Method for expanding capacity by exploiting underground mine by areas from bottom to top

A bottom-up, zoned mining technology, applied in underground mining, surface mining, mining equipment and other directions, can solve the problems of difficult production management, difficult to meet production and construction units, small production increase, etc., to achieve low cost and production. The effect of large capacity and expansion of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

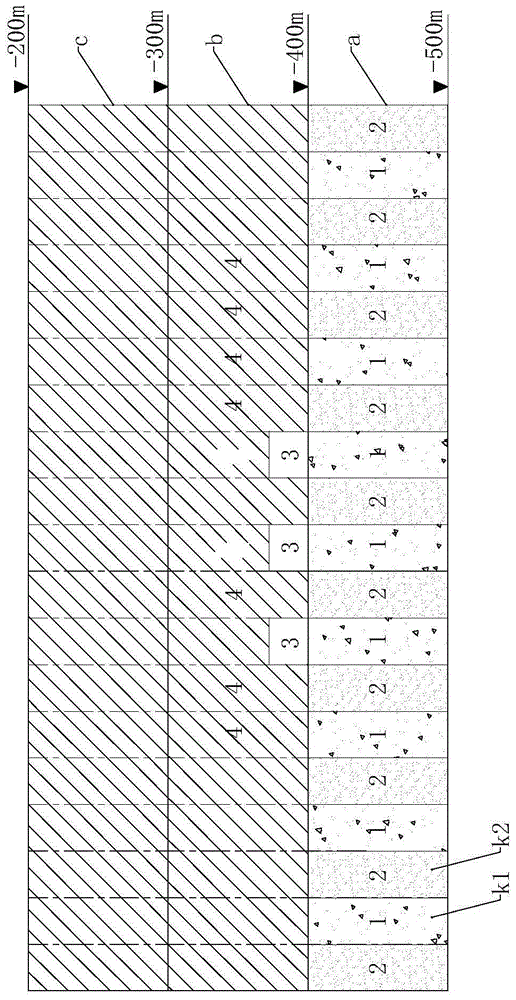

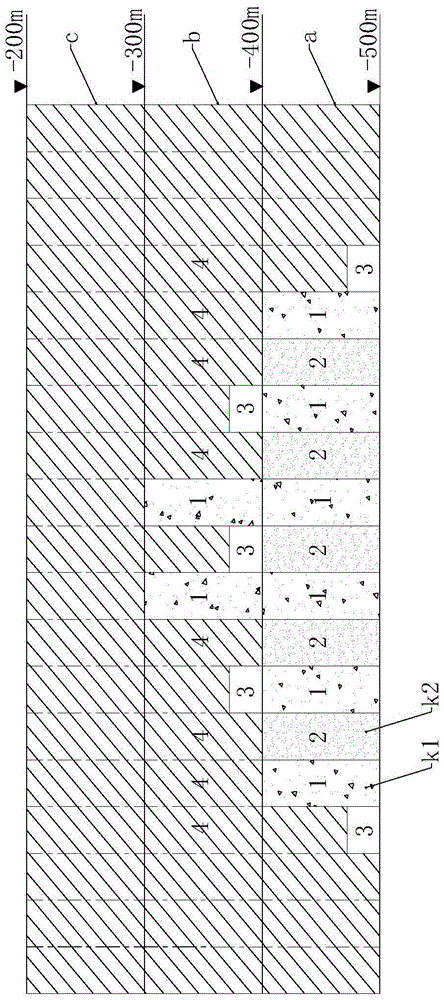

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0028] For the existing and new underground mines, under the condition that the deep ore reserves are relatively large, the present invention proposes a method for expanding production capacity of underground mines from bottom to top, and the method for expanding production capacity includes the following steps:

[0029] S10, calculate the mineral reserves that can be exploited according to the mineral resource reserves and mining scope identified in the geological exploration report; then estimate the scale of mine construction based on the mineable mineral reserves and economic service life of the deposit. This step is to avoid excessive expansion of production capacity. The so-called economic service life is also called the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com