Spiral corrugated pipe structure

A technology of helical corrugated pipe and spiral winding, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problem that the compression resistance and bending resistance cannot meet the needs of use, the bending resistance and compression resistance are insufficient, and the Insufficient bending and compressive performance, etc., it is difficult to achieve compression deformation, improve axial flexural performance, and improve radial compressive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0020] Embodiments of the invention

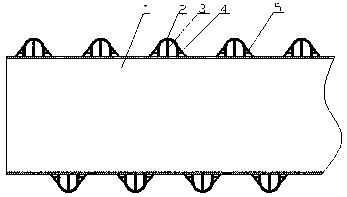

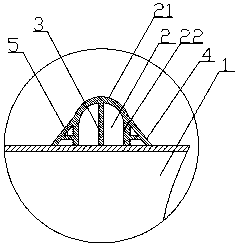

[0021] A spiral corrugated pipe structure, including a smooth-walled pipe 1 inside and a winding pipe 2 spirally wound outside the smooth-walled pipe 1, the middle of the winding pipe 2 is provided with a support stand along the length of the winding pipe 2 Plate 3, the lower side of the support vertical plate 3 is connected to the outer wall of the smooth-walled pipe 1, and the upper side is connected to the top of the winding pipe 2, and the two sides of the winding pipe 2 along the axial direction of the smooth-walled pipe 1 are respectively provided with supporting sloping plates 4 (supporting The inclined plate 4 is a flat plate, and the supporting effect is better), the upper end of the supporting inclined plate 4 is connected with the outer surface of the winding pipe 2, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com