Self-suction type oil pump used for hydraulic retarder

A hydraulic retarder and self-priming technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pumps, etc., can solve the problem of long gas discharge time, poor self-priming effect, and oil absorption Slow speed and other problems, to achieve the effect of simple structure, increase work efficiency and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

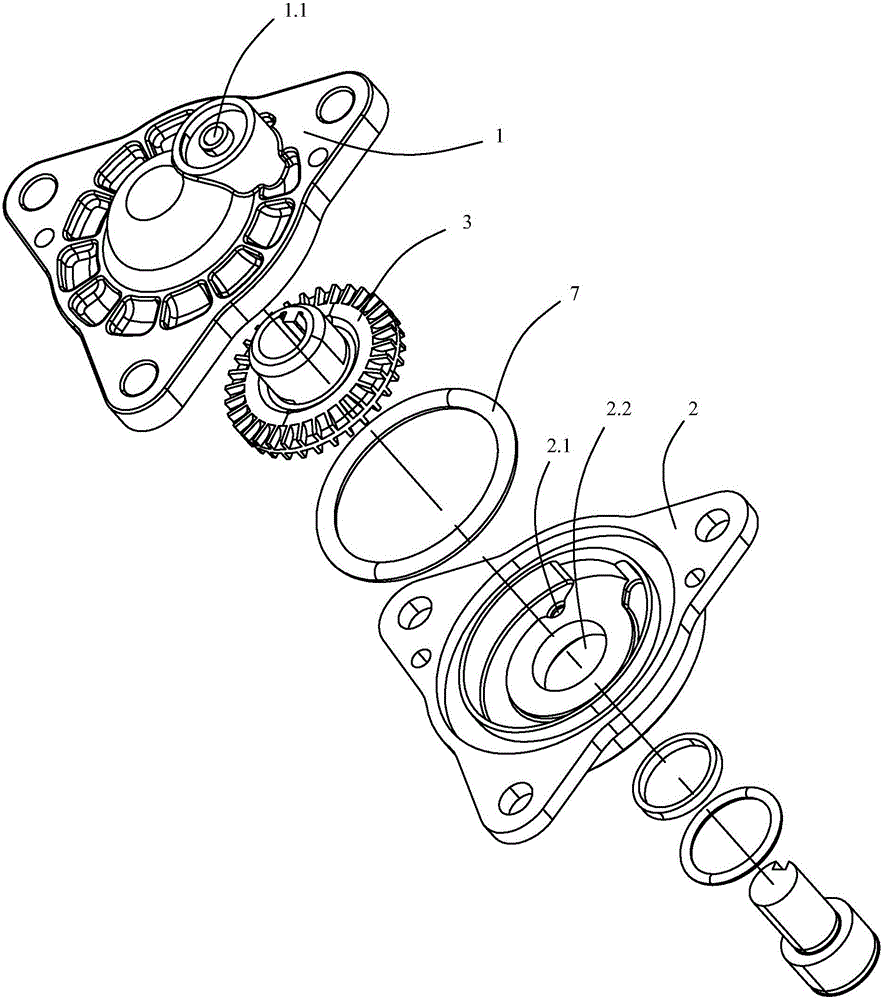

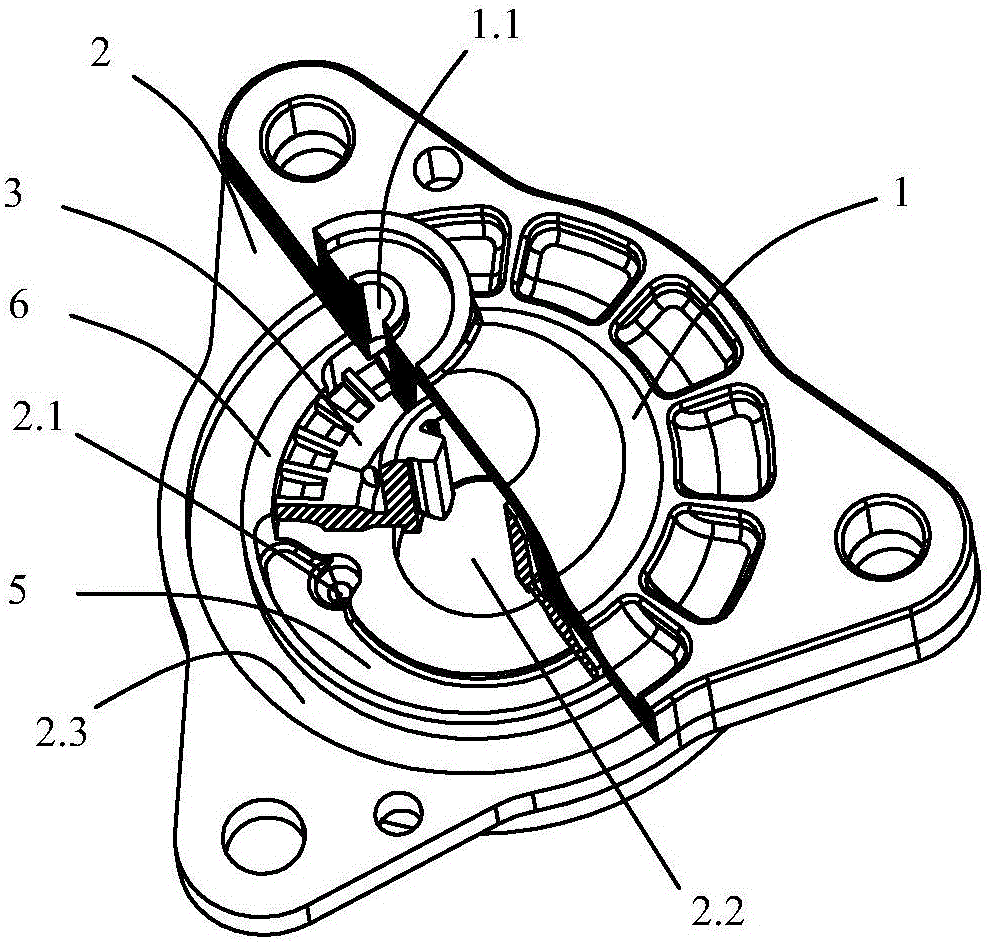

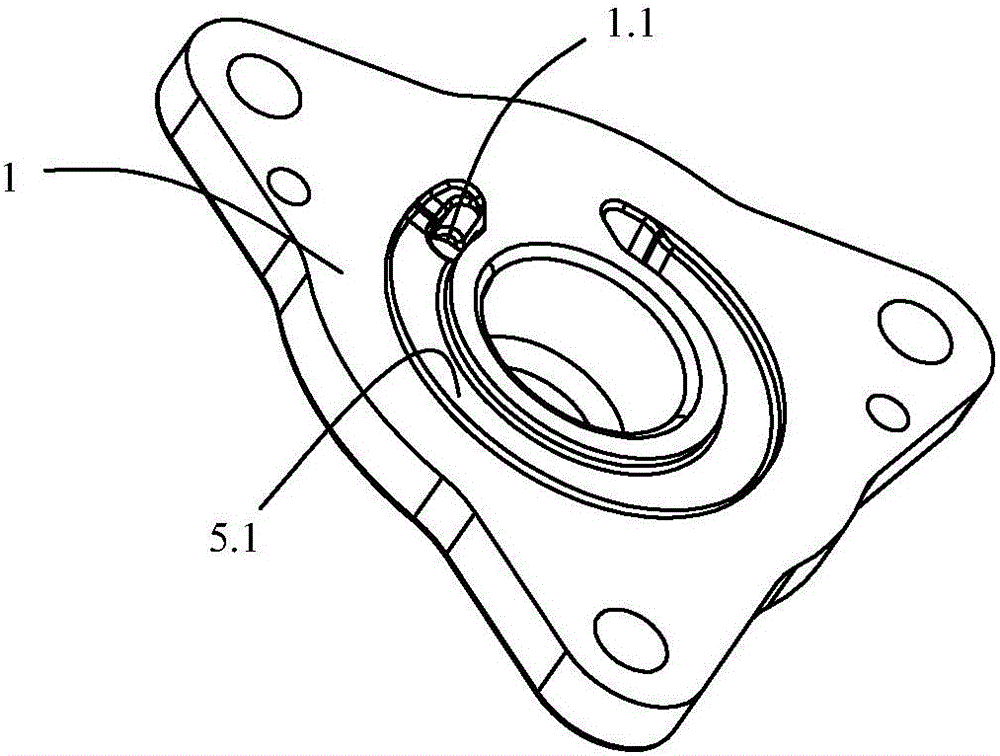

[0019] See attached figure 1 to attach Figure 5 As shown, the self-priming oil pump used in the hydraulic retarder of the present invention includes a pump body and an impeller 3 placed in the pump body; 2 connected, specifically, can be screwed; the first housing 1 is provided with an oil inlet hole 1.1; the second housing 2 is provided with an oil outlet 2.1; the first housing 1 and After the second housing 2 is connected, a circular cavity 4 for accommodating the impeller 3 and an oil passage 5 communicating with the oil inlet hole 1.1 and the oil outlet hole 2.1 are formed; An oil groove 5.1 and a second oil groove 5.2 provided on the second casing 2, after the first casing 1 and the second casing 2 are connected, the first oil groove 5.1 and the second oil groove 5.2 cooperate to form an oil passage 5; The oil passage 5 is annularly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com