Near-infrared quantum tailoring down-conversion luminescence transparent glass ceramics and preparation method thereof

A technology of transparent glass and quantum tailoring, which is applied in the field of rare earth-doped transparent glass ceramics and its preparation technology, can solve the problems of weak absorption strength and difficulty in efficiently using sunlight, etc., and achieve low cost, good mechanical properties and thermal stability Sexuality and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Example 1: Analytical pure SiO 2 、Al 2 o 3 , CaCO 3 , NaF, CaF 2 and EuF with a purity of 99.99% 3 , YbF 3 Powder, according to 45SiO 2 -25Al 2 o 3 -5CaCO 3 -10NaF -12.5CaF 2 -0.5EuF 3 -2YbF 3 After weighing the proportion accurately, put it in an agate mortar, grind it for more than half an hour to make it evenly mixed, then put it in a platinum crucible, heat it to 1350°C in a program-controlled high-temperature box-type resistance furnace, and keep it warm for 2 hours to melt it. Then, the melt was taken out and quickly poured into a copper mold for cooling and forming to obtain a precursor glass; the precursor glass was placed in a resistance furnace, annealed at 430°C for 2 hours and then cooled with the furnace to eliminate internal stress. The annealed glass was kept at 590°C for 6 hours to partially crystallize it to obtain transparent glass ceramics.

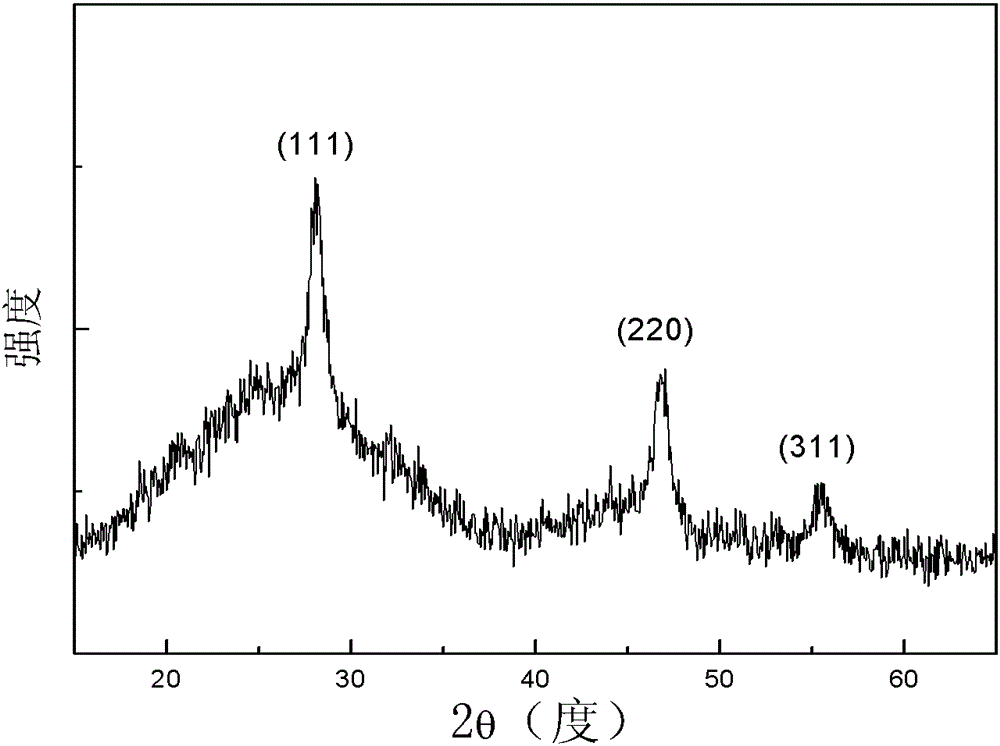

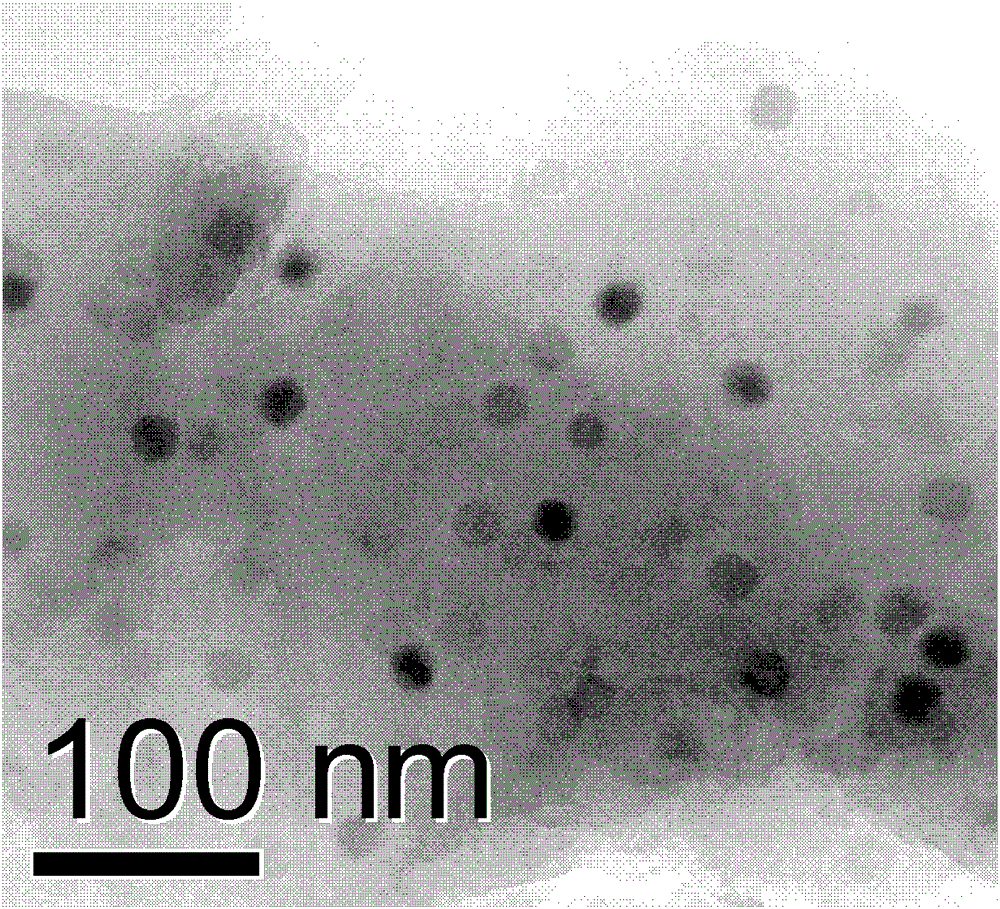

[0020] Powder X-ray diffraction pattern ( figure 1 ) analysis shows that the crystal phase preci...

example 2

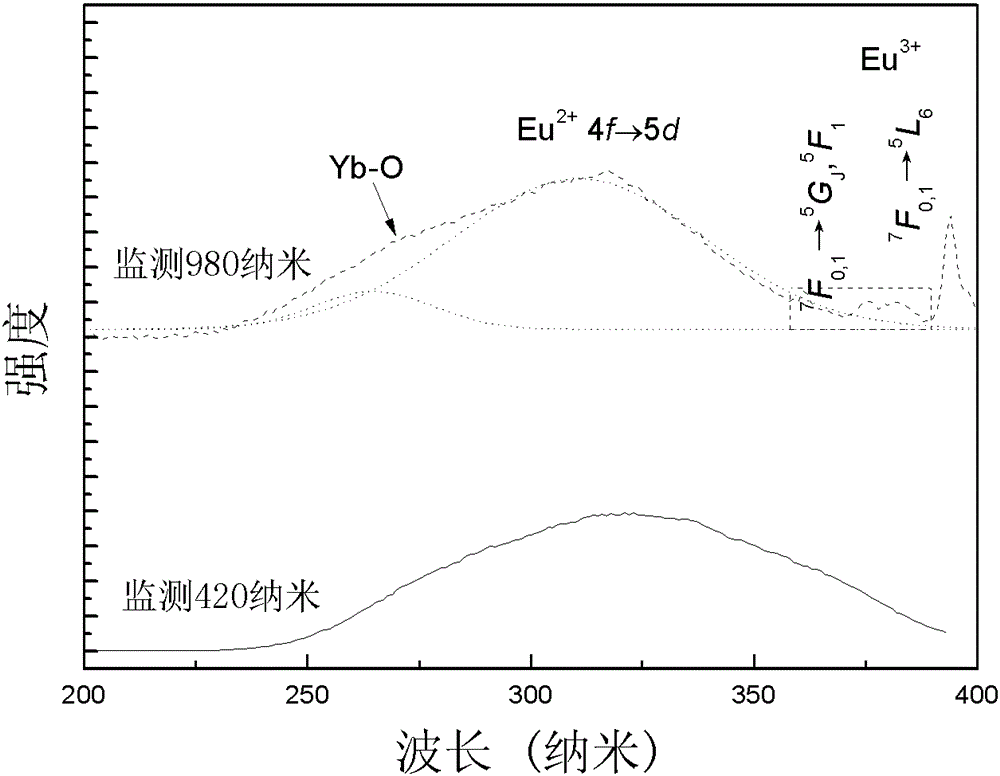

[0021] Example 2: Analytical pure SiO 2 、Al 2 o 3 , CaCO 3 , NaF, CaF 2 and EuF with a purity of 99.99% 3 , YbF 3 Powder, according to 30SiO 2 -35Al 2 o 3 -10CaCO 3-15NaF-8CaF 2 -1EuF 3 -1YbF 3 After weighing the proportion accurately, place it in an agate mortar, grind it for more than half an hour to make it evenly mixed, then place it in a platinum crucible, heat it to 1300°C in a program-controlled high-temperature box-type resistance furnace, and keep it warm for 1 hour to melt it. Then, the melt was taken out and quickly poured into a copper mold for cooling and forming to obtain a precursor glass; the precursor glass was placed in a resistance furnace, annealed at 430°C for 2 hours and then cooled with the furnace to eliminate internal stress. The annealed glass was kept at 590°C for 6 hours to partially crystallize it to obtain transparent glass ceramics. After surface polishing, the sample was measured with FLS920 fluorescence spectrometer at room tempera...

example 3

[0022] Example 3: Analytical pure SiO 2 、Al 2 o 3 , CaCO 3 , NaF, CaF 2 and EuF with a purity of 99.99% 3 , YbF 3 Powder, according to 50SiO 2 -20Al 2 o 3 -10CaCO 3 -5NaF -14.4CaF 2 -0.1EuF 3 -0.5YbF 3 The proportion is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a platinum crucible, heated to 1400°C in a program-controlled high-temperature box-type resistance furnace, and then kept for 3 hours to melt it. Then, the melt was taken out and quickly poured into a copper mold for cooling and forming to obtain a precursor glass; the precursor glass was placed in a resistance furnace, annealed at 430°C for 2 hours and then cooled with the furnace to eliminate internal stress. The annealed glass was kept at 590°C for 6 hours to partially crystallize it to obtain transparent glass ceramics. After surface polishing, the sample was measured with FLS920 fluorescence spectrometer at room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com