Tungstate near infrared quantum cutting material and preparation method and application thereof

A quantum tailoring and near-infrared technology, which is applied in the direction of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems such as damaging human health and polluting the environment, and achieve low work efficiency, wide excitation spectrum, and strong absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the tungstate near-infrared quantum tailoring material of the present invention, wherein, the chemical composition formula of the tungstate near-infrared quantum tailoring material is Ca 0.99-x WO 4 :0.01Nd 3+ , xYb 3+ , Ca 0.99-x WO 4 as the matrix, Nd 3+ , Yb 3+ is the doped rare earth ion, x is the molar weight of the doped rare earth ion, 0.01≤x≤0.3; including the following steps:

[0042] According to the chemical composition formula of the tungstate near-infrared quantum tailoring material, calcium raw material, tungsten raw material, neodymium raw material and ytterbium raw material are mixed according to the stoichiometric ratio, and ground;

[0043] Precalcining the mixed raw materials in air at a temperature of 300-500°C;

[0044] Cool the pre-calcined material to room temperature and grind again;

[0045] Calcining the reground raw materials at a temperature of 900-1000°C;

[0046] Cool the calcined material to room temperat...

Embodiment 1

[0049] Example 1: Tungstate near-infrared quantum tailoring material Ca 0.89 WO 4 :0.01Nd 3+ , 0.1Yb 3+ preparation of

[0050] Calcium carbonate (CaCO 3 )0.5939g, tungsten trioxide (WO 3 ) 1.5457g, neodymium oxide (Nd 2 o 3 )0.0122g and ytterbium oxide (Yb 2 o 3 ) 0.1314g. After the above raw materials were ground and mixed in an agate mortar, they were put into a corundum crucible, and pre-calcined at a temperature of 400°C for 2 hours. Then cool the pre-calcined powder to room temperature, take it out and grind it. Then calcined again at a temperature of 900°C for 4 hours, after cooling, ground again until pulverized and sieved to obtain a tungstate near-infrared quantum tailoring material Ca with a particle size of 100nm-100μm. 0.89 WO 4 :0.01Nd 3+ , 0.1Yb 3+ .

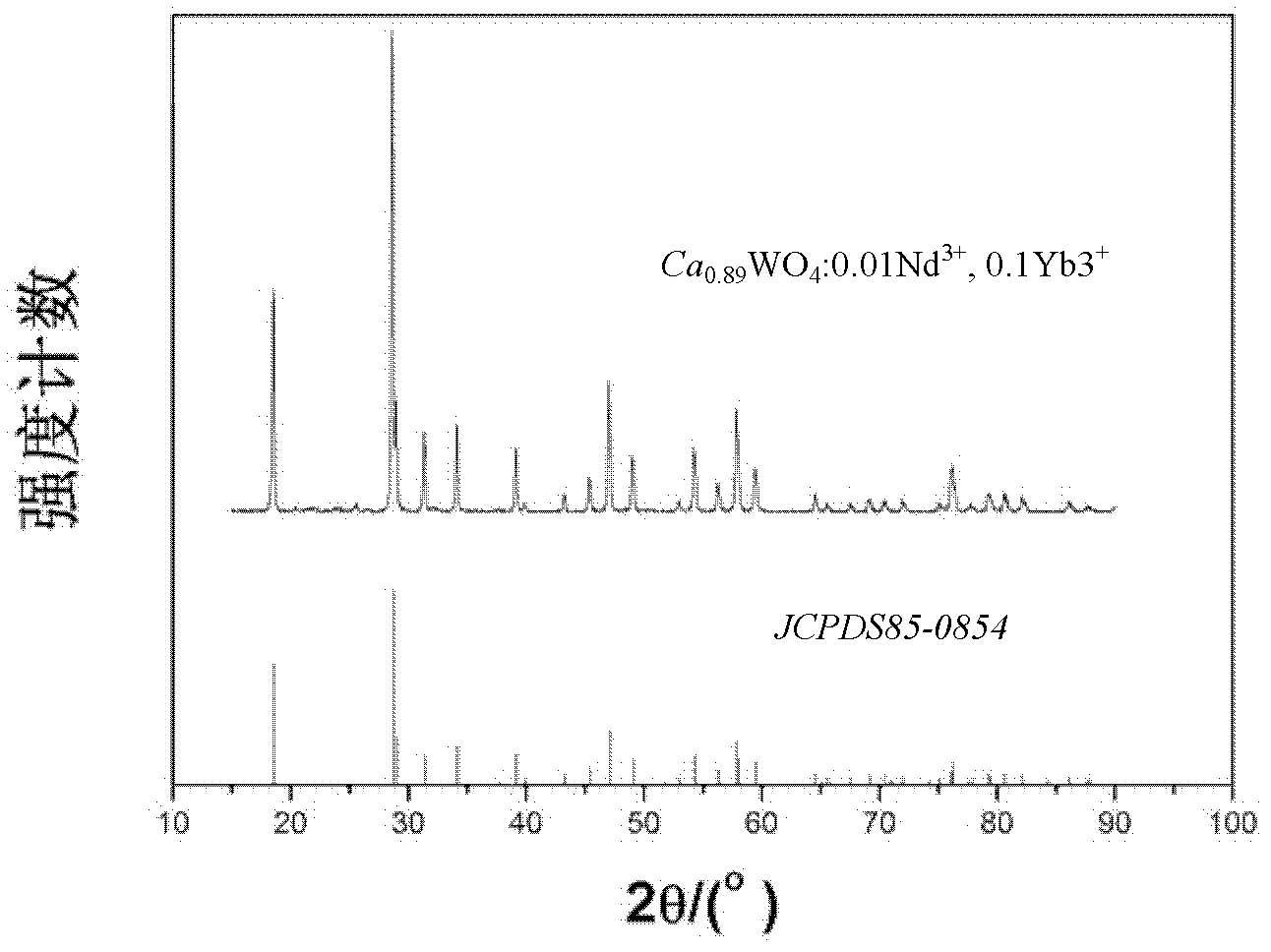

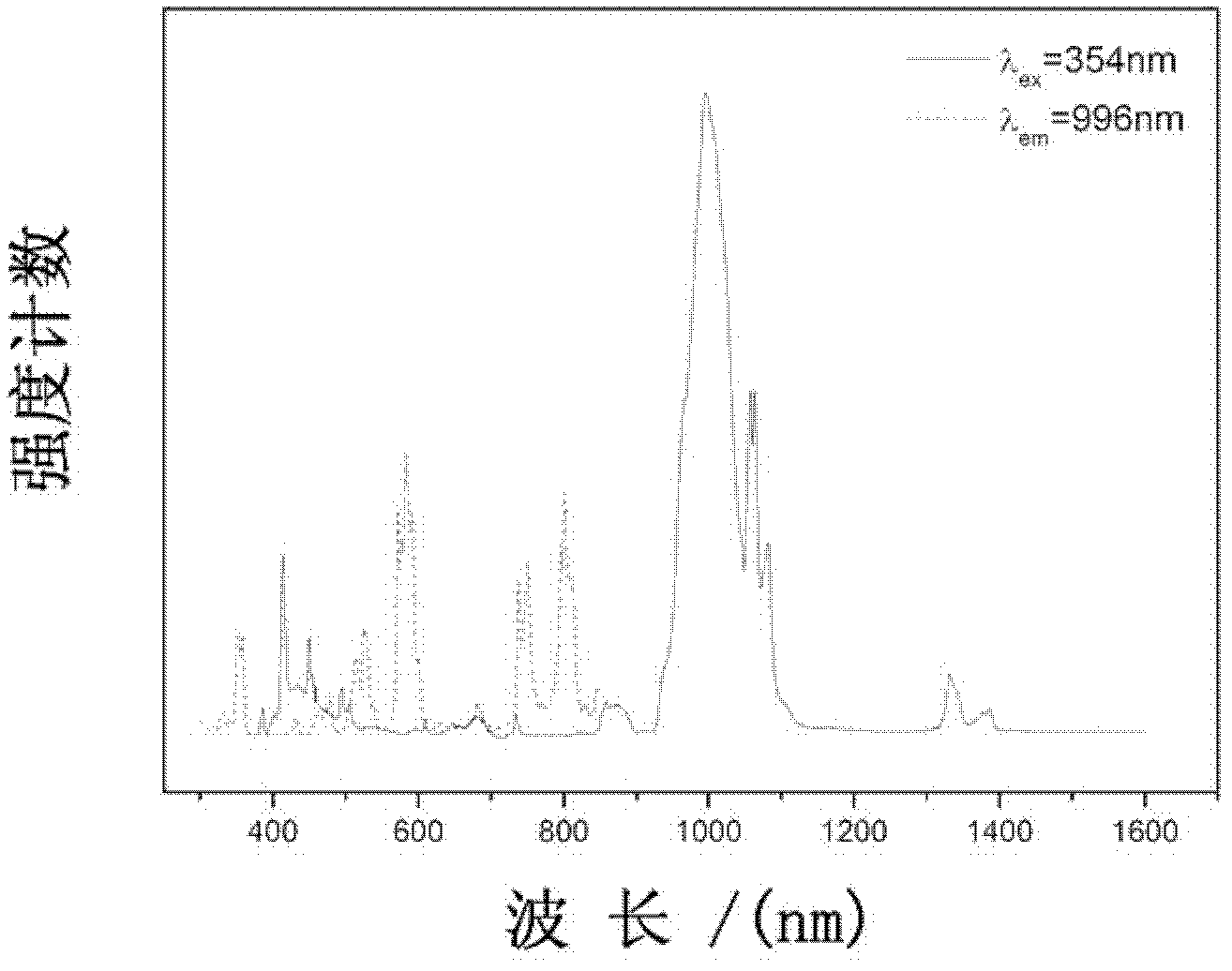

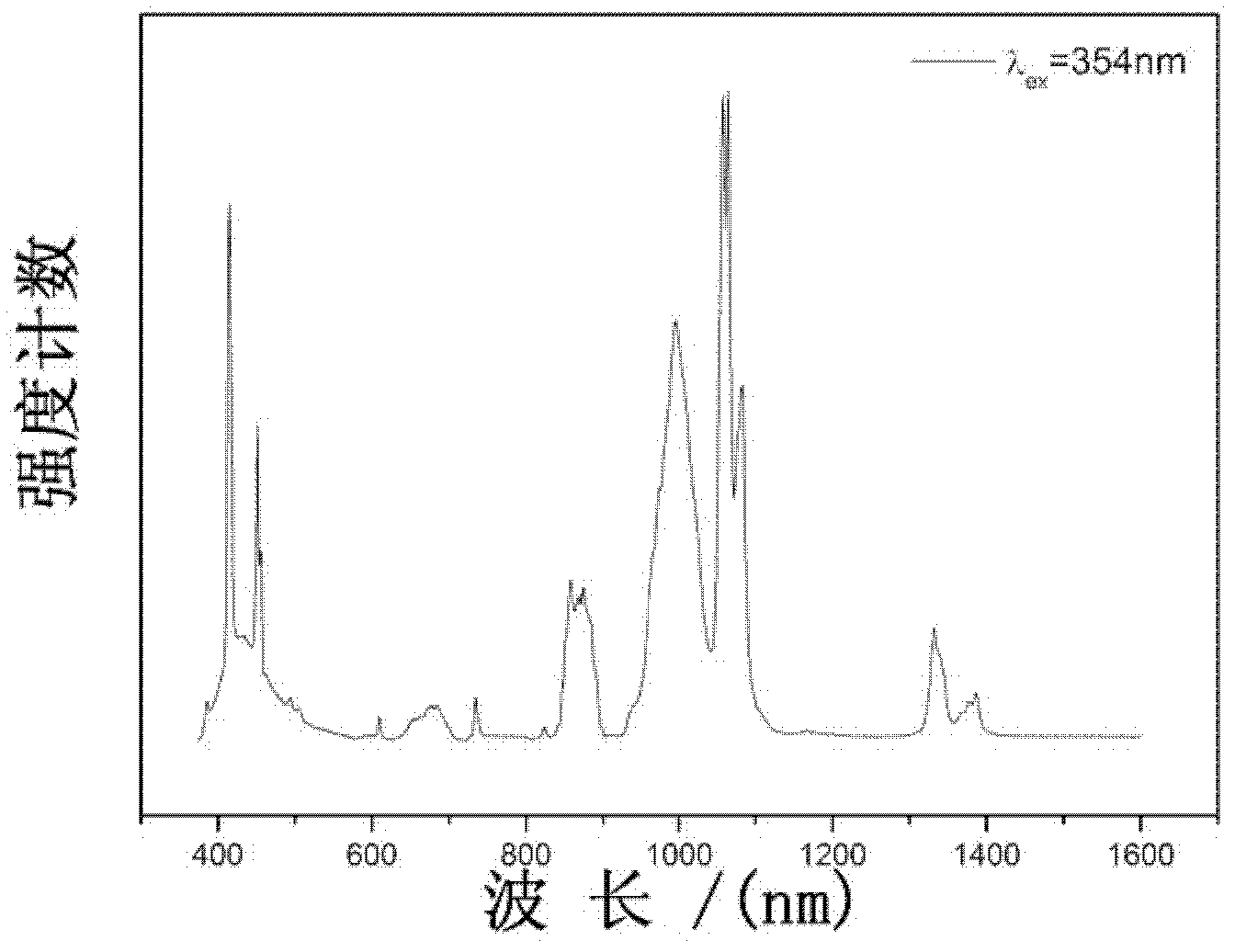

[0051] Adopt Japan Shimadzu XRD-6000 type X-ray polycrystal diffractometer (radiation source is Cu target K α , 40kV, 30mA, λ=0.15406nm, step size 0.02, scan range 10°~90°), measure the X-ray diffr...

Embodiment 2

[0053] Example 2: Tungstate near-infrared quantum tailoring material Ca 0.98 WO 4 :0.01Nd 3+ , 0.01Yb 3+ preparation of

[0054] Weigh calcium nitrate (Ca(NO 3 ) 2 4H 2 O) 1.5428g, tungsten trioxide (WO 3 ) 1.5457g, neodymium nitrate (Nd(NO 3 ) 3 ·6H 2 O) 0.0292g and ytterbium nitrate (Yb(NO 3 ) 3 ·5H 2 O) 0.0299g. After the above raw materials were ground and mixed in an agate mortar, they were put into a corundum crucible and pre-calcined for 3 hours at a temperature of 500°C. Then cool the pre-calcined powder to room temperature, take it out and grind it. Then calcined again at a temperature of 1000°C for 5 hours, after cooling, ground again until pulverized and sieved to obtain a tungstate near-infrared quantum tailoring material Ca with an average particle size of 100nm-100μm 0.98 WO 4 :0.01Nd 3+ , 0.01Yb 3+ .

[0055] Same as Example 1, the X-ray diffraction test shows that the prepared tungstate near-infrared quantum tailoring material is a single cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com