Method for detecting bevel surface cracking inclination angle and depth

A technology for surface cracks and inclination angles, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., to achieve accurate inclination angles and depths, and accurate measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific example the content of the present invention is described in further detail:

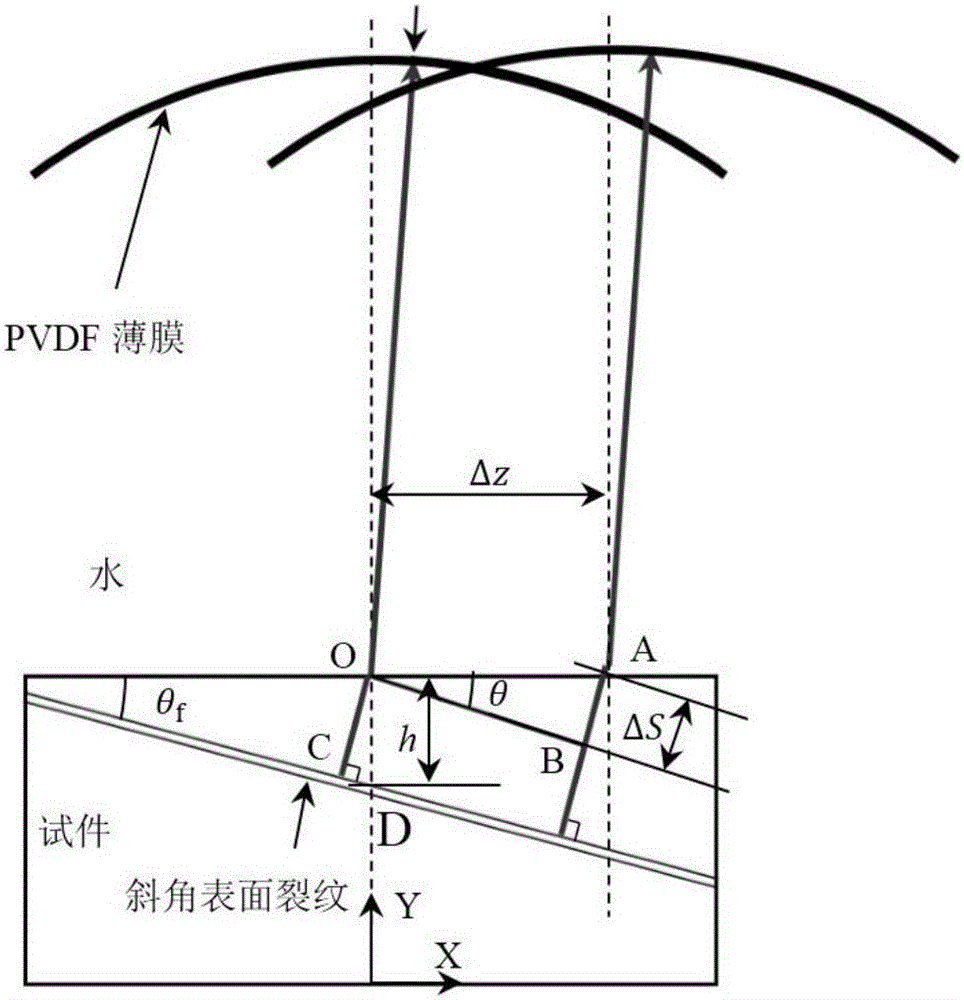

[0032] Step 1): Establish the formula for calculating the inclination angle and depth of the beveled surface crack

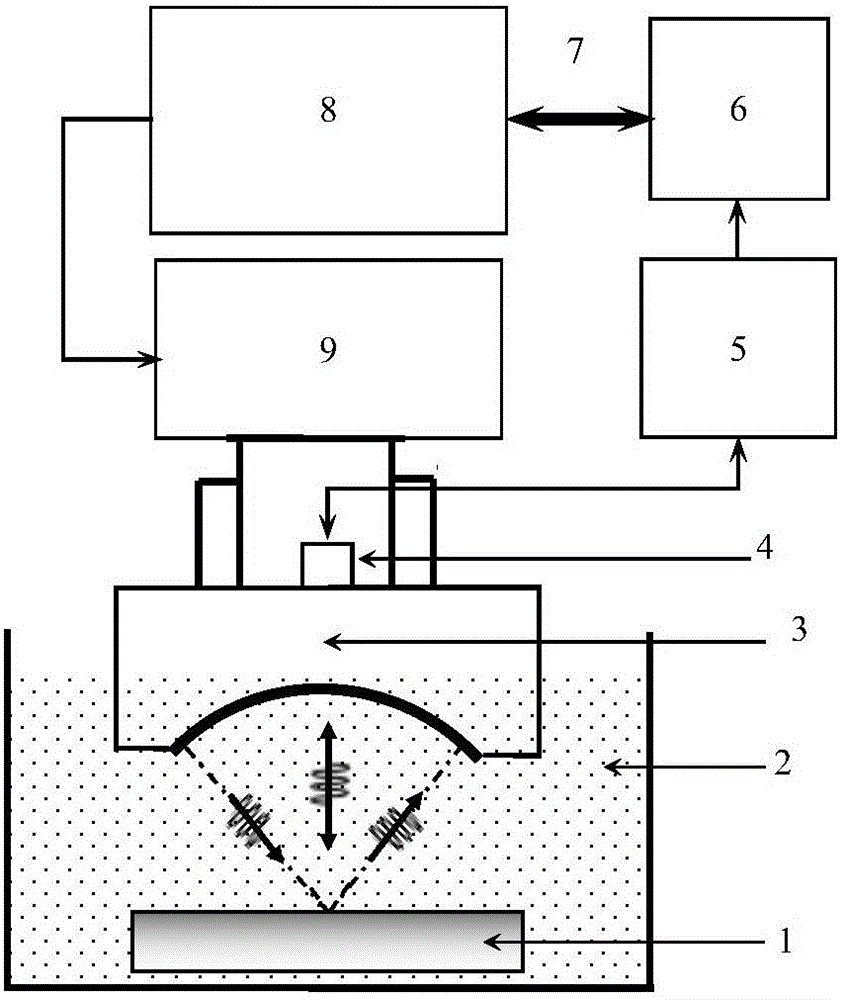

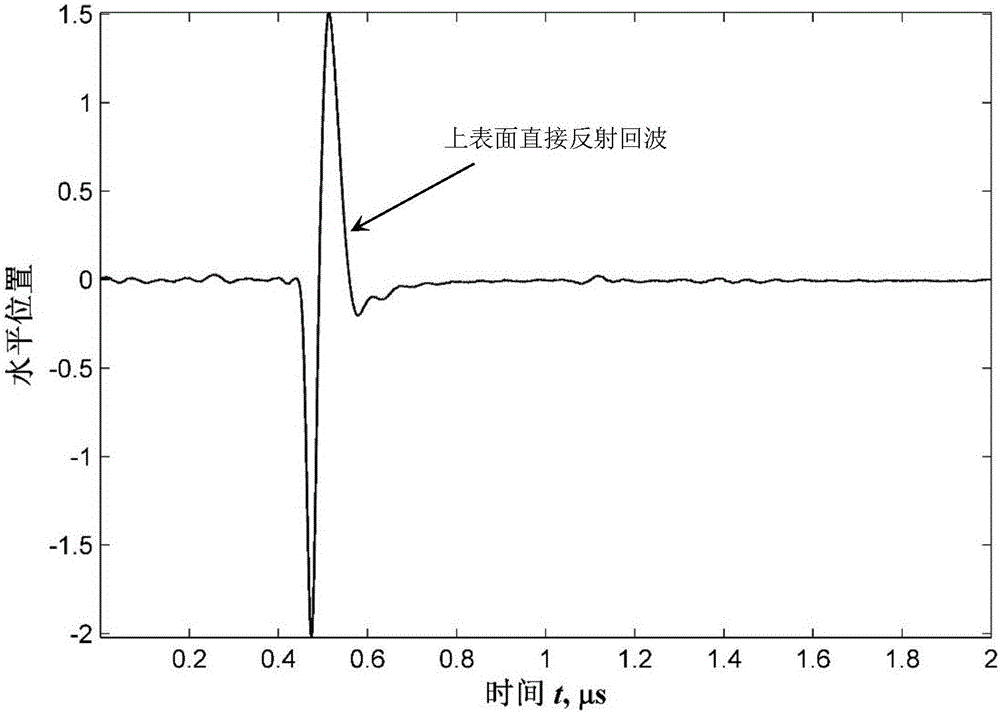

[0033] The working mode is that the transducer excites the ultrasonic signal, propagates to the upper surface of the test piece through the coupling agent water, refracts on the upper surface of the test piece and propagates to the crack on the oblique surface, is reflected by the crack on the oblique surface and returns to the piezoelectric film to be replaced. can be received by the transducer itself. figure 1 The black thick solid line with the arrow in the middle is the propagation path of the echo reflected by the oblique surface crack received by the transducer. When the transducer moves Δz along the X-axis direction, the propagation distance of the sound wave in the water remains unchanged, and the time change of the reflected echo rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com