A quantum-tailored transparent electrode for crystalline silicon solar cells

A technology of solar cells and transparent electrodes, applied in the field of solar cells, can solve the problems of high cost, reduced cell conversion efficiency, high material cost, etc., and achieves the effect of expanding the spectrum utilization range, improving the photoelectric conversion efficiency, and simplifying the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

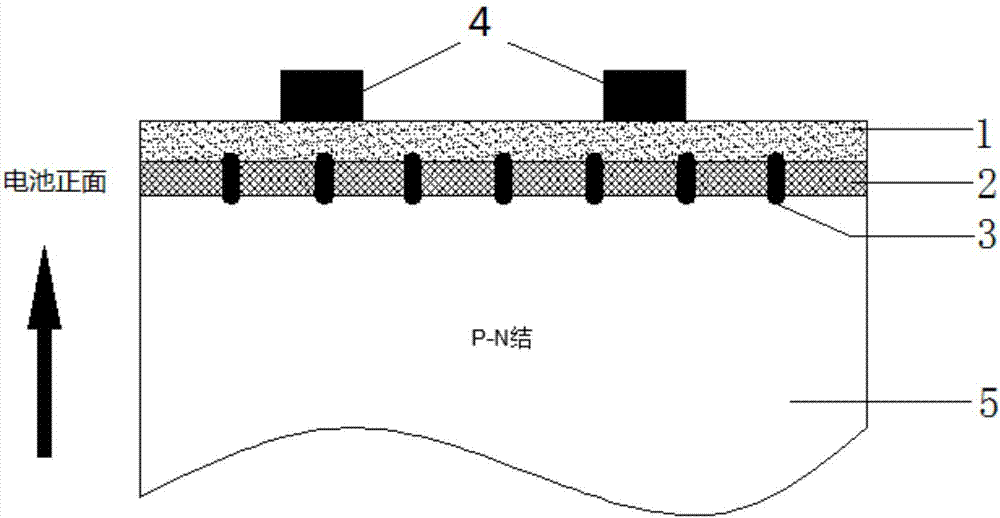

[0036] (1) P-type monocrystalline silicon wafers are processed through processes such as texturing, diffusion, etching, deposition of passivation film and anti-reflection film, and production of back electrodes;

[0037] (2) adopt screen printing method to make dotted silver electrode on the front, the diameter of single dot is 50um, and the distance between dot and dot is 0.8mm;

[0038] (3) Carry out sintering at 300-900°C in the furnace body, and the dotted silver paste on the front side penetrates the anti-reflection film and passivation film to form a good ohmic contact with the silicon substrate;

[0039] (4) Prepare a 100nm doped AZO transparent conductive film by sputtering on the dot electrode, and the doping element is Eu 3+ , the mass fraction of doping is 0.001%;

[0040] (5) On the doped AZO transparent conductive film, adopt the method of screen printing to make silver electrodes. The silver electrode pattern is composed of a group of equidistant parallel grid l...

Embodiment 2

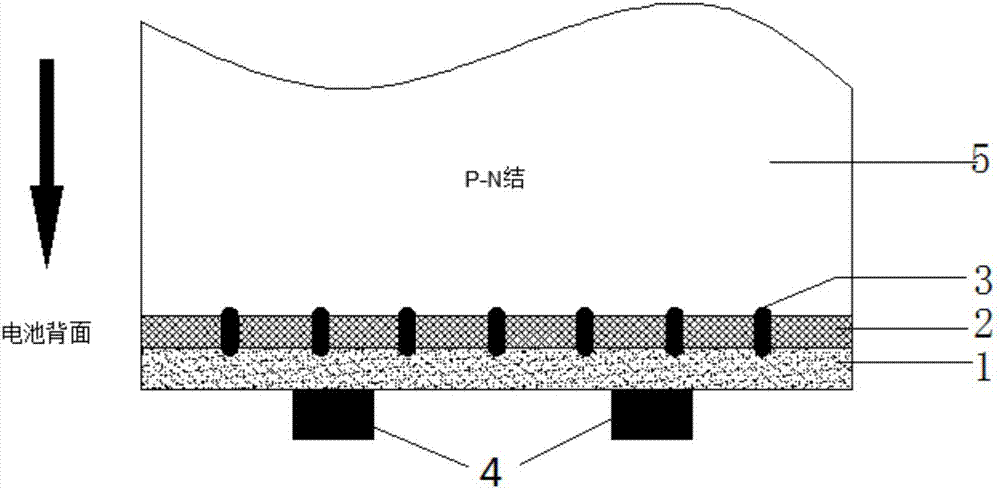

[0042] (1) N-type monocrystalline silicon wafers are processed through processes such as texturing, diffusion, etching, deposition of passivation film and anti-reflection film;

[0043] (2) Laser is used to open the anti-reflection film and passivation film on the front and back in a point array, the diameter of a single point is 100um, and the distance between points is 1.5mm;

[0044] (3) Prepare dot-shaped aluminum electrodes and silver electrodes at the openings on the front and back sides by electroless plating, and then perform annealing treatment at 200-500°C;

[0045] (4) Prepare a 110nm doped ITO transparent conductive film by chemical vapor deposition on the front side, and the doping element is Bi 3+ and Sm 3+ , the total mass fraction of doping is 0.01%;

[0046] (5) Prepare a 110nm doped ITO transparent conductive film by chemical vapor deposition on the back, and the doping element is Yb 3+ and Er 3+ , the total mass fraction of doping is 0.01%;

[0047] (6)...

Embodiment 3

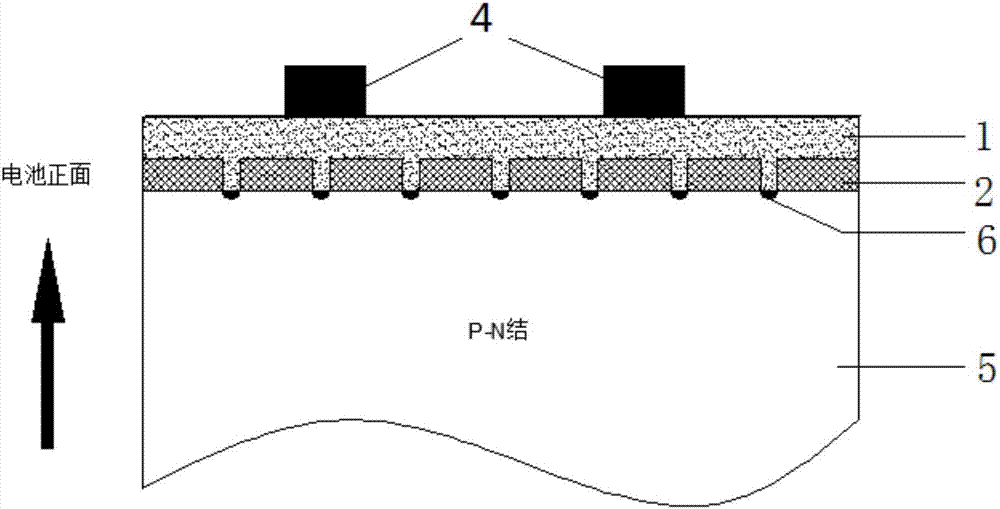

[0050] (1) P-type monocrystalline silicon wafers are processed through processes such as texturing, diffusion, etching, deposition of passivation film and anti-reflection film;

[0051] (2) Print phosphorus-containing dopants and boron-containing dopants on the front and back according to specific patterns, the printed pattern adopts a line segment array, the length of the line segment is 50um, the width is 40um, and the distance between the line segments is 0.5mm;

[0052] (3) Use laser to pulse heat the dopant according to the specific pattern described in step (2), so that phosphorus atoms and boron atoms penetrate the anti-reflection film and passivation film to diffuse to the silicon substrate, on the front side of the silicon wafer and A locally heavily doped region forming a line-segment array on the back;

[0053] (4) Spray doped FTO nanopowder on the front to form a doped transparent conductive film with a thickness of 200nm, and the doping element is Eu 3+ , the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com