Surface nanometer coating modified fiber and preparation method thereof

A coating and modification technology, applied in the direction of fiber type, fiber treatment, textile and papermaking, etc., can solve the problems of poor compression performance, weak compression performance, poor mechanical properties of composite materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the surface nano-coated modified fiber includes polyester fiber and a coating layer coated on the polyester fiber surface from the inside to the outside, and the coating layer includes carbon nanotubes coated on the polyester fiber surface The nanoparticle coating and the polypyrrole outer coating coated on the carbon nanotube nanoparticle coating surface, wherein, the mass ratio of the polyester fiber and the coating layer is 1:0.2, and the carbon nanotube nanoparticle coating and The mass ratio of polypyrrole outer coating is 1:12.

[0026] In the present embodiment, the method for preparing the fiber modified by surface nano-coating, the specific steps are as follows:

[0027] 1) Nano-suspension configuration: get an aqueous solution containing polyethyleneimine with a concentration of 0.5wt% and ferric chloride with a concentration of 2mol / L, and then add carbon nanotube nanoparticles (CNTs) acidified with 60% nitric acid for 1h. ) 1wt%, and at ...

Embodiment 2

[0031] This embodiment is the same as Example 1, and the difference is that the organic fiber is an ultra-high molecular weight polyethylene fiber in the present embodiment, and the raw material of the nanoparticle coating is a vapor-phase grown carbon fiber (VGCF);

[0032] The addition of VGCF nanoparticles is 2wt% in the step (1);

[0033] The drying temperature in step (2) is 95°C.

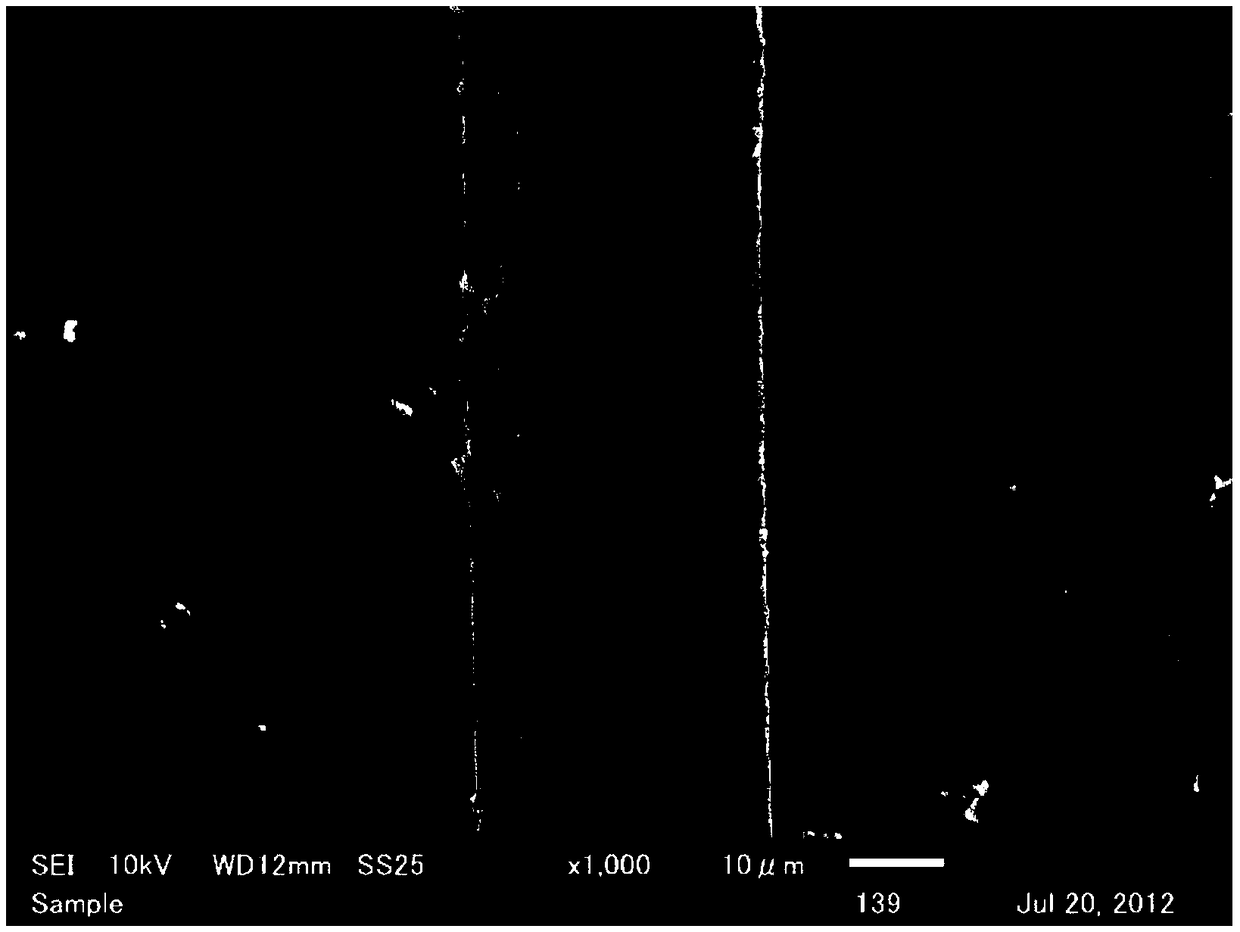

[0034] The topography of the VGCF particle adhesion-pyrrole-coated nano-coated ultra-high molecular weight polyethylene fiber prepared in Example 2 is as follows figure 1 As shown, the uniform distribution of nanoparticles can be seen.

Embodiment 3

[0036] The present embodiment is the same as embodiment 1, and the difference is that in the present embodiment, the organic fiber is a phenylene benzobisoxazole fiber (PBO), and the raw material of the nanoparticle coating is graphene;

[0037] In step (1), the mixed solution is an aqueous solution containing polyethyleneimine with a concentration of 1.5wt% and ferric chloride with a concentration of 2mol / L. The graphene is acidified with 60% nitric acid for 2h and ultrasonically treated for 1min. The addition amount of particle is 2wt%,

[0038] Soak in step (2) for 6 hours, the drying temperature is 95°C, and the duration is 5 minutes;

[0039] Vapor deposition in step (3) for 20 minutes.

[0040] Performance comparison:

[0041] When the transverse compressive strain rate was 0.4, the radial compressive modulus of the unprocessed ultra-high molecular weight polyethylene (UHMWPE1) was 0.025Gpa, and the modified ultra-high molecular weight polyethylene (UHMWPE2) prepared b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com