A manufacturing method for a backside-illumination sensor

A sensor, back-illuminated technology, applied in the field of preparation of back-illuminated sensors, can solve the problems of photon loss, affect the appearance of the wafer, affect the QE and imaging quality, and achieve the effect of reducing the difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

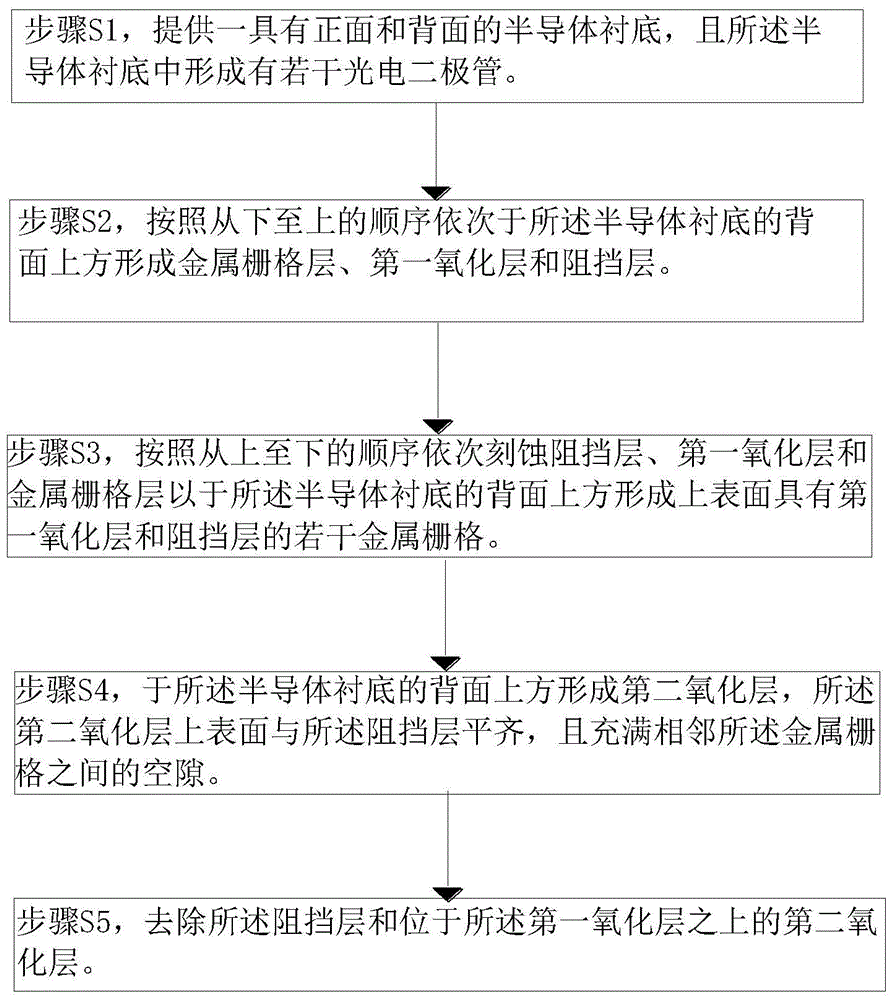

[0027] Such as figure 1 As shown, this embodiment relates to a method for preparing a back-illuminated sensor, which may be a back-illuminated image sensor. Specifically, the method includes the following steps:

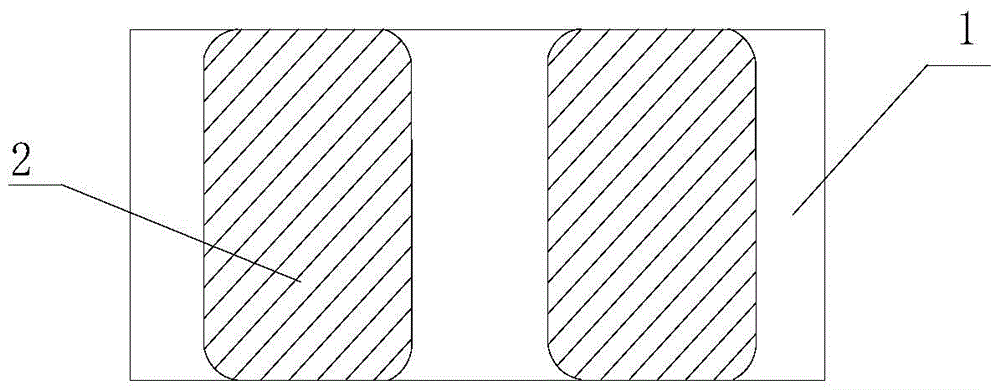

[0028] Step S1, providing a semiconductor substrate 1 with a front side and a back side, and a photodiode array (pixel array) formed by several photodiodes 2 (pixels) is formed in the semiconductor substrate 1; in an embodiment of the present invention, the The semiconductor substrate 1 is a wafer that has completed all the processes before the BSI process; the next process is to define the position of each pixel (photodiode) on the wafer for subsequent formation of color filters (colorfilter) process needs, such as figure 2 structure shown.

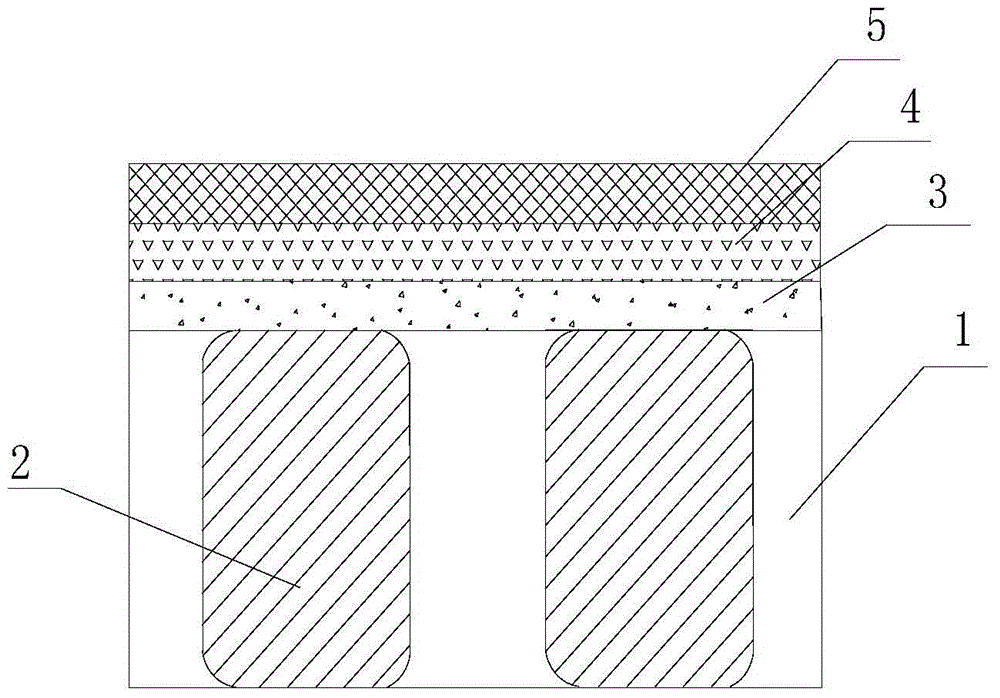

[0029] Step S2, forming a metal grid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com