Mounting device for ultrasonic heat meter reflector

A technology for installing devices and reflectors, which is applied in the direction of measuring devices, measuring heat, calorimeters, etc., can solve the problems of poor installation efficiency and low precision of ultrasonic heat meter reflectors, and achieve vibration displacement prevention, efficiency improvement, and pressure resistance uniform left and right effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

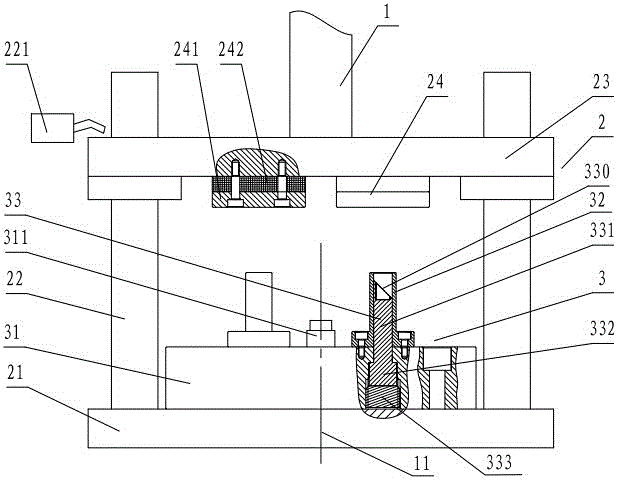

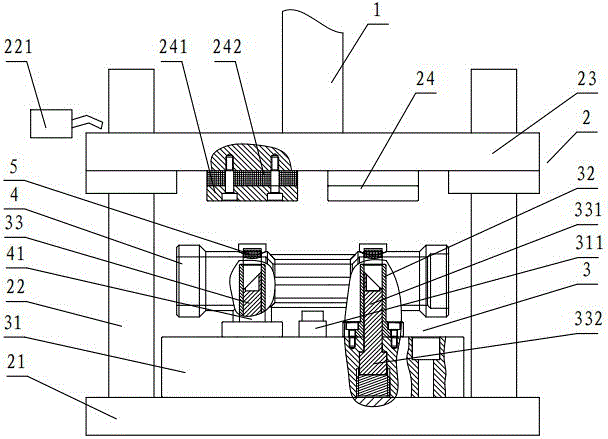

[0020] see figure 1 shown and figure 2 As shown, an installation device for an ultrasonic heat meter reflector includes a press punch 1 , a pressing device 2 and a positioning device 3 . The pipe section body 4 and the reflector 5 of the ultrasonic heat meter are placed on the positioning device 3, and the punch 1 of the press provides the power for punching downward, so that the pressing device 2 acts on the pipe section body 4 to press the reflector. Install.

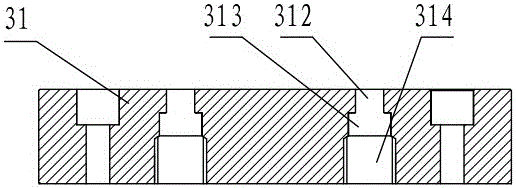

[0021] see figure 1 and figure 2 As shown, the pressing device 2 includes a base plate 21 , guide posts 22 fixed at both ends of the base plate 21 , a press plate 23 movably socketed with the guide posts 22 , and a press block 24 mounted on the press plate 23 . The pressing block 24 can be composed of a metal plate 241 and a tendon plate 242 . The tendon plate 242 and the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com