A pressure-resistant optical cable

A technology of optical cable and anti-pressure layer, which is applied in the direction of optics, light guides, optical components, etc., can solve the problems of weak resistance to radial pressure, collapse deformation, loss, etc., and achieve the effect of high cost performance and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

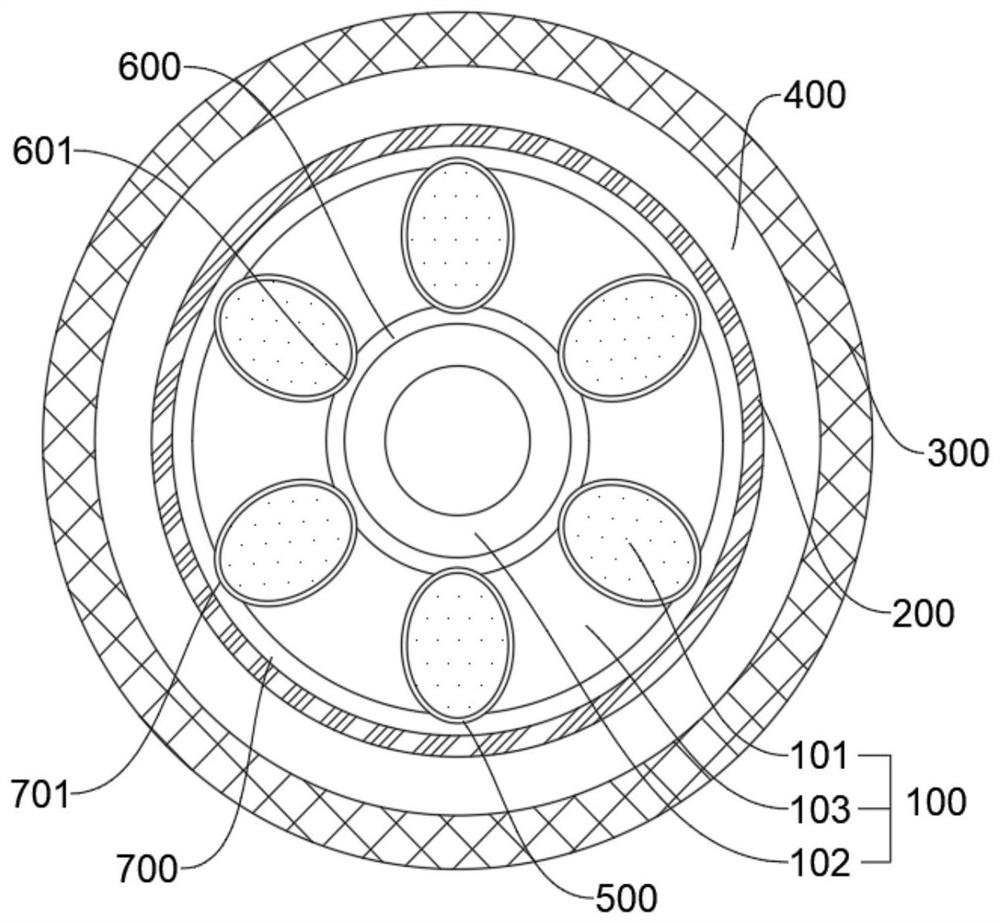

[0049] a kind of like figure 1 The pressure-resistant optical cable shown includes:

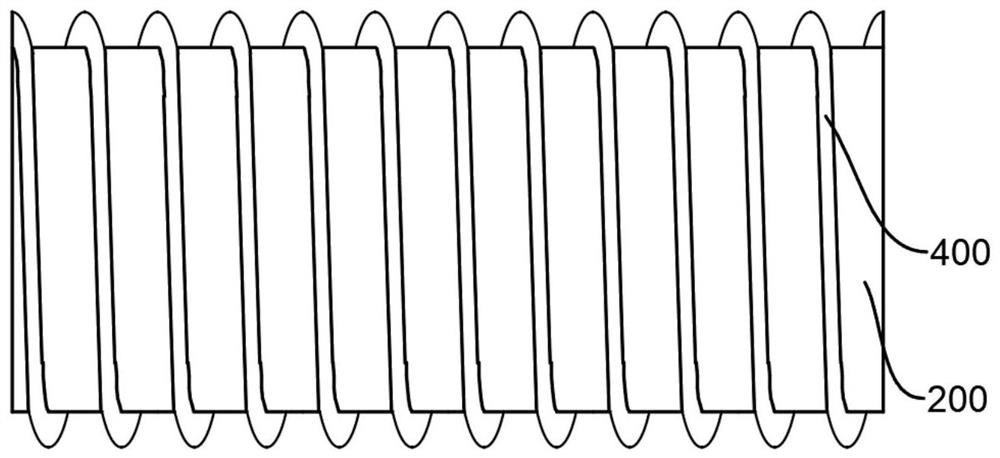

[0050] From the inside to the outside, the cable core 100, the aluminum-plastic composite tape 200 and the sheath layer 300;

[0051] The aluminum-plastic composite tape 200 wraps the cable core 100 to protect the cable core 100, and the sheath tightly covers the outer surface of the aluminum-plastic composite tape 200 to form a complete optical cable structure;

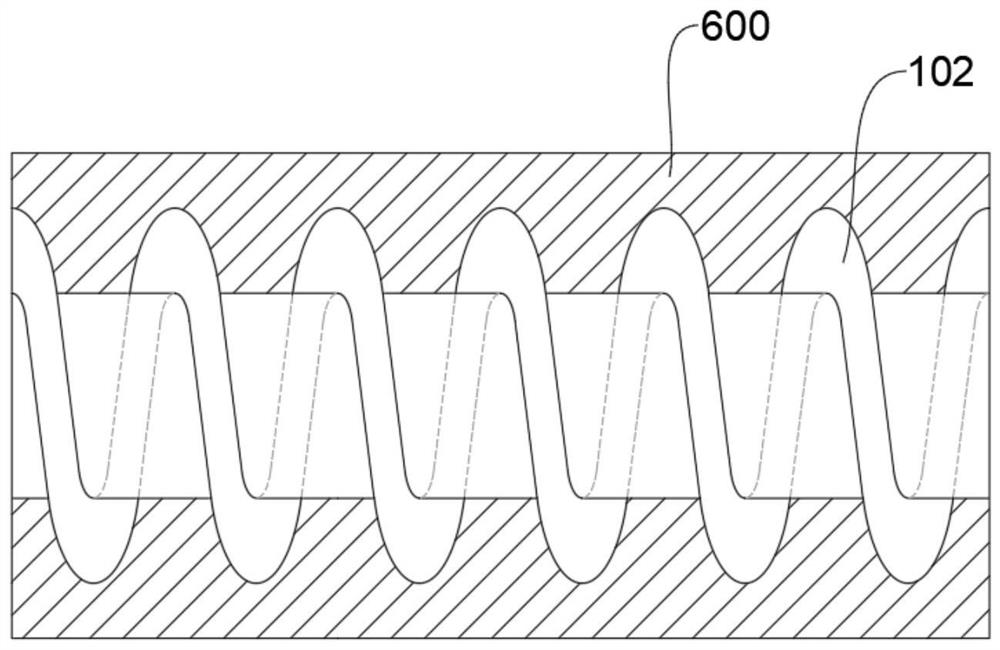

[0052] The cable core 100 includes several optical fiber wires 101 and a central strength member 102. The optical fiber wire 101 is formed by covering a single-mode or multi-mode optical fiber with a plastic sheath 500, and its interior is filled with water-blocking yarn or water-blocking powder to increase the hardness of the optical fiber wire 101, further Shape the optical fiber line 101 and improve the compressive performance of the optical fiber line 101 to a certain extent. The central strength member 102 is located at the ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com