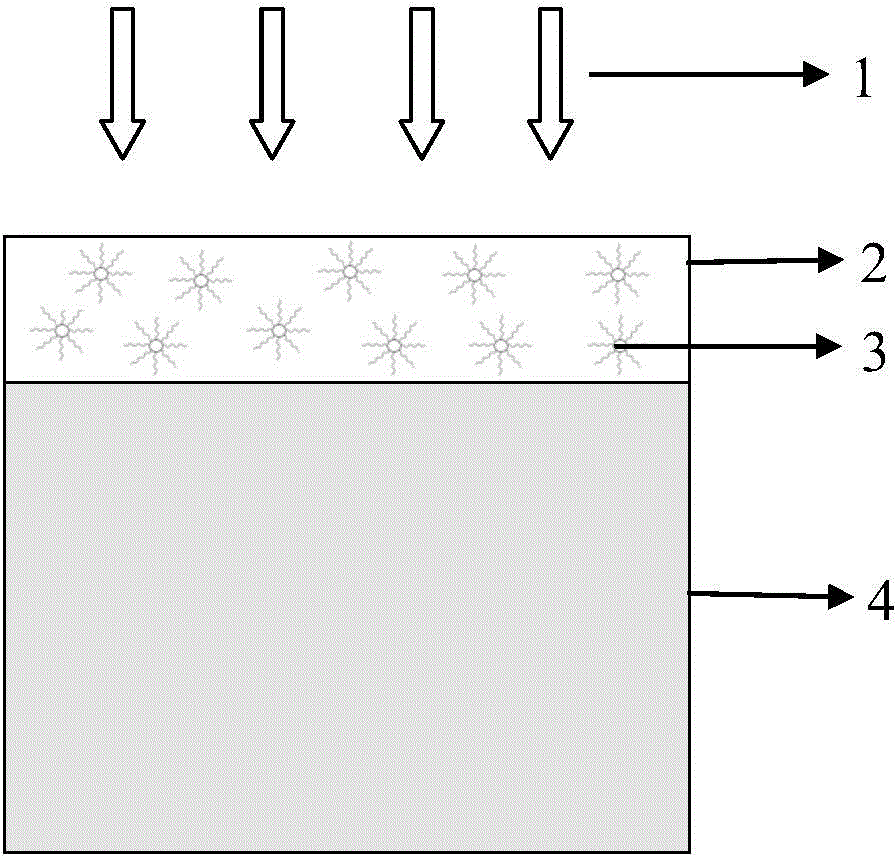

Under-light conversion layer for silicon solar cell and manufacturing method of under-light conversion layer

A technology of silicon solar cells and conversion layers, applied in the field of solar cells, can solve the problems of small molar absorptivity, low absorption cross-section, and difficulty in obtaining high quantum yield by directly exciting rare earth ions, so as to achieve large molar coefficient of light absorption and reduce Energy loss, effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Rare earth organic-inorganic hybrid near-infrared quantum tailoring nanomaterial 5-SSA-NaGdF 4 :1%Tb 3+ ,8Yb 3+ The preparation comprises the following steps:

[0019] (1) Configure 0.2M Gd(NO 3 ) 3 , Tb(NO 3 ) 3 and Yb(NO 3 ) 3 Rare earth nitrate aqueous solution;

[0020] (2) Take by weighing 28mmol trisodium citrate and add deionized water to make 40ml sodium citrate aqueous solution;

[0021] (3) Take 0.2M Gd(NO 3 ) 3 13.16ml, Tb(NO 3 ) 3 0.14ml, Yb(NO 3 ) 3 Add 1.12ml into (2), and stir thoroughly for 40min;

[0022] (4) Add 22ml of 0.4M NaF aqueous solution into (3), and stir thoroughly for 30min;

[0023] (5) Move the mixed solution to a polytetrafluoroethylene reaction kettle, seal it, put it in a vacuum oven, keep it at 180°C for 24h, and then cool it naturally to room temperature;

[0024] (6) Precipitate, centrifuge and wash the reacted solution to obtain NaGdF 4 :1%Tb 3+ ,8Yb 3+ nanomaterials;

[0025] (7) NaGdF will be obtain...

Embodiment 2

[0027] Embodiment 2: the preparation of light conversion layer, flow process is as follows:

[0028] (1) PMMA is added in chloroform and is made into the PMMA chloroform solution that mass percent is 5%;

[0029] (2) 5-SSA-NaGdF 4 :1%Tb 3+ ,8Yb 3+ Added to the above PMMA chloroform solution, 5-SSA-NaGdF 4 :1%Tb 3+ ,8Yb 3+ The mass percentage with PMMA is 5:95, fully stirred for 10 hours to form a colloid, and then left to stand for 12 hours;

[0030](3) Place the silicon solar cell substrate on a spin coater, drop the above-mentioned colloid on the silicon solar cell substrate at a rotation speed of 2000r, keep it for 30s, then remove it and place it in a vacuum drying oven at 25°C for 5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com