Rubber ring and ball type one-way clutch

A technology of one-way clutches and rubber rings, which is applied in one-way clutches, clutches, mechanical equipment, etc., can solve the problems of inflexible ball rotation, large spring force, and burning out, and solve the phenomenon of tooth beating and top teeth, manufacturing Simple processing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

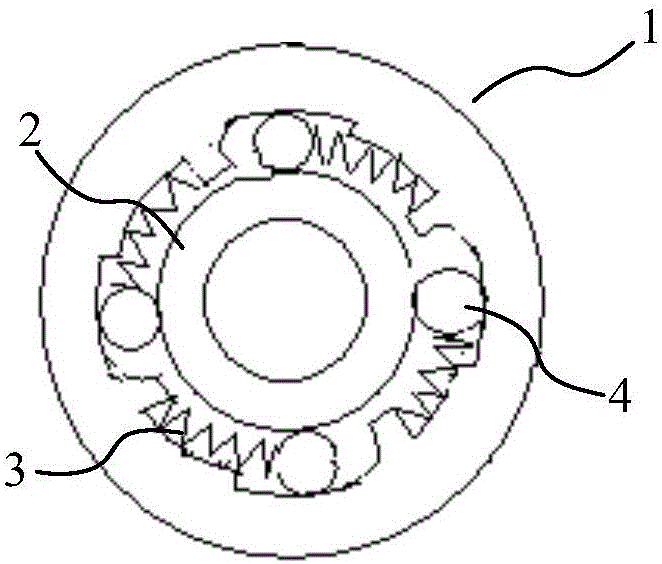

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

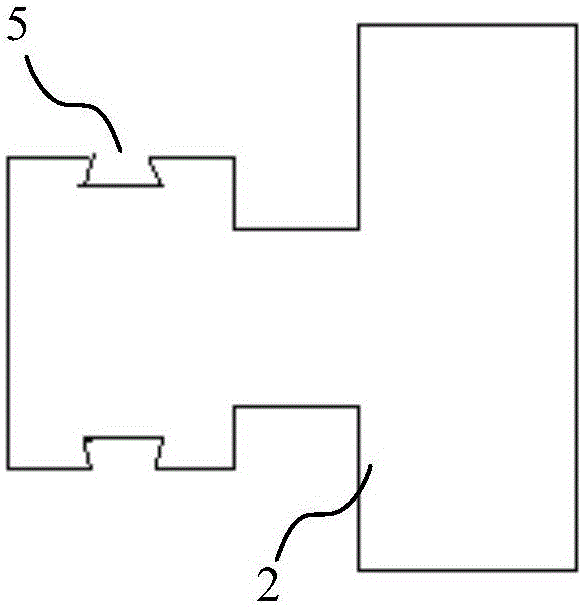

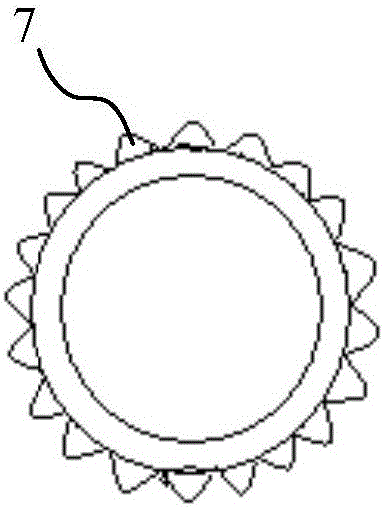

[0030] see figure 2 , the present invention includes a housing, and a driving wheel 1 and a pinion 2 arranged in the housing; a circle of rectangular grooves 5 is provided on the outer surface of the pinion 2, and an oil seal is provided on the rear end surface of the pinion 2 when the pinion reverses. Effect pattern. A rubber ring is fixedly bonded to the rectangular groove 5 by glue, and the outer surface of the rubber ring is provided with a toothed structure 7, and the surface of the toothed structure 7 is provided with patterns for increasing friction. The depth of the rectangular groove 5 is 2 mm, the height of the bottom part of the rubber ring in the rectangular groove 5 is 1.5 mm, and the height of the toothed structure 7 on the upper part of the rubber ring is 1 mm. The top of the rubber ring is higher than the outer surface of the pinion 2; at least three...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap