Solar light condensation plate based on quantum cutting effect

A solar concentrating and effect technology, applied in the field of solar concentrating panels, can solve the problems of low efficiency of solar concentrating panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The preparation method of a high-efficiency solar concentrating panel based on the quantum tailoring effect described in this embodiment comprises the following steps:

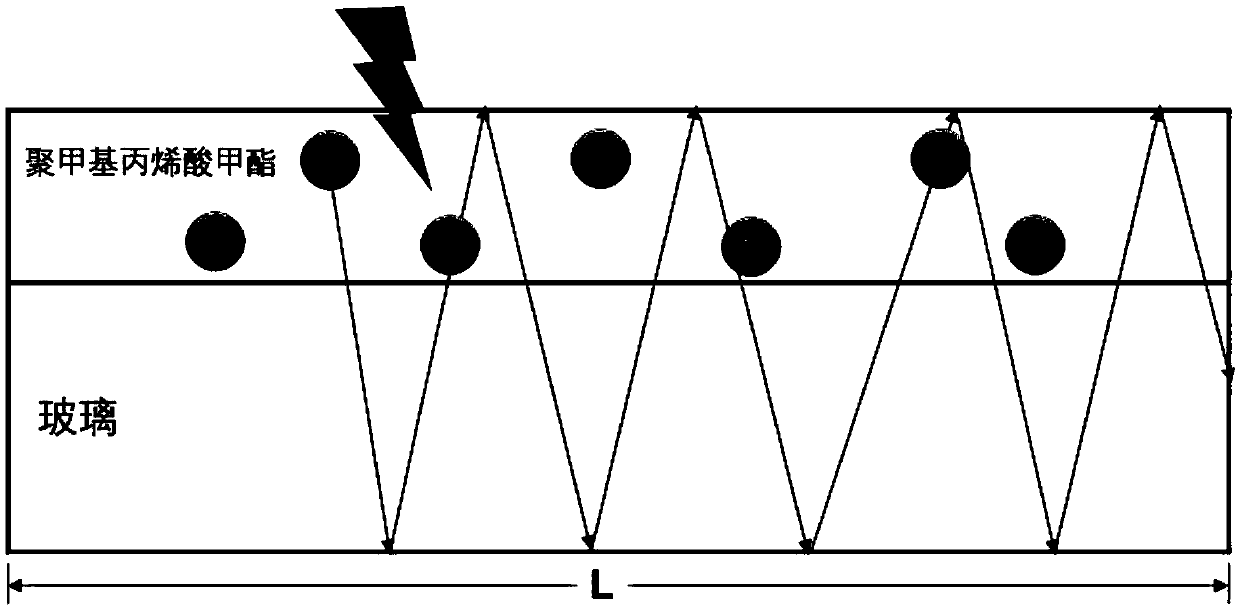

[0020] 0.1 μmol Yb-CsPbCl 3 (the molar doping amount of ytterbium element is 5%) the chloroform solution (7.5mL) of quantum dots (particle size is 8-15 nanometers) and the polymethyl methacrylate (350000 average molecular weight) of 0.83g are mixed and stirred for 10 hours , centrifuge the mixture at a low speed (2000 rpm) to take the supernatant, apply it evenly on the glass substrate by scraper casting method, and let it stand until the solvent is completely volatilized to form a solar concentrator, such as figure 1 shown.

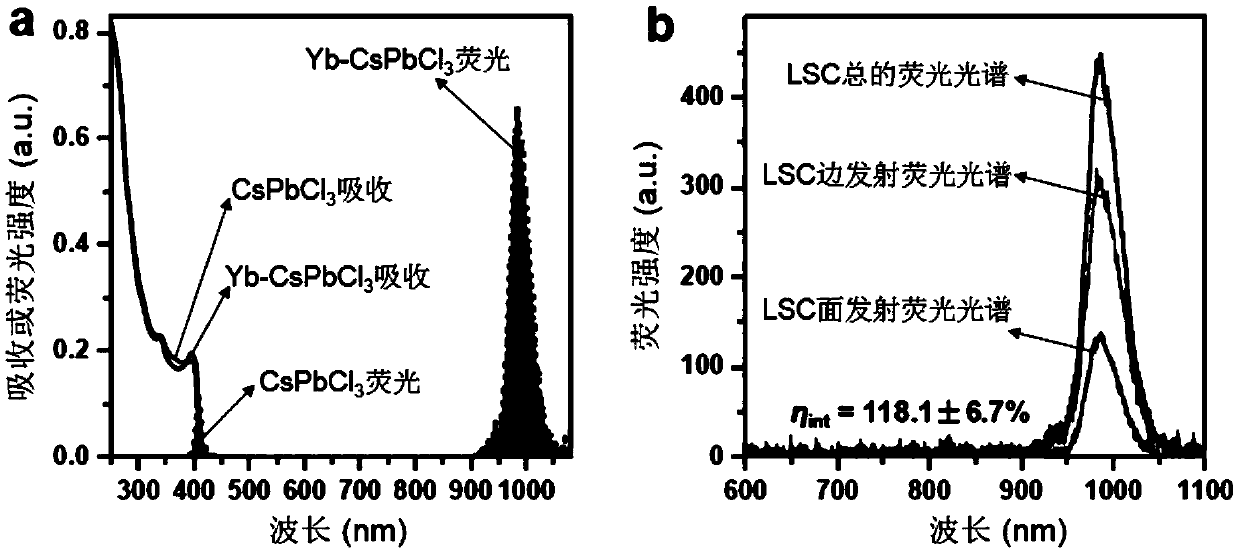

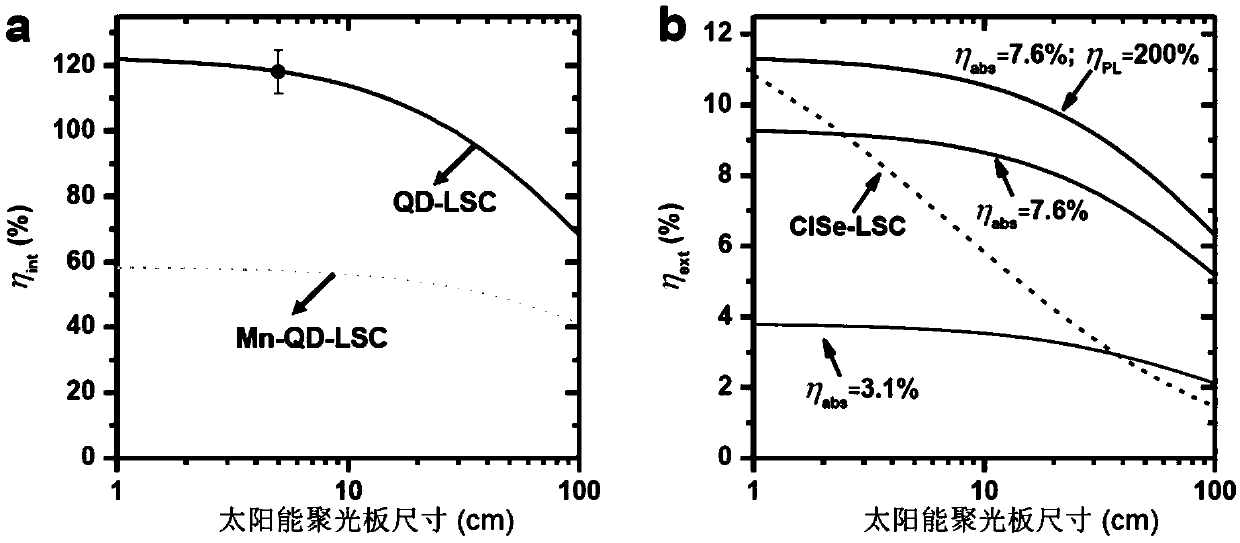

[0021] Whether the solar concentrating panels prepared by us can achieve high optical efficiency needs to be verified by combining optical detection means and theoretical calculations. The verification detection is mainly carried out from the following three aspects:

[0022] (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com