Hollow glass externally inlaid with thermal insulation material section and manufacturing and mounting method thereof

A technology of thermal insulation material and production method, which is applied in the fields of transportation devices and construction, and can solve the problems of profile detachment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

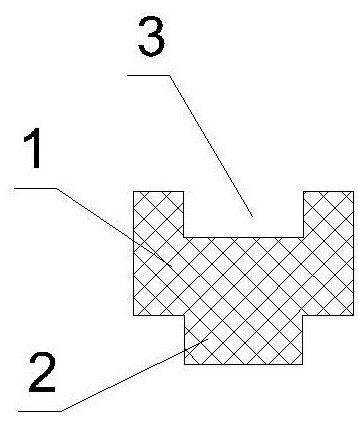

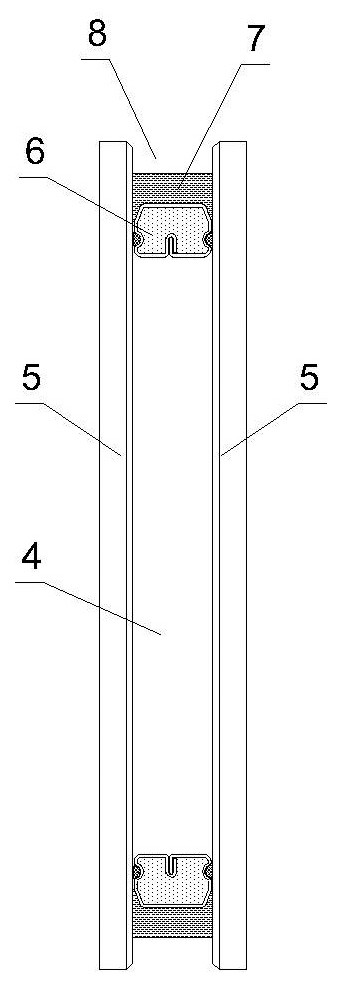

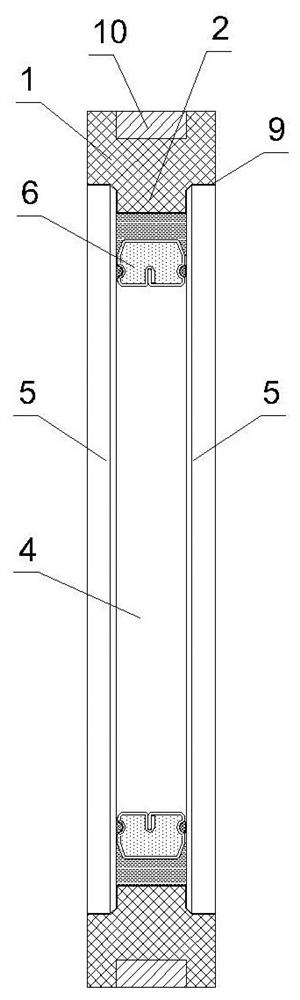

[0044] The end face of a double-layer insulating glass inlaid with thermal insulation material is shown in the figure figure 1 as shown, figure 2 It is the end view of double-layer insulating glass with connecting grooves, image 3 yes figure 1 and figure 2 Assembly drawing, Figure 4 yes image 3 Installation diagram of double-layer insulating glass with externally inlaid thermal insulation material profiles, of which: 1 is externally inlaid thermal insulation material profiles, 2 is the connection tenon of externally inlaid thermal insulation material profiles, 3 is the groove of external thermal insulation material profiles, 4 is double-layer insulating glass, 5 It is glass, 6 is heat insulation strip, 7 is sealant, 8 is double-layer insulating glass connection groove, 9 is glue, 10 is connection corner code, 11 is heat insulation window frame profile, 12 is inlay groove of middle heat insulation profile , 13 is a glass buckle, 14 is a sealing strip, 15 is a glass sp...

Embodiment 2

[0049] The end face of a three-layer hollow glass inlay insulation material profile is as follows Figure 5 as shown, Image 6 It is the end view of three layers of insulating glass with connecting grooves, Figure 7 yes Figure 5 and Image 6 Assembly drawing, Figure 8 yes Figure 7 The installation drawing of the three-layer insulating glass with externally inlaid thermal insulation material profiles, of which: 17 is the externally inlaid thermal insulation material profiles, 18 is the connecting tenon of external inlaid thermal insulation material profiles, 19 is the groove of external thermal insulation material profiles, 20 is the three-layer insulating glass, 21 22 is the outer glass, 22 is the middle glass, 23 is the heat insulation strip, 24 is the sealant, 25 is the connection groove of the three-layer insulating glass, 26 is the glue, 27 is the connection angle code, 28 is the heat insulation window frame profile, 29 is 30 is the foaming material filled in the ...

Embodiment 3

[0054] The end face of a four-layer hollow glass inlaid soft and hard co-extrusion insulation material profile is as follows Figure 9 as shown, Figure 10 It is the end view of the four-layer hollow glass with connecting grooves, Figure 11 yes Figure 9 and Figure 10 Assembly drawing, Figure 12 yes Figure 11 Installation drawing of four-layer insulating glass with soft and hard co-extruded insulation material profiles embedded outside, of which: 35 is the externally embedded hard thermal insulation material profile, 36 is the joint tenon of the externally embedded hard thermal insulation material profile, 37 is the soft thermal insulation material profile, and 38 is the external thermal insulation Material profile groove, 39 is four-layer hollow glass, 40 is outer glass, 41 is middle glass, 42 is heat insulation strip, 43 is sealant, 44 is four-layer hollow glass connection groove, 45 is glue, 46 is insulation Thermal window frame profile, 47 is the inlay groove of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com