Carbon powder cleaning pen

A toner and pen-shaped technology, applied in the direction of printing, printing devices, etc., can solve the problems of low work efficiency, damage to the surface of workpieces such as shells or parts, and pollution of the working environment, and achieve simple structure, small size, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

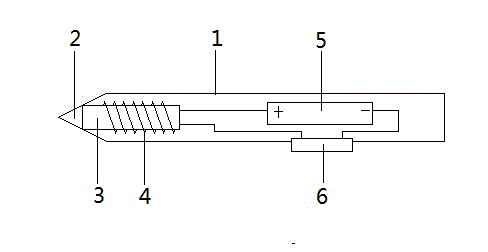

[0011] Such as figure 1 As shown, the present invention includes a pen-shaped casing 1, the head of the casing 1 is provided with an iron nib 2, and a section of iron core 3 is extended from the tail of the nib 2, and a coil 4 is wound outside the iron core 3, and the two ends of the coil 4 are Connect in series with power supply 5 and switch 6.

[0012] In this embodiment, the power supply 5 is arranged inside the shell 1, and the power supply can be a dry battery or a rechargeable lithium battery. And the switch 6 is located on the shell 1, which is convenient to turn on or off the power supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com