Composite solid wheel for rail transit vehicles and its stiffness design method

A rail transit vehicle and wheel technology, which is applied in the field of combined solid wheels for rail transit vehicles and its stiffness design, can solve the problems of mounting bolts destroying the rail, glue opening, bulging, and high replacement and maintenance costs, so as to improve safety and reliability. Effect of preventing permanent compression deformation, reducing cost and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

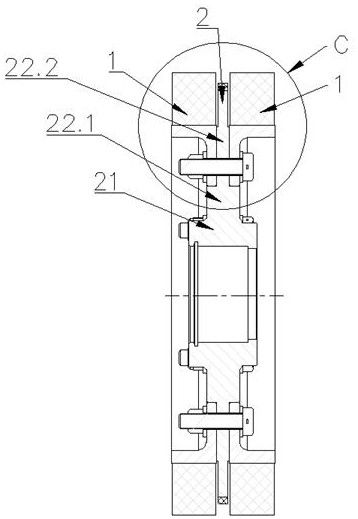

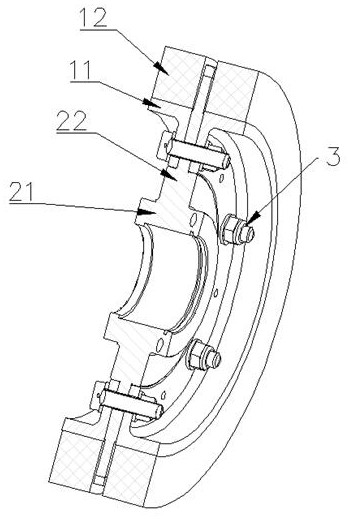

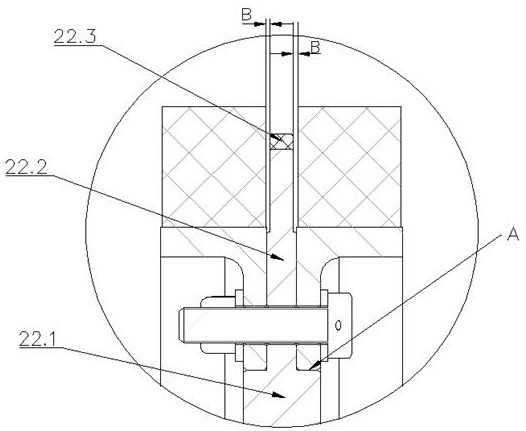

[0030] Combine below Figure 1 to Figure 4 The embodiments of the present invention will be described in detail.

[0031] The combined solid wheel for rail transit vehicles is characterized in that it includes a wheel vulcanized body 1 formed by vulcanizing the inner layer metal and the outer layer rubber and a flange connection plate 2 that can be installed in cooperation with the axle, and the number of the wheel vulcanized body 1 is Two and coaxially aligned, the flange connection plate 2 is sandwiched between two wheel vulcanization bodies 1, and is detachably connected with the wheel vulcanization body 1, and the outer diameter of the flange connection plate 2 is smaller than the wheel vulcanization body 1 , and the flange connection plate 2 extends between the rubber layers of the two wheel vulcanized bodies 1 .

[0032] like figure 1 As shown, the left and right sides of the flange connection plate 2 are respectively connected with a wheel vulcanized body 1 to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com