Application of single rare earth infrared first-order quantum cutting in solar cell

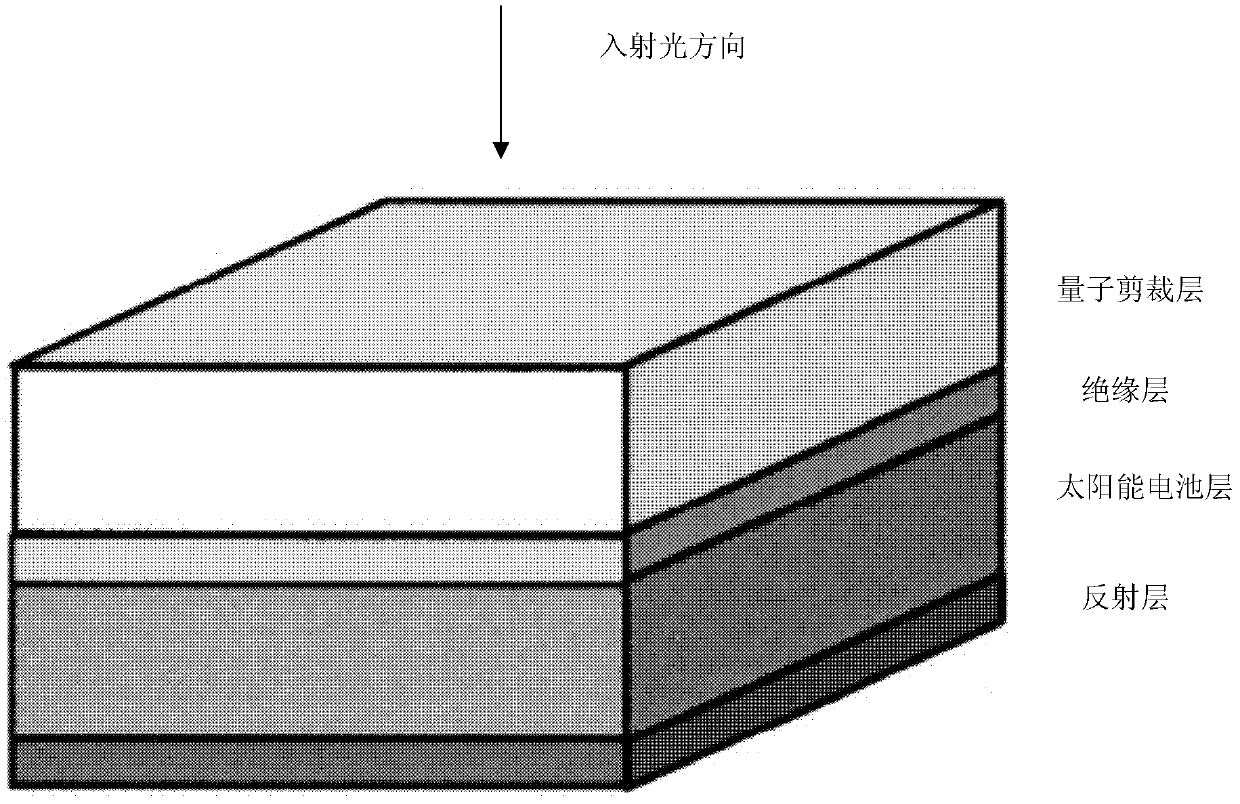

A solar cell and quantum tailoring technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high cost and low efficiency of solar energy, and achieve the effect of high quantum tailoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Er 0.3 Gd 0.7 VO 4 Infrared Quantum Tailoring Effect of Crystal Materials

[0029] First, prepare a high concentration of Er 0.3 Gd 0.7 VO 4 crystal material. With a purity of 99.99% V 2 o 5 , Gd 2 o 3 and Nd 2 o 3 Chemical reagents are used as starting materials. Weigh according to the stoichiometric ratio, mix evenly, and burn at 850°C for 7 hours to obtain Nd:GdVO 4 polycrystalline material.

[0030] Nd:GdVO4 crystal growth adopts medium frequency induction heating method, the growth vessel is iridium crucible, filled with N 2 As a protective atmosphere (adding an appropriate amount of O 2 ), the crystal growth direction is a or c, and the process parameters of crystal growth are related to the diameter of the crystal and the crucible. Usually, the pulling speed is 1-2mm / h when the crystal grows with equal diameter.

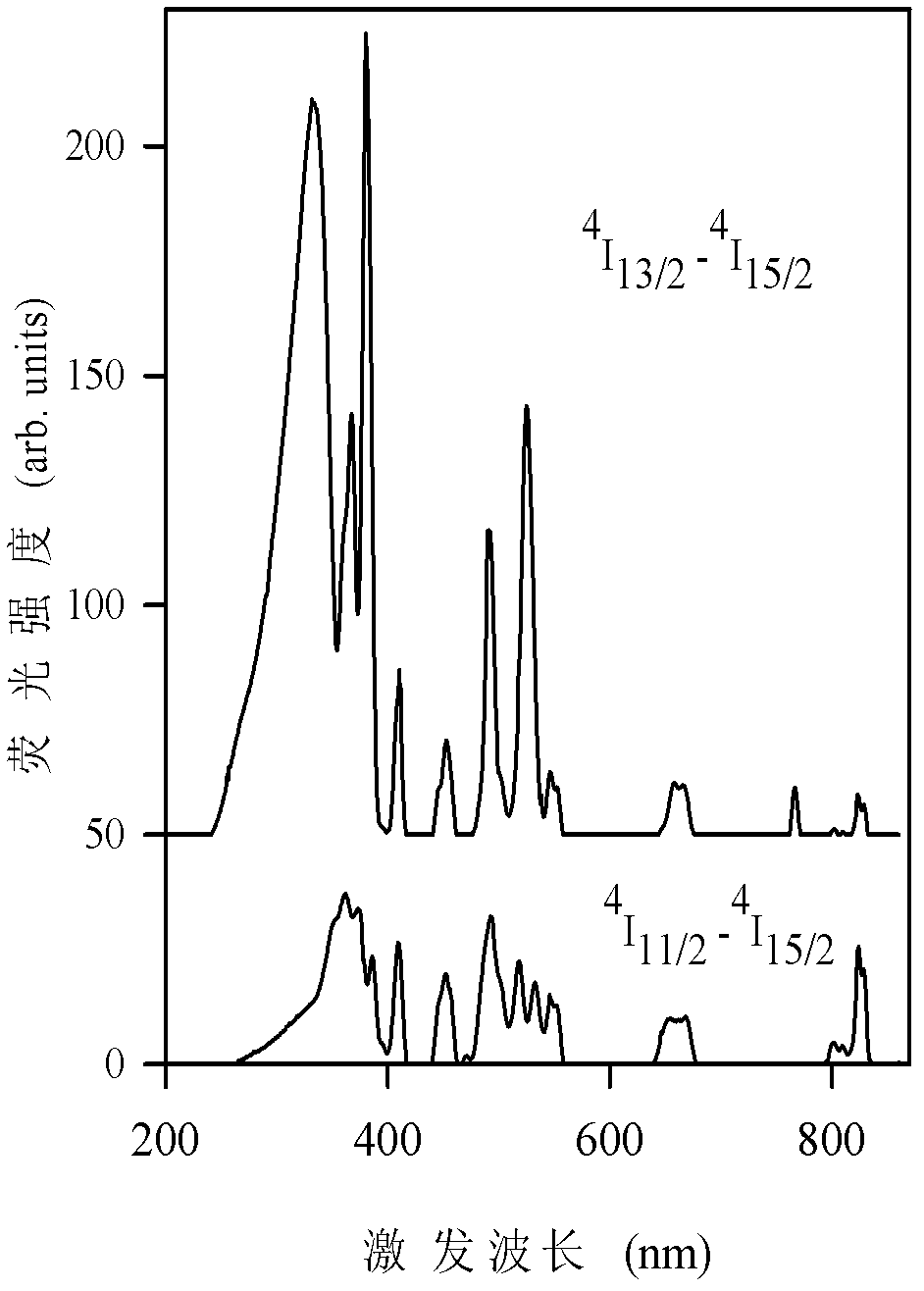

[0031] Measure Er 0.3 Gd 0.7 VO 4Excitation and fluorescence spectra of crystalline materials. figure 2 Shows Er 0.3 Gd...

Embodiment 2

[0042] Embodiment 2.Er 0.1 Gd 0.9 VO 4 Infrared Quantum Tailoring Effect of Crystal Materials

[0043] Similar to Example 1, Er was prepared and measured 0.1 Gd 0.9 VO 4 The emission spectrum and excitation spectrum of the material, and its peak position and Er 0.3 Gd 0.7 VO 4 The crystalline materials are roughly the same, but their spectral peak intensities vary considerably.

[0044] First, the measured Er 0.1 Gd 0.9 VO 4 The excitation spectrum of the material, 4 I 13 / 2 → 4 I 15 / 2 The excitation spectrum of the fluorescence transition has several excitation peaks at 368.0, 382.0, 408.7, 453.8, 490.7, 525.0, (546.7, 552.8), 655.8, and 805.0 nm, corresponding to 4 G 9 / 2 , 4 G 11 / 2 , ( 2 G, 4 F, 2 h) 9 / 2 , 4 f 5 / 2 , 4 f 7 / 2 , 2 h 11 / 2 , 4 S 3 / 2 , 4 f 9 / 2 ,and 4 I 9 / 2 Energy level absorption. measurement discovery 4 I 11 / 2 → 4 I 15 / 2 , 4 S 3 / 2 → 4 I 15 / 2 , 4 f 9 / 2 → 4 I 15 / 2 ,and 4 I 9 / 2 → 4 I 15 / 2 The wavelength position of t...

Embodiment 3

[0048] Embodiment 3. Infrared quantum tailoring effect of nanophase oxyfluoride glass ceramics [Er(3):FOV] doped with erbium

[0049] Made of silicon oxide (SiO 2 ), zinc fluoride (ZnF 2 ), lead fluoride (PbF 2 ), lutetium fluoride (LuF 3 ) and Erbium Fluoride (ErF 3 ) to prepare Er(3):FOV:SiO with the following composition 2 (45%), ZnF 2 (17.1%), PbF 2 (30%), LuF 3 (4.9%) and ErF 3 (3%).

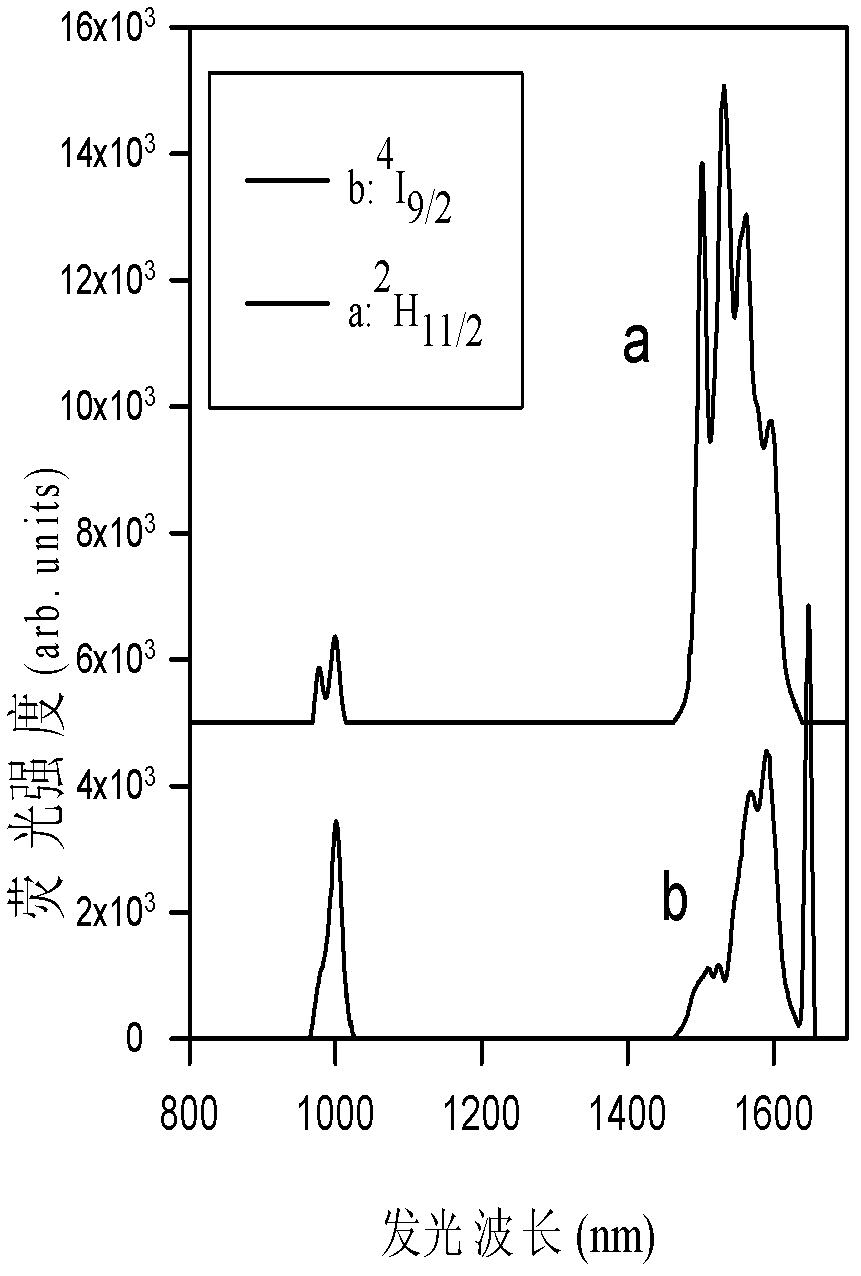

[0050] Measurement of Er(3): Er in FOV 3+ The energy level structure of , see the results Figure 5 . From Figure 5 Visible, for 802.5nm light excitation 4 I 9 / 2 When the energy level (PE 03 ), 4 I 9 / 2 The number of particles in the energy level can be determined by spontaneous emission, non-radiative multiphonon relaxation and { 4 I 9 / 2 → 4 I 13 / 2 , 4 I 15 / 2 → 4 I 13 / 2}ET r31 -ET a01 Cross energy transfer channel transfers the particle population to the first excited state 4 I 13 / 2 energy level. From calculations of the rates of various processes, 4 I 9 / 2 → ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com