Near-infrared quantum-cutting down-conversion luminescent transparent glass ceramic and preparation method and application thereof

A technology of quantum tailoring and transparent glass, which is applied in the field of rare earth-doped transparent glass ceramics and its preparation technology, can solve the problems of limiting the practical application of solar cells and poor transparency, and achieve improved photoelectric conversion efficiency, low cost, and reduced thermalization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

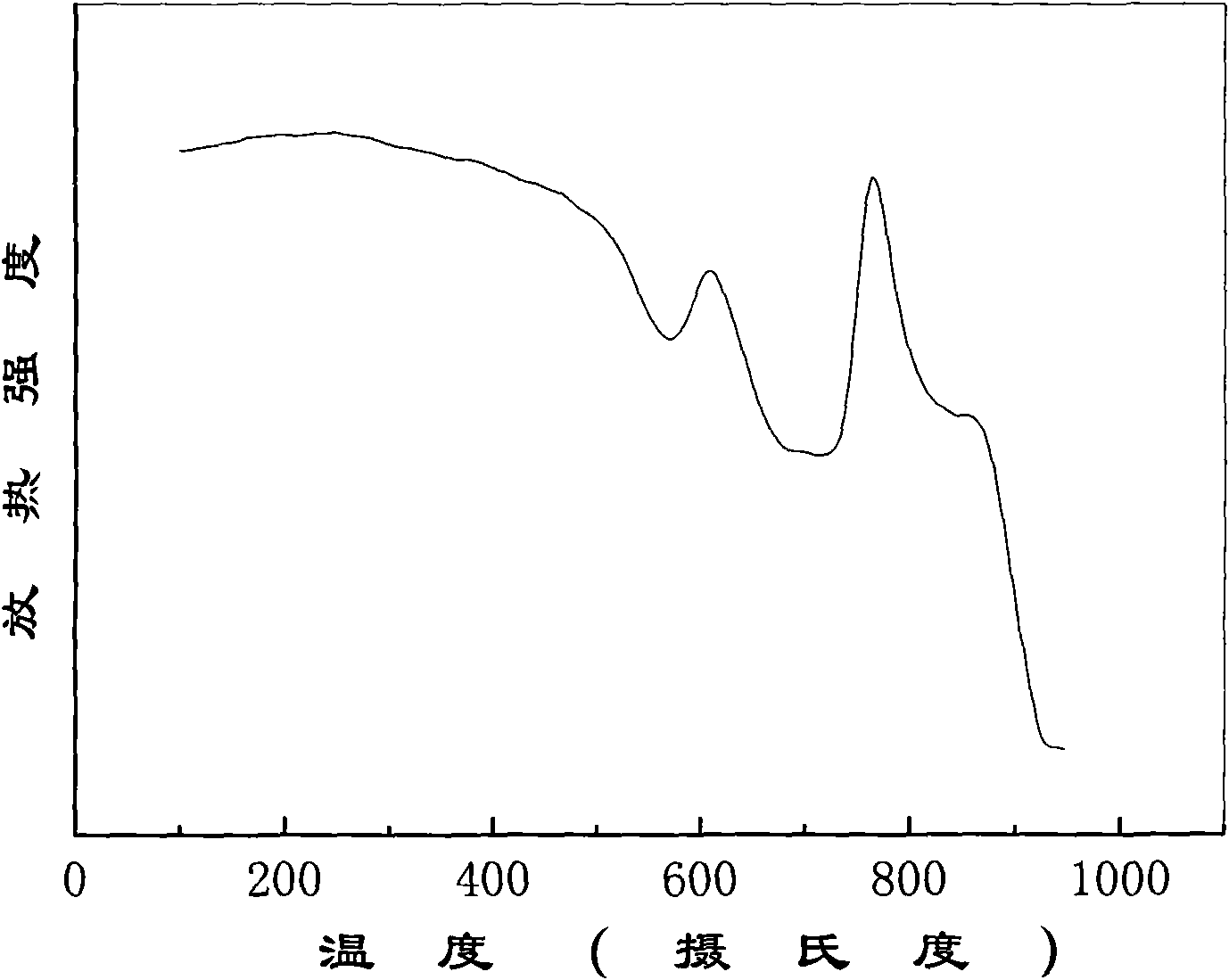

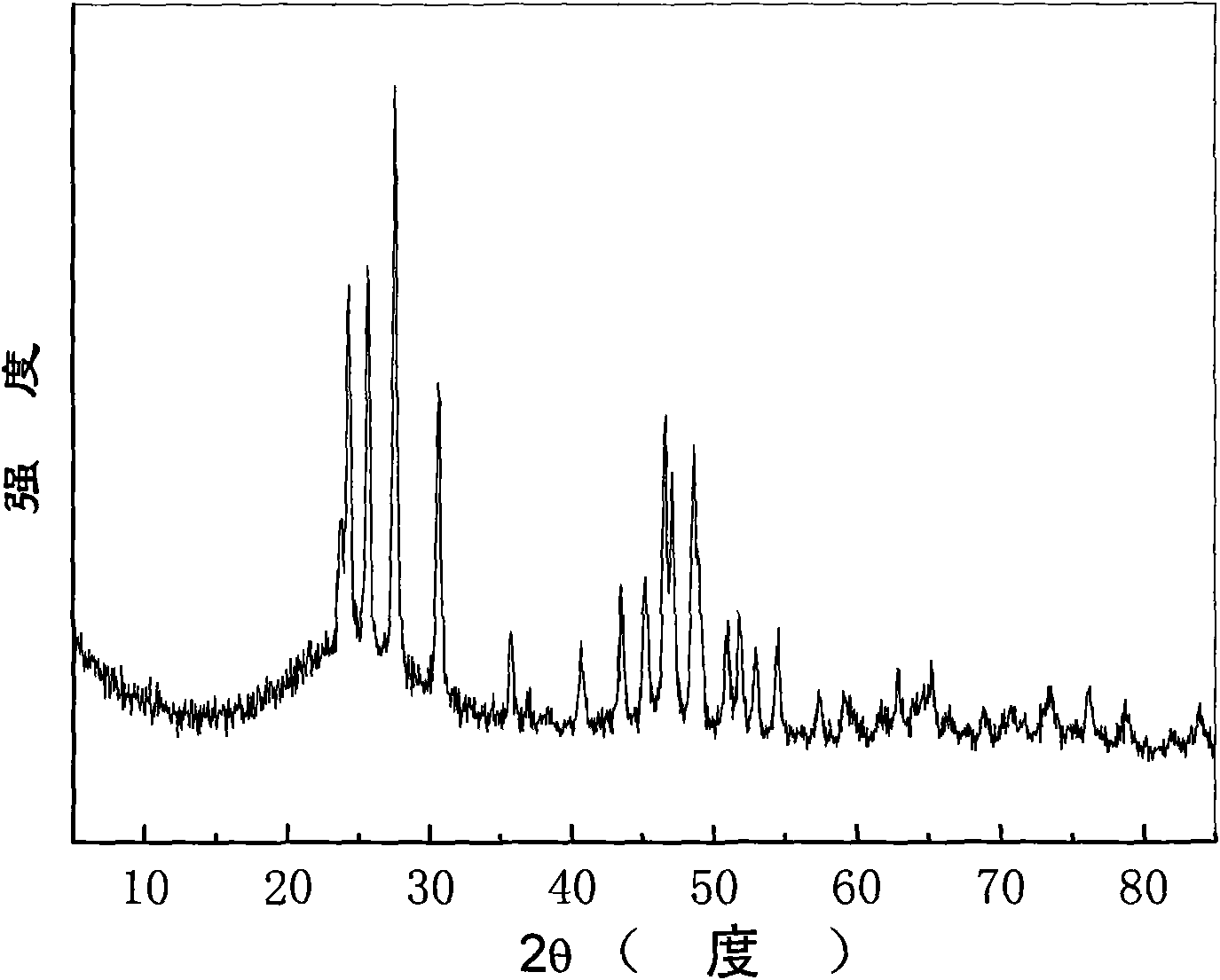

[0022] Example 1: Analytical pure SiO 2 , Al 2 O 3 , NaF, YF 3 and PrF with a purity of 99.99% 3 , YbF 3 Powder, according to 0.1PrF 3 : 0.5YbF 3 : 52SiO 2 : 25Al 2 O 3 : 12.4NaF: 10YF 3 (molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a platinum crucible, heated to 1500 ℃ in a program-controlled high temperature box-type resistance furnace, and kept for 6 hours Then, pour the glass melt into the copper mold quickly to form; put the obtained precursor glass into a resistance furnace, anneal at 600 °C for 2 hours, and then cool with the furnace to eliminate internal stress. According to the results of differential thermal analysis (such as figure 1 ), the annealed glass was kept at 650 °C for 5 hours to obtain a light green transparent glass-ceramic; X-ray diffraction results showed that YF with an orthogonal structure was precipitated in the glass matrix 3 crystal phase (suc...

example 2

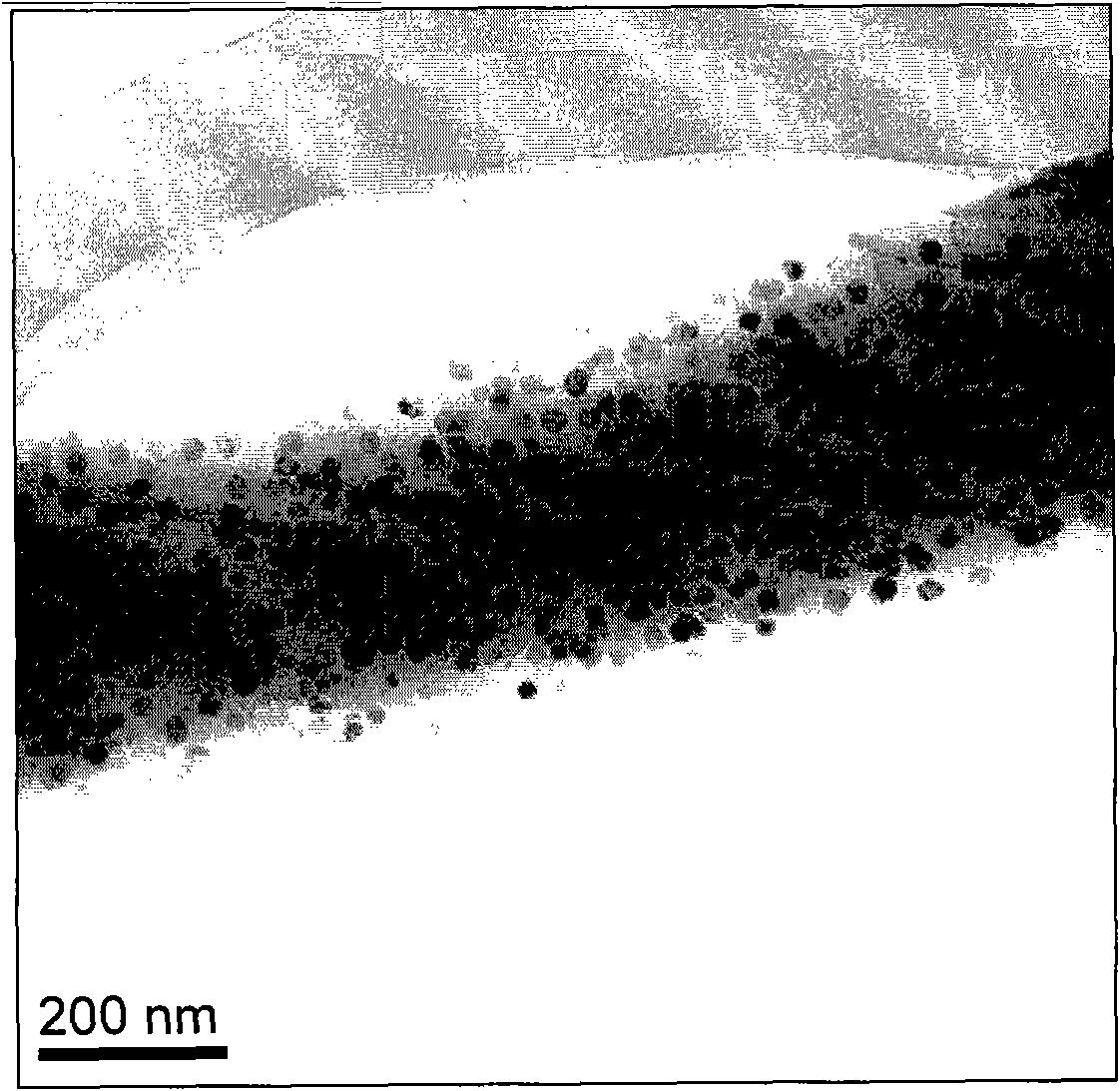

[0025] Example 2: Analytical pure SiO 2 , Al 2 O 3 , LiF, YF 3 and YbF with a purity of 99.99% 3 and PrF 3 Powder, according to 0.1PrF 3 : 1.0YbF 3 : 55SiO 2 : 25Al 2 O 3 : 3.9LiF: 15YF 3 (molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a platinum crucible, heated to 1400°C in a program-controlled high-temperature box-type resistance furnace, and kept for 2 hours Then, pour the glass melt into the copper mold quickly to form; put the obtained precursor glass into a resistance furnace, anneal at 500 °C for 2 hours and then cool with the furnace to eliminate internal stress; keep the annealed glass at 600 °C In 2 hours, a pale green transparent glass ceramic was obtained. X-ray diffraction results show that YF with orthorhombic structure is precipitated in the glass matrix 3 Crystallographic phase; transmission electron microscopy observations show that a large amount of YF wi...

example 3

[0026] Example 3: Analytical pure SiO 2 , Al 2 O 3 , NaF, YF 3 and YbF with a purity of 99.99% 3 and TbF 3 Powder, according to 0.5TbF 3 : 2YbF 3 : 50SiO 2 : 25Al 2 O 3 : 10.5NaF: 12YF 3 (molar ratio) is accurately weighed, and after the same preparation and heat treatment process as in Example 1, a colorless and transparent glass-ceramic is obtained. The results of X-ray diffraction, transmission electron microscopy and energy dispersive spectroscopy showed that YF was precipitated in the glass ceramics. 3 crystal phase, and rare earth ions Tb and Yb are aggregated in the crystal phase. The surface of the sample was polished, and the emission spectrum at room temperature was measured with a FLS920 fluorescence spectrometer under the excitation condition of 487nm laser, and it was observed that the emission spectrum corresponds to Yb 3+ : 2 F 5 / 2 → 2 F 7 / 2 The quantum-tailored near-infrared light emission band of the transition (centered at 976 nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com