Hydrodynamically Optimized Filter Candle

A filter candle and fluid technology, which is applied in the field of fluid dynamics optimized filter candles, can solve the problems of inability to achieve filtration and segregation of turbid particles, and achieve the effect of uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

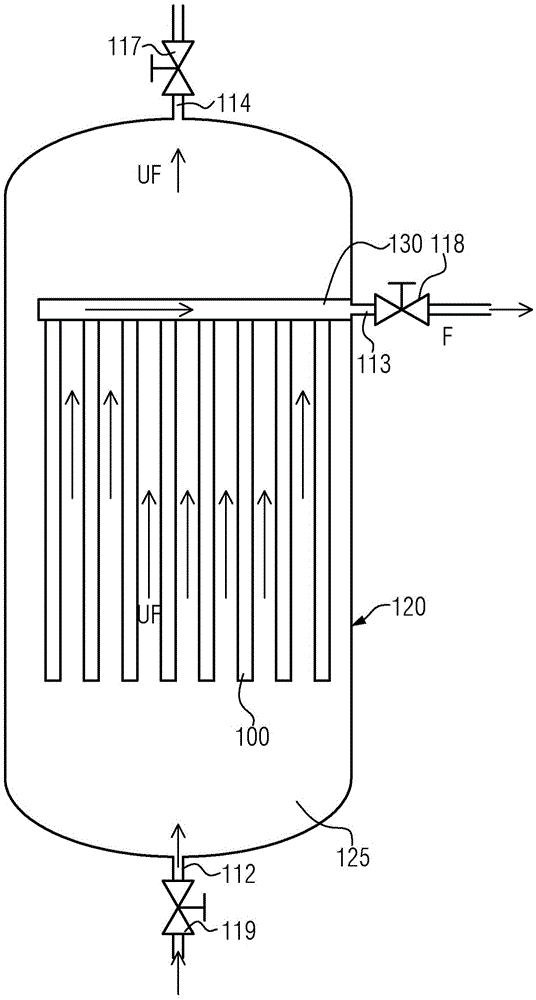

[0053] figure 1 A schematic longitudinal section through a conventional precoat filter is shown. The precoat filter comprises, as is known from the prior art, a filter container 120 with a continuous non-filtrate chamber 125 , an inlet 112 for the non-filtrate and an outlet 114 for the non-filtrate. In the illustrated embodiment of the precoat filter, a plurality of filter candles 100 are fastened suspended in the form of a matrix on a piping outlet 130 for the filtrate. Here, the filter candle outlets are brought together via a pipe system and can be led off individually. The calandria outlet 130 is thus the outlet 113 for the filtrate F, wherein the outlet volume can be adjusted via a regulating device, for example a regulating valve 118 .

[0054] The feed of non-filtrate via the injection 112 can be regulated by means of a regulating valve 119 . Alternatively, valve 119 may simply refer to a shut-off valve. The regulation of the non-filtrate delivery is then by means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com