High-low-temperature oil cooling machine used in cooperation with test of traction motor

A technology for traction motors and oil coolers, applied to refrigerators, compressors, refrigeration components, etc., can solve problems such as inability to accurately detect pressure, manual flow adjustment, and inability to simulate high and low temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

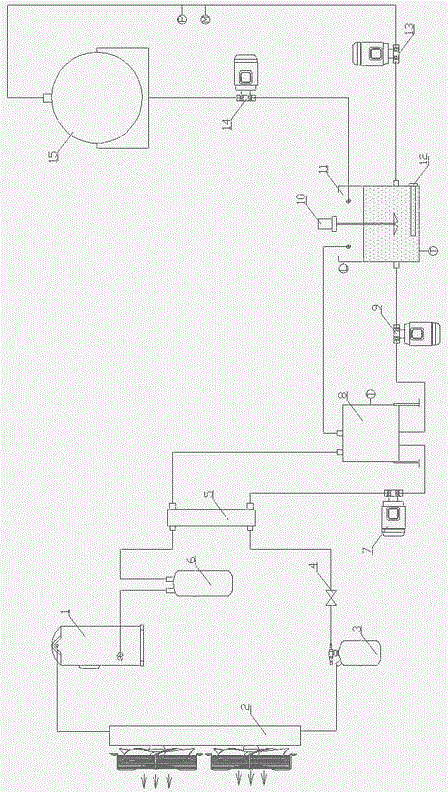

[0018] The present invention will be further described in conjunction with accompanying drawing

[0019] 1. Refrigeration unit: The refrigeration unit refrigeration system of this system consists of compressor (1), air-cooled condenser (2), throttling device (4), plate heat exchanger (5) and other main components, liquid storage tank (3 ), gas-liquid separator (6) and other corresponding accessories to provide a constant cooling source for the entire equipment, and the temperature sensor (M) in the oil tank A (8) senses the temperature change in the oil tank and uploads it to the PLC for control In the compressor, the temperature of the oil tank A is always controlled at a lower temperature range by adjusting the output power of the compressor controlled by the PLC controller. The temperature control range of fuel tank A is within 5°C±1°C, and its temperature value can be set by the host computer or manually

[0020] 2. Internal circulation system: Oil tank A (8) is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com