Organic electroluminescent element, display device, and illumination device

An electroluminescent element and electroluminescent technology, applied in lighting devices, electroluminescent light sources, electrical components, etc., can solve the problems of unclearness and high driving voltage, and achieve the effects of high luminous efficiency, excellent driving voltage and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

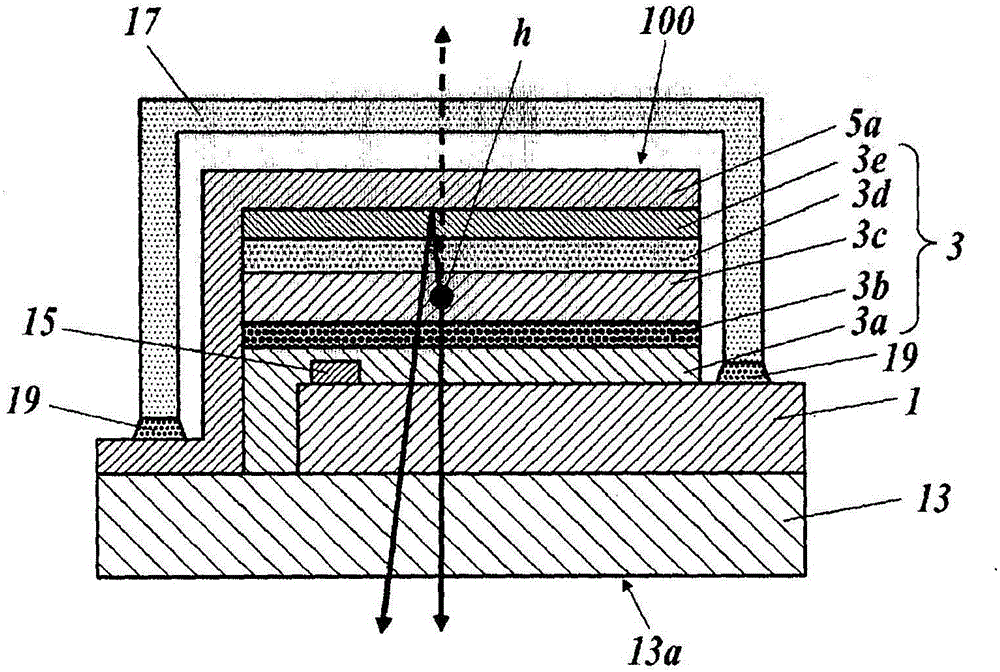

[0583] "Fabrication of Inverse Layer Type Blue Phosphorescent Organic EL Elements"

[0584] (1) Fabrication of organic EL element 1-1

[0585] A substrate (NA45 manufactured by NH Technoglass Co., Ltd.) in which ITO was formed into a film of 100 nm as a cathode on a glass substrate of 100 mm×100 mm×1.1 mm was patterned. Then, the transparent substrate provided with the ITO transparent electrode was ultrasonically cleaned with isopropanol, dried with dry nitrogen, and cleaned with UV ozone for 5 minutes.

[0586] This transparent substrate was fixed to a substrate holder of a commercially available RF sputtering apparatus. As the sputtering target, an n-type amorphous oxide semiconductor in which C12A7 was formed into a flat plate by referring to the method described in JP-A-2013-40088 was used.

[0587] Sputtering was performed in an atmosphere of 500 mPa of argon gas, the substrate temperature was room temperature (25° C.), and the input power was 100 W. An electron injecti...

Embodiment 2

[0627] "Fabrication of Blue Phosphorescent Organic EL Elements of Inverse Layer Type: n-doped ETL Type"

[0628] (1) Fabrication of organic EL element 2-1

[0629] In the fabrication of the organic EL element 1-1 of Example 1, as the electron transport layer, Alq 3 Lithium and metal were co-evaporated on the electron injection layer made of C12A7 at evaporation rates of 0.1nm / sec and 0.006nm / sec, respectively, to form an n-doped electron transport layer with a thickness of 100nm.

[0630] Then it will just be Alq 3 Similarly, the electron transport layer of the n-doped electron transport layer was co-deposited at the evaporation rate of 0.1nm / sec to form an electron transport layer with a layer thickness of 10nm. Fabrication of organic EL element 2-1.

[0631] (2) Production of organic EL elements 2-3, 2-5, 2-8, 2-15, 2-18, 2-19, 2-22

[0632] Alq used in organic EL element 2-1 3 The organic EL elements 2-3, 2-5, 2-8, 2-15, 2-18, 2-19, 2-22 with n-doped electron transport...

Embodiment 3

[0637] "Fabrication of Green Phosphorescent Organic EL Elements Constructed by Layers"

[0638] (1) Production of organic EL element 3-1

[0639] The ITO substrate patterned and cleaned in the same manner as in Example 1 was mounted in a vacuum vapor deposition apparatus, and each crucible for vapor deposition was filled with the constituent materials of each layer in an optimal amount for device production. As the crucible for vapor deposition, a crucible made of a material for resistance heating made of molybdenum or tungsten was used.

[0640] Decompress to vacuum degree 1×10 -4 After Pa, the crucible for vapor deposition equipped with HAT was energized and heated, and vapor-deposited on the ITO transparent electrode at a vapor deposition rate of 0.1 nm / sec to form a hole injection layer with a thickness of 20 nm.

[0641] Next, α-NPD was deposited in the same manner to form a hole transport layer having a thickness of 20 nm.

[0642] Next, CBP and GD-1 were co-deposited...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap