Leaf crown working face abrasion detecting tool

A technology for detecting tools and working surfaces, which is applied in the direction of measuring devices, instruments, etc., can solve problems such as the inability to meet the needs of rapid detection of repaired parts in mass production, and achieve the effects of reliable structure, convenient storage, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

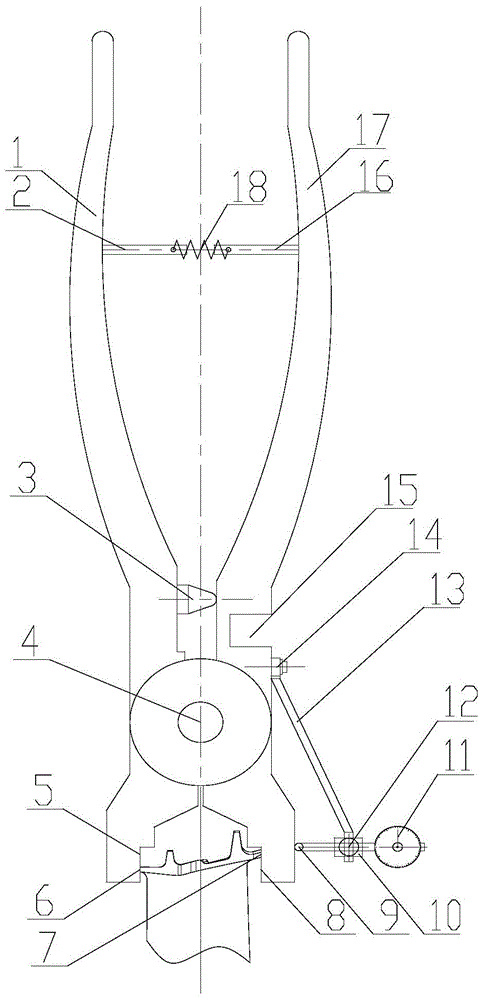

[0015] This embodiment provides a wear detection tool for the working face of the blade shroud, which is characterized in that: the wear detection tool for the working face of the blade shroud includes a pressing handle I1, a pull rod I2, a rotating shaft 4, a measuring chuck I5, and a front edge of the shroud 6. Trailing edge of leaf crown 7, measuring chuck II8, measuring gauge head 9, clamping frame 10, measuring gauge 11, knurled screw 12, bracket 13, pin shaft 14, stabilizing groove 15, pull rod II16, compression handle II17 , tension spring 18;

[0016] Among them: the compression handle I1 is integrated with the measuring chuck II8, the compression handle II17 is integrated with the measuring chuck I5, and the two are hinged through the rotating shaft 4; A pull rod II16 is installed on the inner side of the tail of the handle II17; a tension spring 18 is installed between the pull rod I2 and the pull rod II16;

[0017] There is a stabilizing groove 15 on the outside of...

Embodiment 2

[0021] This embodiment provides a wear detection tool for the working face of the blade shroud, which is characterized in that: the wear detection tool for the working face of the blade shroud includes a pressing handle I1, a pull rod I2, a rotating shaft 4, a measuring chuck I5, and a front edge of the shroud 6. Trailing edge of leaf crown 7, measuring chuck II8, measuring gauge head 9, clamping frame 10, measuring gauge 11, knurled screw 12, bracket 13, pin shaft 14, stabilizing groove 15, pull rod II16, compression handle II17 , tension spring 18;

[0022] Among them: the compression handle I1 is integrated with the measuring chuck II8, the compression handle II17 is integrated with the measuring chuck I5, and the two are hinged through the rotating shaft 4; A pull rod II16 is installed on the inner side of the tail of the handle II17; a tension spring 18 is installed between the pull rod I2 and the pull rod II16;

[0023] There is a stabilizing groove 15 on the outside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com