Patents

Literature

43 results about "Quantum cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material having cooperative frequency light conversion performance and preparation method and application thereof

InactiveCN101942306AImprove efficiencyWeaken additional heatPhotovoltaic energy generationLuminescent compositionsRare-earth elementHydrothermal synthesis

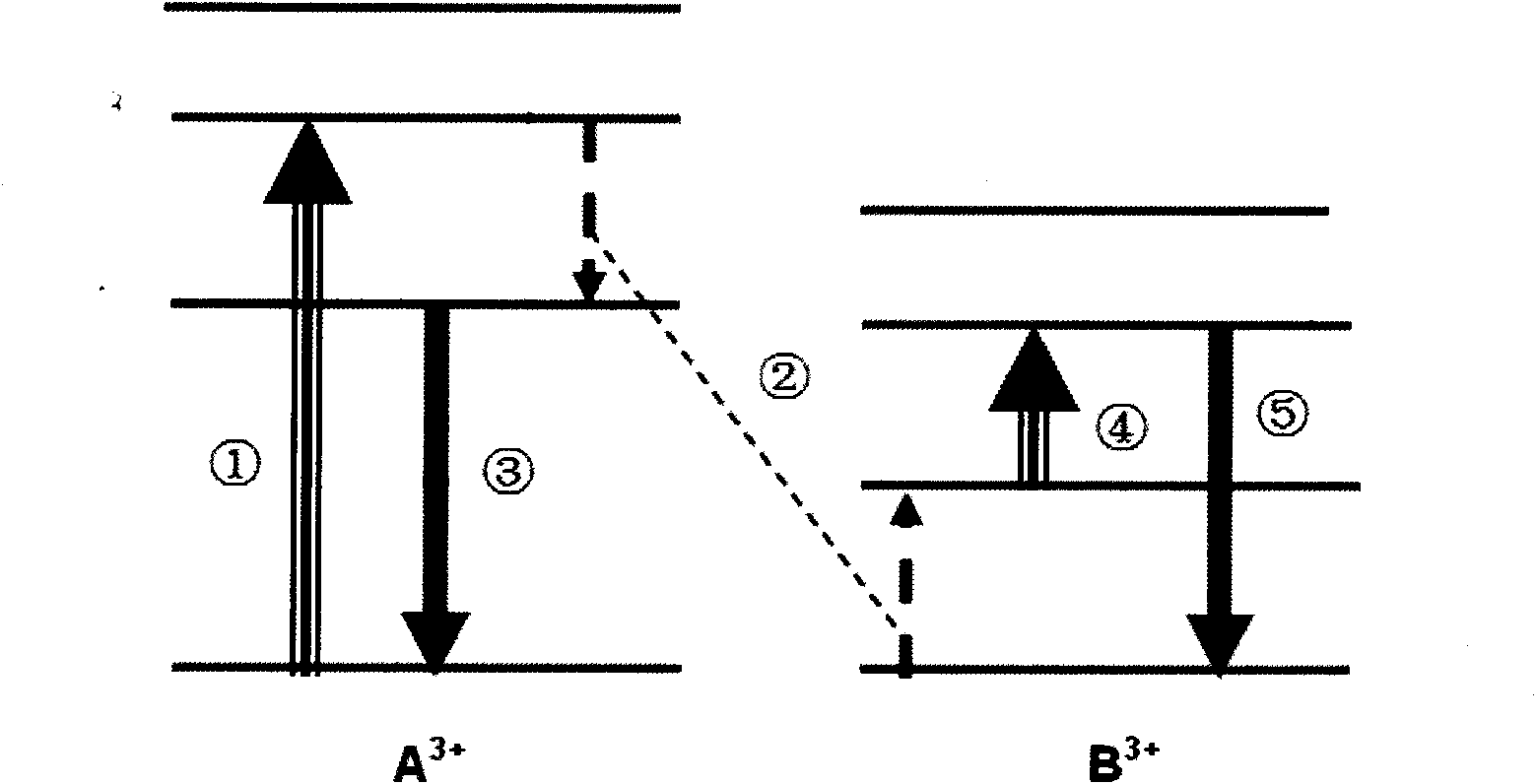

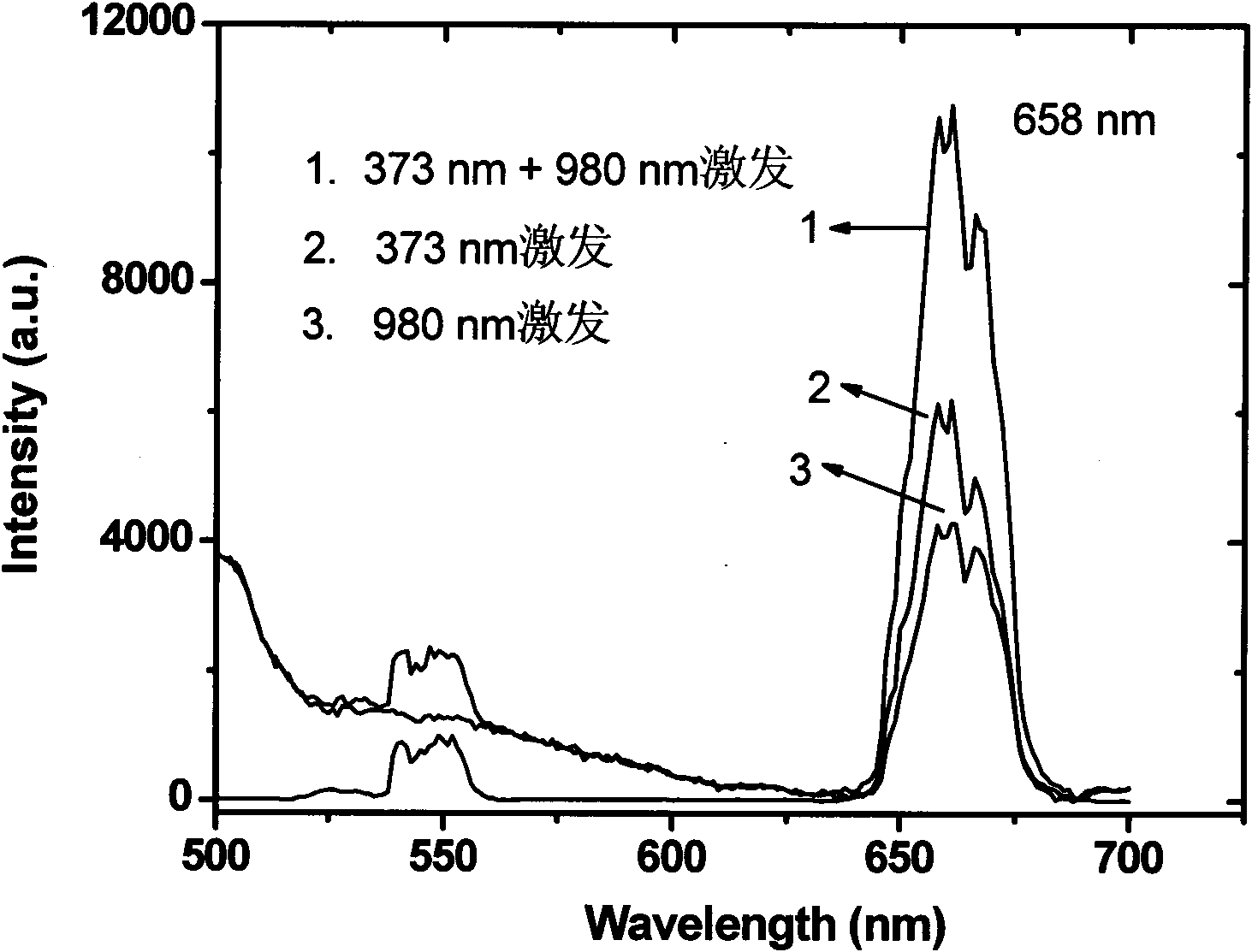

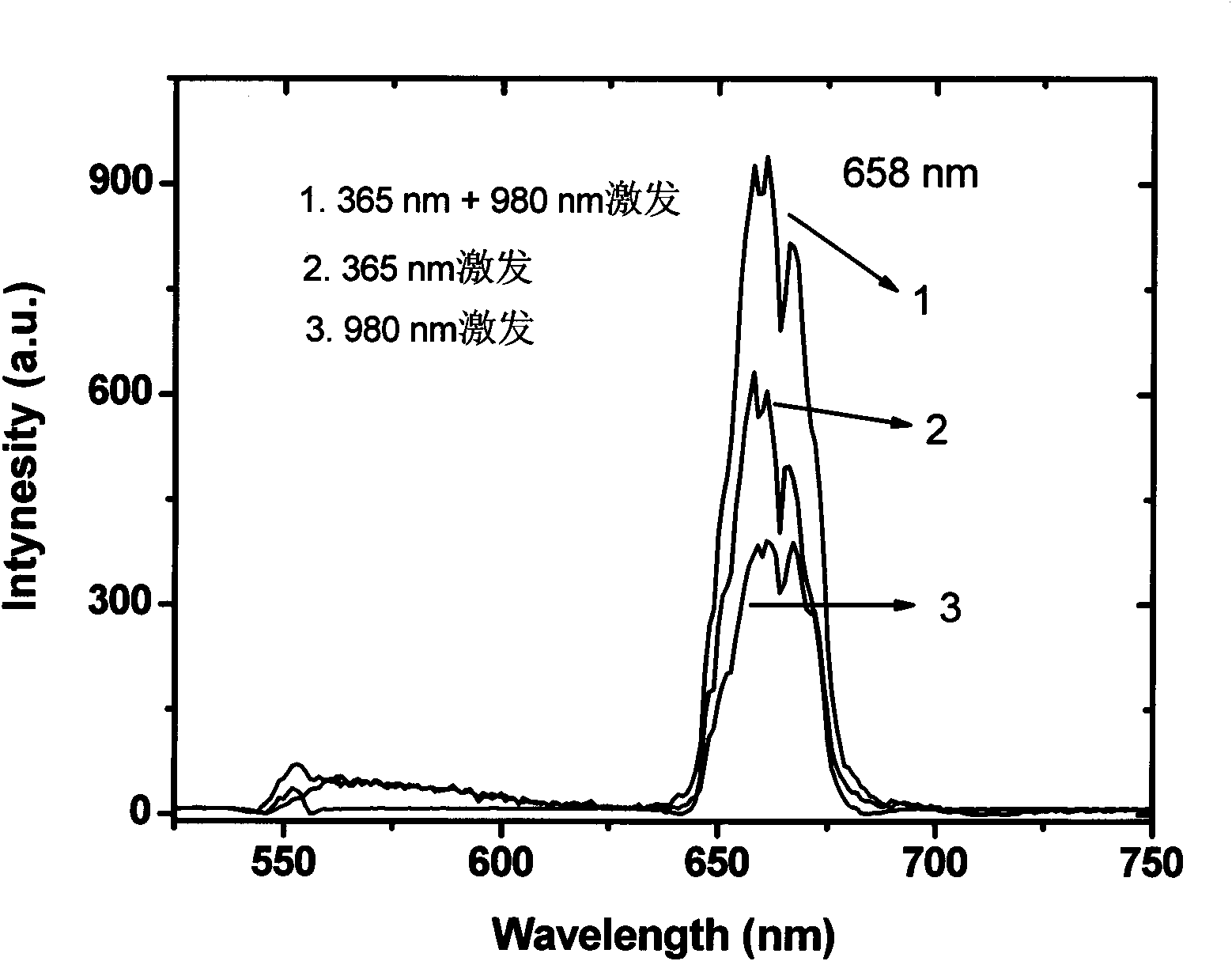

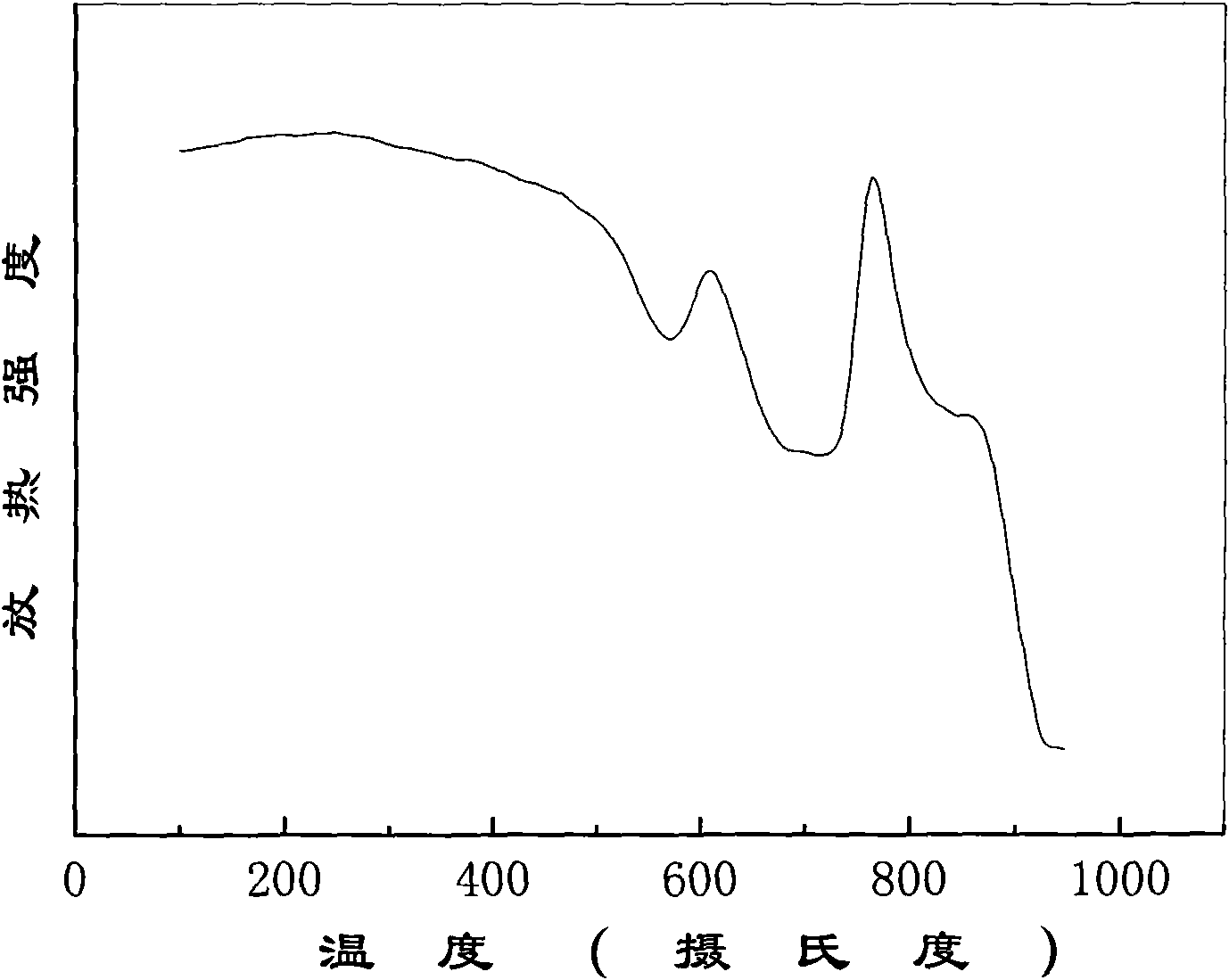

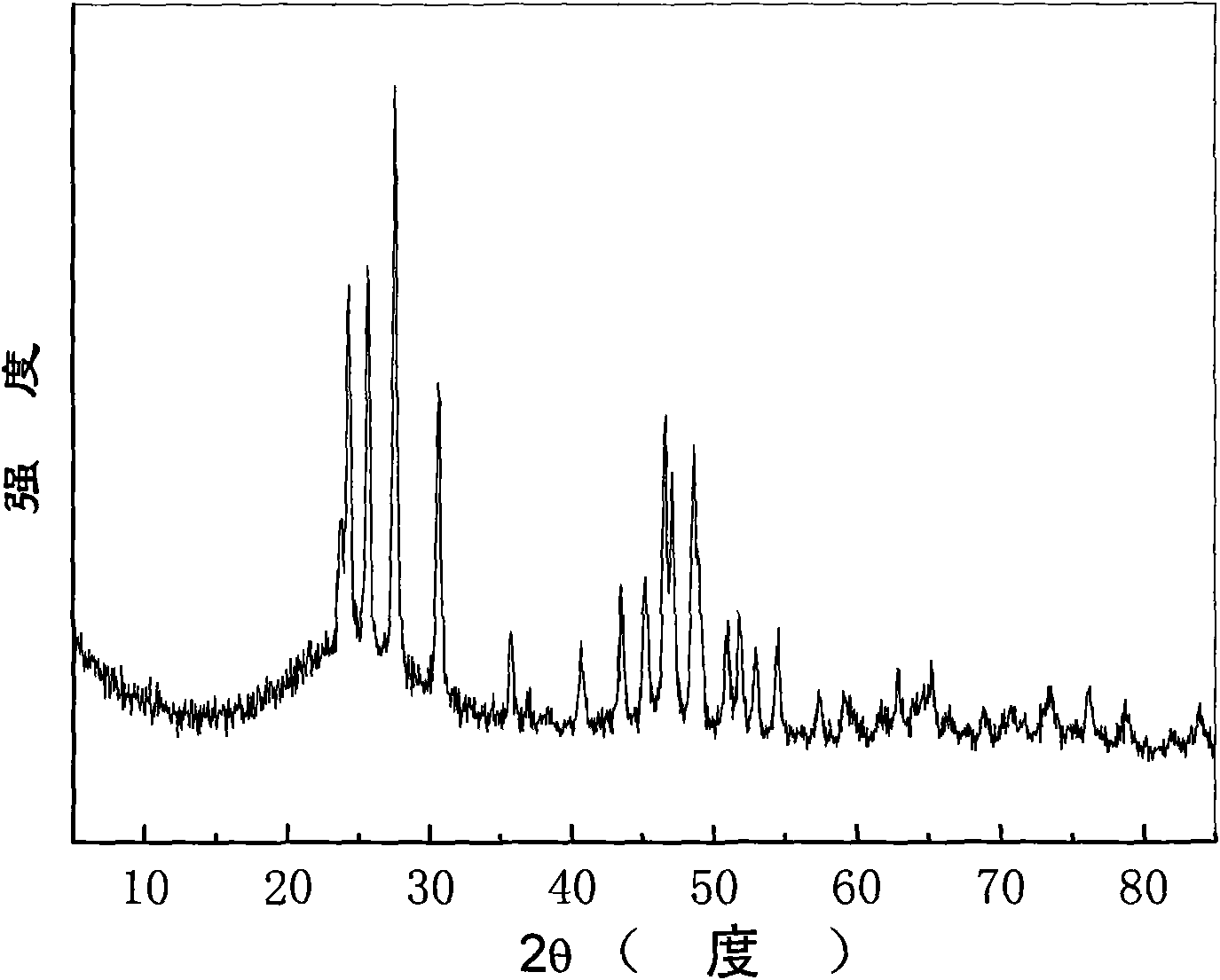

The invention discloses a material having cooperative frequency light conversion performance, and a preparation method and application thereof. The material having cooperative frequency light conversion performance has the molecular formula: YxYby(sigma Ln)zF3, wherein x is not less than 0 but less than 1, y is more than 0 but less than 1, z is more than 0 but not more than 0.50, Ln is any one or more than one of the rare earth elements including Ce, Tm, Er, Ho, Dy, Tb, Gd, Eu, Sm, Nd and Pr. The preparation method of the material having cooperative frequency light conversion performance is any one of the group consisting of conventional high-temperature solid phase method, hydrothermal synthesis method and co-precipitation method. The fluoride material having cooperative frequency light conversion performance according to the invention realizes the combination of two mechanisms, i.e. upper conversion and quantum cutting lower conversion, effectively converts ultraviolet and infrared lights into a visible light at certain frequency simultaneously while the reinforcement twice as much as the intensity of the visible light at the frequency is obtained, and has the advantages of low cost, simple and convenient synthesis method and batch production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Application of down-conversion luminescent material on dye-sensitized solar cells

InactiveCN101582332AAvoid instabilityImprove photoelectric conversion efficiencyLight-sensitive devicesSolid-state devicesSemiconductor materialsPhosphate

The invention discloses an application of down-conversion luminescent material on dye-sensitized solar cells, which covers down-conversion luminescent material doped by nano particles with particle size of 5 to 50nm and rare earth taking phosphate, silicate and vanadate with a core-shell structure as a substrate on the surface of the dye-sensitized solar cell, dopes the down-conversion luminescent material into a nano TiO2, nano ZnO or SnO2 semiconductor material porous membrane to prepare a nano semiconductor photoelectrode with down-conversion function or disperses the down-conversion luminescent material in the electrolyte of the dye-sensitized solar cell. The invention utilizes the down-conversion luminescent material to convert ultraviolet light into visible light, thus not only solving the problem of instability of a solar cell caused by the ultraviolet light, but also absorbing an ultraviolet spectrum by the quantum cutting technology to emit the visible light so as to cause the cell to utilize sunlight to the maximum extent, and improve the photoelectric conversion efficiency and the performance stability of the cell.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

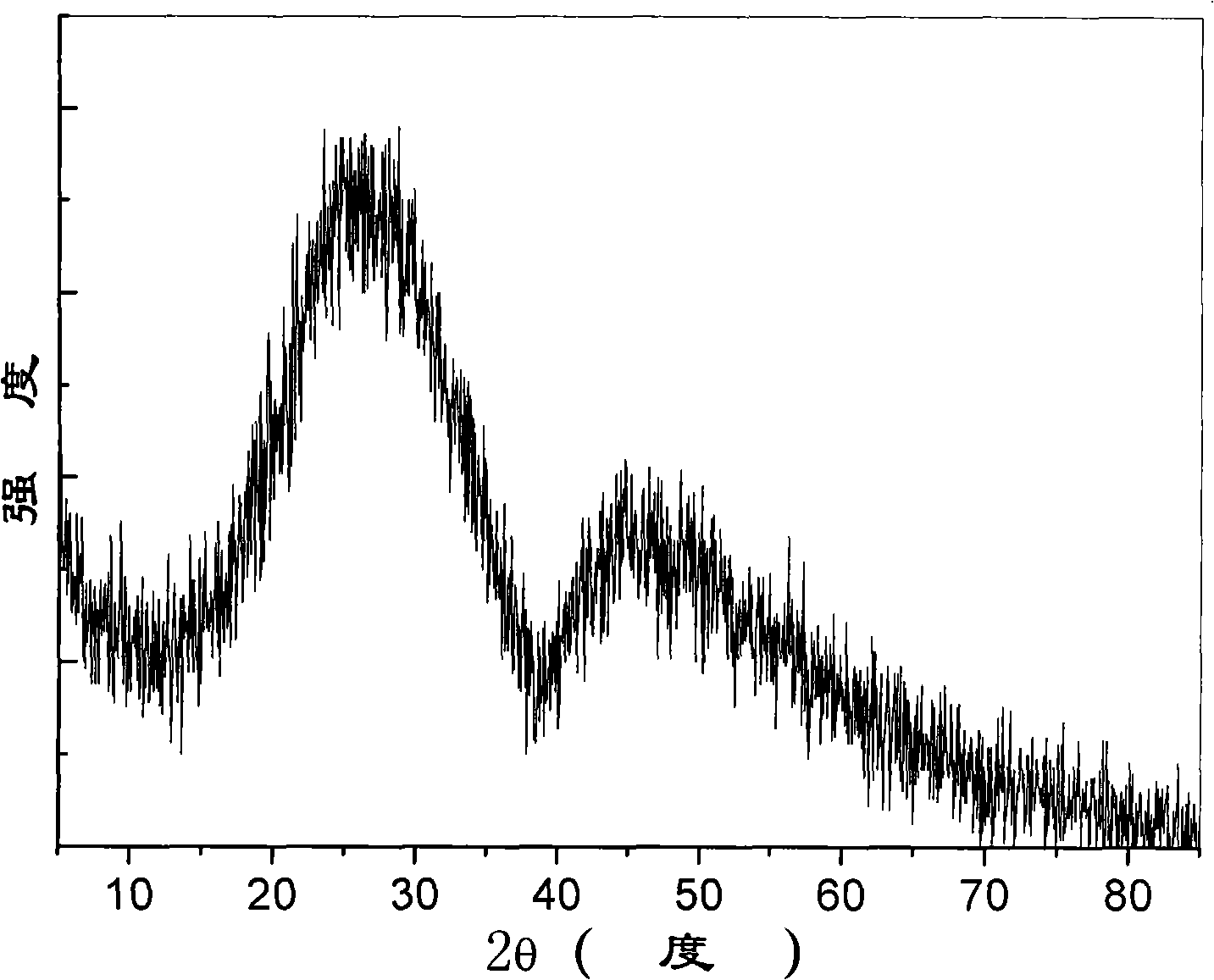

Near-infrared quantum-cutting down-conversion luminescent transparent glass ceramic and preparation method and application thereof

The invention discloses a near-infrared quantum-cutting down-conversion luminescent transparent glass ceramic and a preparation method and application thereof. The glass ceramic comprises the following compositions: 40 to 60 mol percent of SiO2, 10 to 30 mol percent of Al2O3, 5 to 25 mol percent of YF3, 0 to 15 mol percent of NaF, 0 to 15 mol percent of LiF, 0.01 to 5 mol percent of YbF, 0.01 to 5 mol percent of ReF, less than 0.5 mol percent of MSO4, and less than 0.02 mol percent of Fe, wherein the Re refers to Pr or Tb or Tm; M refers to Mg or Ca or Bar o Sr; and the contents of the NaF and the LiF are not 0 simultaneously. The glass ceramic can realize high-efficiency near-infrared quantum-cutting down-conversion luminescence under the excitation of blue light. The transparent glass ceramic is coupled with a silicon solar cell, and is hopeful to reduce the thermalization effect of the silicon solar cell and improve the photoelectric conversion efficiency of the cell.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

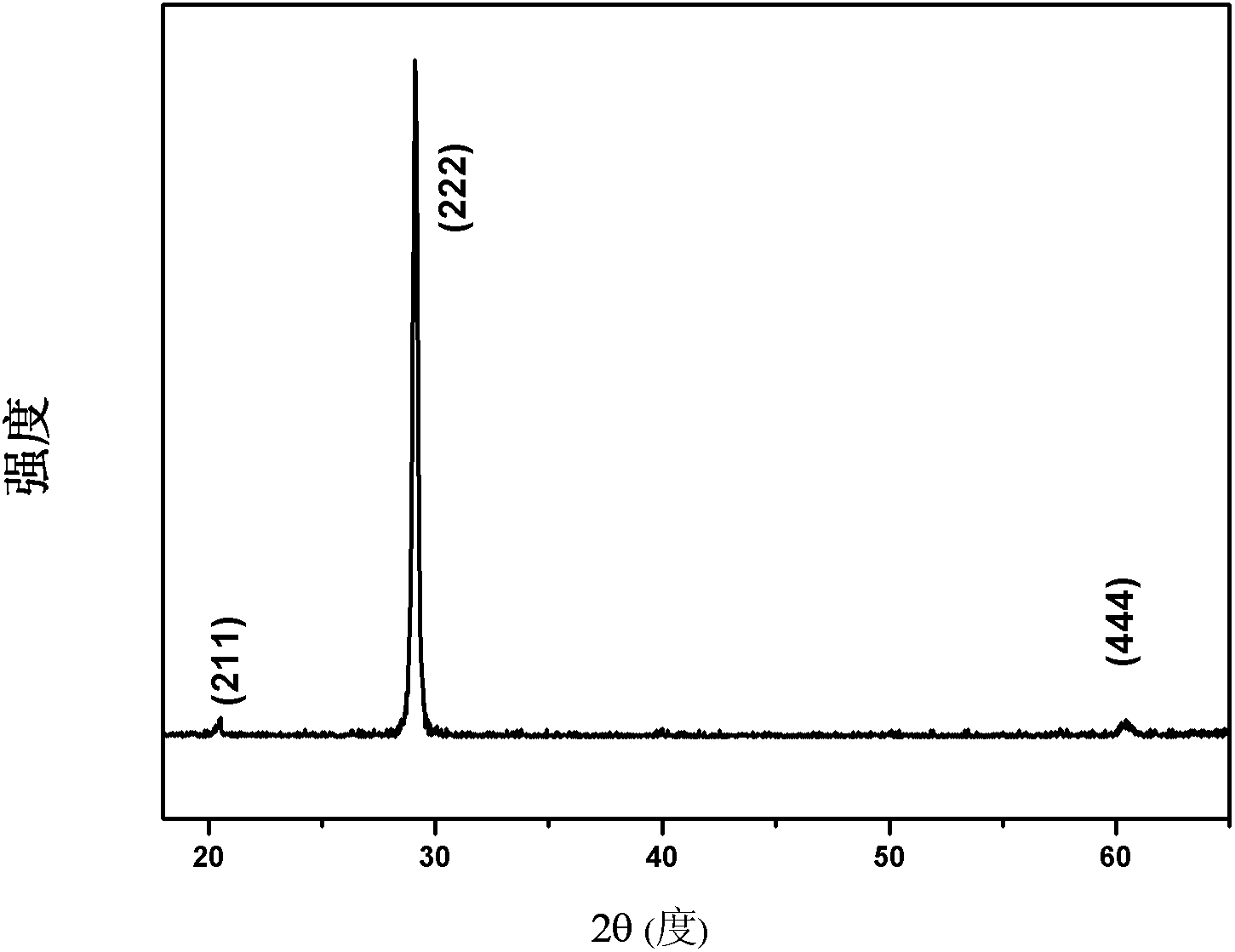

Near-infrared quantum cutting transparent film and preparation method thereof

InactiveCN102321476ALow quantum efficiencyImprove low work efficiencyVacuum evaporation coatingSputtering coatingUltraviolet lightsSilicon solar cell

The invention discloses a near-infrared quantum cutting transparent film and a preparation method thereof and belongs to the field of solid luminescence materials. The raw materials of the film include Y2O3, Bi2O3 and Yb2O3; the mole fraction of the Bi2O3 is 0.25-1% and the mole fraction of the Yb2O3 is 0.5-5%. The preparation method comprises the following steps of: adding Bi2O3 powder and Yb2O3 powder to Y2O3 powder, ball-milling and mixing, drying and then calcinating at the temperature of 1200 DEG C for 12h and pressing into ceramic targets by using a hot pressing method; introducing oxygen by using a silicon wafer or quartz as a substrate through a laser pulse deposition method, wherein the temperature of the substrate is 400-800 DEG C, the distance between target bases is 5-8 cm, the working pressure is 0.5-10 Pa and the laser energy is 100-400 mJ / pulse. When the film is excited by the ultraviolet light, the efficient near-infrared quantum cutting down-conversion luminescence can be realized; and the heating effect of silicon solar cells is expected to be reduced and the photoelectric conversion efficiency of the cells is increased.

Owner:BEIJING UNIV OF TECH

Praseodymium-doped tungstate luminescent material and use thereof

InactiveCN100999663AThe preparation process is matureLow costLuminescent compositionsFluorescenceSingle crystal

The present invention relates to light emitting, display and scintillation material technology, and is especially one kind of light-emitting Pr doped tungstate material and its use. The light-emitting Pr doped tungstate material may be in monocrystal, powder or glass form. By means of the quantum cutting of Pr3+ ion and the energy transfer between tungstate radical and Pr3+ ion, one photon in deep ultraviolet area or in even short wavelength area is converted into two visible photons for human eye and CCD to sense, so as to realize quantum cutting to the 490-650 nm visible light area in the total quantum efficiency over 100 %. The light-emitting Pr doped tungstate material is used as the ultraviolet and even short wavelength ray excited light emitting material and the scintillation material in short wavelength photon detector and high energy particle detector.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

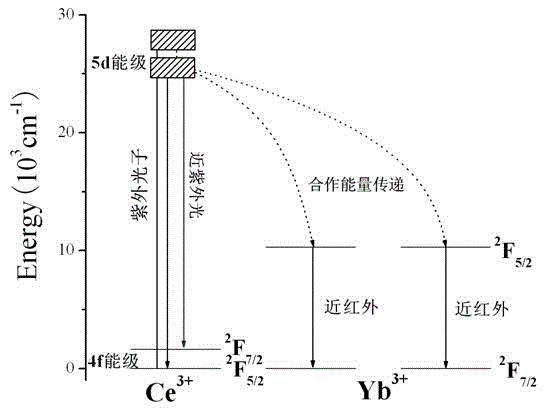

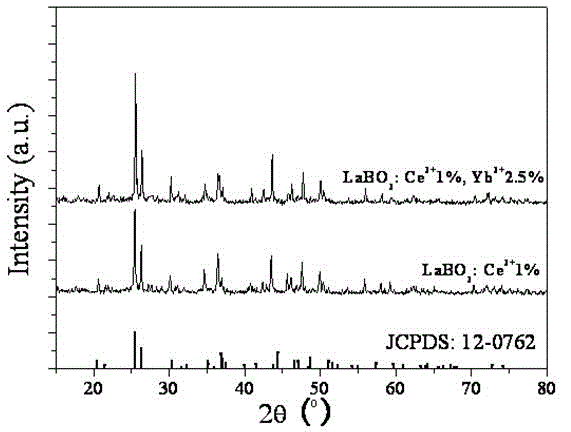

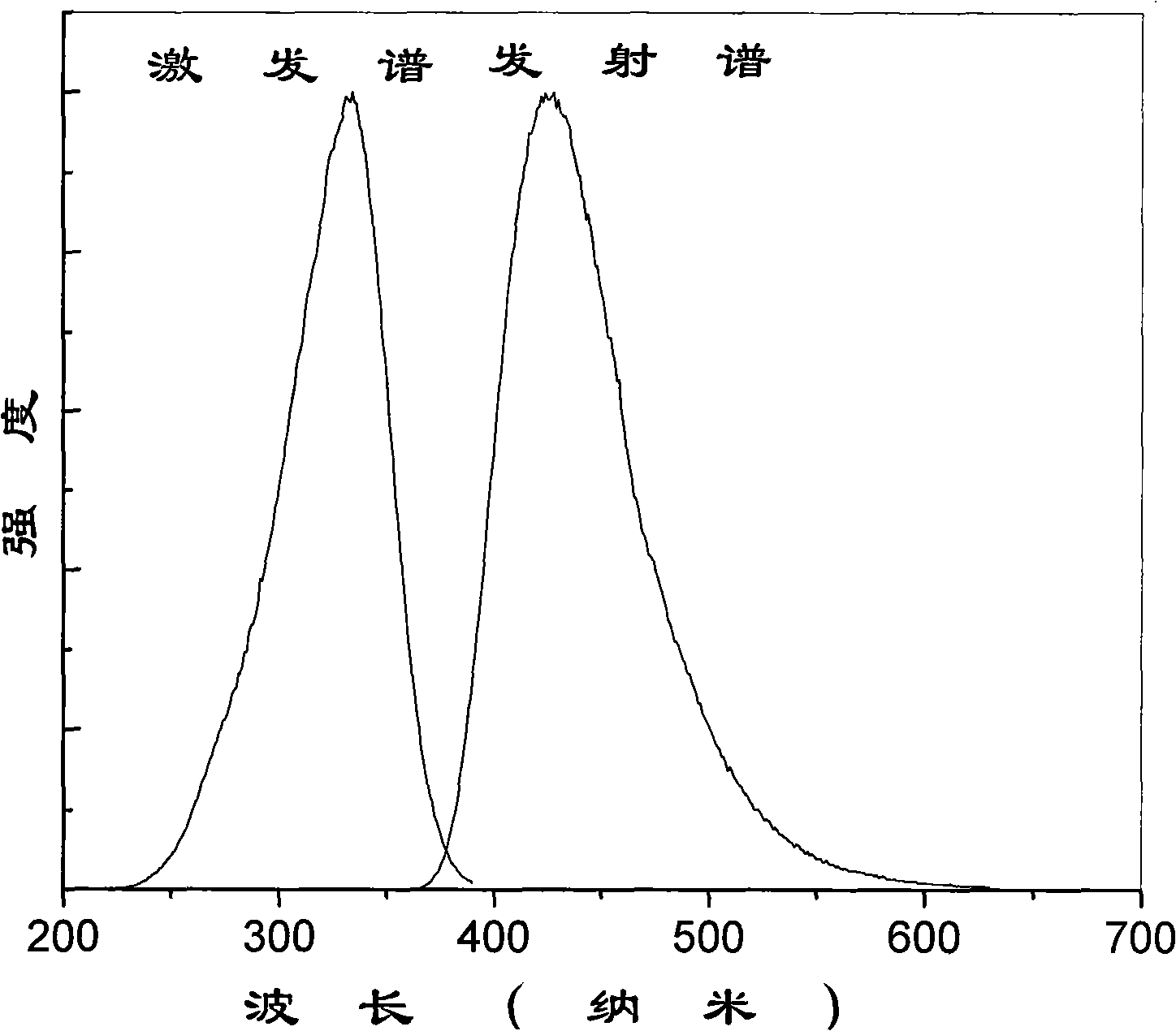

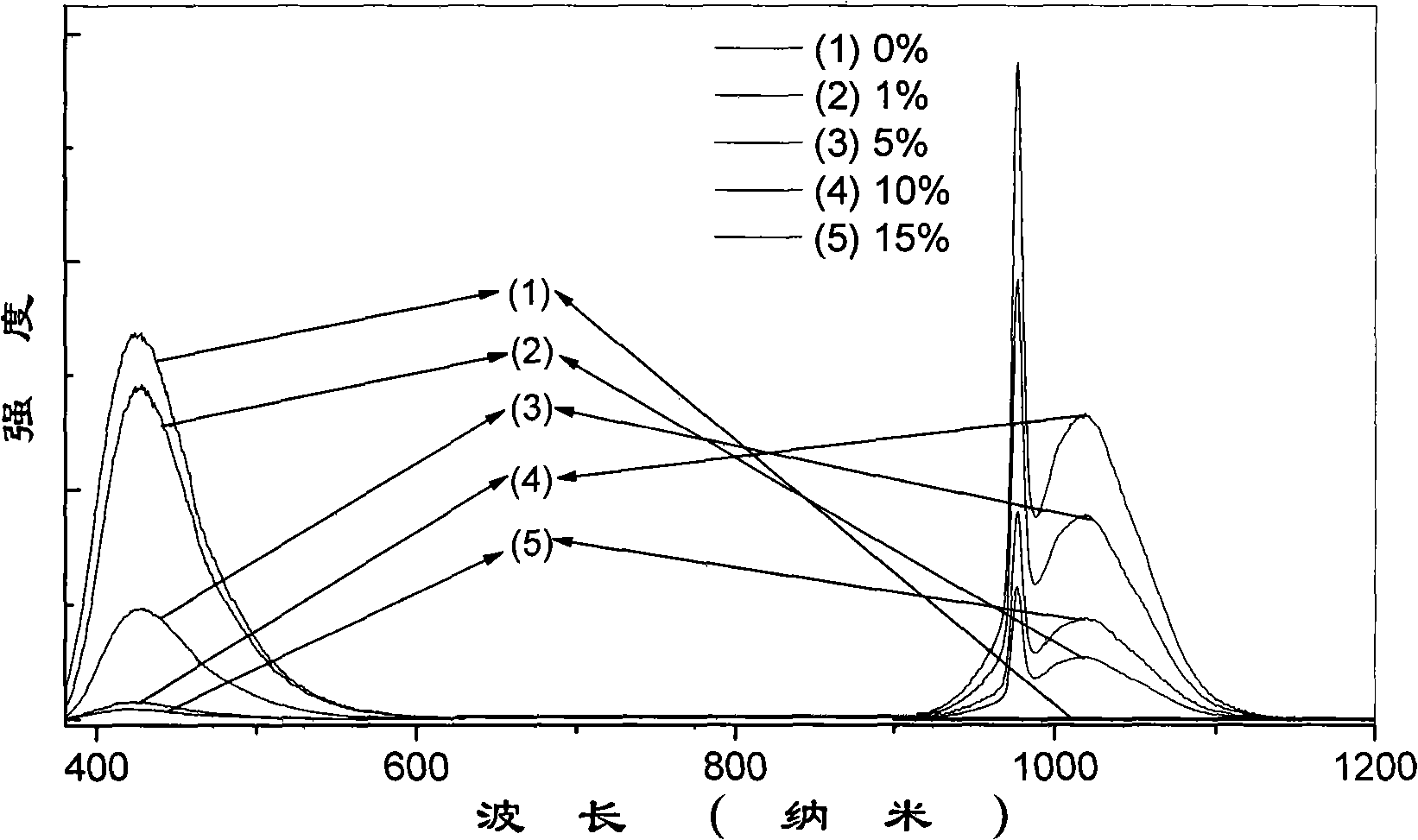

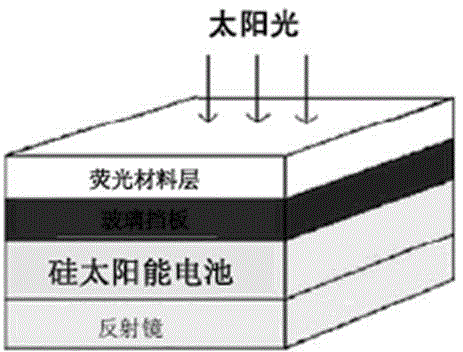

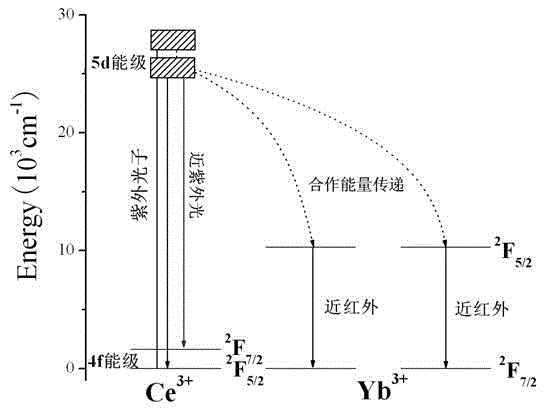

Near-infrared quantum cutting fluorescent powder capable of increasing silicon solar cell efficiency and preparation method thereof

ActiveCN103333690AExpand the scope of absorptionImprove conversion efficiencyPhotovoltaic energy generationLuminescent compositionsPhoton emissionUltraviolet

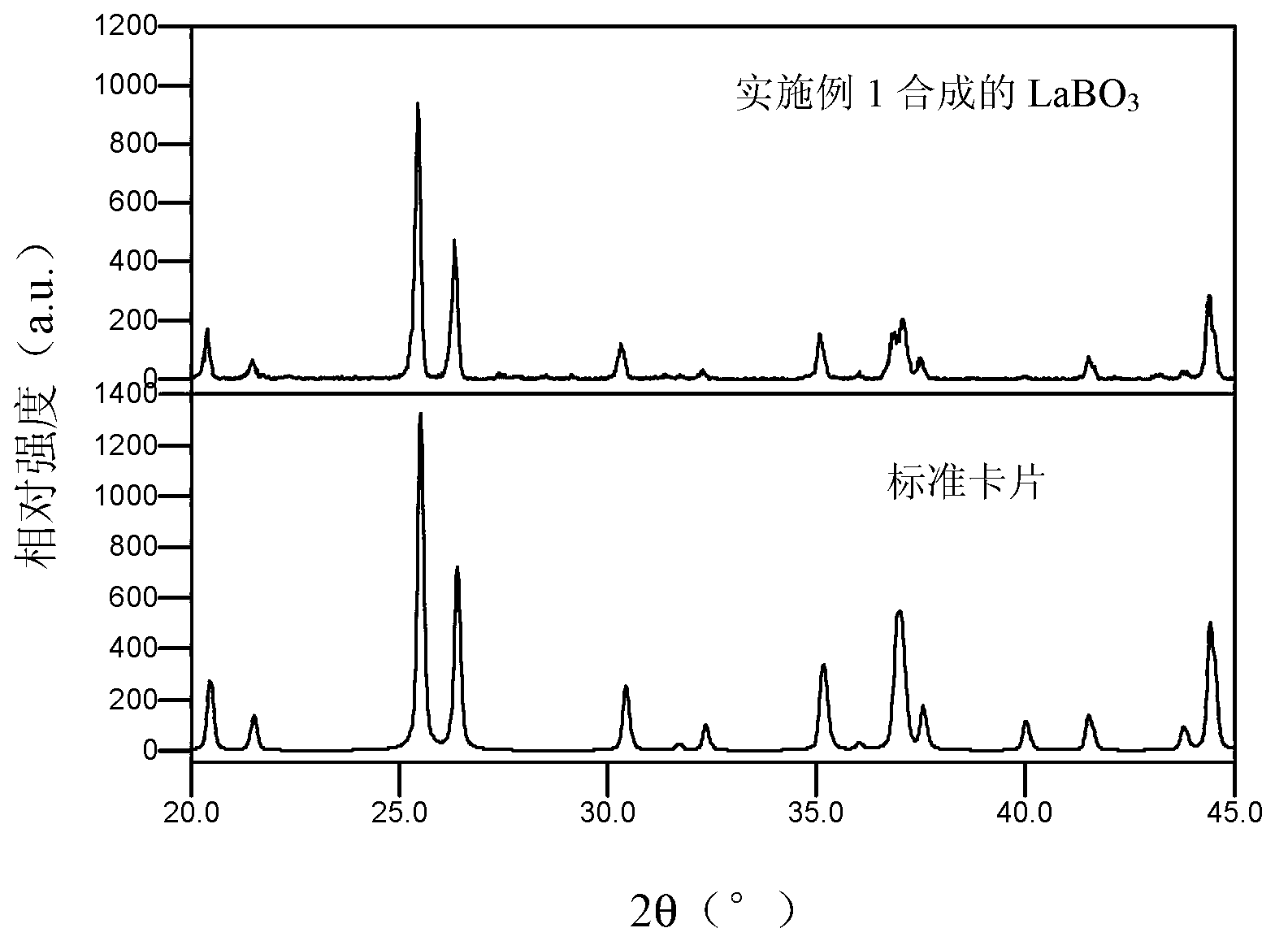

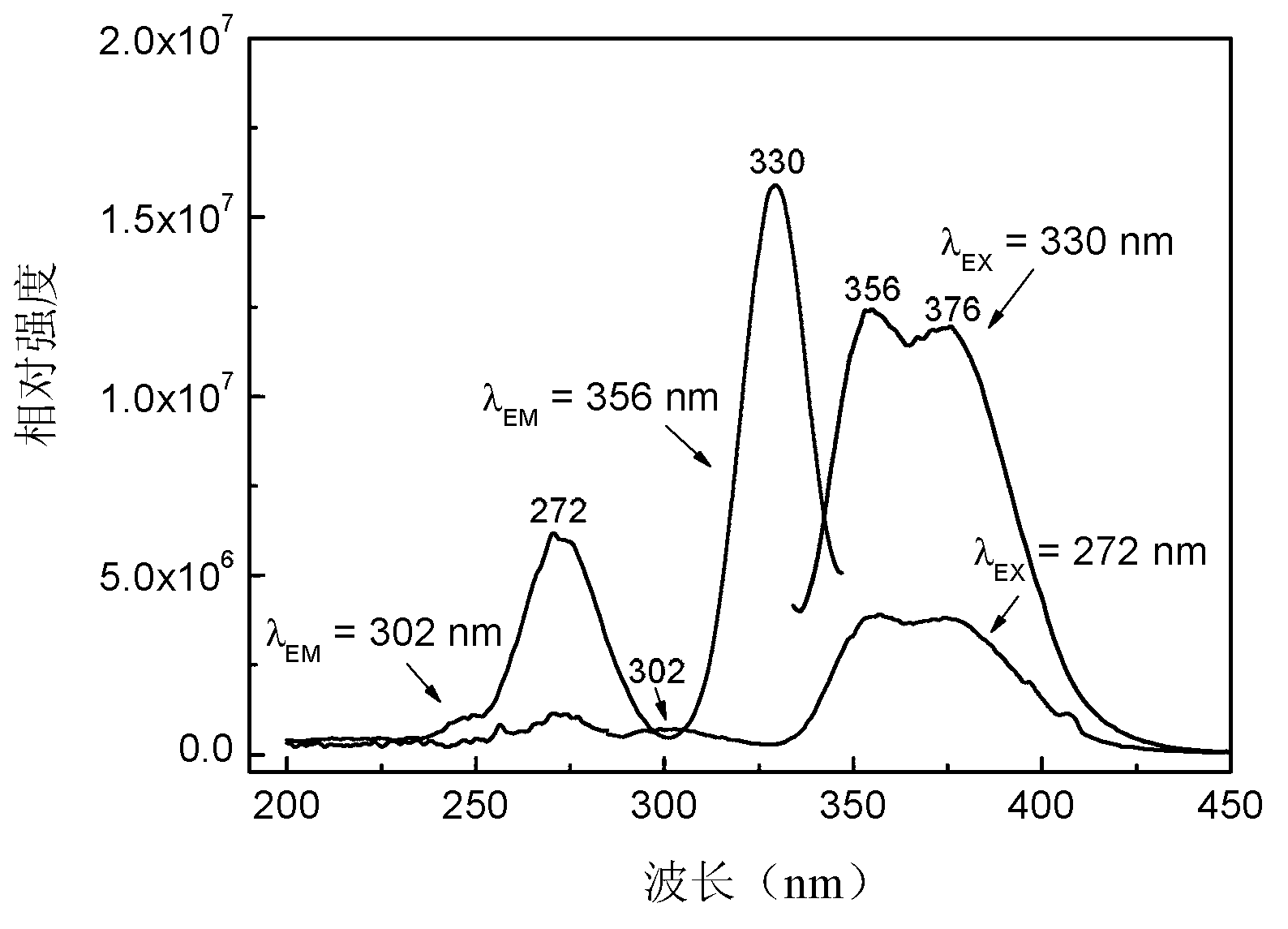

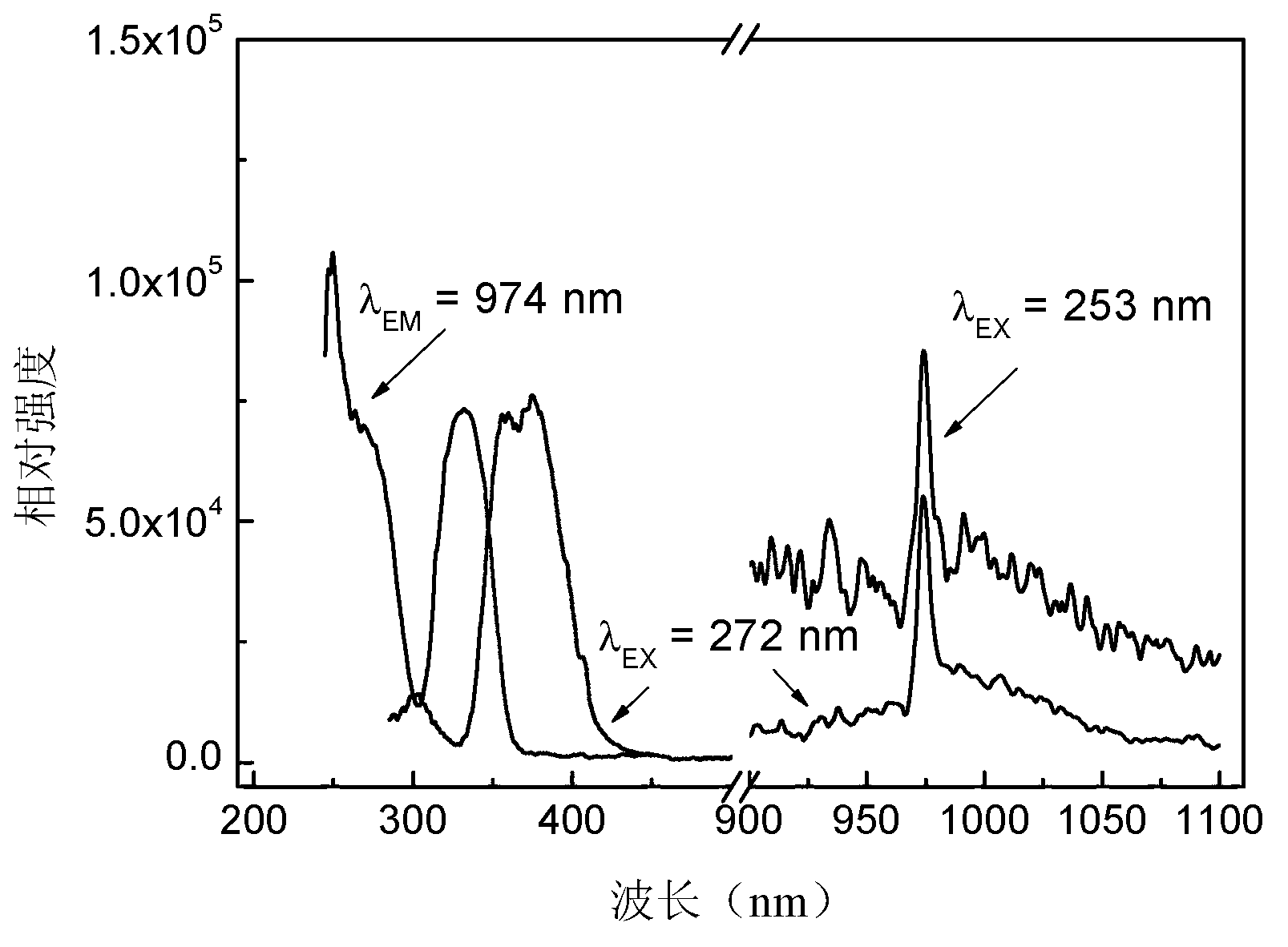

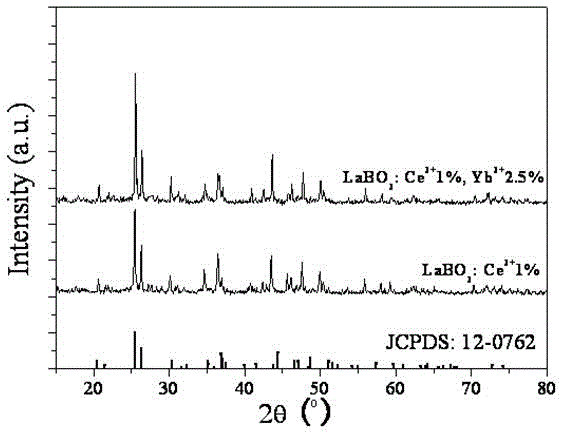

The invention relates to the technical field of fluorescent powder production, and discloses a near-infrared quantum cutting fluorescent powder capable of increasing silicon solar cell efficiency and a preparation method thereof. The near-infrared quantum cutting fluorescent powder has a chemical formula as follows: LaBO3:Ce<3+>(1%),Yb<3+>(x%), wherein the x is not less than 2 and not more than 3. According to the near-infrared quantum cutting fluorescent powder, when each ultraviolet photon is absorbed, a Ce<3+>-Yb<3+> ion pair can emit two near-infrared photons through cooperation energy transmission, thus emitting 980 nm near infrared light. The near-infrared quantum cutting fluorescent powder is advantageous in that silicon solar cell spectrum absorption scope can be widened, and therefore the silicon solar cell conversion efficiency can be increased.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

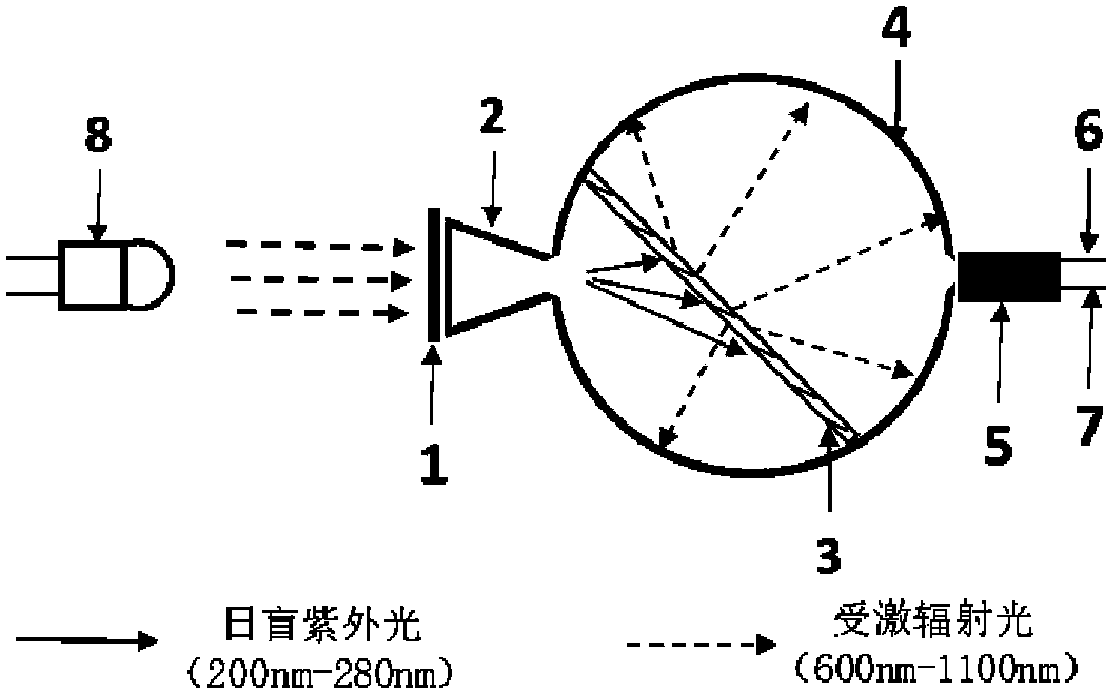

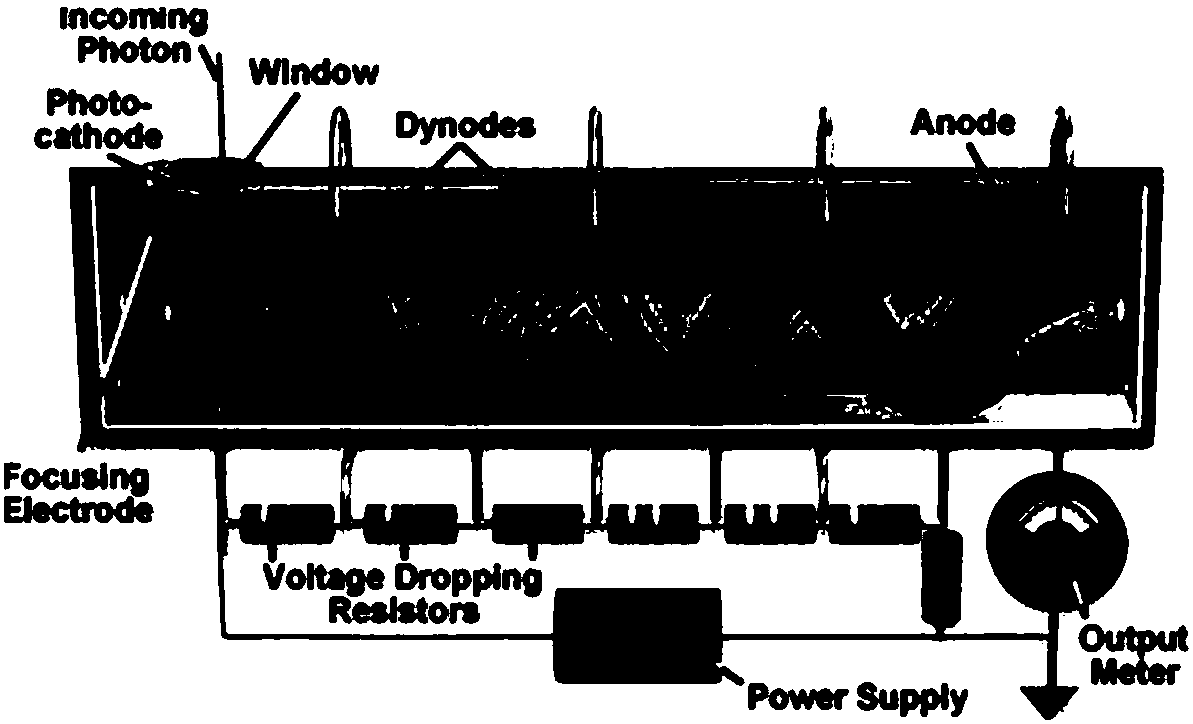

Solar-blind ultraviolet light detecting device

The invention discloses a solar-blind ultraviolet light detecting device, which uses the quantum tailoring technology to complete the wavelength conversion and photon number amplification function ofprobe light. The quantum-cut fluorescent glass in an integrating sphere absorbs 200 nm to 280 nm of solar-blind ultraviolet photons, and is stimulated to radiate 2 to 3 times the number of long-wavelength photons; an exit window end of the integrating sphere is connected to a photomultiplier tube of an active device, the output current of the photomultiplier tube is proportional to the number of the received photons, and the sensitivity to the visible band light is 2 to 10 times that of the solar-blind ultraviolet light. The filtering effect of a filter arranged on an incident window of the integrating sphere can strictly limit the detection wavelength range, and can multiply the sensitivity of detection of solar-blind ultraviolet light.

Owner:NANJING UNIV OF POSTS & TELECOMM

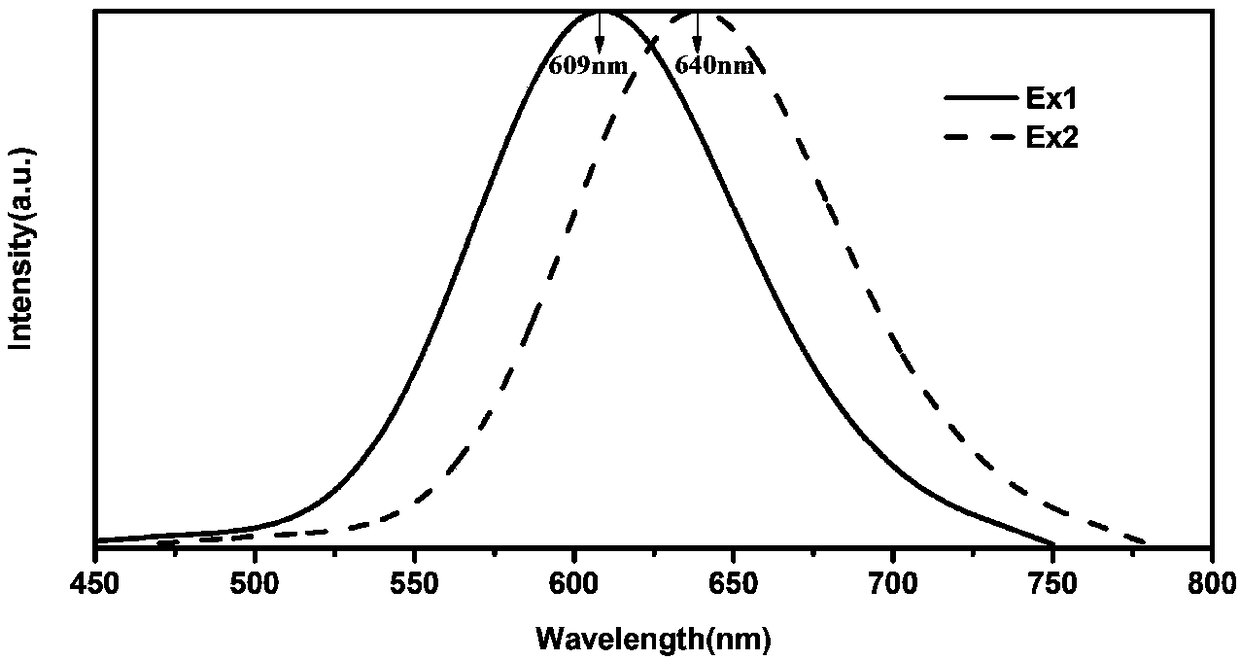

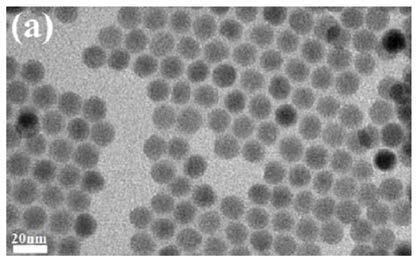

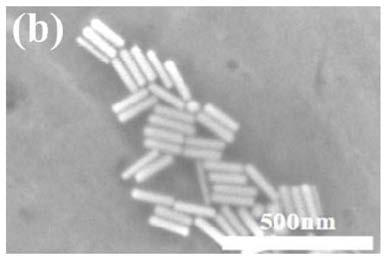

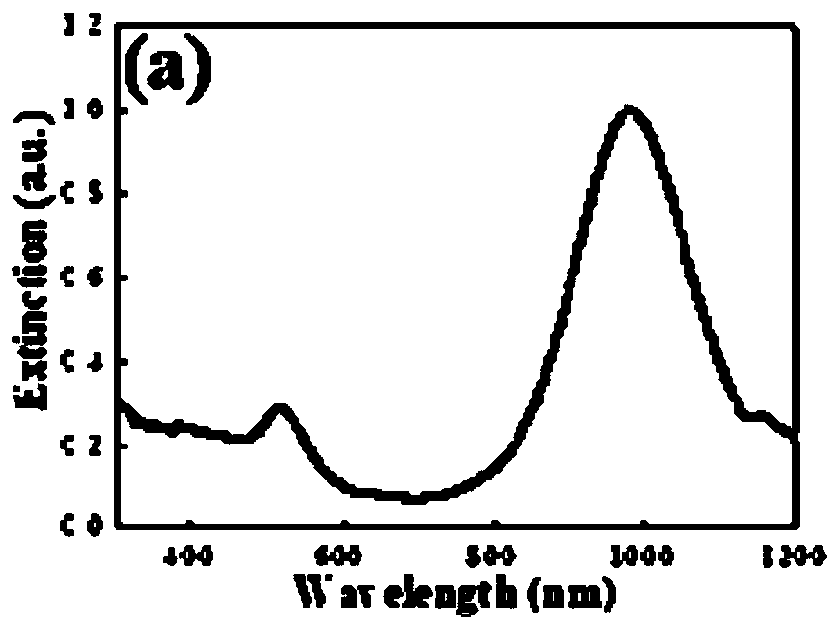

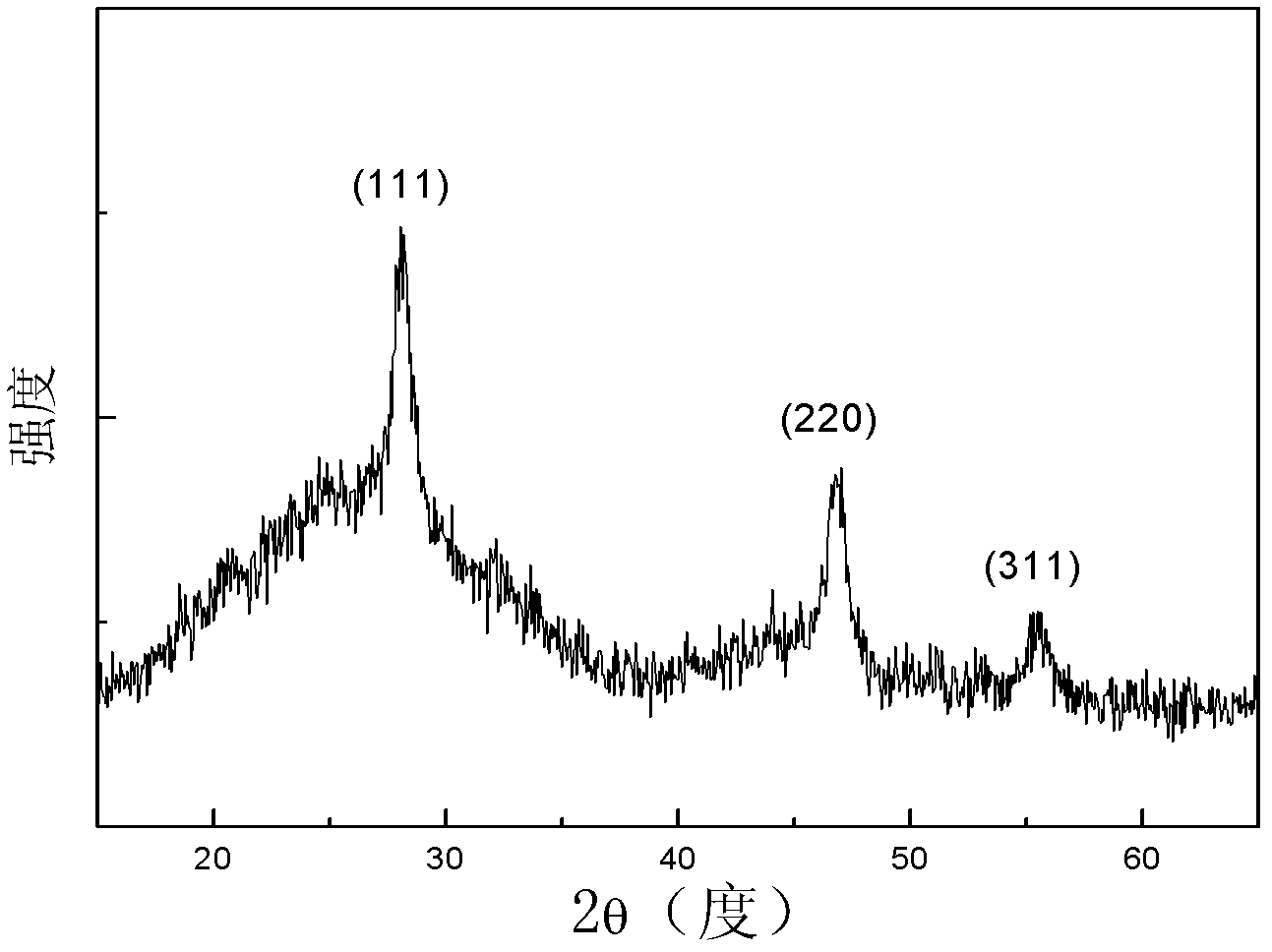

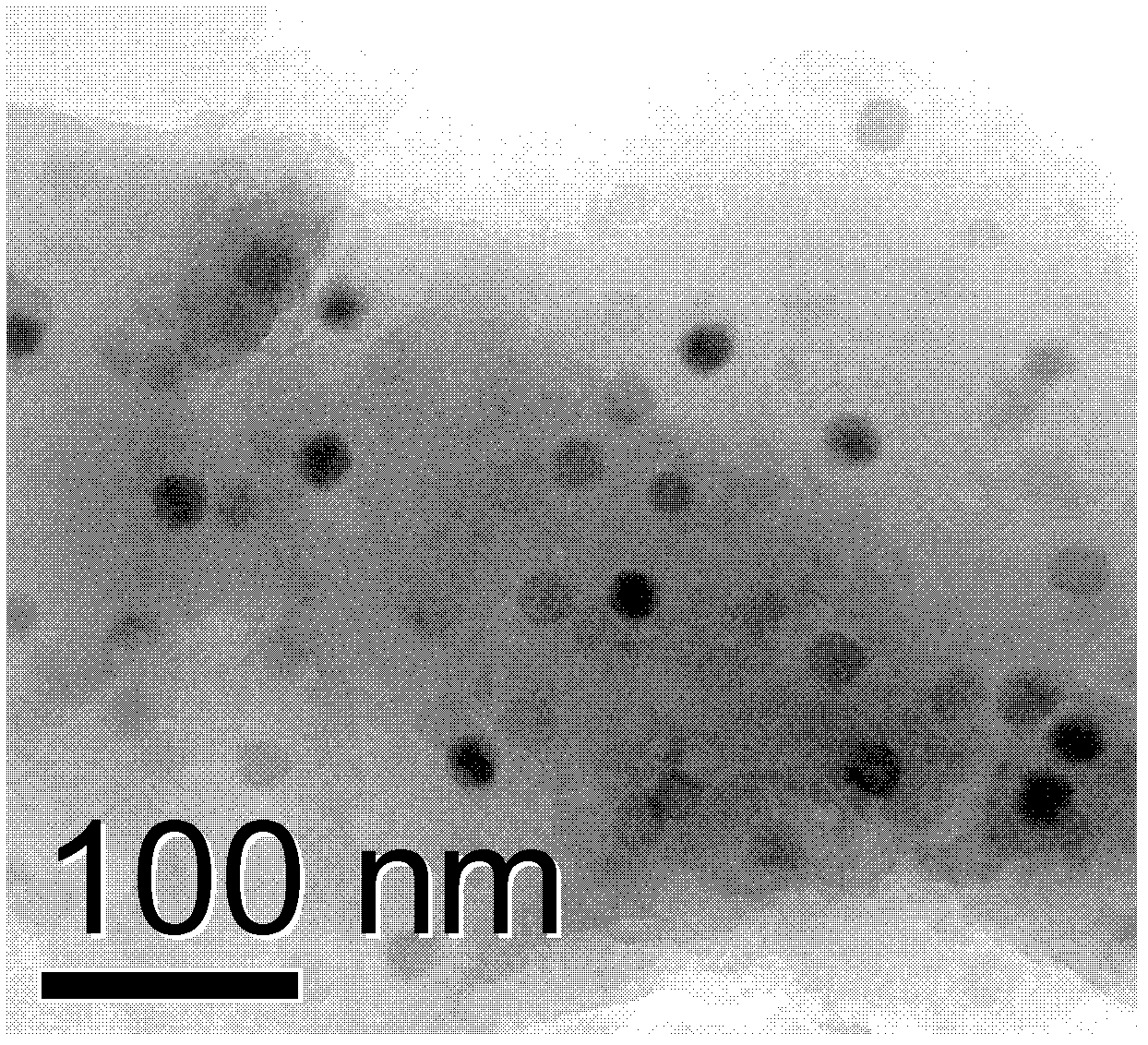

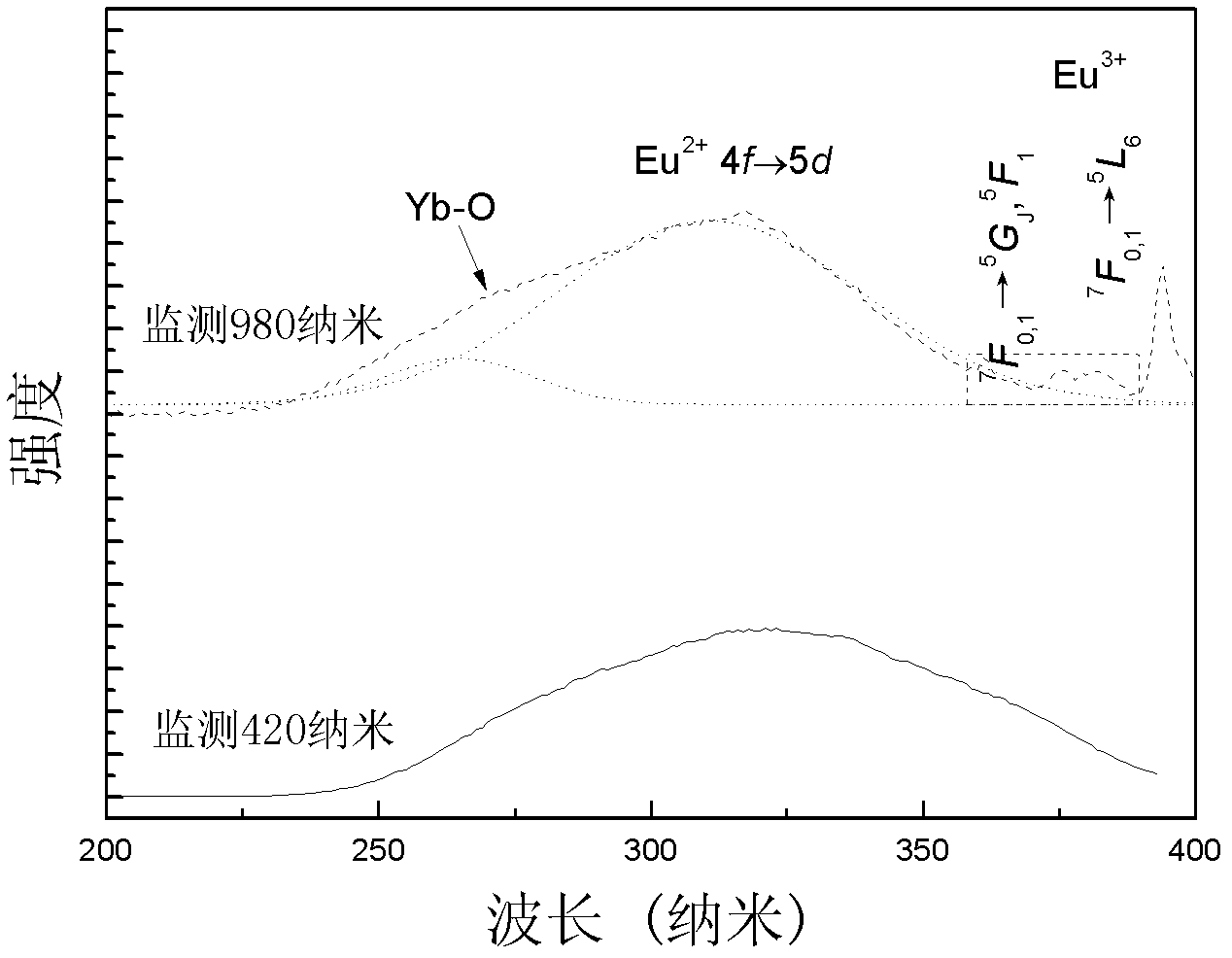

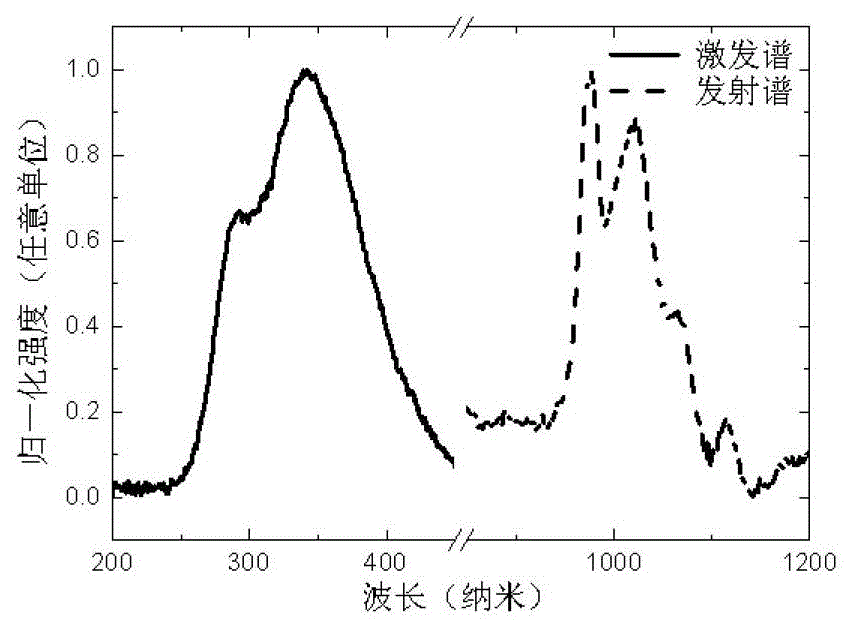

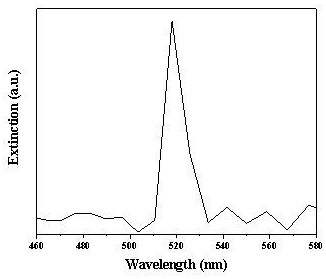

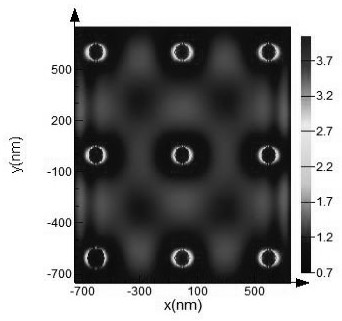

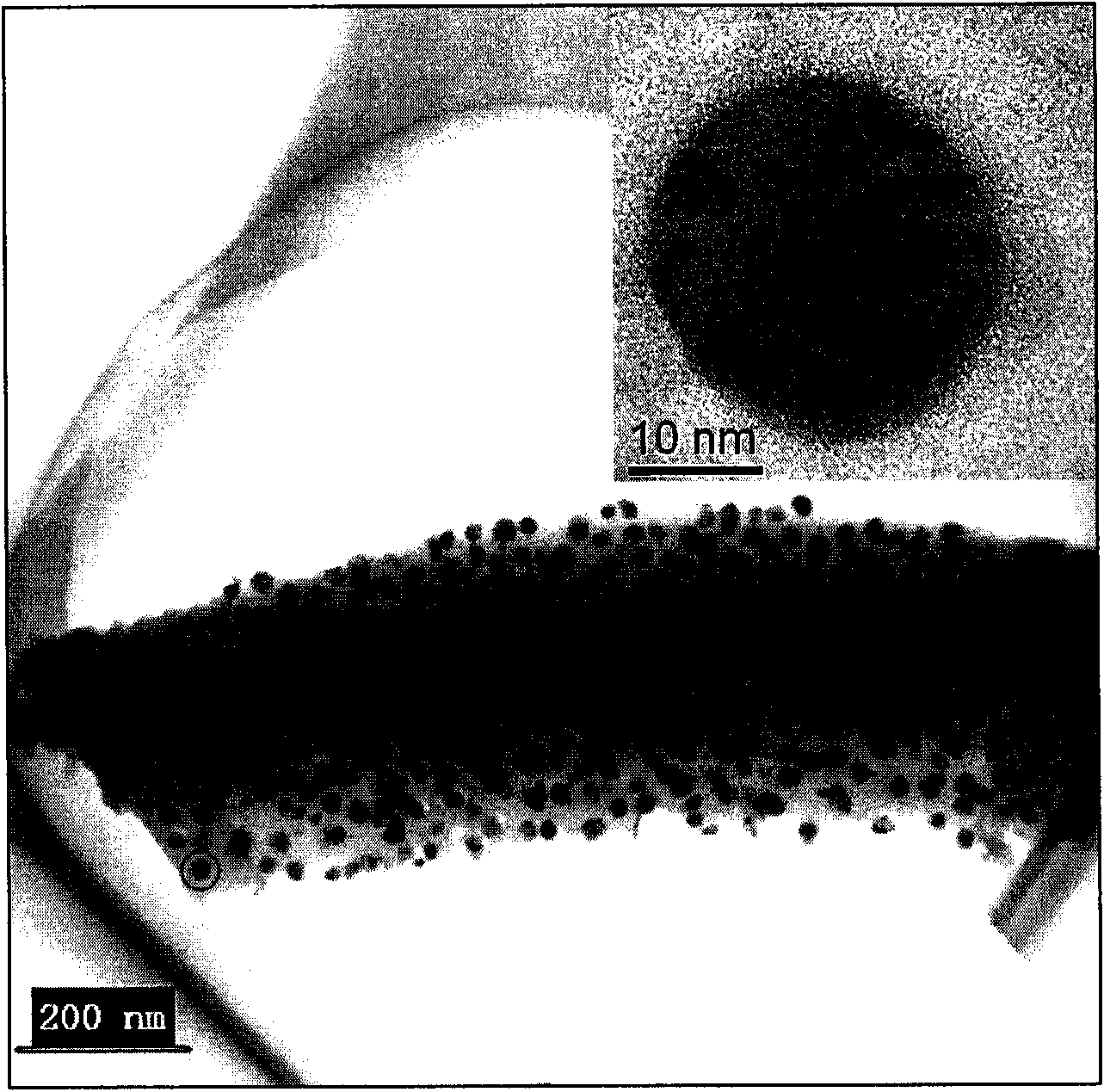

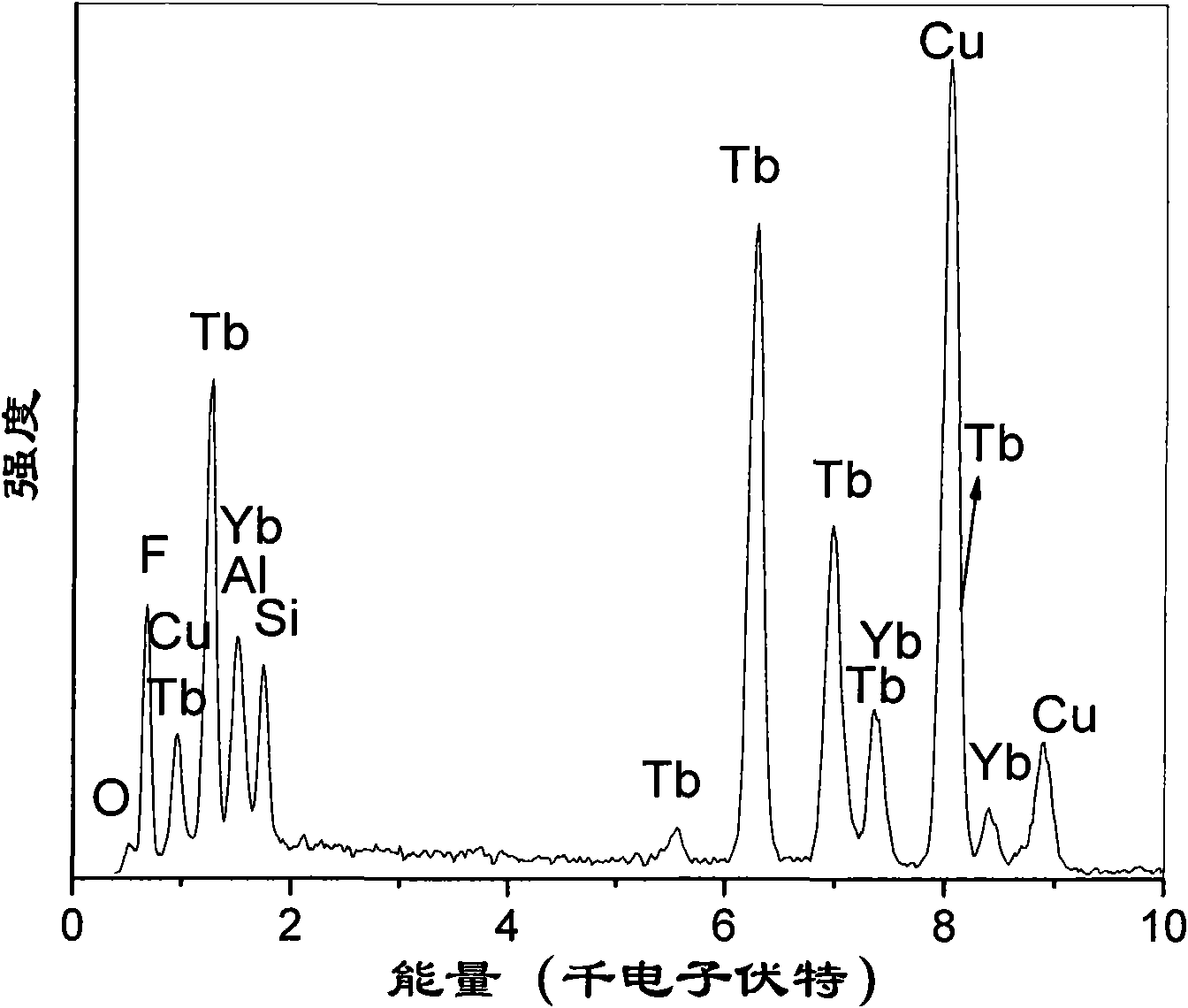

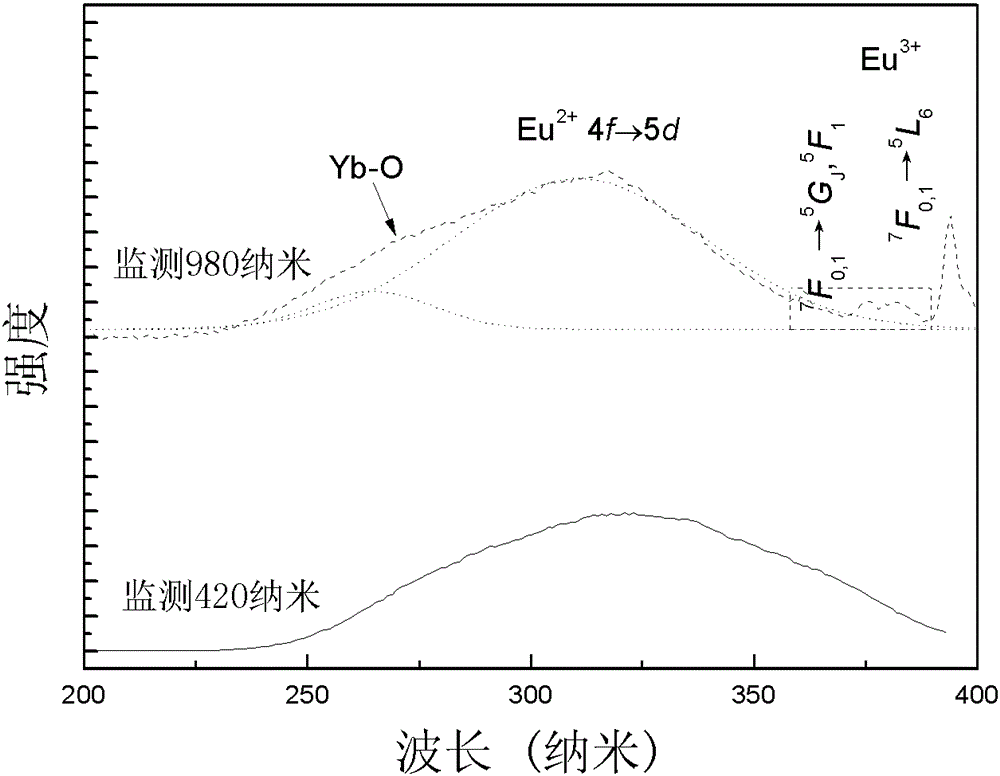

Noble metal-rare earth nano composite system for modulating solar spectrum and preparation method of noble metal-rare earth nano composite system

PendingCN110408395ASignificant quantum tailoring luminous enhancement effectEnhanced Quantum Clipping Glow Enhancement EffectTransportation and packagingMetal-working apparatusRare earthSolar spectra

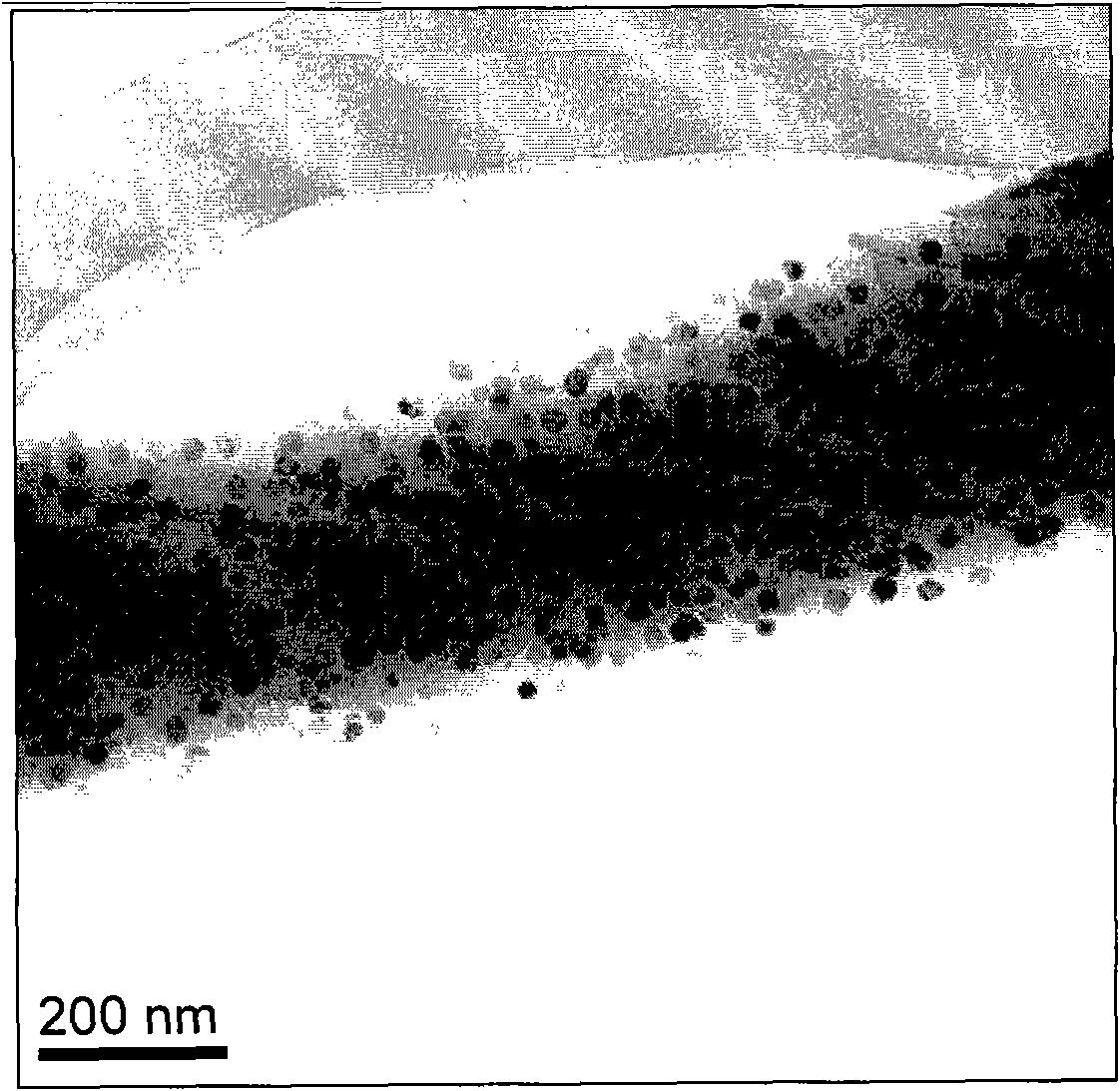

The invention discloses a noble metal-rare earth nano composite system for modulating solar spectrum and a preparation method of the noble metal-rare earth nano composite system. The chemical constitution of the nano composite system is Au NRs-NaYF4: Er3+, the effective excitation wavelength of the nano composite system is 486 nm, and the emission peak is 980 nm. When the length-diameter ratio ofAu NRs is 6 and the doping concentration of Au NRs is 0.225%, the luminescence enhancement effect of quantum cutting of the nano composite system is the most significant, and the maximum enhancement factor is 2.47. The invention provides a noble metal nanoparticle-rare earth nanoparticle nano composite system for modulating the solar spectrum for the first time. The noble metal nanoparticle-rare earth nanoparticle nano composite system for modulating the solar spectrum is simple in preparation process, low in cost and high in efficiency. The nano composite system is made into a light conversion layer and is placed on a solar cell, so that visible light which is absorbed by the solar cell at low efficiency in sunlight can be converted into a near infrared spectrum which can be efficiently absorbed by the solar cell, and the photoelectric conversion efficiency of the solar cell is effectively improved.

Owner:FUJIAN NORMAL UNIV

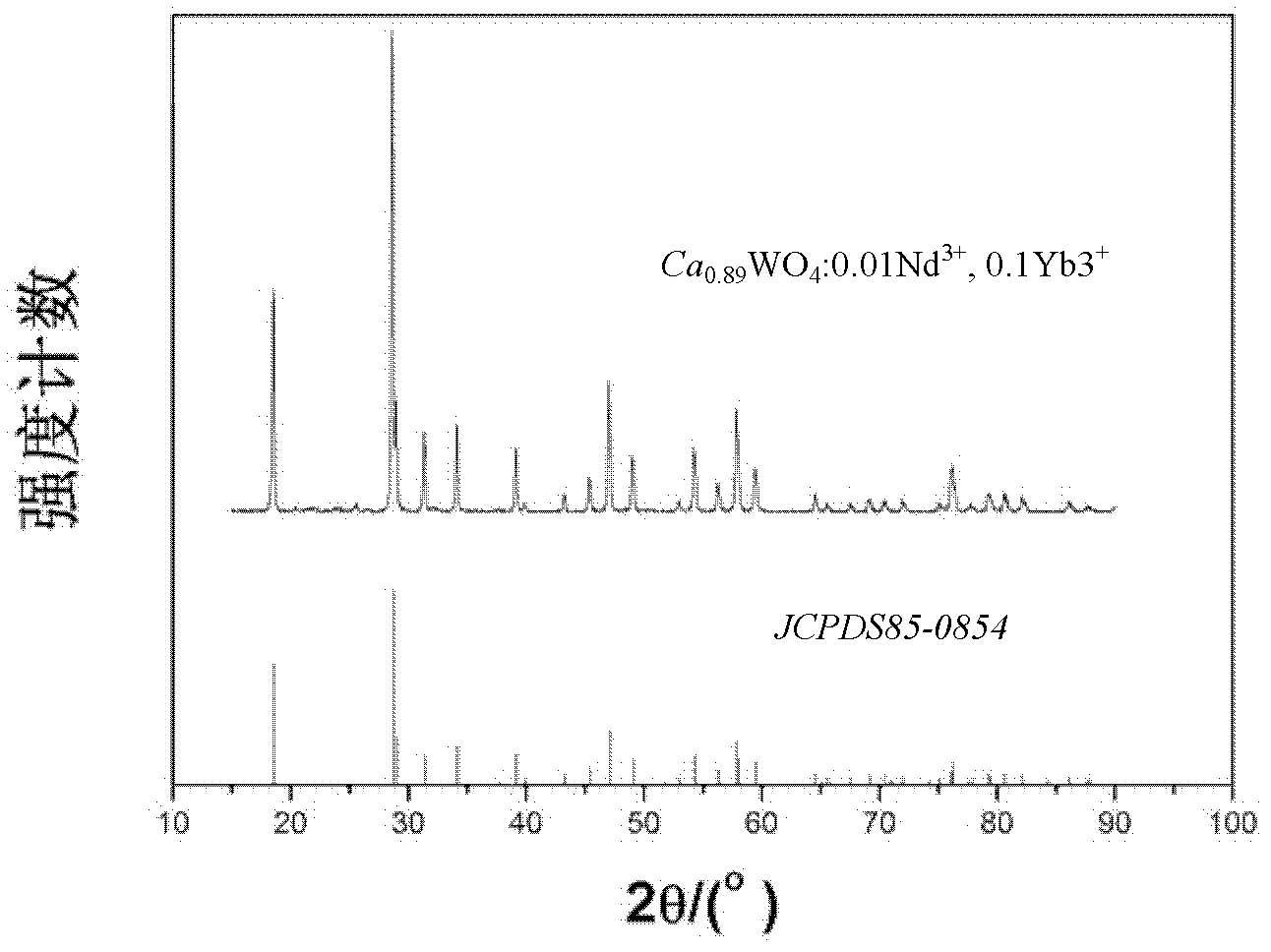

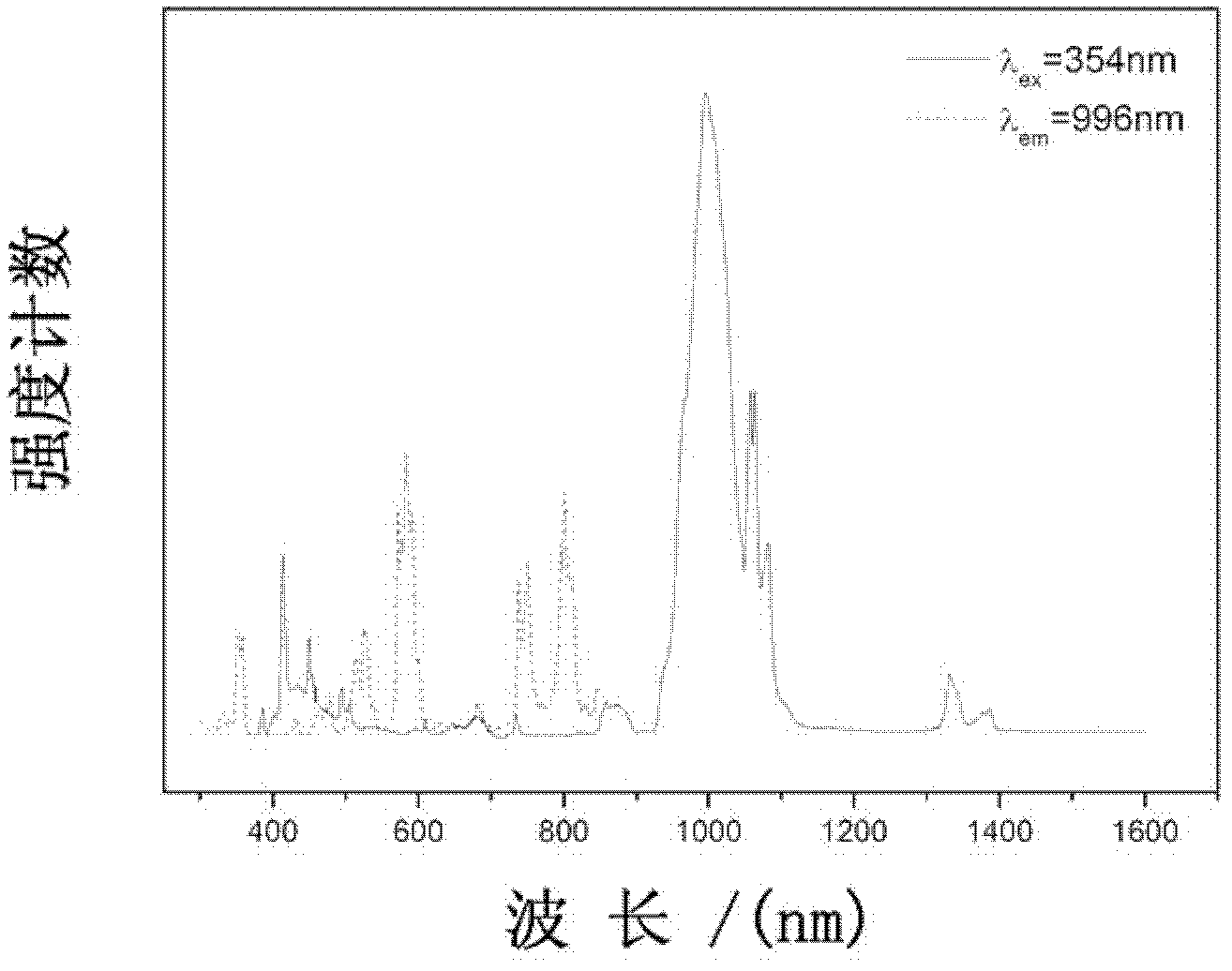

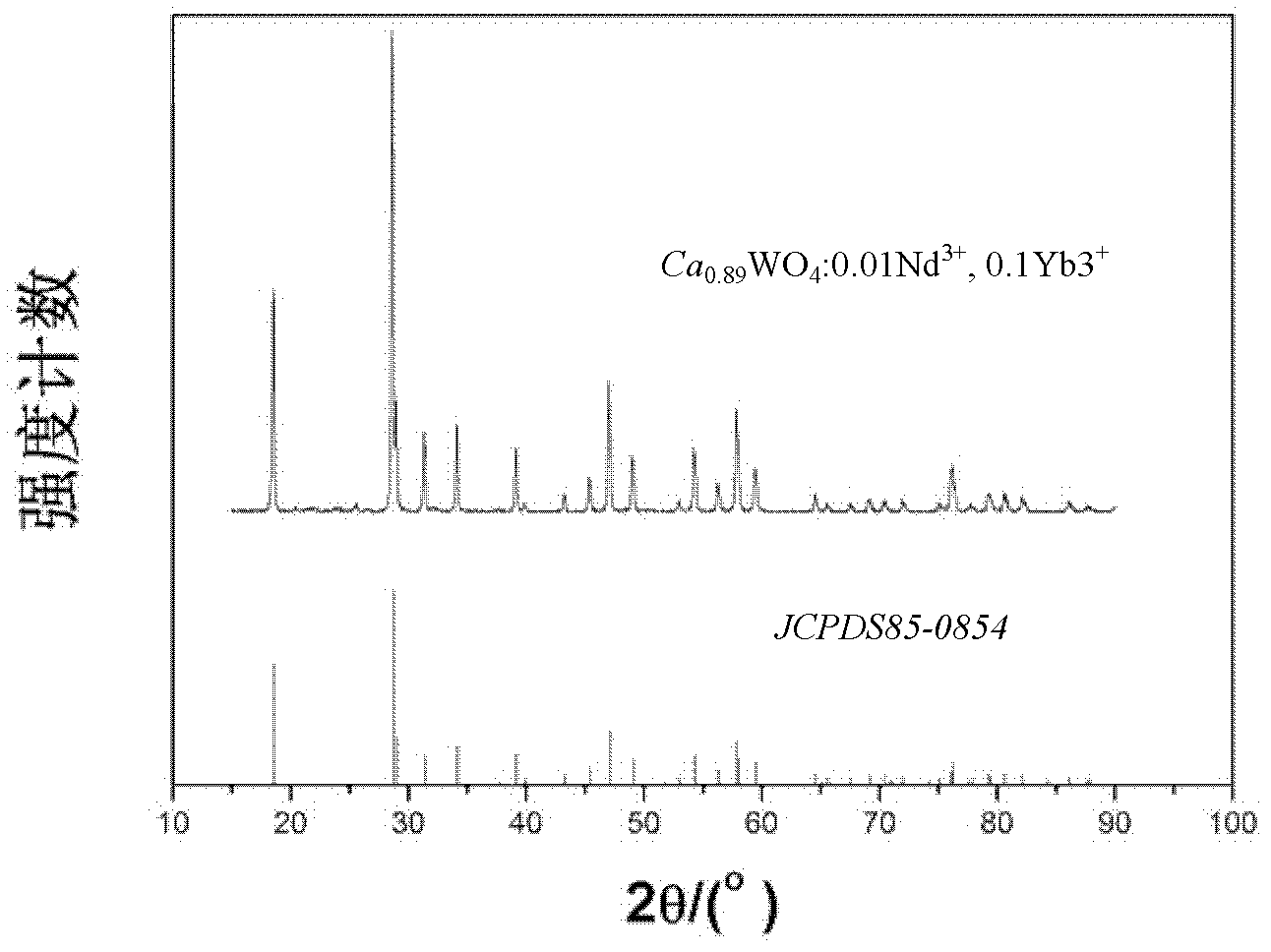

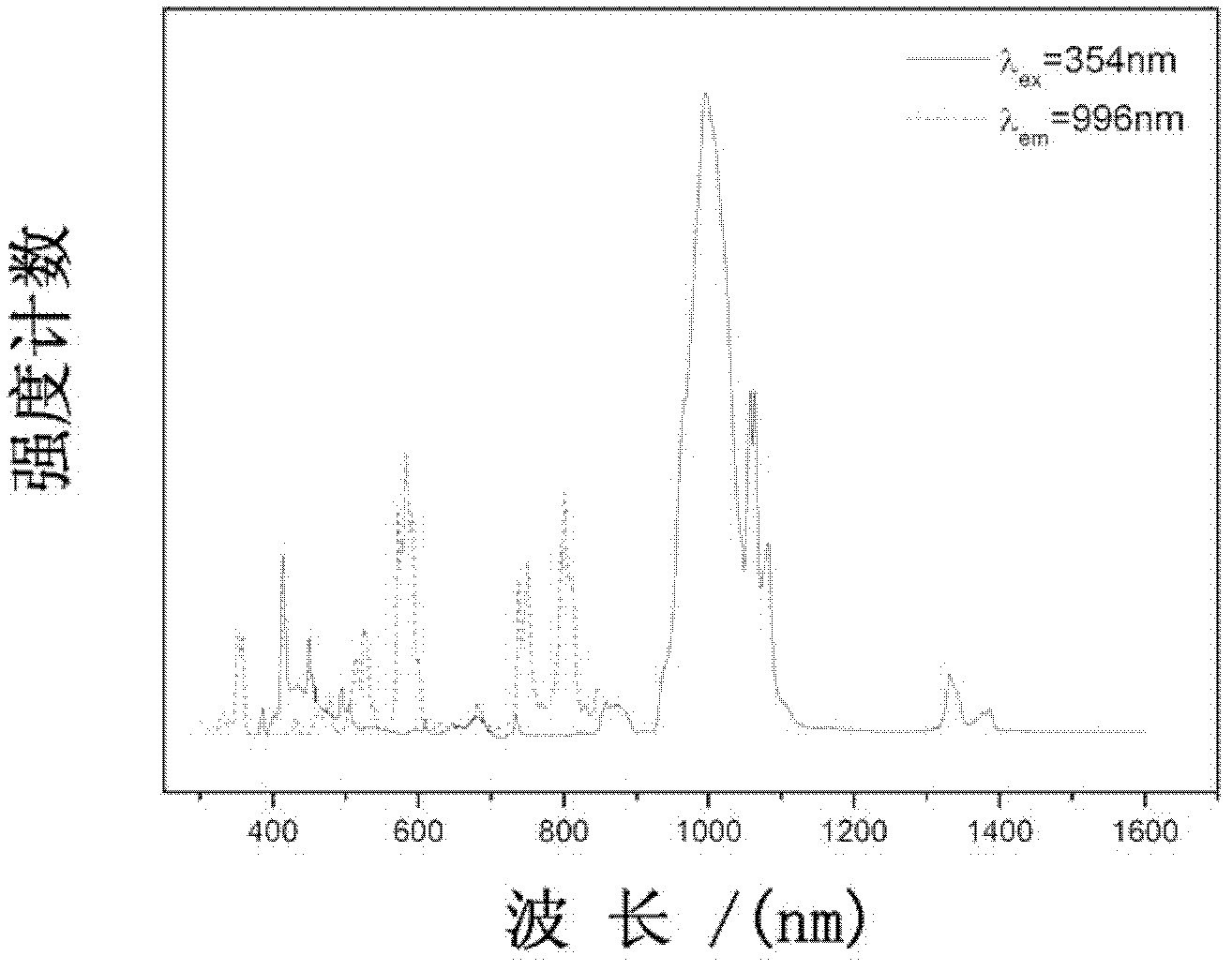

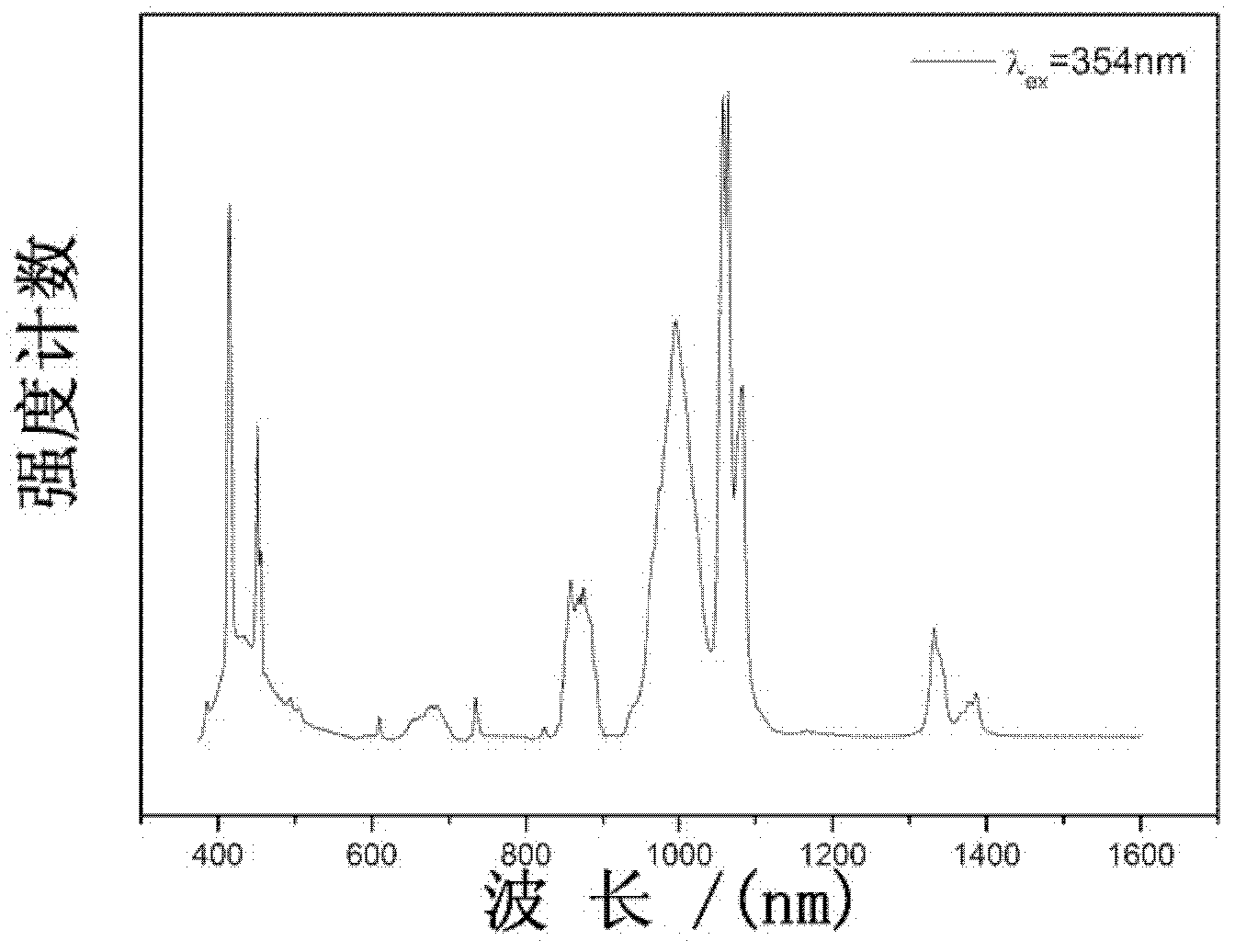

Tungstate near infrared quantum cutting material and preparation method and application thereof

InactiveCN102424750AWide excitation spectrumStrong absorption capacitySolid-state devicesSemiconductor/solid-state device manufacturingLight energyTungstate

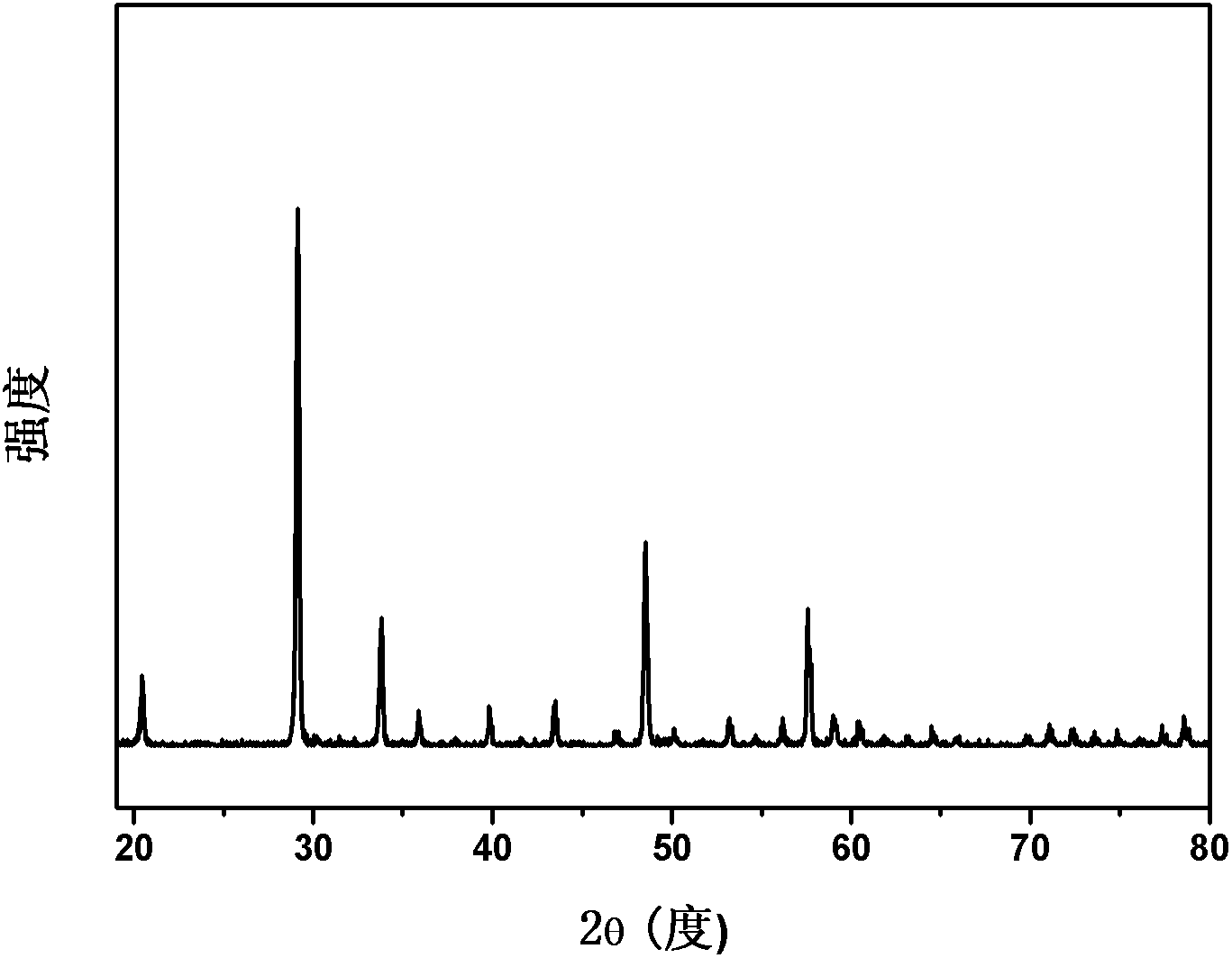

The invention provides a tungstate near infrared quantum cutting material and a preparation method and an application thereof, and the chemical composition formula of the quantum cutting material is Ca0.99-xWO4:0.01Nd3+, xYb3+, wherein Ca0.99-xWO4 is a substrate; Nd3+ and Yb3+ are doped rare earth ions; x is the molar quantity of the doped rare earth ion Yb3+, and 0.01<=x<=0.3. The preparation method of the quantum cutting material adopts a traditional high temperature solid phase calcining method to synthesize the tungstate near infrared quantum cutting material. The tungstate near infrared quantum cutting material can be excited by visible light of 300-700 nm, and emit high-intensity near infrared light within a range of 900-1500 nm; the light within the wave band can be effectively absorbed by silicon-based solar energy cells, and has calculated quantum efficiency of up to 181%. The tungstate near infrared quantum cutting material is applicable to the preparation of solar energy cells.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

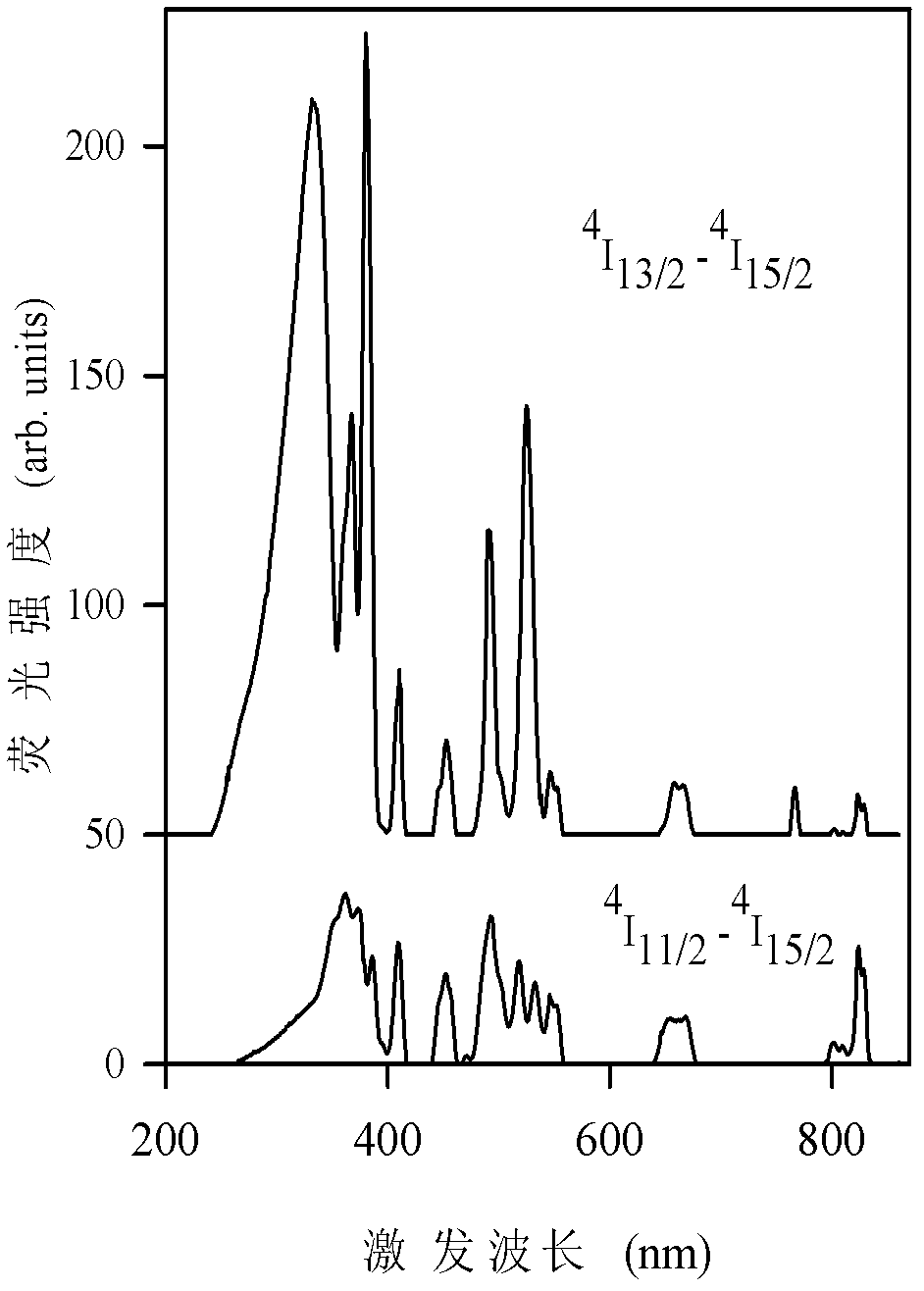

Application of single rare earth infrared first-order quantum cutting in solar cell

InactiveCN103311326AQuantum tailoring worksHigh Quantum Tailoring EfficiencyPhotovoltaic energy generationSemiconductor devicesRare earthSolar cell

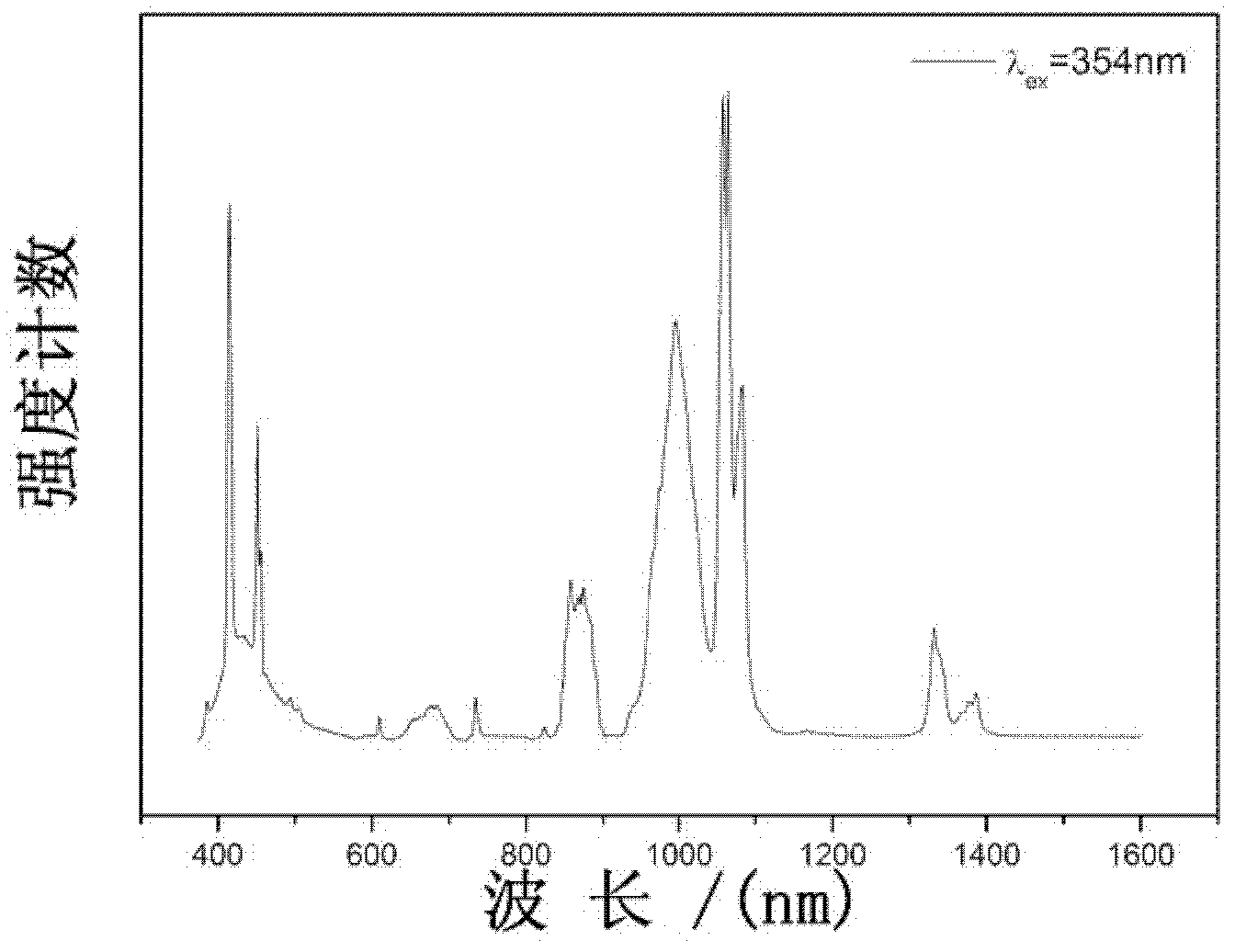

The invention relates to an application of a single rare earth infrared first-order quantum cutting in a solar cell. The single rare earth is an Er <3+> ion or a Tm <3+> ion which exists in a quantum cutting layer on a light incident surface of the solar cell; and infrared quantum cutting of a three-photon or four-photon excited by light ultraviolet and visible light is realized.

Owner:BEIJING NORMAL UNIVERSITY

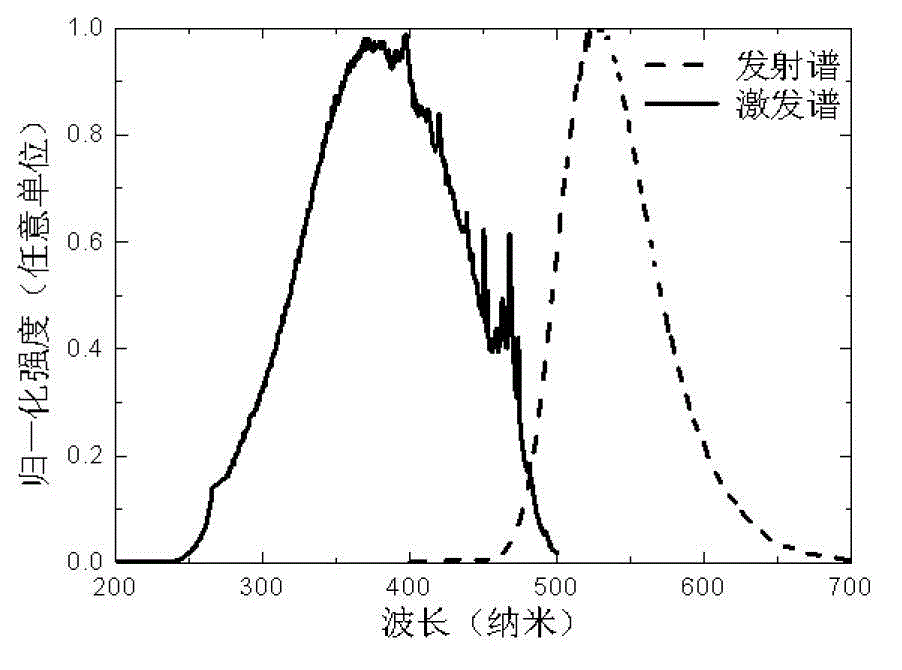

UV-near infrared quantum cutting phosphor and preparation method thereof

The invention discloses a UV-near infrared quantum cutting phosphor and preparation method thereof. The molecular formula of the quantum cutting phosphor is LaBO3: xCe3+, yYb3+, wherein, 0.01<=x<=0.3, 0.005<=y<=0.1. Under the reduction condition, the mixture of lanthana, cerium oxide, ytterbium oxide and boric acid are pre-sintered and sintered in order, and the UV-near infrared quantum cutting phosphor is obtained. The phosphor provide by the invention does not shine in the visible light range, and is used for the aspects of novel false proof technology as well as military and common safety, and the phosphor can be excited by 365nm ultraviolet light without damage for human body, and is convenient for popularization and application.

Owner:PEKING UNIV

Transparent glass ceramic capable of conversion luminescence under near-infrared quantum cutting and preparation method thereof

The invention discloses a transparent glass ceramic capable of conversion luminescence under near-infrared quantum cutting. The glass ceramic comprises the following components expressed in mole percent: 30 to 50 mol% of SiO2, 20 to 35 mol% of Al2O3, 5 to 20 mol% of CaCO3, 5 to 20 mol% of NaF, 9.6 to 14.5 mol% of CaF2, 0.1 to 1.0 mol% of EuF3 and 0 to 2 mol% of YbF3. A sample is prepared by using a melt quenching process and subsequent heat treatment; a preparation method for the transparent glass ceramic is simple, produces no pollution and costs little. Coupling of the transparent glass ceramic with a silicon solar cell can hopefully reduce the thermalization effect of the silicon solar cell and improve photoelectric conversion efficiency of the cell.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

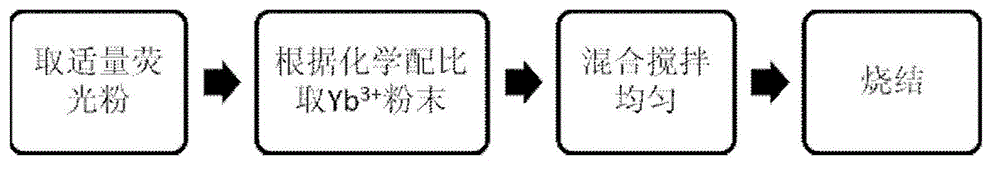

Preparation method of downconversion fluorescent material

InactiveCN102977880ARealize Quantum Tailoring EffectLuminescent compositionsFluorescent materialsRaw material

The invention relates to a preparation method of a downconversion fluorescent material, which comprises the following steps: 1, selecting fluorescent powder which has a chemical general formula shown in the specification or preparing raw materials of the fluorescent powder; 2, adding powder containing Yb<3+> into the fluorescent powder; 3, evenly mixing and stirring; and 4, sintering to form the downconversion fluorescent material which has a chemical general formula shown in the specification. According to the invention, the quantum cutting effect can be achieved, and the quantum efficiency can exceed 100%.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI +1

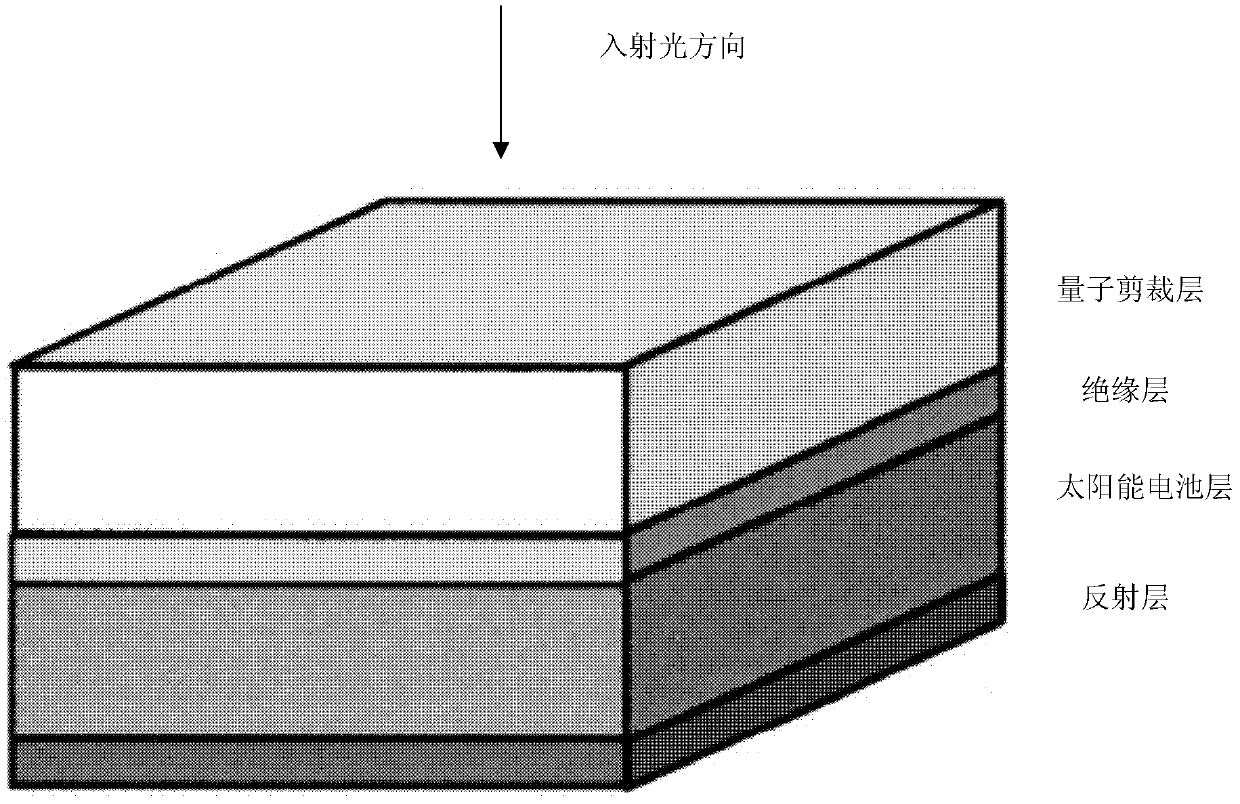

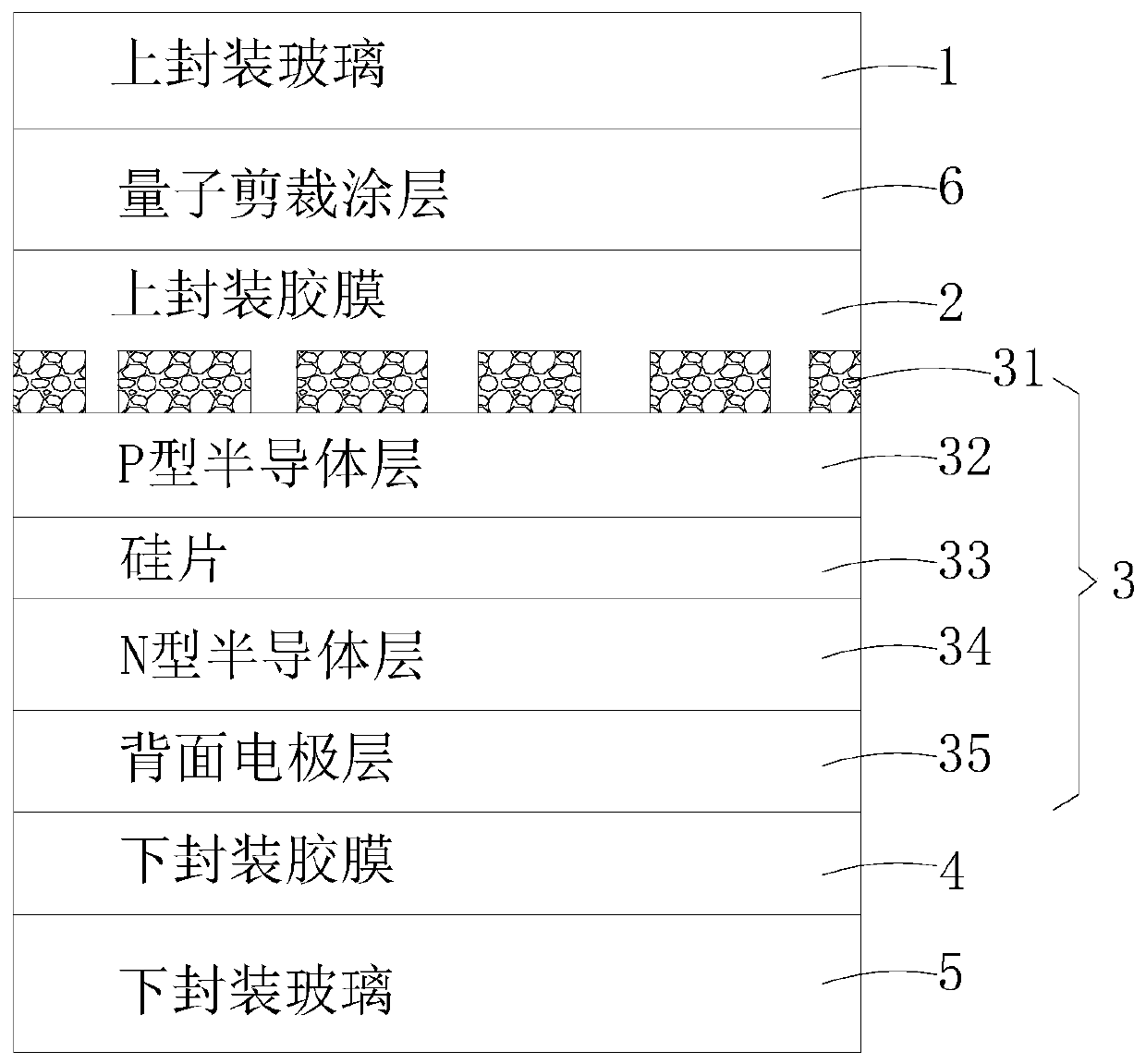

Quantum Tailored Photovoltaic Modules

InactiveCN102299195AReduce thermal effectsReduce the adverse effects of the output voltagePhotovoltaic energy generationSemiconductor devicesRheniumRare-earth element

A quantum tailoring photovoltaic module. It is mainly to solve the problem of low efficiency of existing photovoltaic modules. The packaging film contains rare earth elements with quantum tailoring effect, such as adding BaF2, rhenium Re3+, ytterbium Yb3+ ions, etc. to the EVA film, which can improve the photoelectric conversion efficiency of the cell. Mainly used for solar cell power generation.

Owner:HUNAN TLNZ SOLAR TECH

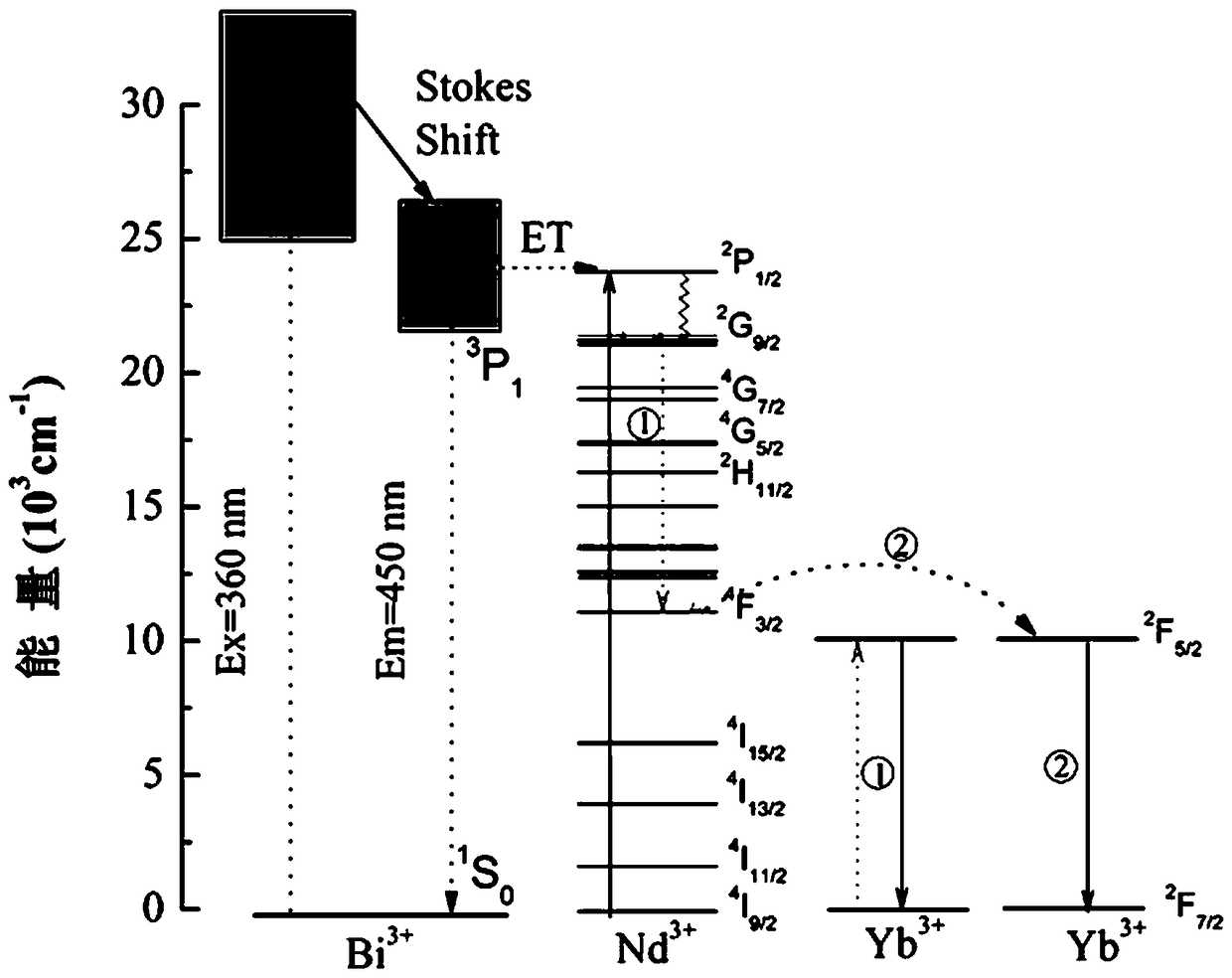

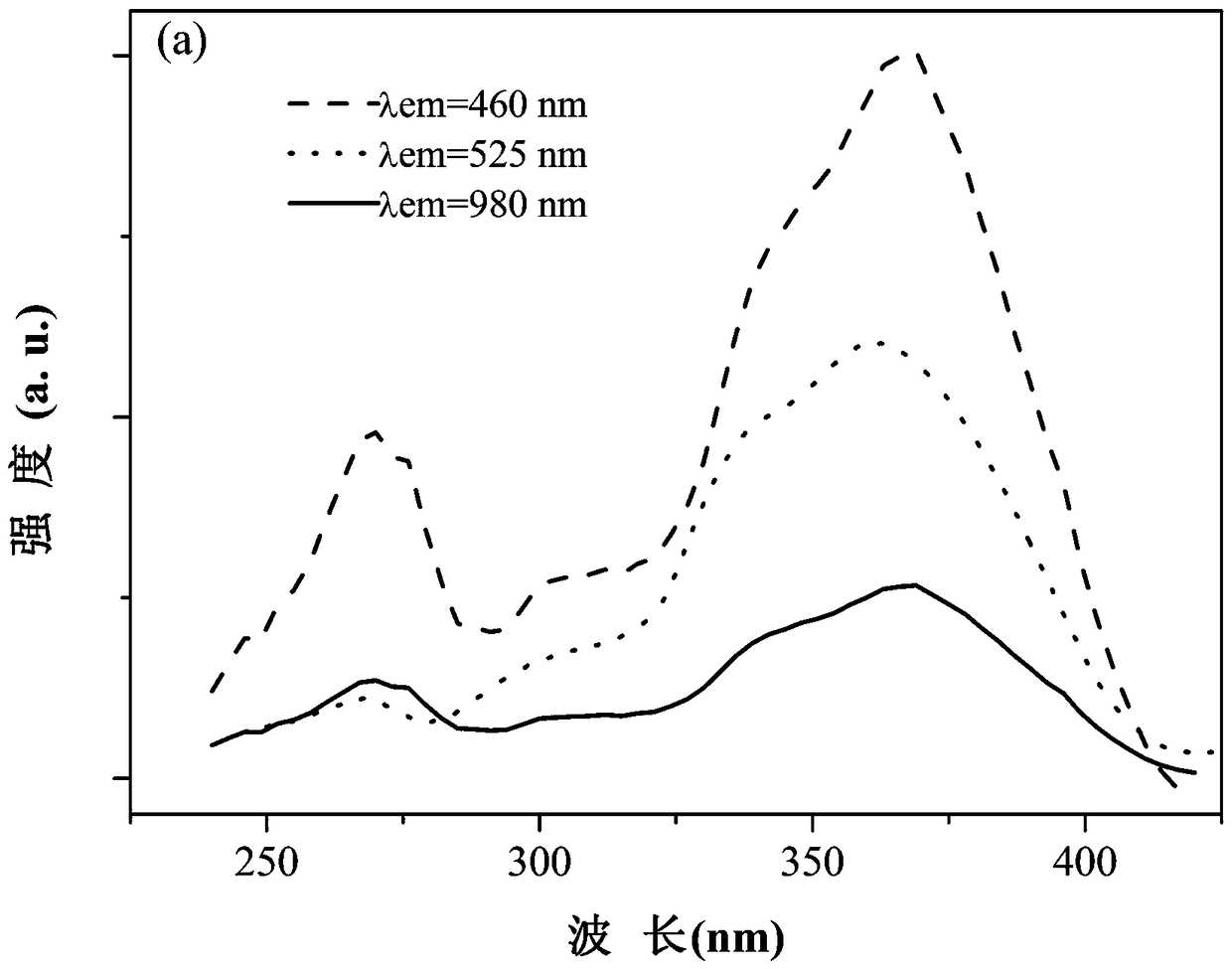

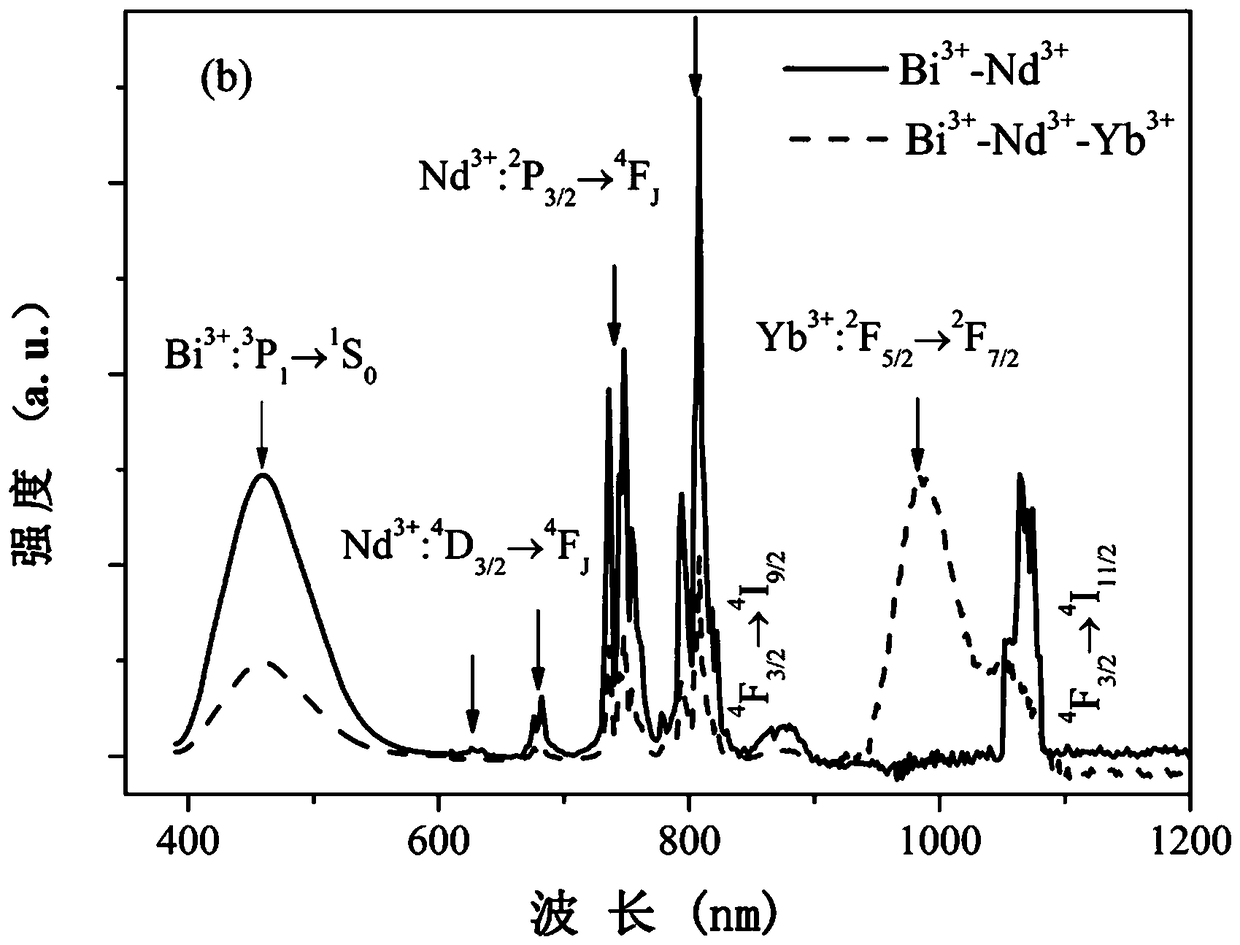

Bi-Nd-Yb co-doped YAG high-efficiency and wide-spectrum quantum cutting luminescent material

ActiveCN108192613AEfficient broad-spectrum conversion and utilizationHigh energyLuminescent compositionsHigh energyBroadband absorption

The invention provides a Bi-Nd-Yb co-doped YAG high-efficiency and wide-spectrum quantum cutting luminescent material. A composition general formula of the luminescent material is Y3Al5O12:xBi<3+>, yNd<3+>, zYb<3+>, wherein x is greater than or equal to 0.5*10<-2> and less than or equal to 1*10<-2>, y is greater than or equal to 0.5*10<-2> and less than or equal to 2*10<-2> and z is greater than or equal to 1*10<-2> and less than or equal to 10*10<-2>. According to the Bi-Nd-Yb co-doped YAG high-efficiency and wide-spectrum quantum cutting luminescent material provided by the invention, Nd<3+>-Yb<3+> co-doping belongs to two-step energy transmission and has relatively high energy conversion efficiency; Bi<3+> in the luminescent material can be used for effectively expanding an absorption section of Nd<3+> through a sensitization effect; sunlight is subjected to broadband absorption so that high-efficiency and wide-spectrum conversion type near-infrared quantum cutting is realized; finally, the sunlight is sufficiently utilized and the conversion efficiency of a crystalline silicon solar cell is improved.

Owner:HENAN UNIV OF SCI & TECH

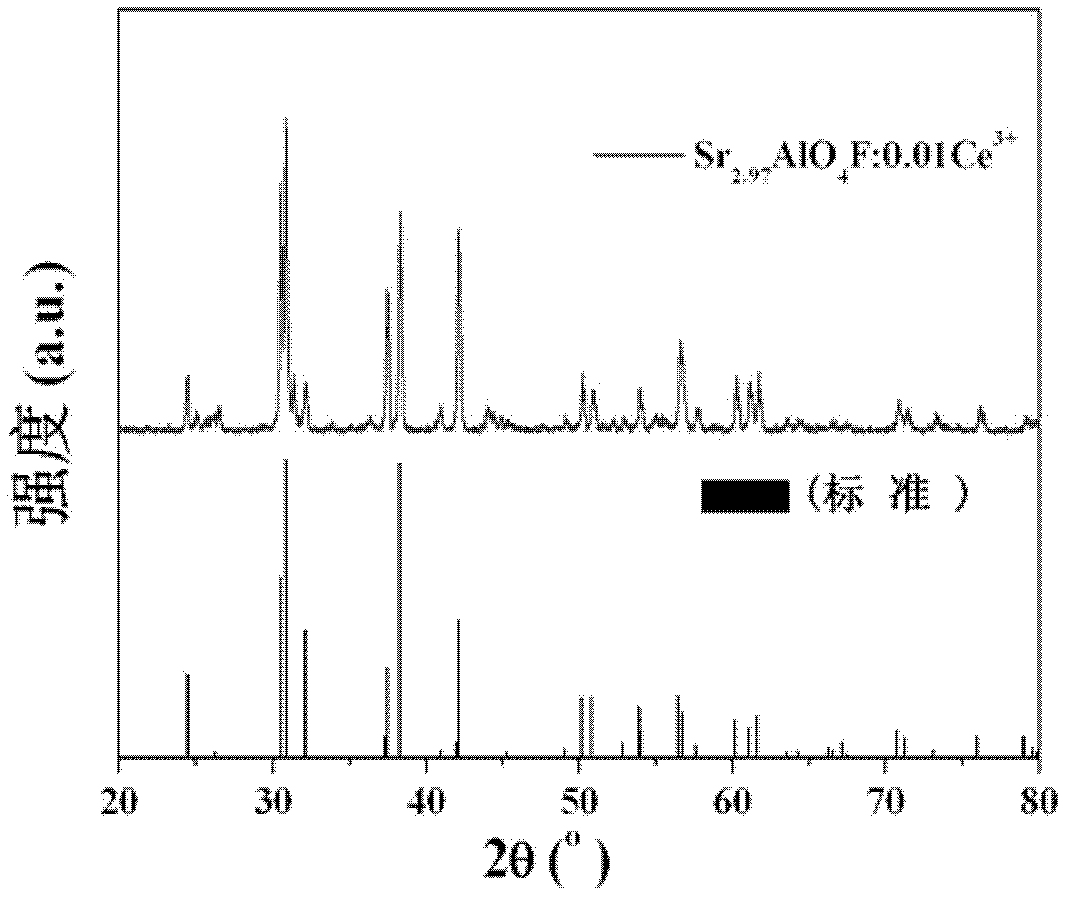

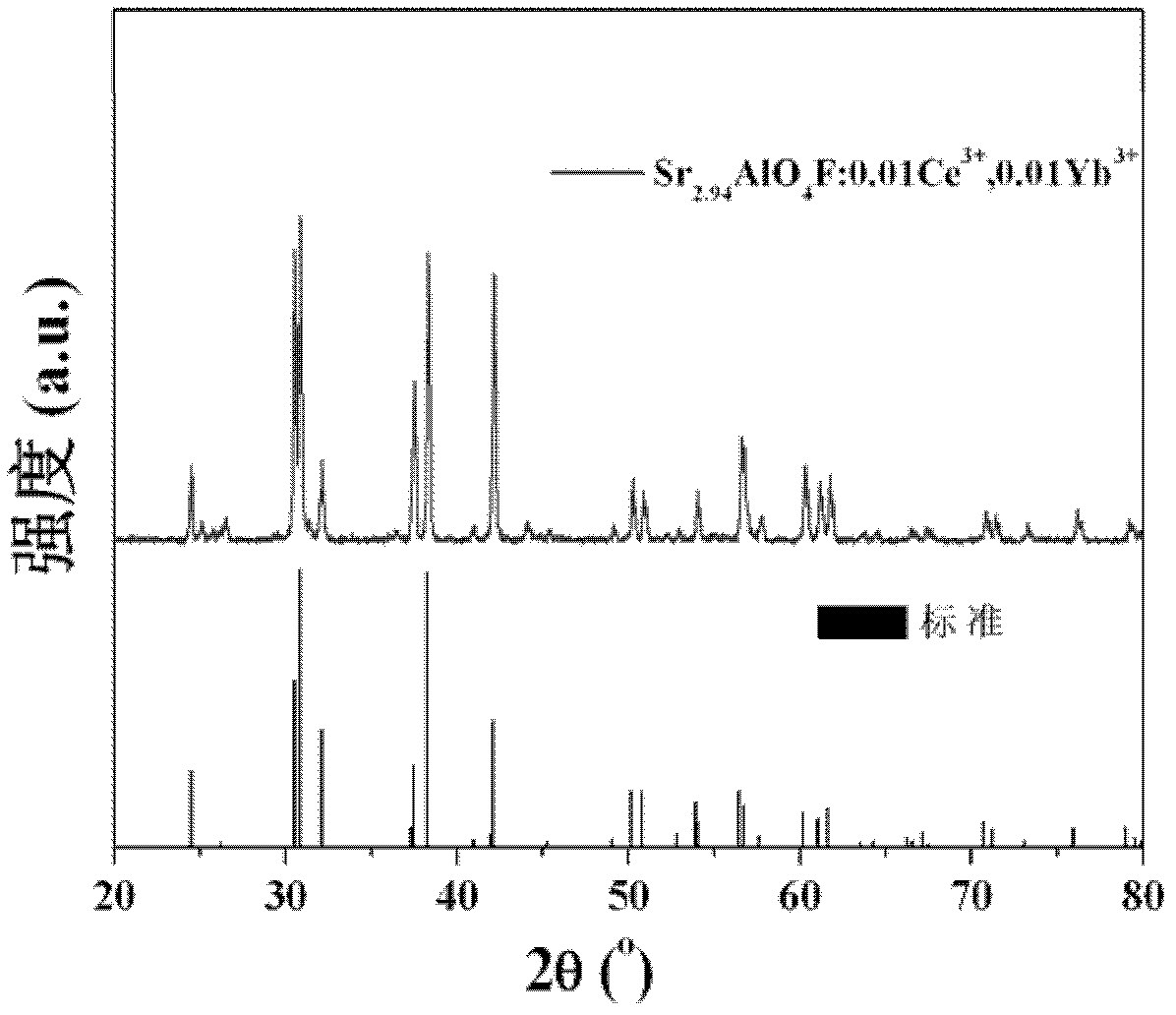

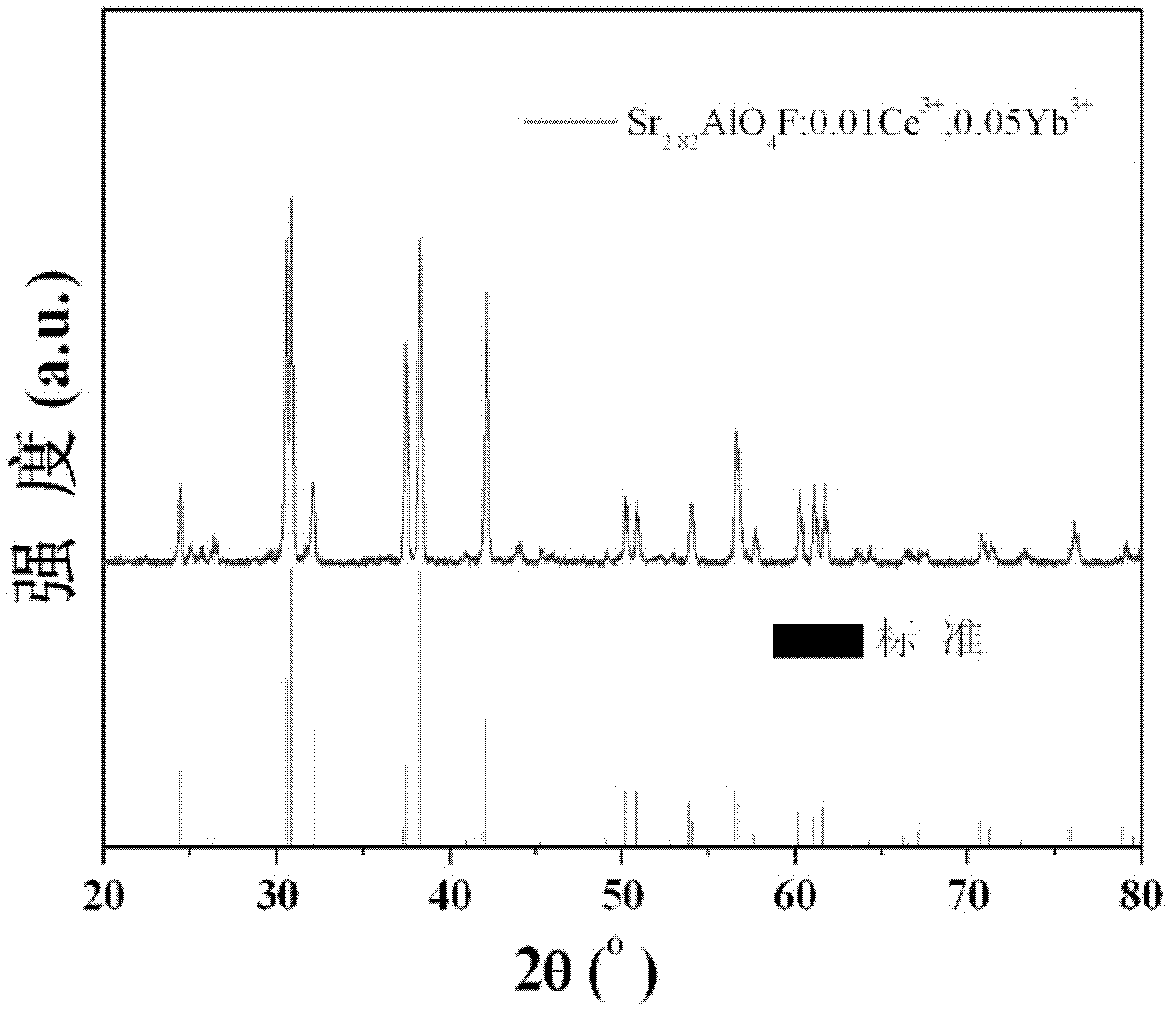

Fluoroaluminate near-infrared quantum cutting material, and preparation method and application thereof

InactiveCN102585811AWide excitation spectrumThe synthesis method is simplePhotovoltaic energy generationLuminescent compositionsLuminous intensityCerium

The invention discloses a fluoroaluminate near-infrared quantum cutting material, and a preparation method and application thereof. The fluoroaluminate near-infrared quantum cutting material has a chemical formula: Sr3(0.99-x)AlO4F: 0.01Ce<3+> and xYb<3+> (x is not less than 0 and not more than 0.1). The preparation method for the fluoroaluminate near-infrared quantum cutting material comprises the followings steps of: weighing a strontium raw material, an aluminium raw material, a cerium raw material and a ytterbium raw material according to the molar ratio in the chemical formula; and grinding each material and mixing uniformly, then heating to 1200 DEG C at the speed of 600 DEG C / h under the CO reducing atmosphere, keeping the constant temperature of 1200 DEG C for 4 h, and cooling to obtain the powdered fluoroaluminate near-infrared quantum cutting material. The fluoroaluminate near-infrared quantum cutting material disclosed by the invention has the advantages of high luminous intensity, good stability, high quantum efficiency and environment-friendliness.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

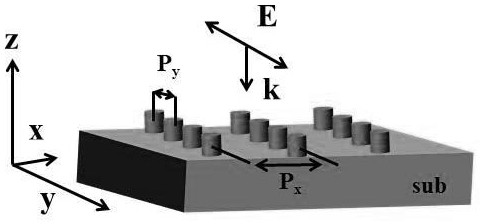

Gold nano array substrate and preparation method thereof, and composite structure of gold nano array substrate and near-infrared quantum cutting luminescent material, and preparation method thereof

ActiveCN111682085AImprove photoelectric conversion efficiencySimple preparation processMaterial nanotechnologyNanostructure assemblyPhysical chemistryLuminescent material

The invention provides a gold nano array substrate and a preparation method thereof, and a composite structure of the gold nano array substrate and a near-infrared quantum cutting luminescent material, and a preparation method thereof. According to the invention, a gold nano array substrate with a single-mode, narrow-linewidth and high-quality factor surface lattice resonance peak is designed, onthe basis, a composite structure of the array substrate and a near-infrared quantum cutting luminescent material is constructed, and highly localized surface lattice resonance is utilized to enhance three-photon near-infrared quantum cutting luminescence of a specific wavelength; and the preparation process is simple, the operation is convenient, the cost is low, an efficient solar cell light conversion sheet can be provided, the photoelectric conversion efficiency of the solar cell is improved, and the solar cell light conversion sheet is suitable for popularization.

Owner:MINJIANG UNIV

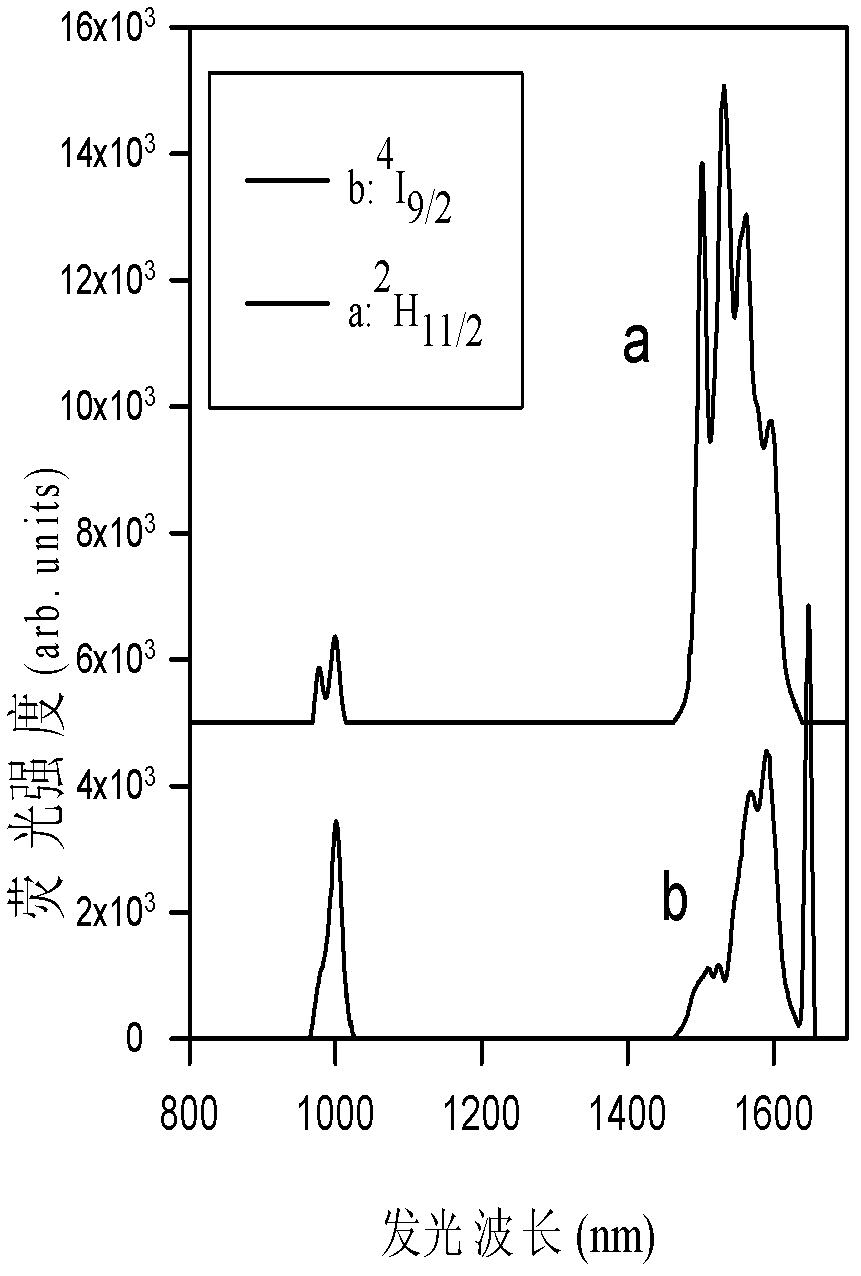

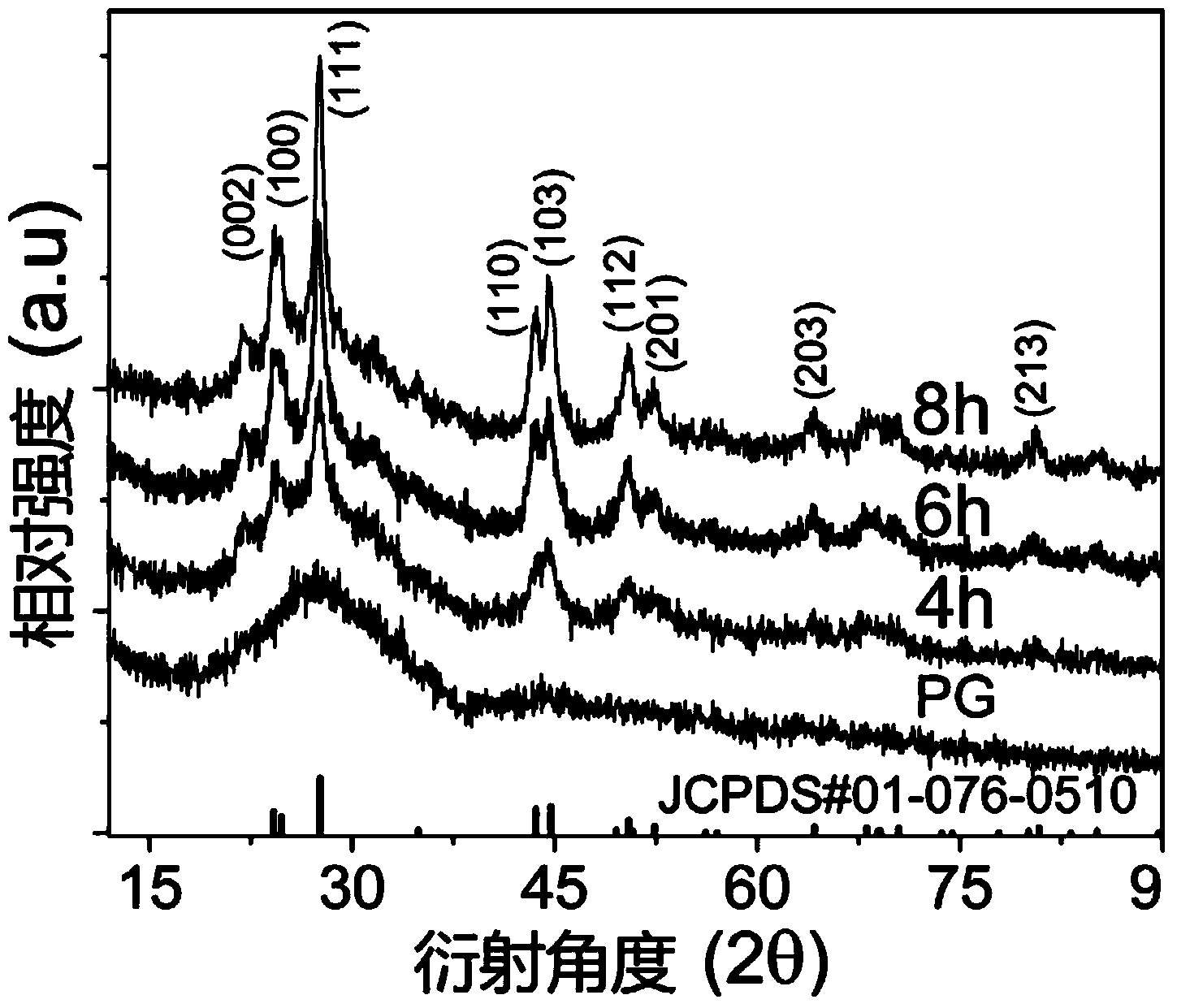

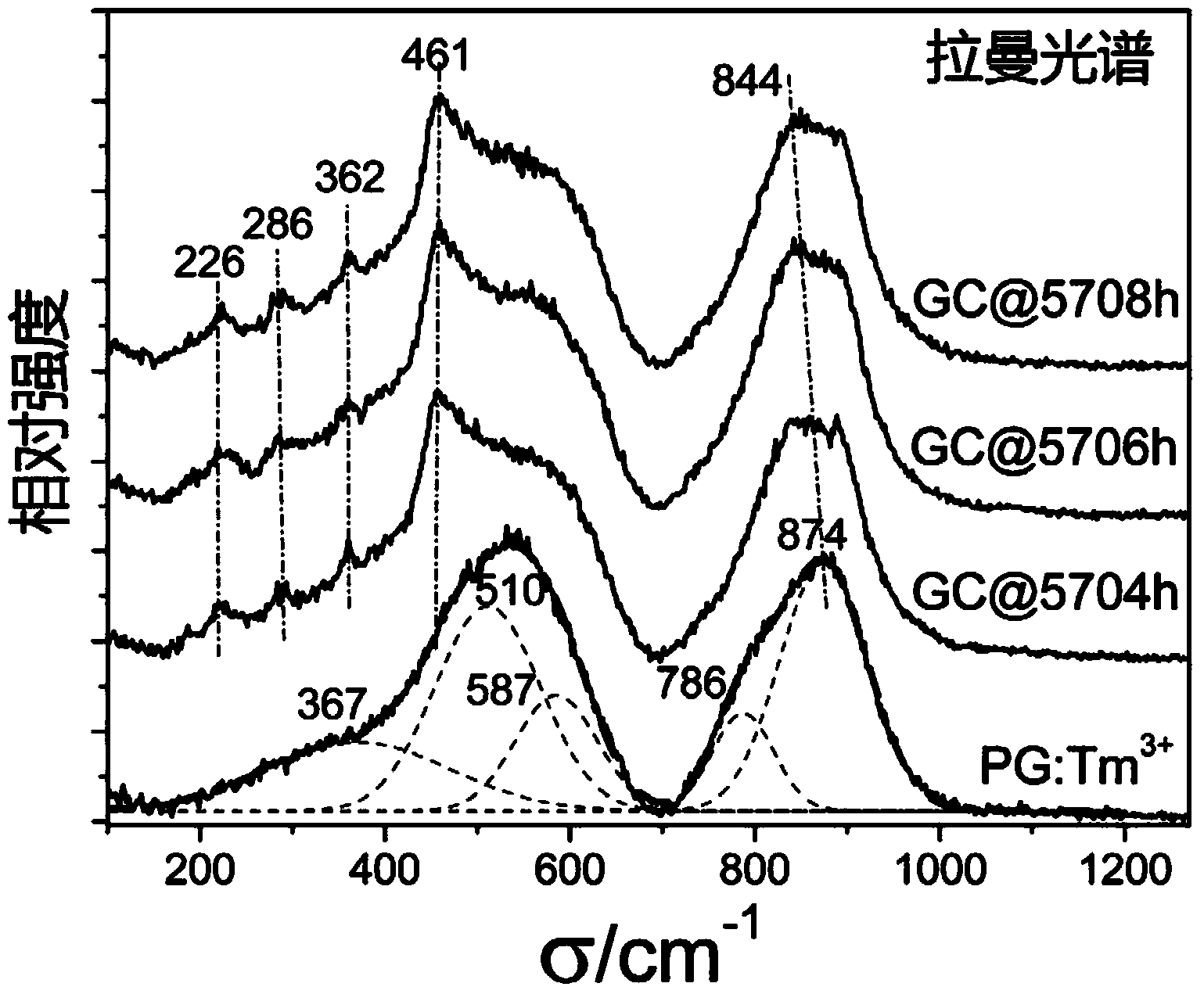

Tm<3+> single-doped three-photon infrared quantum cutting microcrystalline glass as well as preparation method and application thereof

InactiveCN103771714AImprove quantum efficiencyImprove photoelectric conversion efficiencyMelt quenchingQuantum

The invention discloses a Tm<3+> single-doped three-photon infrared quantum cutting microcrystalline glass as well as a preparation method and an application thereof. The microcrystalline glass is formed with LaF3 nanocrystal-containing oxofluorogermanate transparent microcrystalline glass as a matrix and Tm<3+> as activating agent ions, and the composition, in a molar ratio, of the microcrystalline glass is 50GeO2-20Al2O3-15LaF3-15LiF-xTmF3, wherein x is greater than or equal to 0.05 and less than or equal to 1.00. During preparation, GeO2, Al2O3, LaF3, LiF and TmF3 are taken as raw materials, and weighing and proportioning the raw materials according to the nominal composition 50GeO2-20Al2O3-15LaF3-15LiF-xTmF3 in the molar ratio, wherein x is greater than or equal or 0.05 and less than or equal to 1.00, and then taking the method of melt quenching in combination with subsequent heat treatment. The microcrystalline glass is capable of effectively absorbing 455-485nm blue light photons to excite the Tm<3+> ions to the energy state 1G4, and also capable of emitting three infrared photos in succession with 3H4 and 3F4 as intermediate energy states. The quantum efficiency of the Tm<3+> single-doped three-photon infrared quantum cutting microcrystalline glass is calculated within the range from 1.59 to 1.61.

Owner:SOUTH CHINA UNIV OF TECH

Transparent glass ceramics with quantum cutting luminescence characteristics and preparation method thereof

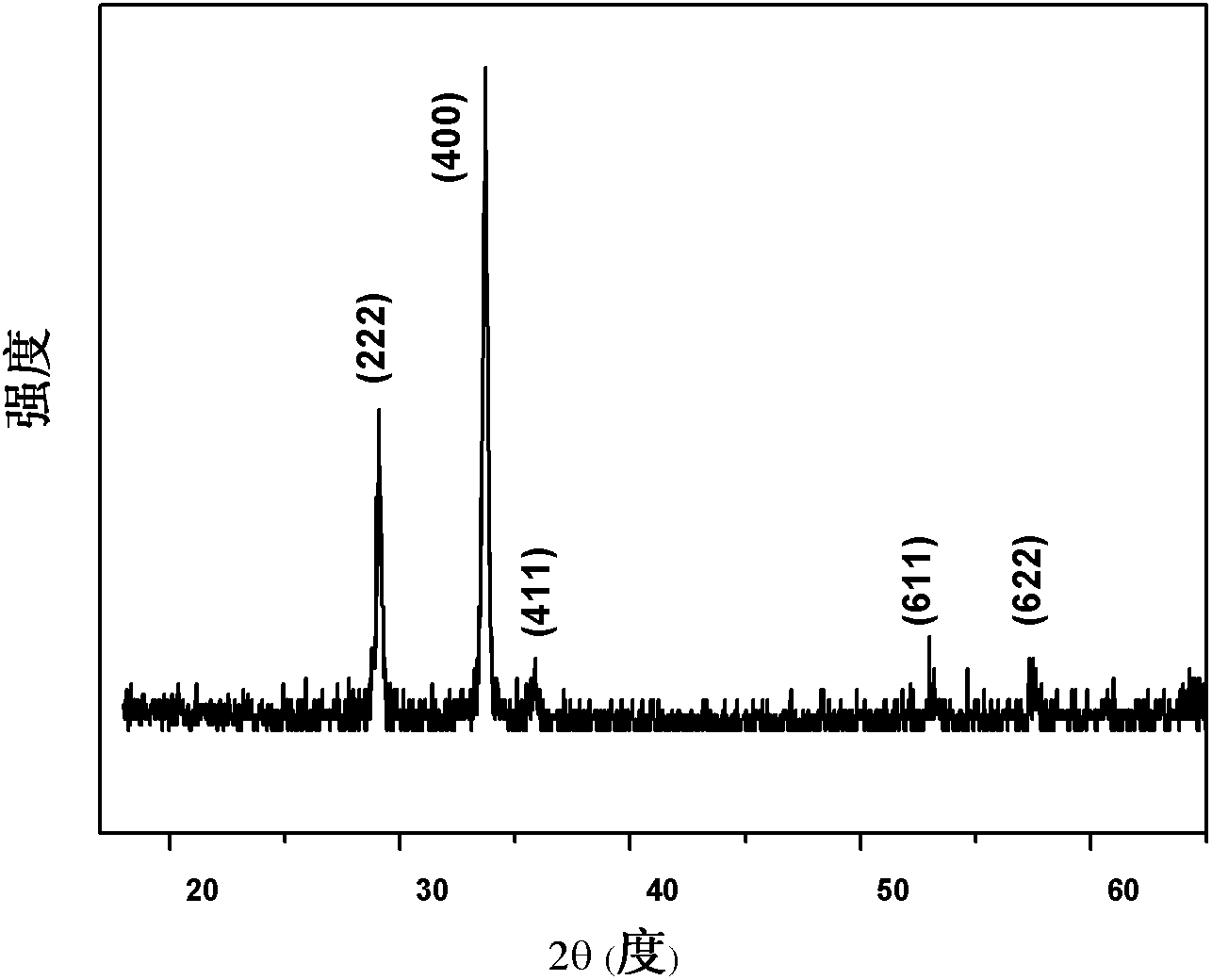

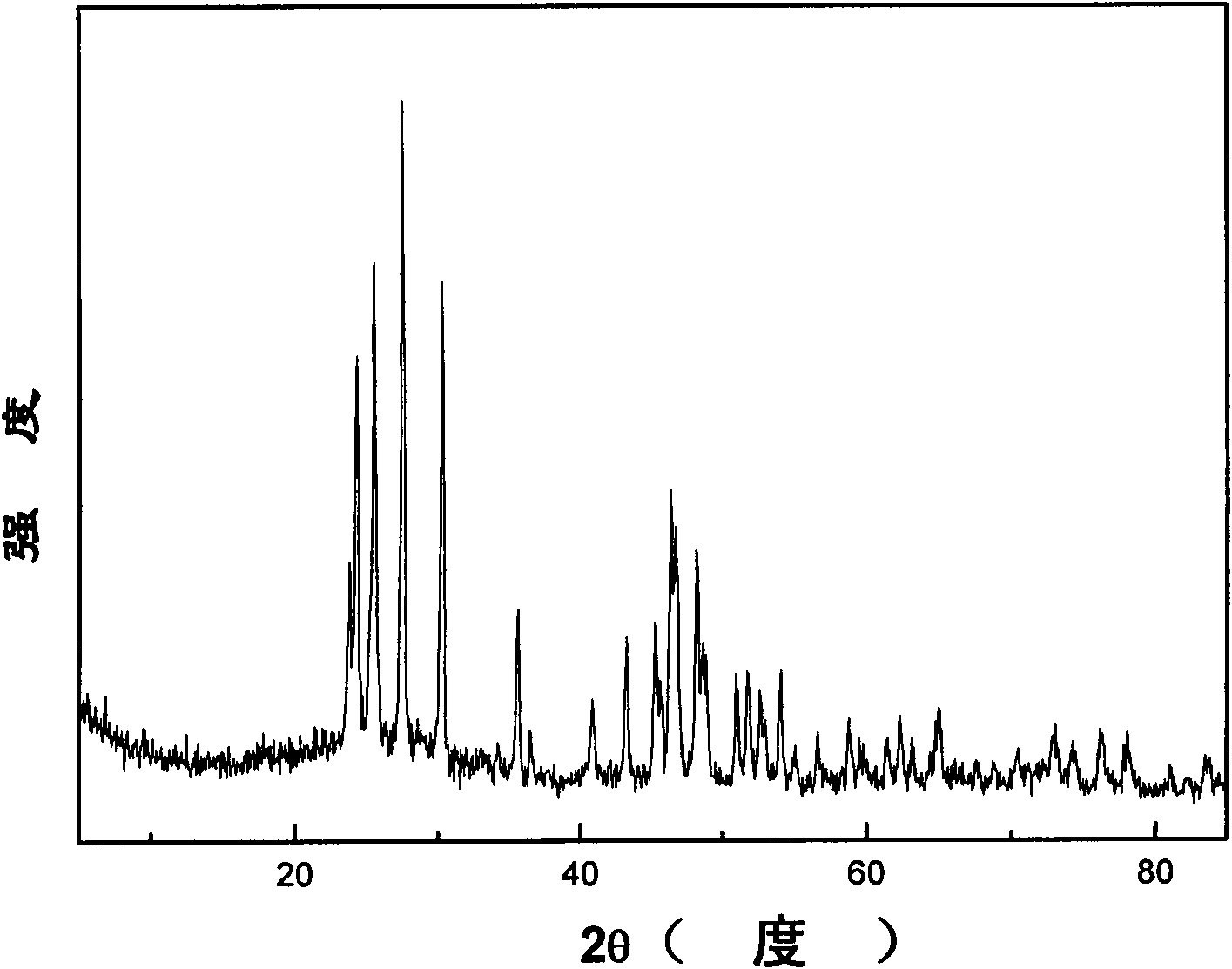

InactiveCN101857374ASimple preparation processLow costPhotovoltaic energy generationSemiconductor devicesRare earthHeating effect

The invention discloses transparent glass ceramics with quantum cutting luminescence characteristics and a preparation method and purposes thereof. The glass ceramics comprises the following components: 40 to 60mol percent of SiO2, 10 to 30mol percent of Al2O3, 5 to 25mol percent of TbF3, 0 to 15mol percent of NaF, 0 to 15mol percent of LiF, 0.01 to 5mol percent of YbF3, less than 0.5mol percent of MSO4, less than 0.02mol percent of Fe, and M refers to Mg, Ca, Ba or Sr. The glass ceramics has the following microstructure characteristic that: TbF3 nanocrystallines which are doped with rare earth and is an orthogonal structure are uniformly distributed in a glass substrate. The glass ceramic material can be excited by blue light to realize converting and giving off light under the high-efficiency near infrared quantum cutting. By being coupled with a silicon solar cell, the transparent glass ceramics is expected to reduce the heating effect of the solar cell and improve the photoelectric conversion efficiency of the cell.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

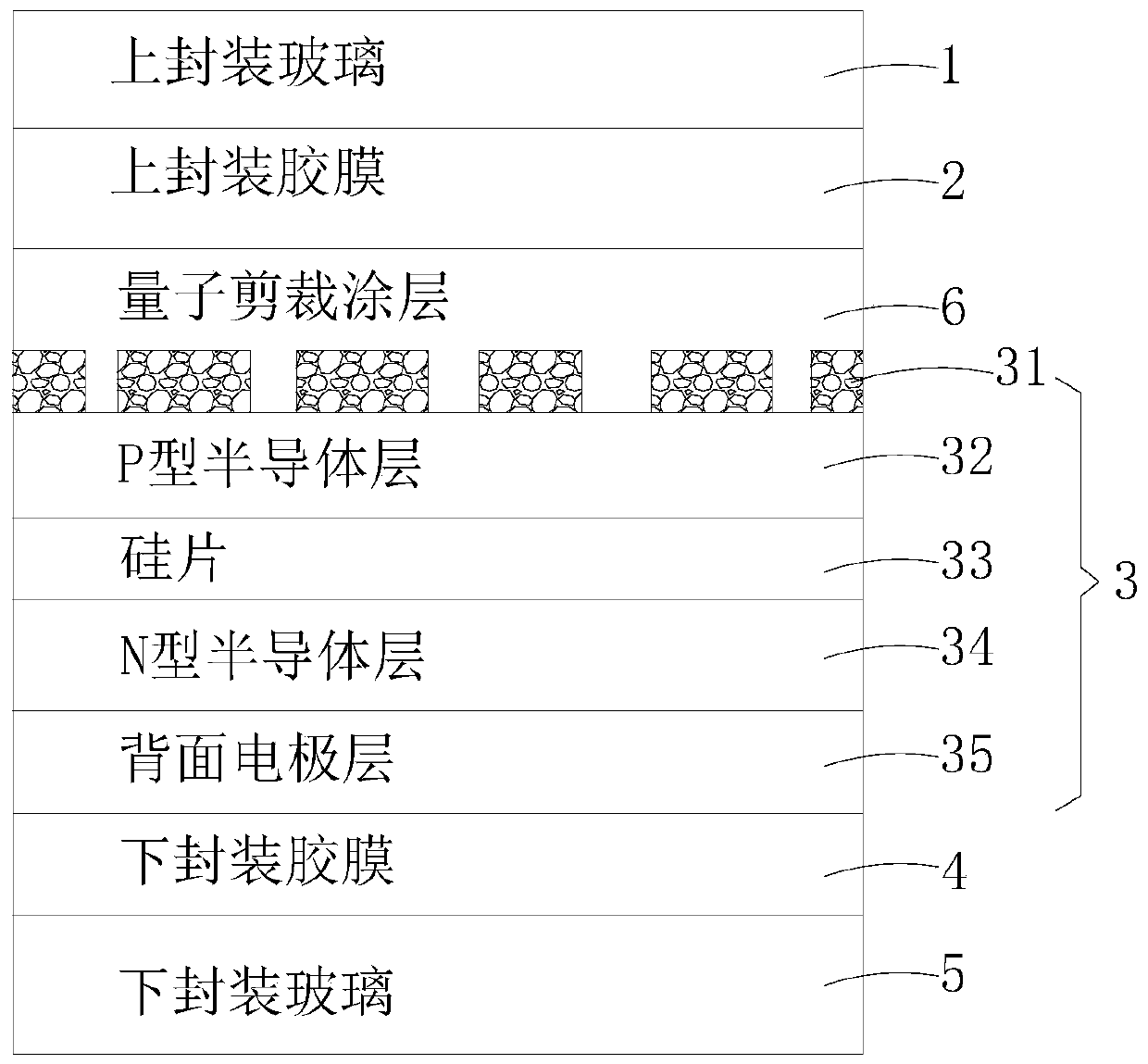

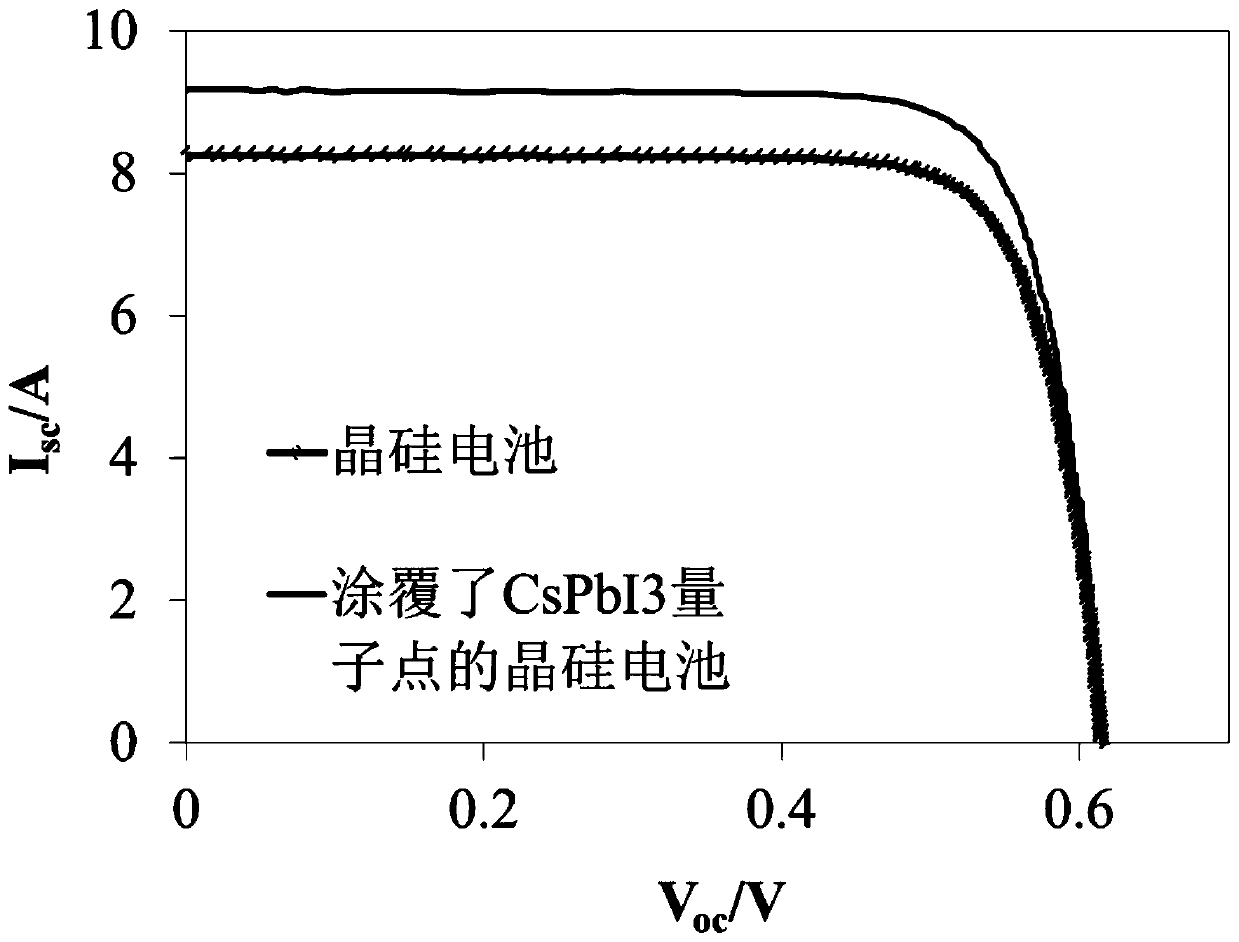

Crystalline silicon battery assembly containing quantum cutting coating and preparation method thereof

InactiveCN111029427AImprove light energy conversion efficiencyTake advantage ofFinal product manufacturePhotovoltaic energy generationQuantum dotCrystalline silicon

The invention relates to a crystalline silicon battery assembly containing a quantum cutting coating. A layer of perovskite quantum dot material with a light down-conversion function is deposited on the surface of the crystalline silicon assembly or the top packaging glass of the crystalline silicon assembly. The absorption visible light (550 nm-560 nm) which cannot be absorbed by the crystallinesilicon assembly is down converted into the infrared light which can be absorbed by the crystalline silicon assembly, so that the absorption of the crystalline silicon assembly to the infrared light is increased, and the energy conversion efficiency of the crystalline silicon assembly is improved by about 10%. The invention further discloses a preparation method of the crystalline silicon batteryassembly containing the quantum cutting coating, and the preparation method is simple in preparation process and suitable for mass production.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

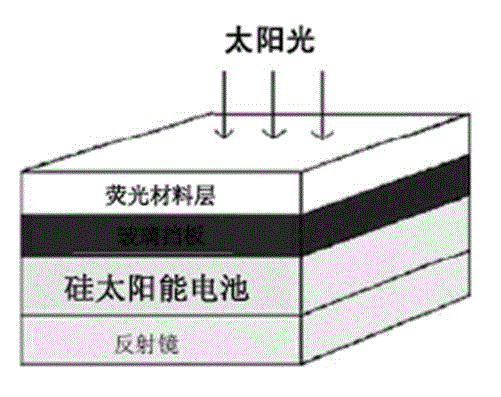

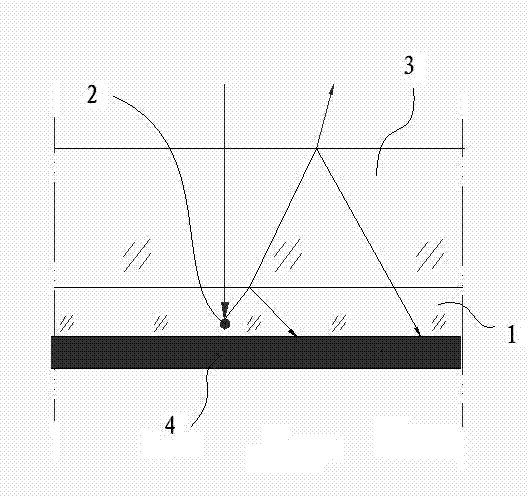

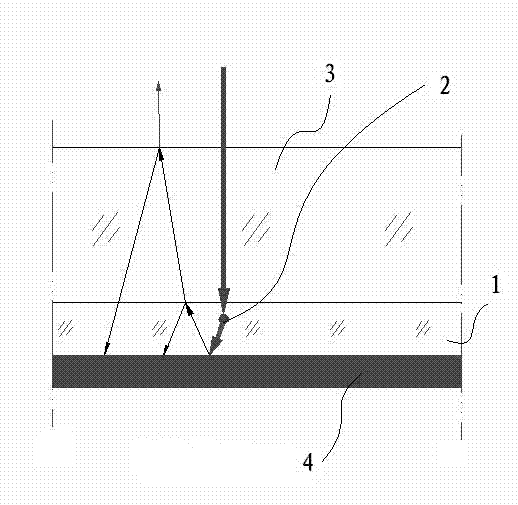

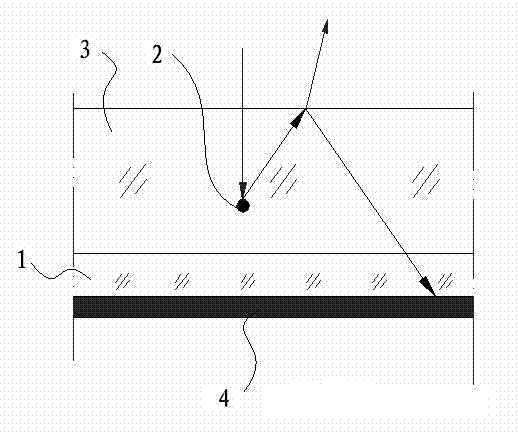

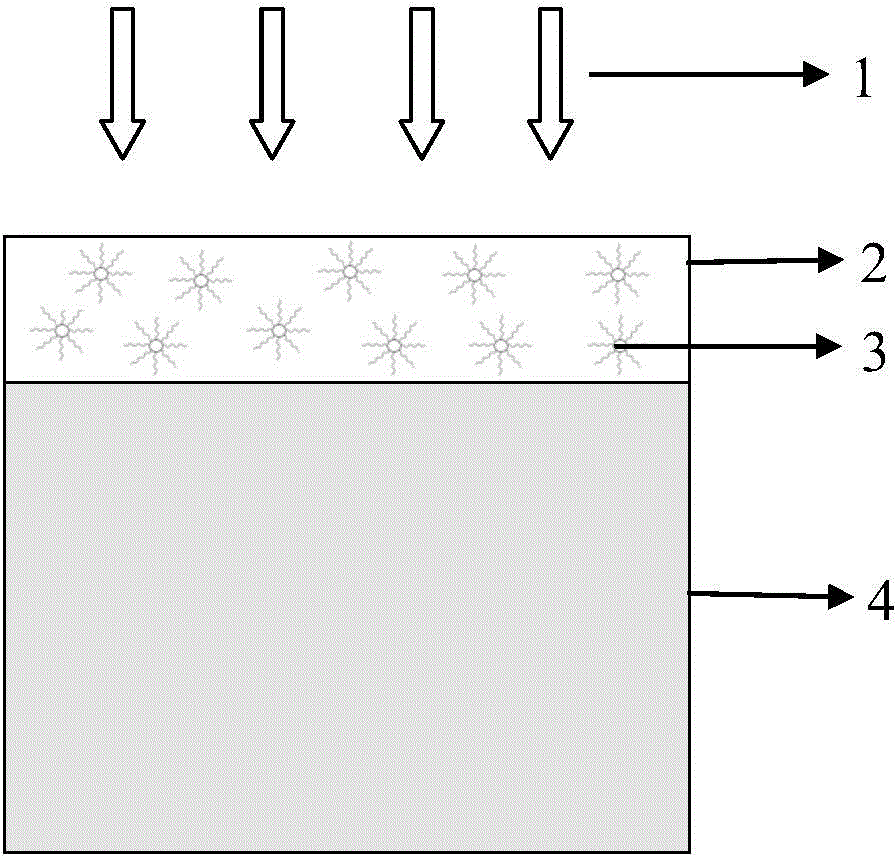

Under-light conversion layer for silicon solar cell and manufacturing method of under-light conversion layer

InactiveCN105870239AImprove photoelectric conversion efficiencyOvercoming light and heatFinal product manufactureLuminescent compositionsElectrical batteryRare earth

The invention relates to an under-light conversion layer for a silicon solar cell and a manufacturing method of the under-light conversion layer. Firstly, a rare earth organic-inorganic hybrid near-infrared quantum cutting nano material is prepared and is evenly dispersed in a transparent polymer, and the under-light conversion layer for a silicon solar cell is prepared by means of a spin-coating method or a dip-coating method. The rare earth organic-inorganic hybrid near-infrared quantum cutting nano material in the conversion layer has a large light absorption molar coefficient and a wide absorption band, comprises an inorganic matrix which protects cations at the luminescence center from luminescence quenching of a non-radiative passivating source, and is compatible with high-molecular polymers. The rare earth organic-inorganic hybrid near-infrared quantum cutting nano material can effectively absorb short wavelength photons with poor cell spectrum response in sun light and emit near-infrared photons with good silicon solar cell spectrum response, so that silicon solar cell spectrum response can be improved, energy loss of a silicon solar cell caused by spectrum mismatch can be reduced, and the photoelectric conversion efficiency of the silicon solar cell can be improved.

Owner:CHANGCHUN INST OF TECH

Solar cell backboard with down-conversion function and preparation method thereof

PendingCN113314634AAvoid degradation damageImprove power generation efficiencySynthetic resin layered productsElectrical equipmentFluorescenceHigh energy

The invention relates to a solar cell backboard with a down-conversion function, and the backboard comprises an inner layer film, a first adhesive layer, a base layer film, a second adhesive layer and an outer layer film which are arranged in sequence; the inner layer film is a PEVE film layer with a double-layer structure, the PEVE film layer comprises a PEVE film fluorescent layer and a PEVE film reflective layer, the PEVE film fluorescent layer is doped with a rare earth compound with a down-conversion function, which is converted into near-infrared light. The inner layer film is arranged to be the PEVE film layer of the double-layer structure, the PEVE film layer comprises the PEVE film fluorescent layer doped with the rare earth compound with the down-conversion effect and the PEVE film reflective layer, and due to the fact that the rare earth compound fluorescent agent with the quantum cutting effect is added into the PEVE film fluorescent layer, high-energy ultraviolet light can be absorbed; high-energy ultraviolet light rays are converted into low-energy near-infrared light which can be absorbed by the silicon cell in a quantum cutting mode, so degradation damage of the photovoltaic back plate caused by irradiation of the ultraviolet light rays is avoided, and the power generation efficiency of the silicon cell is also improved.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS +1

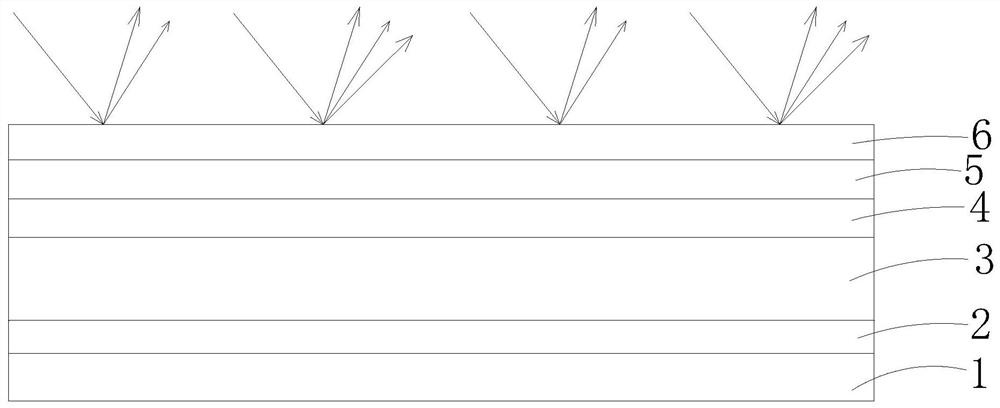

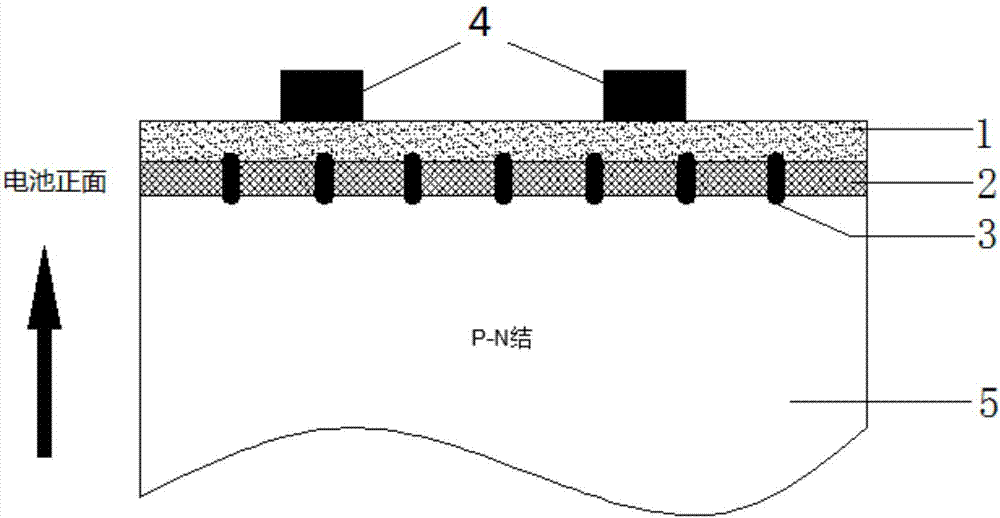

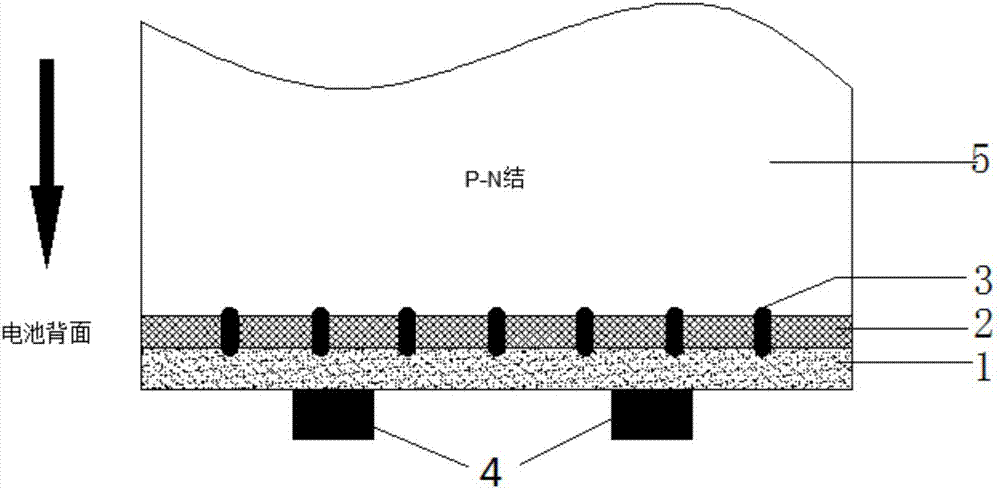

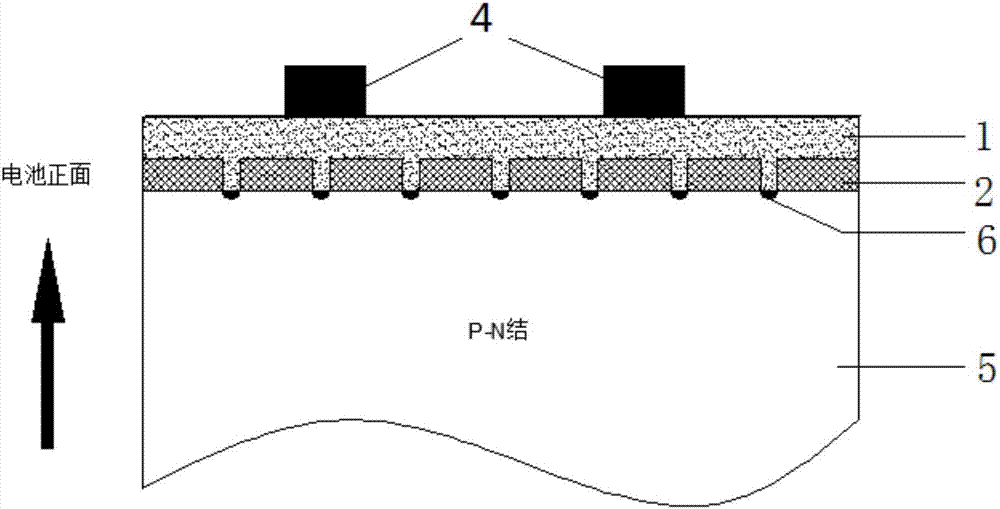

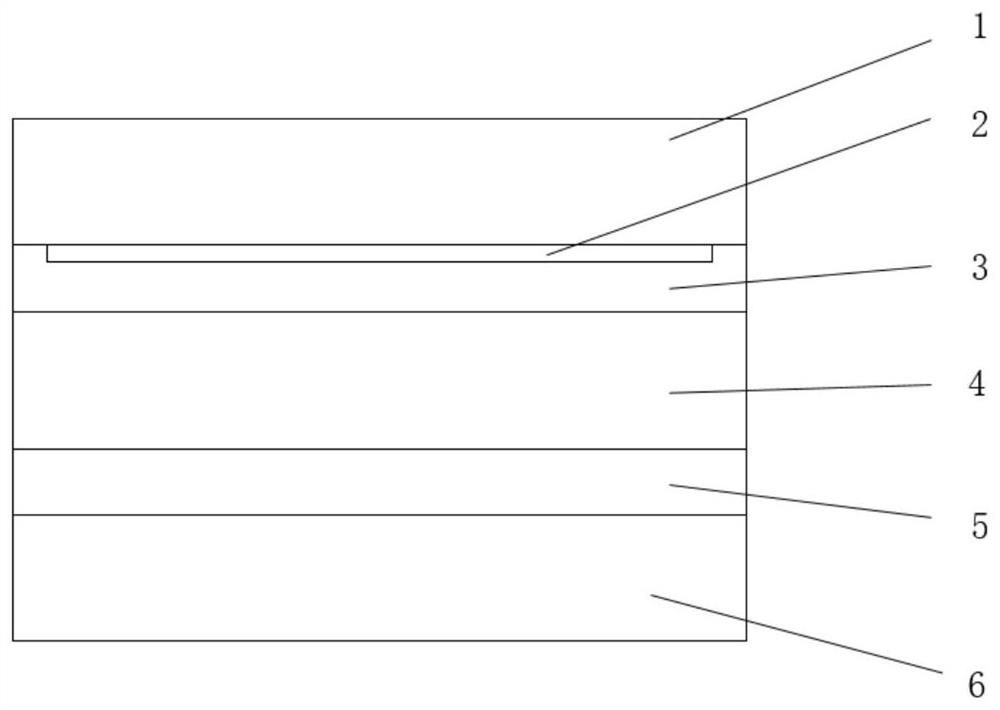

A quantum-tailored transparent electrode for crystalline silicon solar cells

ActiveCN105720114BLow costImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesSilicon solar cellCrystalline silicon

Owner:LONGI SOLAR TECH CO LTD

Preparation method of quantum cutting coating, solar cell, solar module and preparation method

PendingCN114300560AImprove uniformityAvoid problems such as uneven coating and affecting the conversion efficiency of componentsLuminescent paintsPhotovoltaic energy generationOrganic solventPhysical chemistry

The invention belongs to the technical field of solar cell preparation, and particularly relates to a preparation method of a quantum cutting coating, a solar cell, an assembly and a preparation method. The method comprises the following steps: mixing a down-conversion material with organic glue, coating the surface of a glass substrate with the mixture, and curing to obtain the quantum cutting coating. The patterned quantum cutting coating is prepared on the glass substrate creatively by adopting an organic glue pre-curing mode, so that the quantum cutting coating does not move relative to a glue film in the subsequent laminating process, the uniformity of the film layer is improved, and the problems that in the prior art, due to the fact that the quantum cutting coating is prepared by adopting an organic solvent, the coating is not uniform, and the quality of the film layer is poor are solved. And the conversion efficiency of the assembly is influenced.

Owner:WUXI UTMOST LIGHT TECH CO LTD

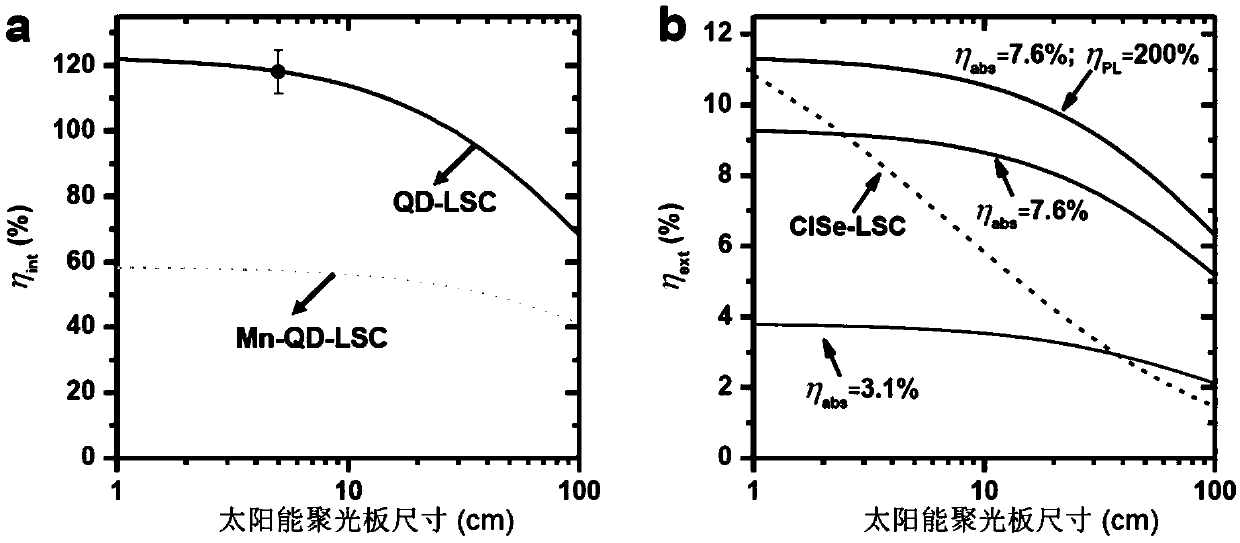

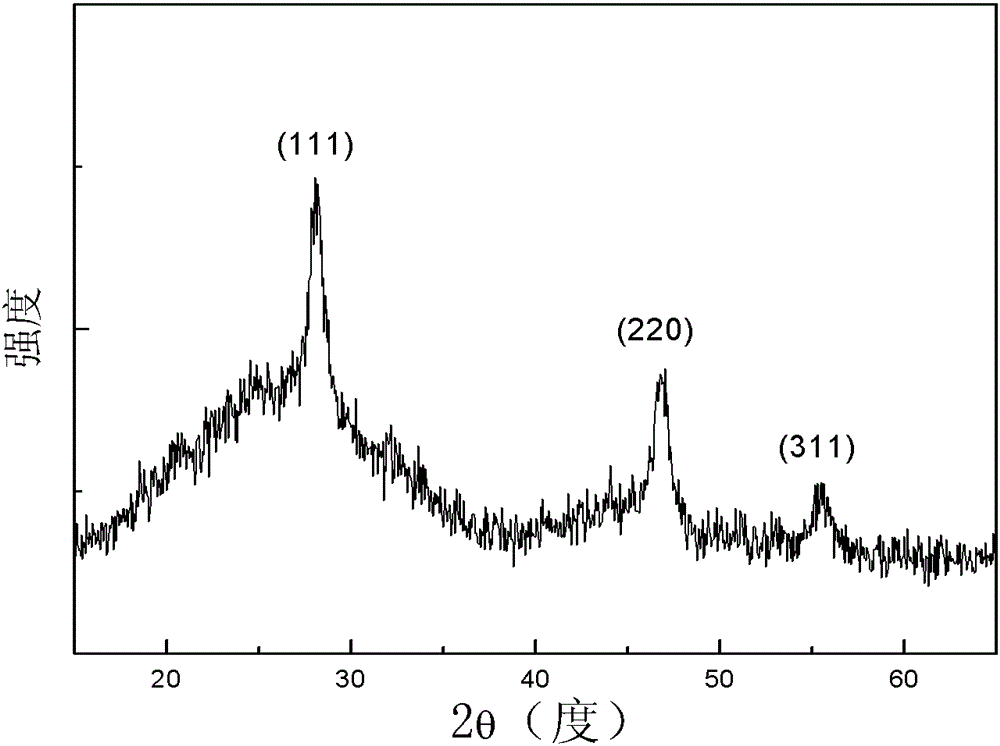

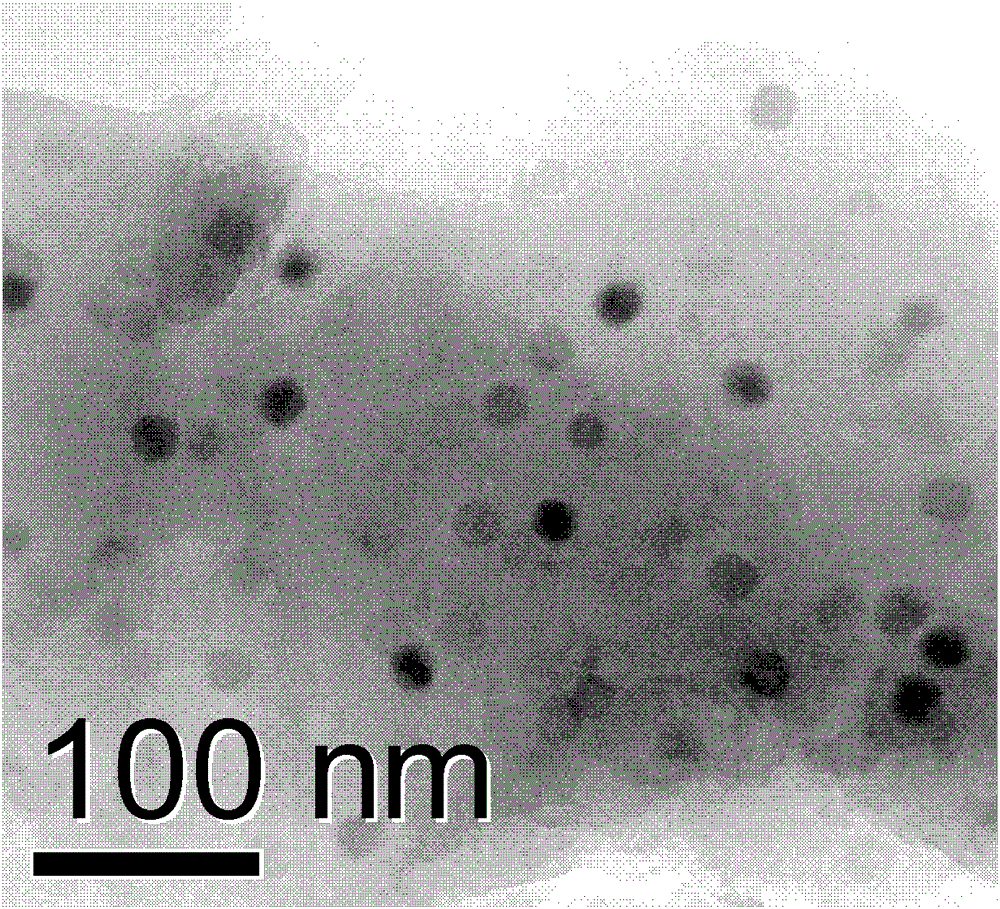

Solar light condensation plate based on quantum cutting effect

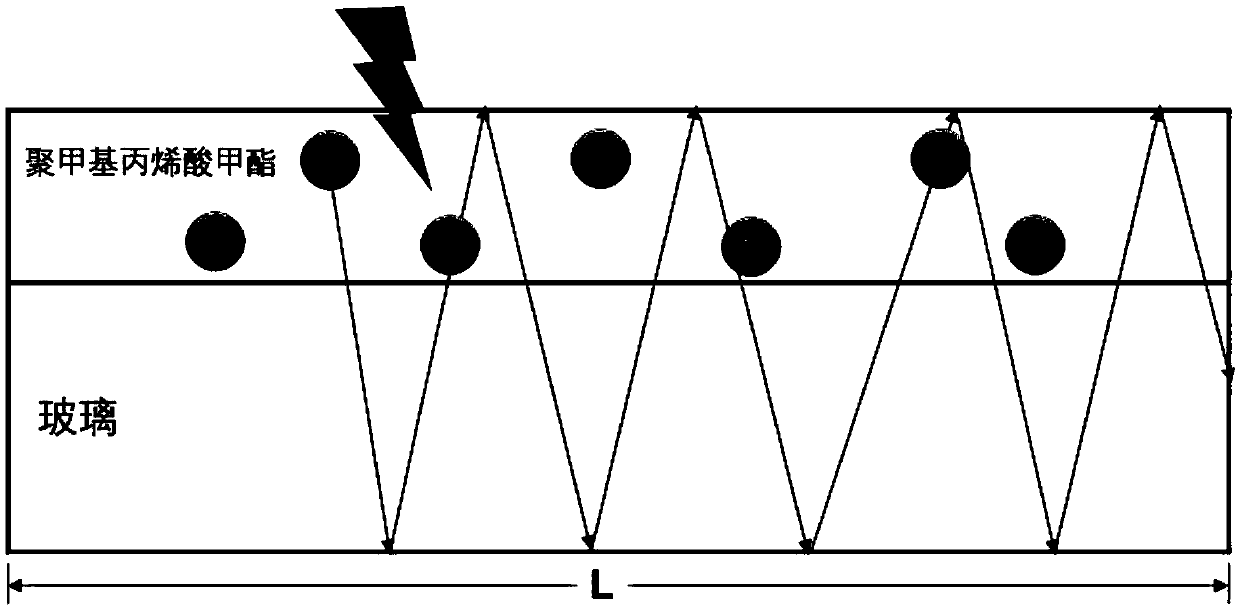

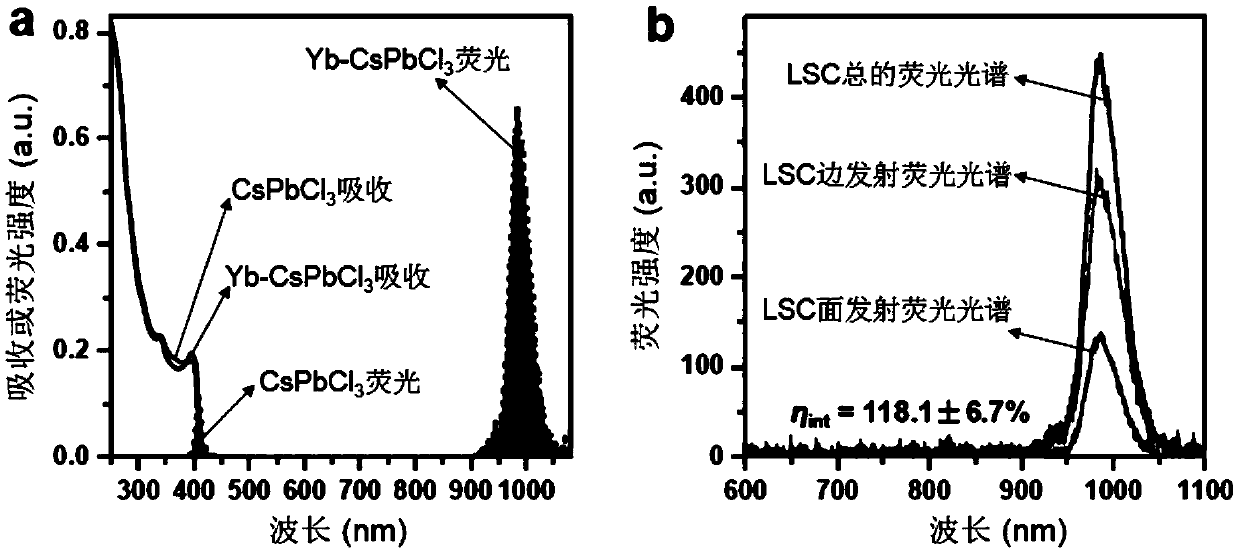

ActiveCN111170646ASolve technical problems with low efficiencyCoatingsLuminescent compositionsSolar lightElectrical battery

The invention relates to a solar light condensation plate based on a quantum cutting effect. According to the solar light condensation plate, quantum dots with a quantum cutting effect are mainly usedas a light absorption and emission material, and a polymer is used as an optical waveguide medium; the quantum dots have a high extinction coefficient so as to absorb light efficiently, achieve largespectral Stokes shift through the quantum cutting effect so as to effectively reduce self-absorption loss, and achieve multiplied fluorescence quantum efficiency, and finally the light is waveguidedto a solar cell on the side face through the polymer to achieve photoelectric conversion; and as a preferred scheme, polymethyl methacrylate (PMMA) is selected as the polymer, rare earth metal ytterbium (Yb) doped cesium lead chloride perovskite quantum dots (Yb-CsPbCl3) are selected as the quantum dots, and finally the internal quantum efficiency up to 118% is obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Near-infrared quantum tailoring down-conversion luminescence transparent glass ceramics and preparation method thereof

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Tungstate near infrared quantum cutting material and preparation method and application thereof

InactiveCN102424750BWide excitation spectrumStrong absorption capacitySolid-state devicesSemiconductor/solid-state device manufacturingLight energyTungstate

The invention provides a tungstate near infrared quantum cutting material and a preparation method and an application thereof, and the chemical composition formula of the quantum cutting material is Ca0.99-xWO4:0.01Nd3+, xYb3+, wherein Ca0.99-xWO4 is a substrate; Nd3+ and Yb3+ are doped rare earth ions; x is the molar quantity of the doped rare earth ion Yb3+, and 0.01<=x<=0.3. The preparation method of the quantum cutting material adopts a traditional high temperature solid phase calcining method to synthesize the tungstate near infrared quantum cutting material. The tungstate near infrared quantum cutting material can be excited by visible light of 300-700 nm, and emit high-intensity near infrared light within a range of 900-1500 nm; the light within the wave band can be effectively absorbed by silicon-based solar energy cells, and has calculated quantum efficiency of up to 181%. The tungstate near infrared quantum cutting material is applicable to the preparation of solar energy cells.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Photoluminescent transparent inorganic glass converted under far infrared quantum cutting and preparation method thereof

The invention discloses a fluorescent transparent inorganic glass converted under far infrared quantum cutting and a preparation method thereof. The fluorescent transparent inorganic glass comprises the following components in mol by percentage, 60-80mol percent of B2O3, 7-15 mol percent of Al2O3, 5-10 mol percent of CaO, 5-10 mol percent of Li2CO3, 0-5 mol percent but not 0 mol percent of CeF3 and 0-10 mol percent but not 0 mol percent of Yb2O3, wherein the total mole content of Al2O3, CeF3 and Yb2O3 is 15 percent. The inorganic glass material can realize high-efficiency converting fluorescence under the excitation of ultraviolet light.

Owner:福建省德化县腾兴陶瓷有限公司

Near-infrared quantum cutting fluorescent powder capable of increasing silicon solar cell efficiency and preparation method thereof

ActiveCN103333690BExpand the scope of absorptionImprove conversion efficiencyLuminescent compositionsPhotovoltaic energy generationPhoton emissionUltraviolet

The invention relates to the technical field of fluorescent powder production, and discloses a near-infrared quantum cutting fluorescent powder capable of increasing silicon solar cell efficiency and a preparation method thereof. The near-infrared quantum cutting fluorescent powder has a chemical formula as follows: LaBO3:Ce<3+>(1%),Yb<3+>(x%), wherein the x is not less than 2 and not more than 3. According to the near-infrared quantum cutting fluorescent powder, when each ultraviolet photon is absorbed, a Ce<3+>-Yb<3+> ion pair can emit two near-infrared photons through cooperation energy transmission, thus emitting 980 nm near infrared light. The near-infrared quantum cutting fluorescent powder is advantageous in that silicon solar cell spectrum absorption scope can be widened, and therefore the silicon solar cell conversion efficiency can be increased.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

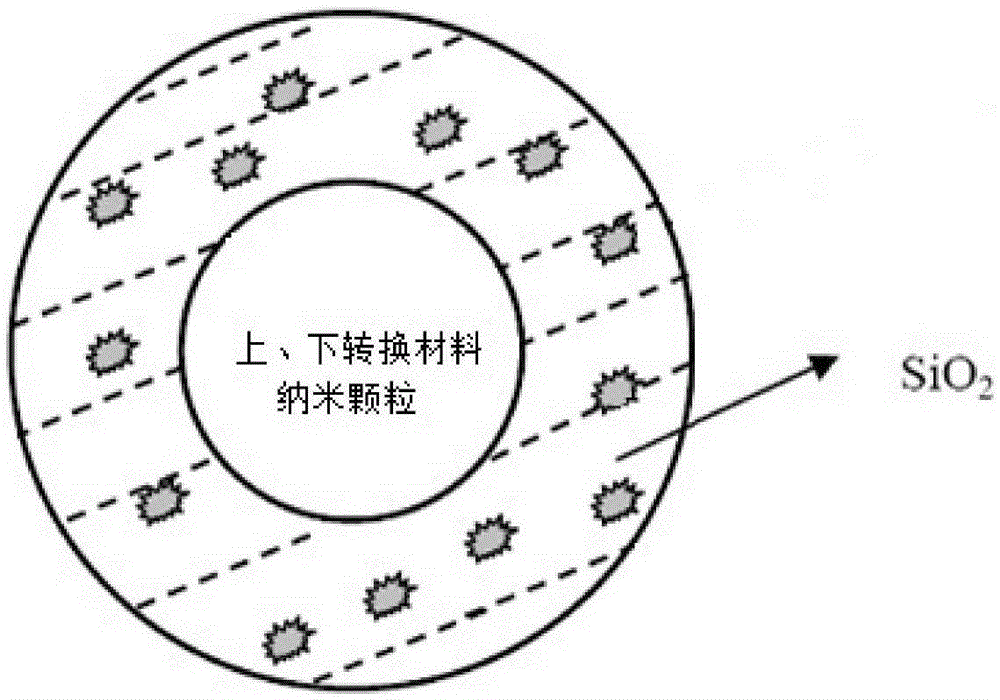

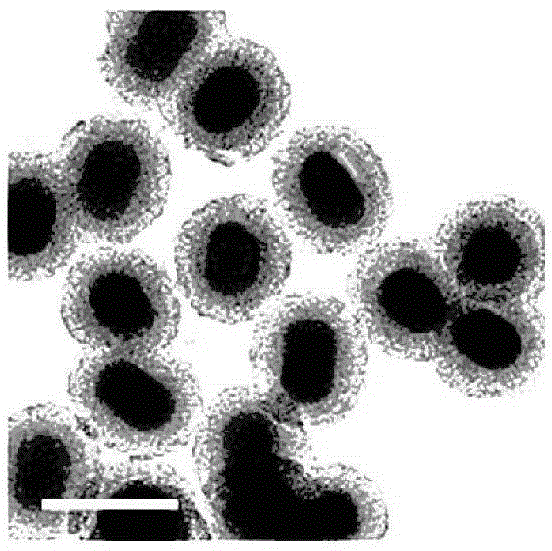

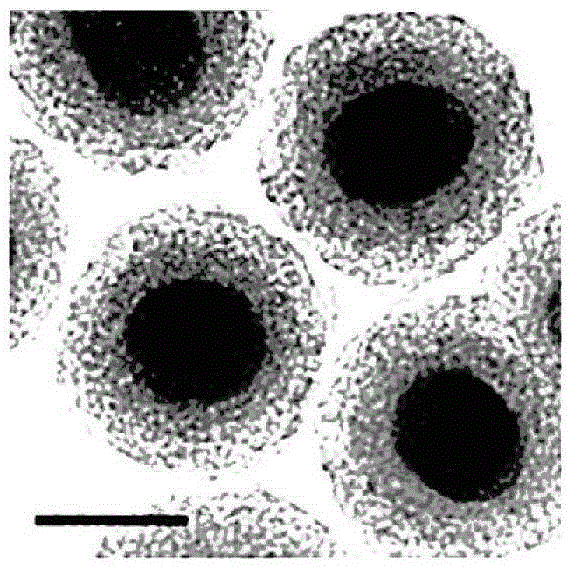

A new approach to quantum tailoring to improve the efficiency of thin-film silicon solar cells

ActiveCN103887374BImprove utilization efficiencyImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationNano sio2Ultraviolet lights

The invention discloses a novel method for improving the efficiency of a Si-film solar cell through quantum cutting. A functional nanometer SiO2 film containing an upper conversion material and a lower conversion material is adopted to increase the absorption of light by the Si-film solar cell, SiO2 sol containing the upper conversion material and the lower conversion material is firstly prepared, then a film with controllable SiO2 particles is prepared through a rotary coating or pulling method, the film can protect a Si film and a Ag or Al metal film from being affected, the upper conversion material and the lower conversion material contained by the film gather infrared light to be visible light, and reduce ultraviolet light to be visible light and infrared light, the infrared light is then converted into visible light through quantum cutting, the light use efficiency of the Si-film solar cell is largely improved, and quantum cutting can be carried out on long-wavelength infrared light and short-wavelength ultraviolet light which can not be absorbed by the solar cell to convert the long-wavelength infrared light and the short-wavelength ultraviolet light into usable visible light. The conversion efficiency of the solar cell is improved, and decrease of the conversion efficiency and performance degradation of the solar cell caused by temperature rise of the cell are avoided at the same time.

Owner:NANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com