Material having cooperative frequency light conversion performance and preparation method and application thereof

A performance and frequency technology, applied in the field of synergistic frequency conversion materials and its preparation, can solve the problems of photovoltaic device damage and thermal effects, and achieve the effects of eliminating thermal effects, low cost, and improving battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

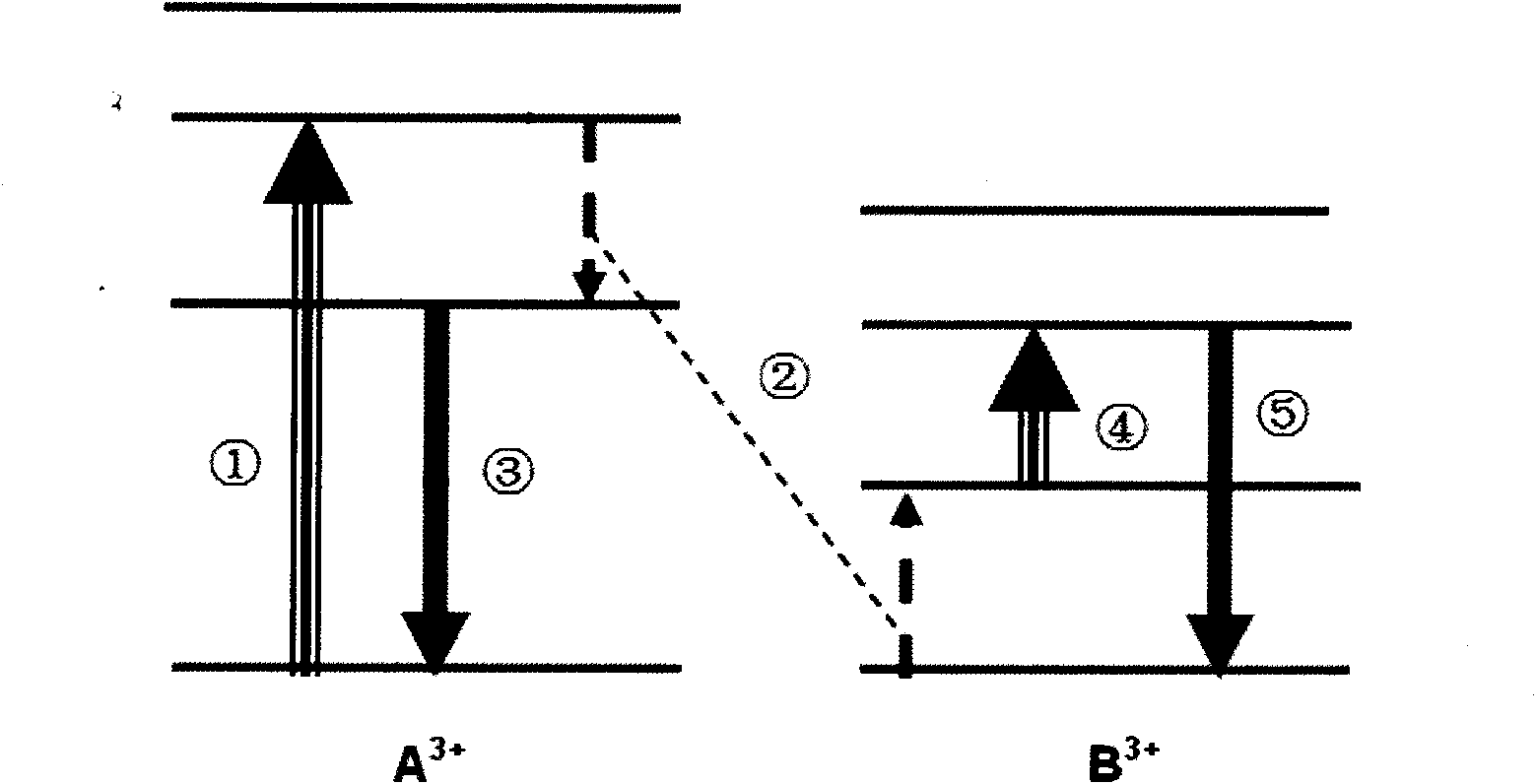

Method used

Image

Examples

Embodiment 1

[0038] The molecular formula of the synthetic fluoride with synergistic frequency conversion performance is Yb 0.90 Er 0.10 f 3 . The specific preparation method is: dissolve the rare earth element oxide Yb with hydrochloric acid 2 o 3 and Er 2 o 3 , configure 0.2mol / L of YbCl 3 and ErCl 3 solution, take 25.65ml of YbCl 3 and 3.865ml of ErCl 3 solution, and the mixture was magnetically stirred for half an hour. Take 1g NH 4 HF 2 Dissolve in 10ml of deionized water, then add dropwise to the mixture, and magnetically stir the mixture for half an hour. The mixed solution after the reaction was centrifuged to obtain a white precipitate, which was washed three times under the condition of ultrasonic separation, and then dried in air at 50° C. for 5 hours. Calcined at 600°C for 6 hours, then naturally cooled to room temperature.

Embodiment 2

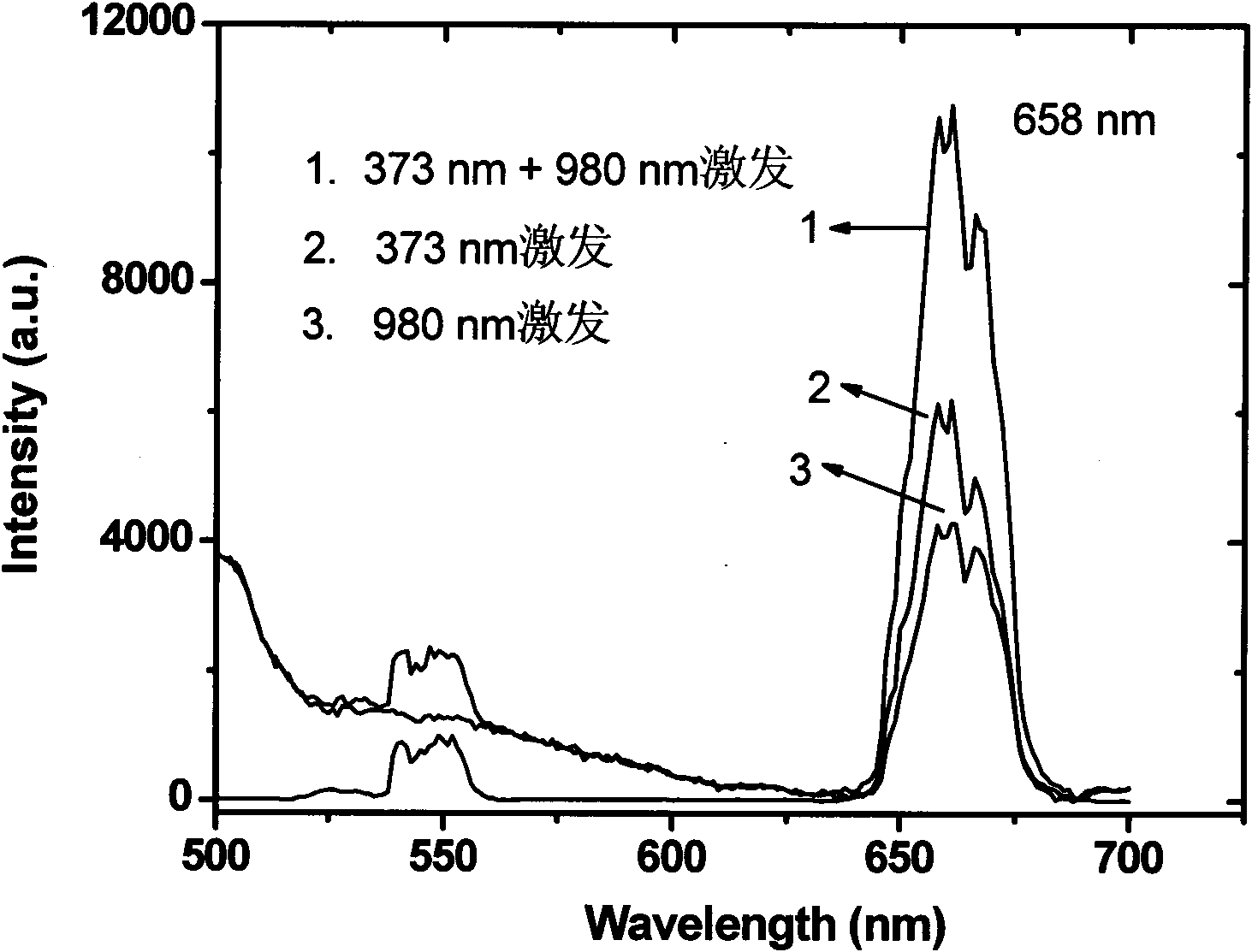

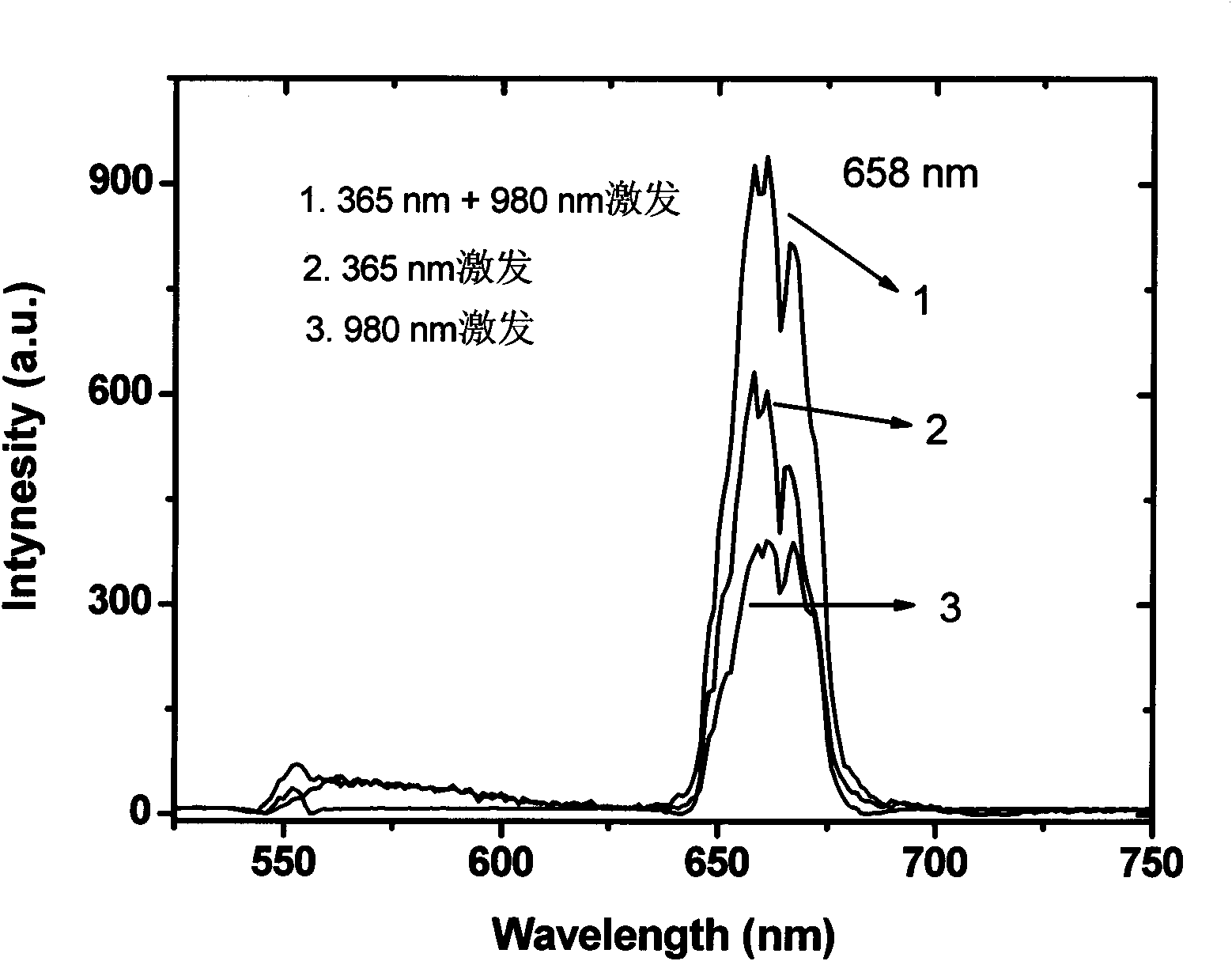

[0040] The molecular formula of the synthetic fluoride with synergistic frequency conversion performance is Yb 0.87 Er 0.13 f 3 . Dissolving rare earth element oxide Yb with hydrochloric acid 2 o 3 and Er 2 o 3 , configure 0.2mol / L of YbCl 3 and ErCl 3 solution, take 26ml of YbCl 3 and 3.32ml of ErCl 3 solution, and the mixture was magnetically stirred for half an hour. Take 2g NH 4 HF 2 Dissolve in 10ml of deionized water, then add dropwise to the mixture, and magnetically stir the mixture for half an hour. The mixed solution after the reaction was centrifuged to obtain a white precipitate, which was washed three times under the condition of ultrasonic separation, and then dried in air at 70° C. for 5 hours. Calcined at 750°C for 2 hours, then naturally cooled to room temperature. For the luminescence spectrum of the prepared sample under the common excitation of 373nm and 980nm, see figure 2 . For the luminescence spectrum of the prepared sample under the co...

Embodiment 3

[0042] The molecular formula of the synthetic fluoride with synergistic frequency conversion performance is Yb 0.50 Er 0.50 f 3 . Dissolving rare earth element oxide Yb with hydrochloric acid2 o 3 and Er 2 o 3 , configure 0.2mol / L of YbCl 3 and ErCl 3 solution, take 15ml of YbCl 3 and 15ml of ErCl 3 solution, and the mixture was magnetically stirred for half an hour. Take 2g NH 4 F was dissolved in 10 ml of deionized water, then added dropwise to the mixture, and the mixture was magnetically stirred for half an hour. The mixed solution after the reaction was centrifuged to obtain a white precipitate, which was washed three times under the condition of ultrasonic separation, and then dried in air at 50° C. for 5 hours. Calcined at 800°C for 2 hours, then naturally cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com