An internally supported hole-protecting pipe for gas pumping in soft coal seams and its preparation method

A soft coal seam and supporting technology, which is applied in the field of soft coal seam gas pumping and the preparation of internally supported borehole protection pipes, can solve the problems of low hole collapse resistance of the borehole protection pipes, and facilitate the transportation of pipes and the operation of hole protection processes , tube body weight control, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

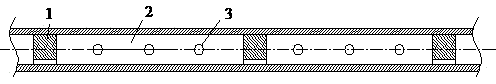

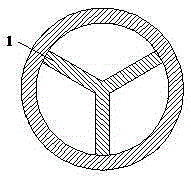

[0029] Embodiment 1: The pipe is made of antistatic and flame-retardant materials, and the internal structure of the pipe is arranged in a circular manner according to the inner support section and the hollow section; The inner support section is a herringbone inner support structure 1 or a cross-shaped inner support structure 8; the hollow section is a hollow structure 2, and there are screen holes 3 on the pipe body of the hollow structure 2.

[0030] The construction drilling diameter is 89mm and the hole depth is 100m. The pipe is a thin-walled hollow hard PE plastic pipe with a length of 4m and a wall thickness of 8mm. The internal structure of the tube is arranged circularly according to the herringbone inner support structure 1 and the hollow structure 2 (see attached figure 1 ), the length of the herringbone inner support structure 1 of the hole protection pipe is 20cm, the length of the hollow structure 2 is 100cm, and there are sieve holes 3 on the pipe body of the ...

Embodiment 2

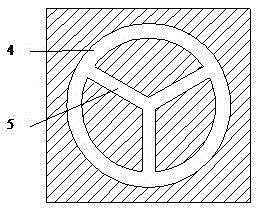

[0038] Embodiment 2: The diameter of the construction drilling hole is 94mm, and the hole depth is 120m. The pipe is a thin-walled hollow PVC plastic pipe with a length of 4m and a wall thickness of 8mm. The internal structure of the tube is arranged circularly according to the cross-shaped inner support structure 8 and the hollow structure 2 (see attached Figure 5 ), the length of the cross-shaped inner support structure 8 of the hole guard pipe is 25cm, and the length of the hollow structure 2 is 120cm.

[0039] as attached Figure 6 As shown, the cross-shaped inner support structure 8 is composed of four support bodies distributed at an angle of 90°, the four support bodies are connected to the center of the pipe, and the ends are respectively connected to the pipe wall. The support body is in the shape of a cuboid with a thickness of 4-6 mm and a width equal to the inner diameter of the tube.

[0040] The processing technology of the inner support type protective hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com