Preparation method of downconversion fluorescent material

A fluorescent material and fluorescent powder technology, which is applied in the field of preparation of down-conversion fluorescent materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

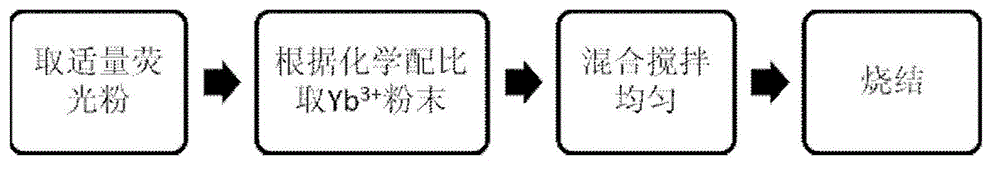

[0013] see figure 1 As shown, the present invention provides a kind of preparation method of down conversion fluorescent material for the first time, comprises the steps:

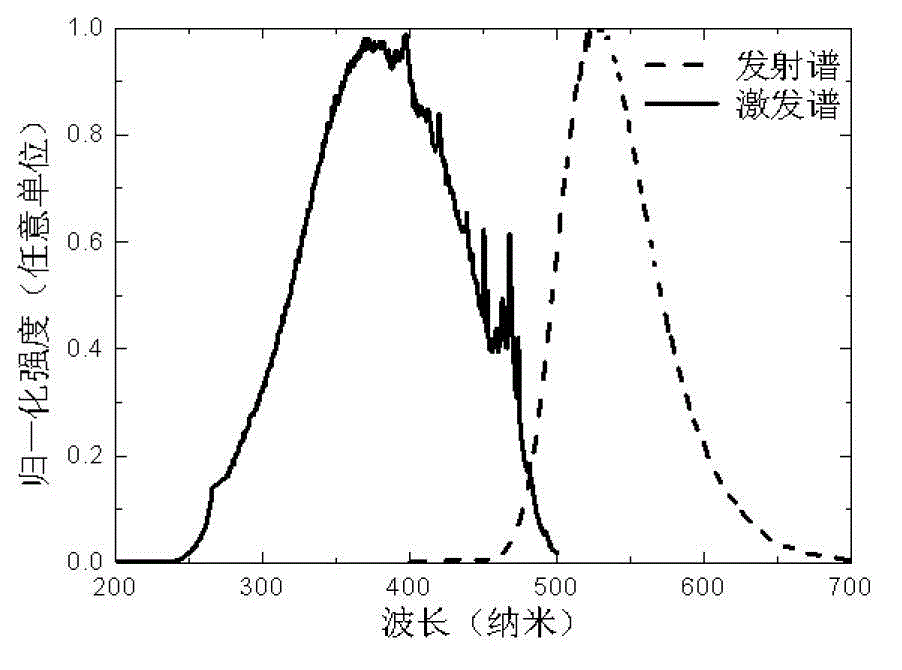

[0014] Step 1: Take a general chemical formula as Phosphor powder or raw materials for preparing the phosphor powder. In the experiment, a chemical formula (Sr 0.6 Ba 0.4 ) 2 SiO 4 :Eu 2+ Green phosphor, its emission spectrum and excitation spectrum are as follows figure 2 shown.

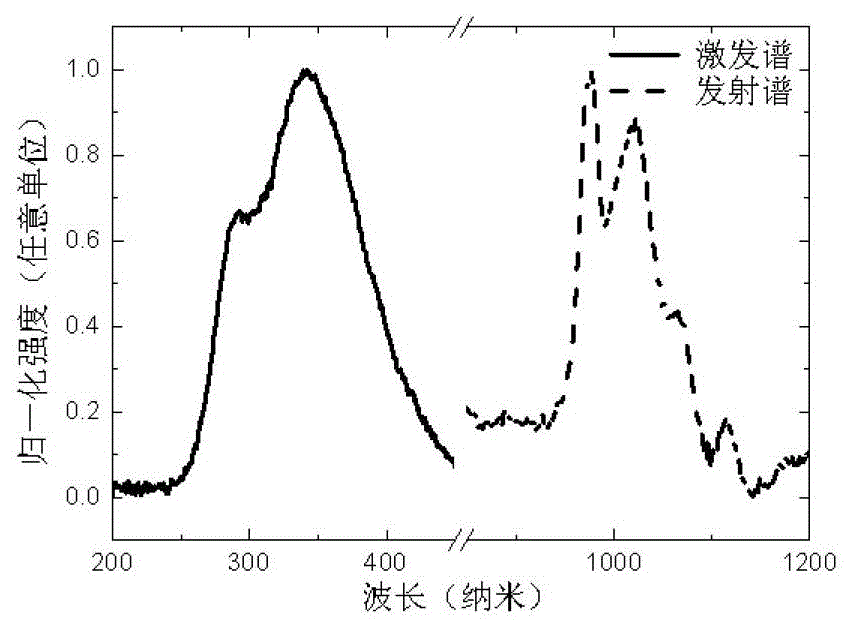

[0015] Step 2: Add Yb to the phosphor powder 3+ powder. where Yb 3+ The powder material is YbF 3 or Yb 2 o 3 , YbF was used in the experiment 3 A powder whose size is comparable to that of a phosphor.

[0016] Step 3: Mix and stir well. In the experiment, the phosphor and YbF 3 Put it into an agate mortar and add an appropriate amount of ethanol to grind and mix well;

[0017] Step 4: Sintering. Sintering methods include high-temperature solid-phase method, combustion method, sol-gel method, precipitation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com