Glued laminated timber side splicing solid wood floor

A technology of solid wood flooring and glulam, applied in the field of glulam side-jointed solid wood flooring, can solve problems such as poor dimensional stability, warping deformation, dimensional deformation, etc., achieve high wear resistance and strength, prevent compression deformation, and resist deformation strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

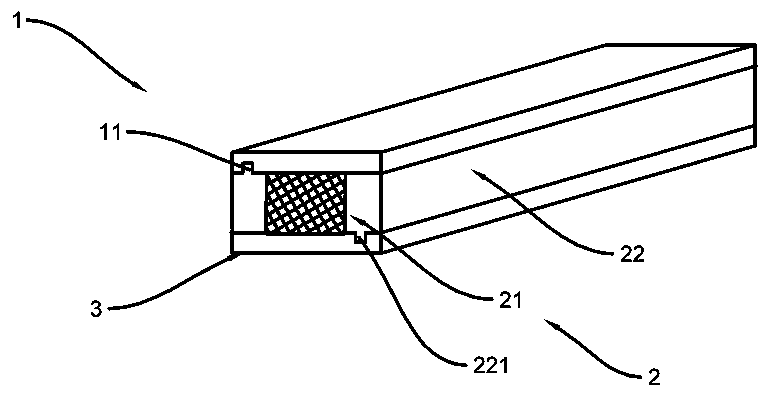

[0021] see figure 1 , a glulam side-jointed solid wood floor, which includes a surface layer 1, a base layer 2, and a bottom layer 3 from top to bottom. The wood board 21, the side splicing wood strips 22 arranged on both sides of the glued wood board 21 for clamping the glued wood board 21, the side splicing wood strips 22 are provided with holes that cooperate with the mortise 11 Tenon 221.

[0022] In the present invention, the glulam board 21 is arranged between the bottom layer 3 and the bottom plate of the surface layer 1, which can ensure the strength of the floor surface. Compared with the floor surface layer of the glulam board material in the prior art, the wear resistance and strength are higher. At the same time, side splicing wooden strips 22 are provided on both sides of the base material layer 2, which can play a supporting role. The tenon 221 is set on the side splicing wooden strip 22, and the surface layer 1 and the bottom layer 3 are provided with a mortis...

Embodiment 2

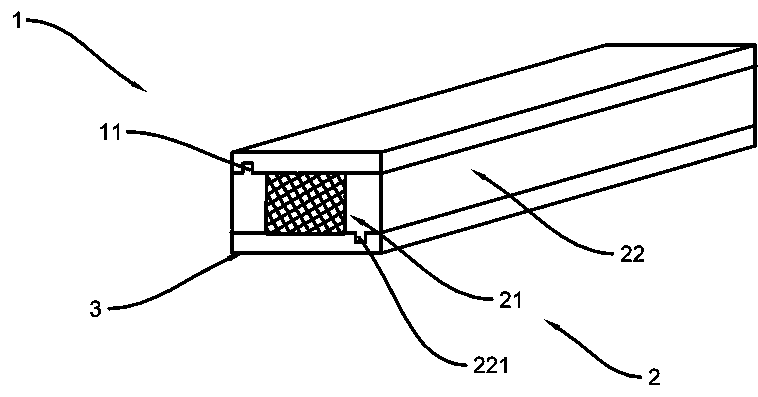

[0032] see figure 2 , a glulam side-jointed solid wood floor, which includes a surface layer 1, a base layer 2, and a bottom layer 3 from top to bottom. The wood board 21, the side splicing wood strips 22 arranged on both sides of the glued wood board 21 for clamping the glued wood board 21, the side splicing wood strips 22 are provided with holes that cooperate with the mortise 11 Tenon 221.

[0033] In the present invention, the glulam board 21 is arranged between the bottom layer 3 and the bottom plate of the surface layer 1, which can ensure the strength of the floor surface. Compared with the floor surface layer of the glulam board material in the prior art, the wear resistance and strength are higher. At the same time, side splicing wooden strips 22 are provided on both sides of the base material layer 2, which can play a supporting role. The tenon 221 is set on the side splicing wooden strip 22, and the surface layer 1 and the bottom layer 3 are provided with a morti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com