Superjunction and method of making the same

A manufacturing method and super junction technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of weak electromagnetic interference performance and fast switching speed of devices, so as to improve the time of complete reverse bias, reduce on-resistance, The effect of etch and fill process simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

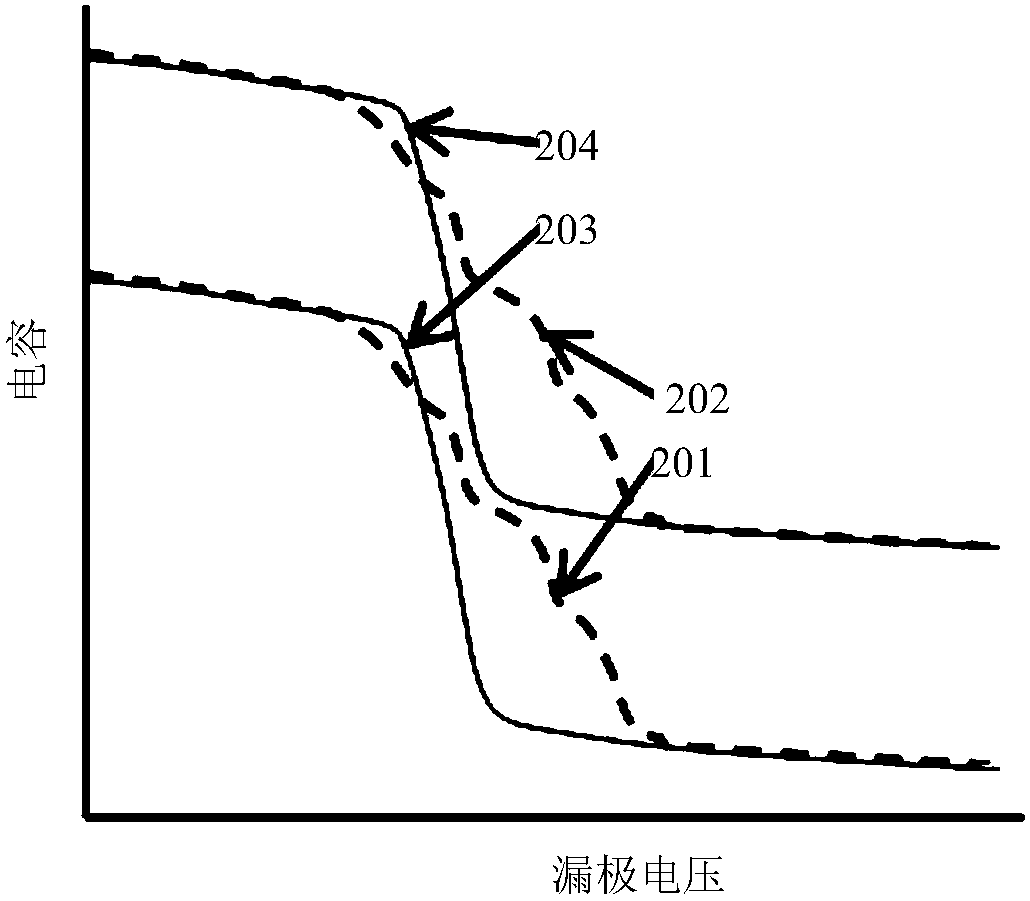

[0047] First of all, let me explain the EMI problem caused by the continuous improvement of the super junction process: the current mass production process has a diffusion resistance (RSP) close to 10mohm cm 2 . This brings about a substantial reduction in device area, which is a huge advantage in terms of manufacturing costs. However, due to the sharp reduction of device area, some other problems have also been brought about, and EMI problem is one of them. EMI is due to the fact that after the device is reduced, all parasitic capacitances are also reduced due to the reduction in area, resulting in a sharp increase in device switching speed, higher dV / dt, dI / dt is very easy to cause oscillations in the parasitic capacitance and inductance in the circuit, resulting in Excessive electromagnetic radiation, that is, EMI problem. In the existing method, the EMI problem of the super junction device formed by trench filling is more prominent than that of the super junction device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com