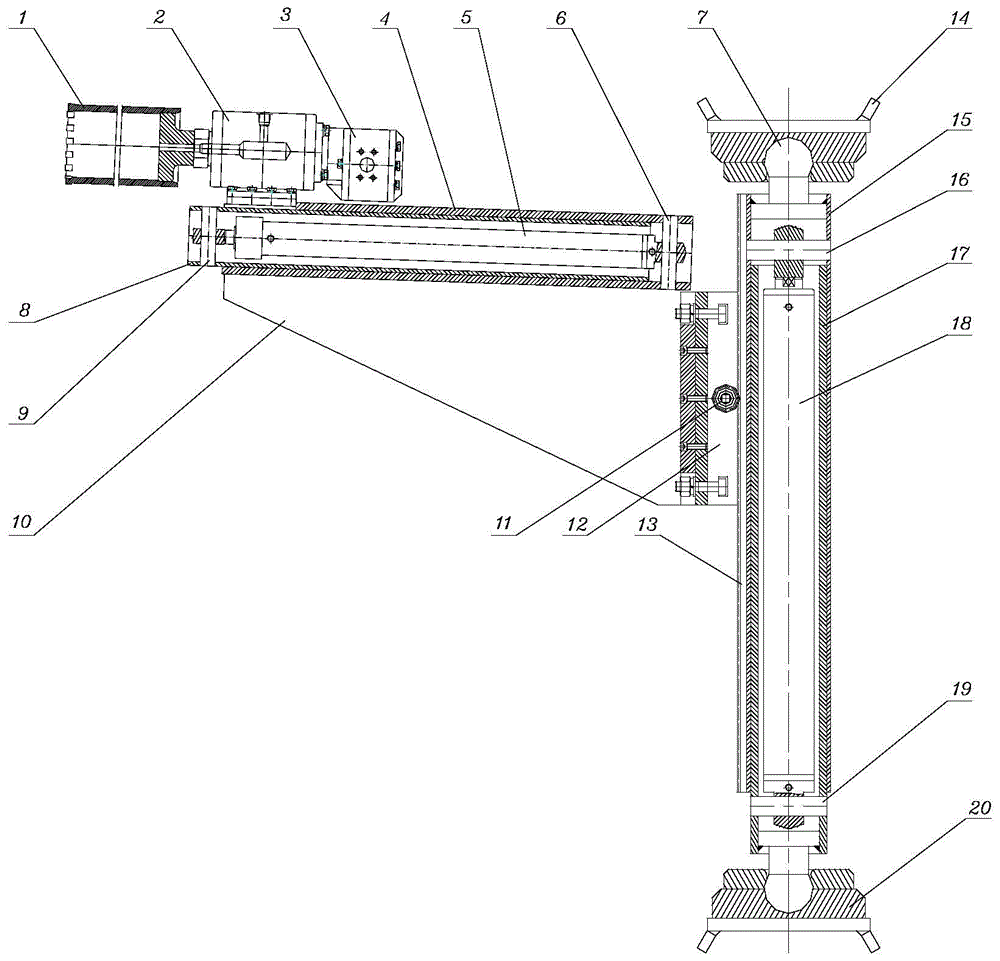

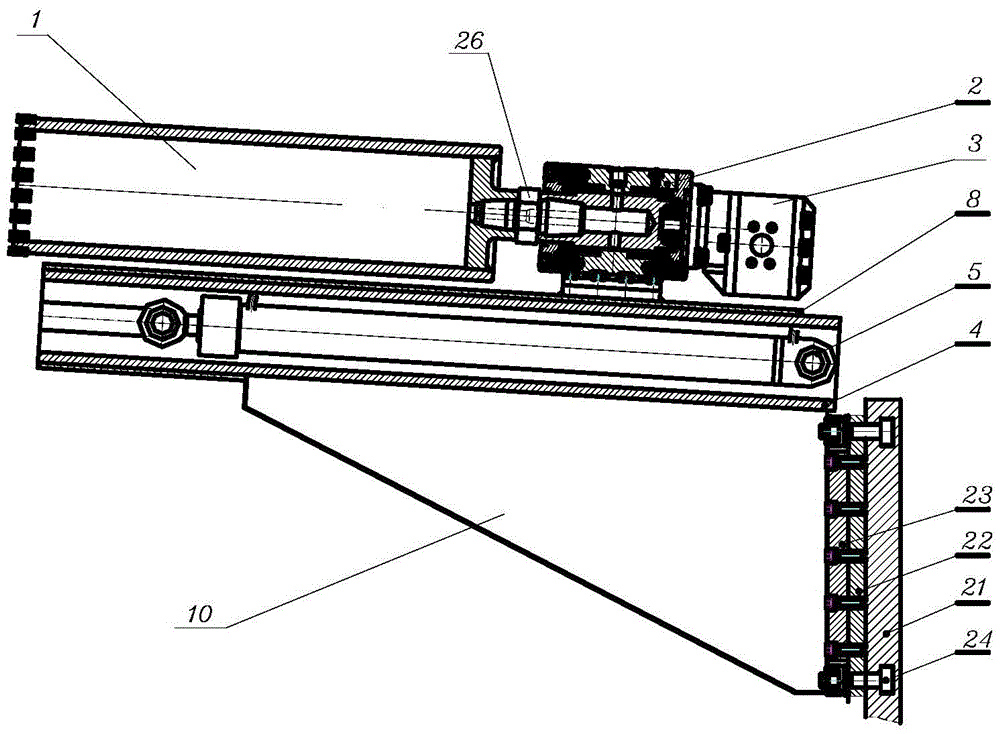

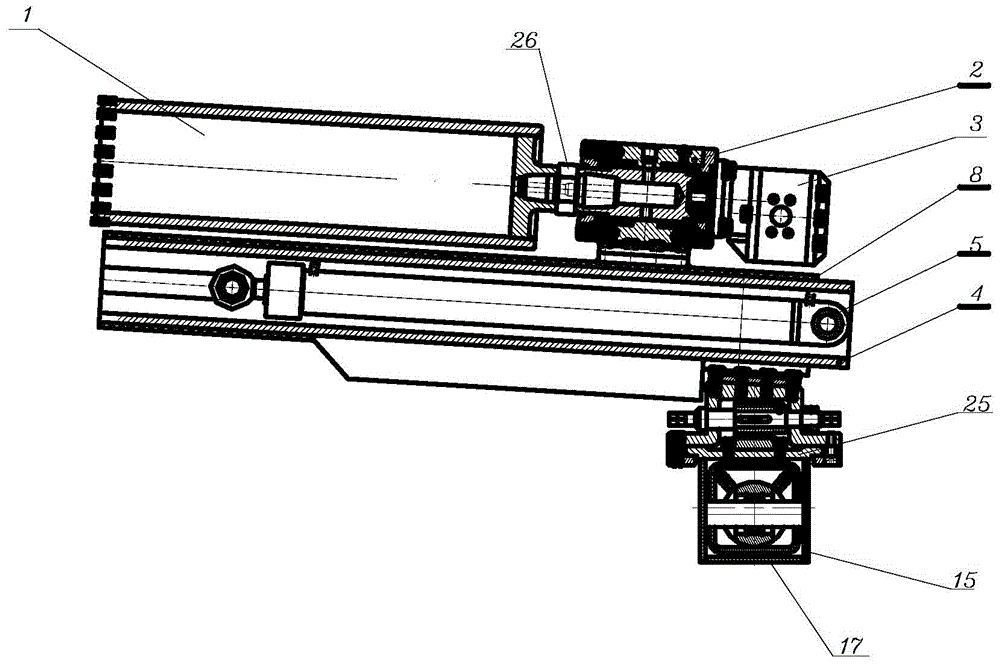

[0019] The structure of this embodiment is as Figure 1 to Figure 3 As shown, a drilling and rock splitting device includes a supporting device, the supporting device includes a strut fixed sleeve 17 containing a strut cylinder 18, the strut fixed sleeve 17 is externally connected with a strut movable sleeve 15, and the strut cylinder 18 passes through the The strut fixed sleeve hinge shaft 19 and the strut movable sleeve hinge shaft 16 connect the strut fixed sleeve 17 and the strut movable sleeve 15, and the two ends of the strut extend outward until the center of the support base 20, and the extended ends of the strut form a brace. The rod head 7 is connected with the depression in the center of the support base 20, and the design of the ball head is convenient for adjusting the support angle, so that the support is more stable. The supporting base 20 has a three-layer structure, and the layer width increases layer by layer from top to bottom. The lower end of the base is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com