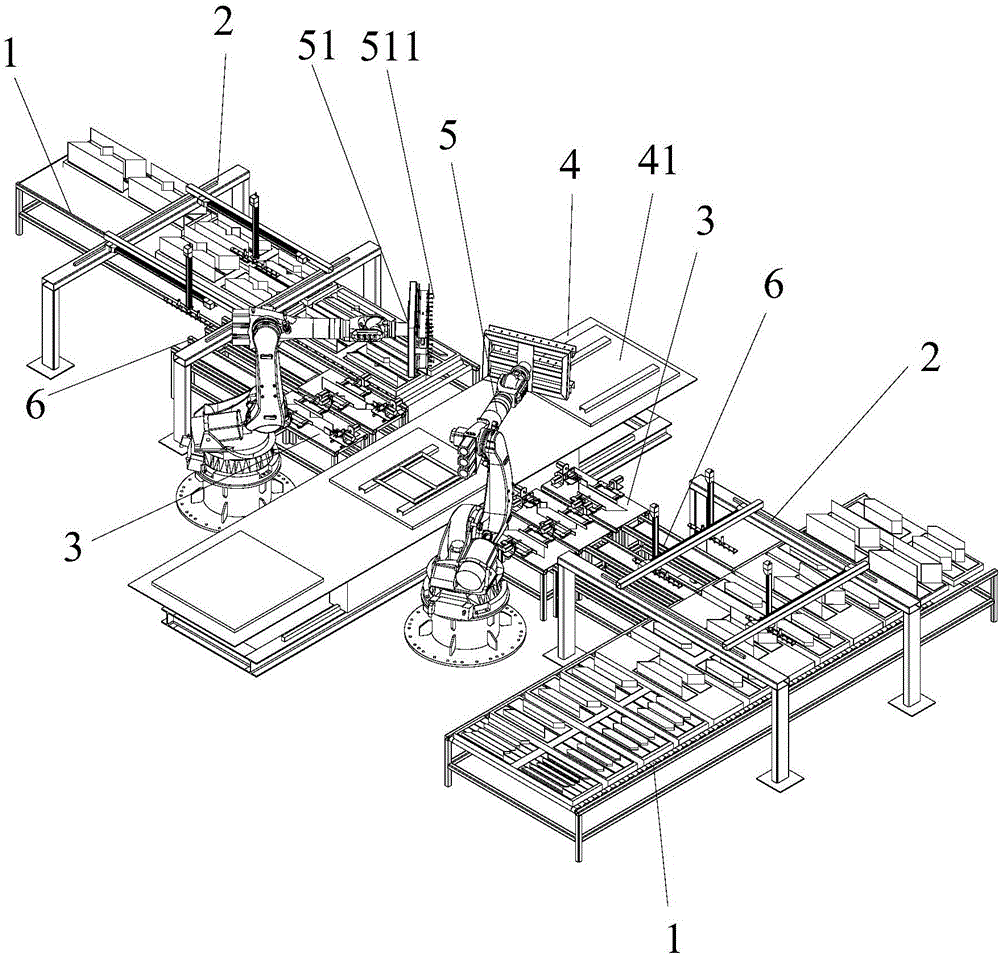

Automatic laminated sheet assembly method and system

An assembly system and assembly method technology, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of complex feeding, low processing efficiency, poor compatibility, etc., to improve processing efficiency, high degree of intelligence, The effect of reducing the difficulty of front-end feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0045] A preferred embodiment of the present invention provides an automatic lamination assembly method, which is used in the field of automatic stacking assembly of sheets. The method in this embodiment includes:

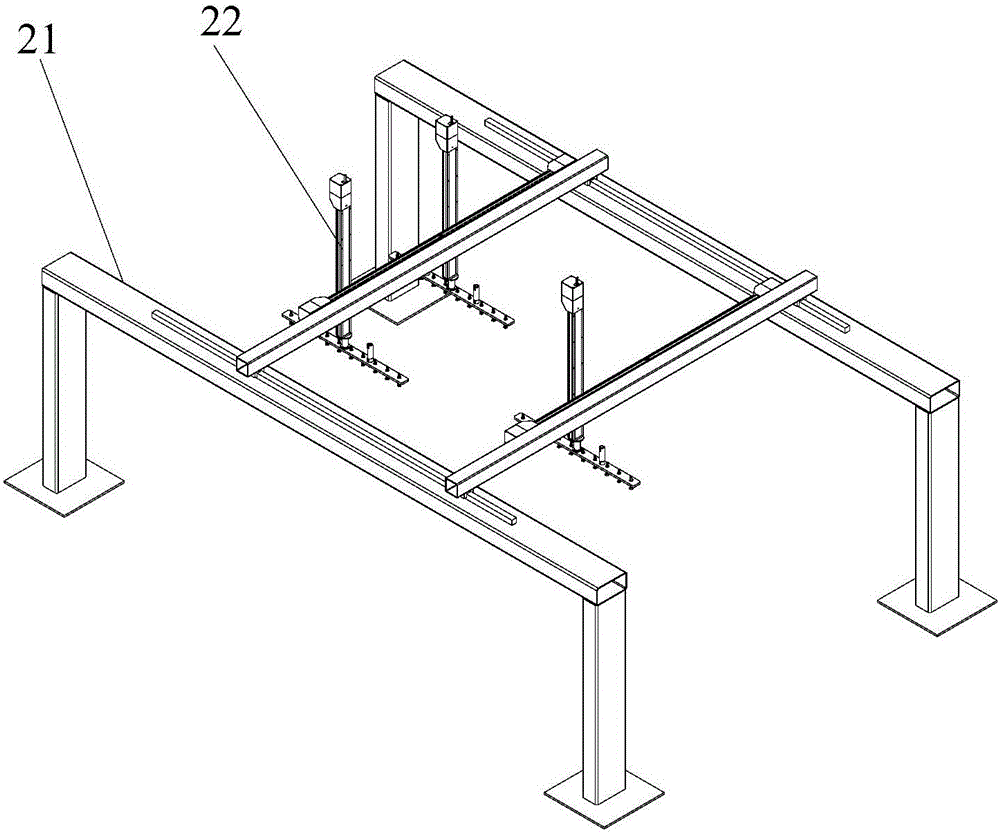

[0046] Group the components that make up the same laminate according to the structure and shape of the same laminate in the assembly that needs to be laminated, and the grouped components are transferred by the assembly line for calling the laminate assembly;

[0047] Initially grab each group of components in the group and transfer them to the positioning platform, and multiple components in the same group are grabbed synchronously;

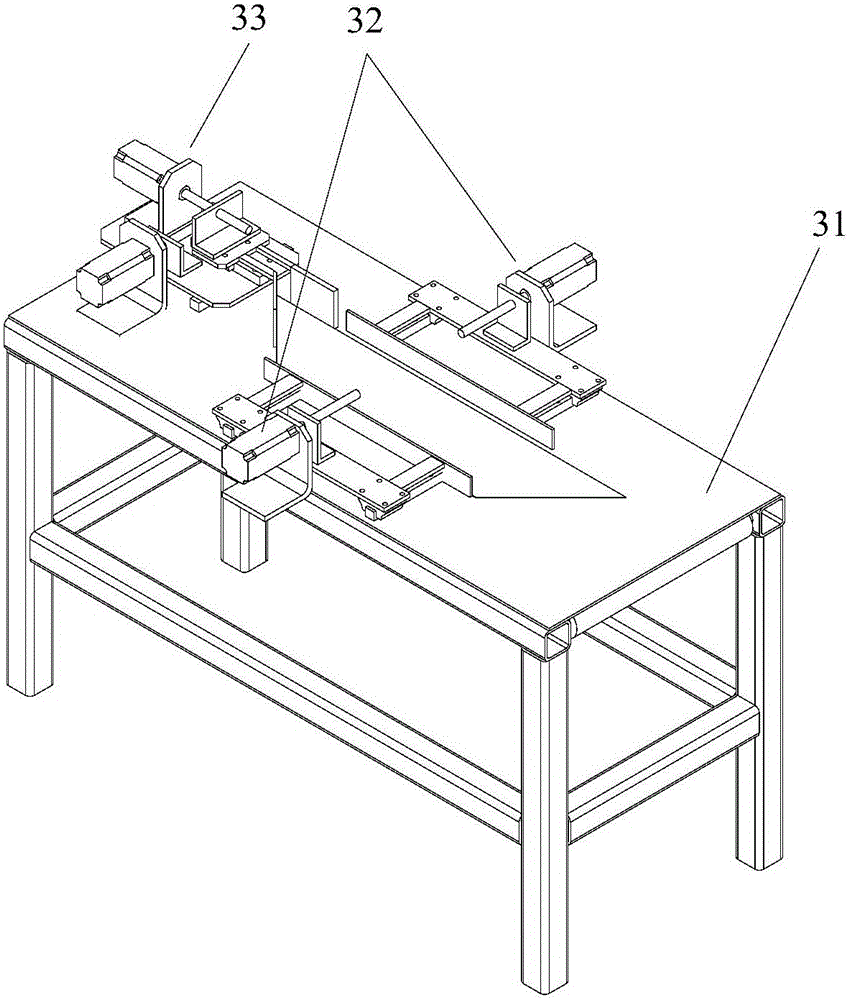

[0048] Precise positioning of multiple compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com