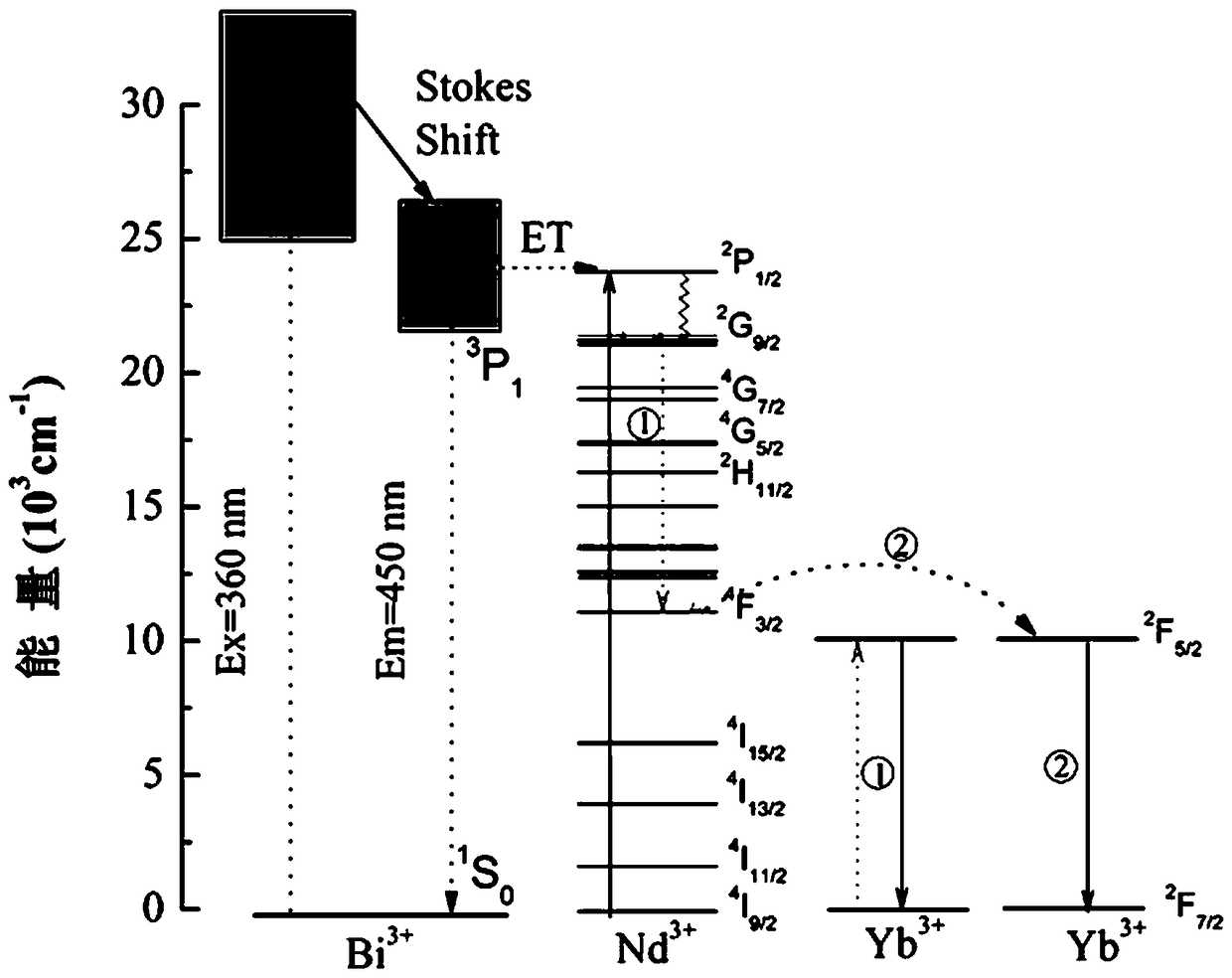

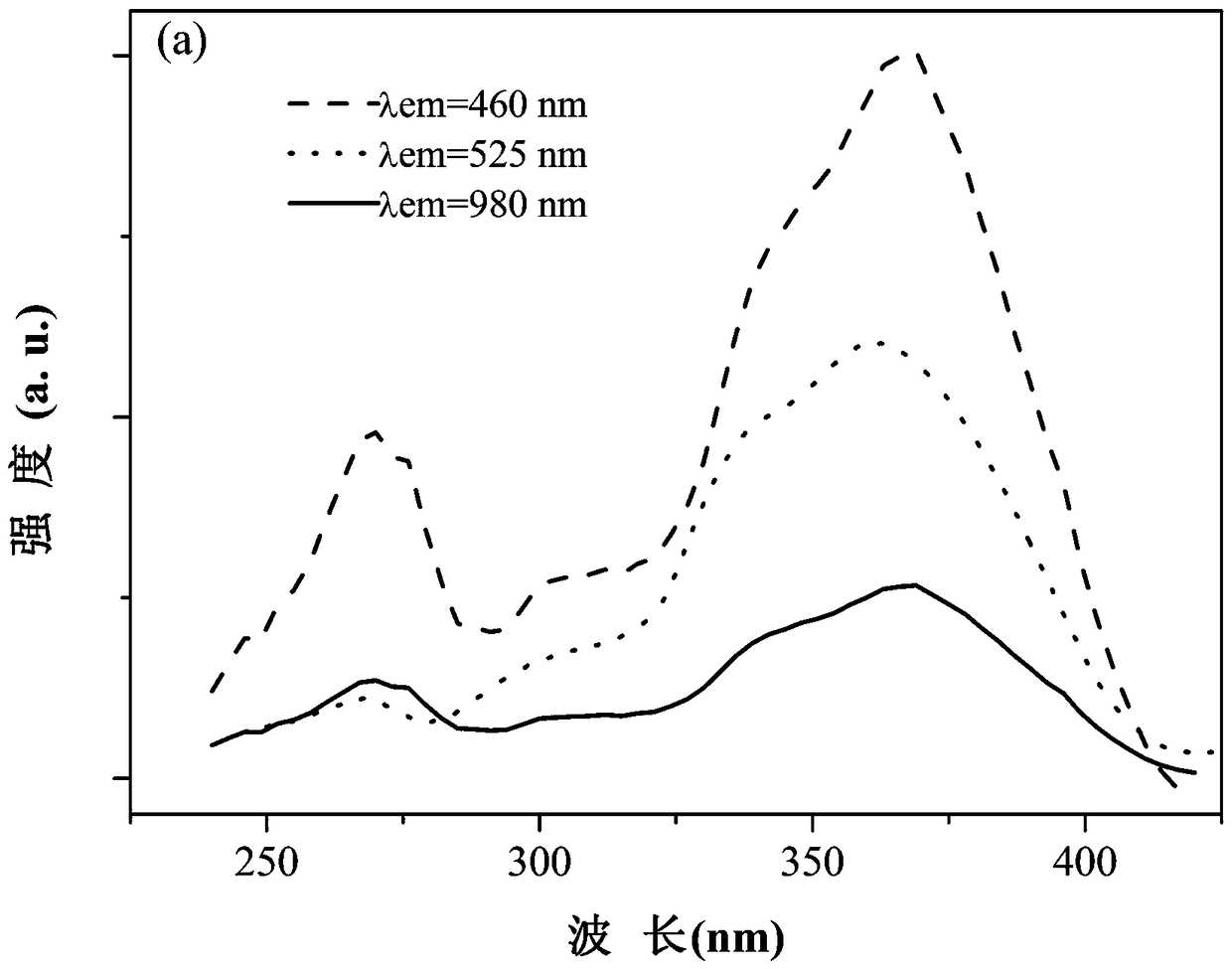

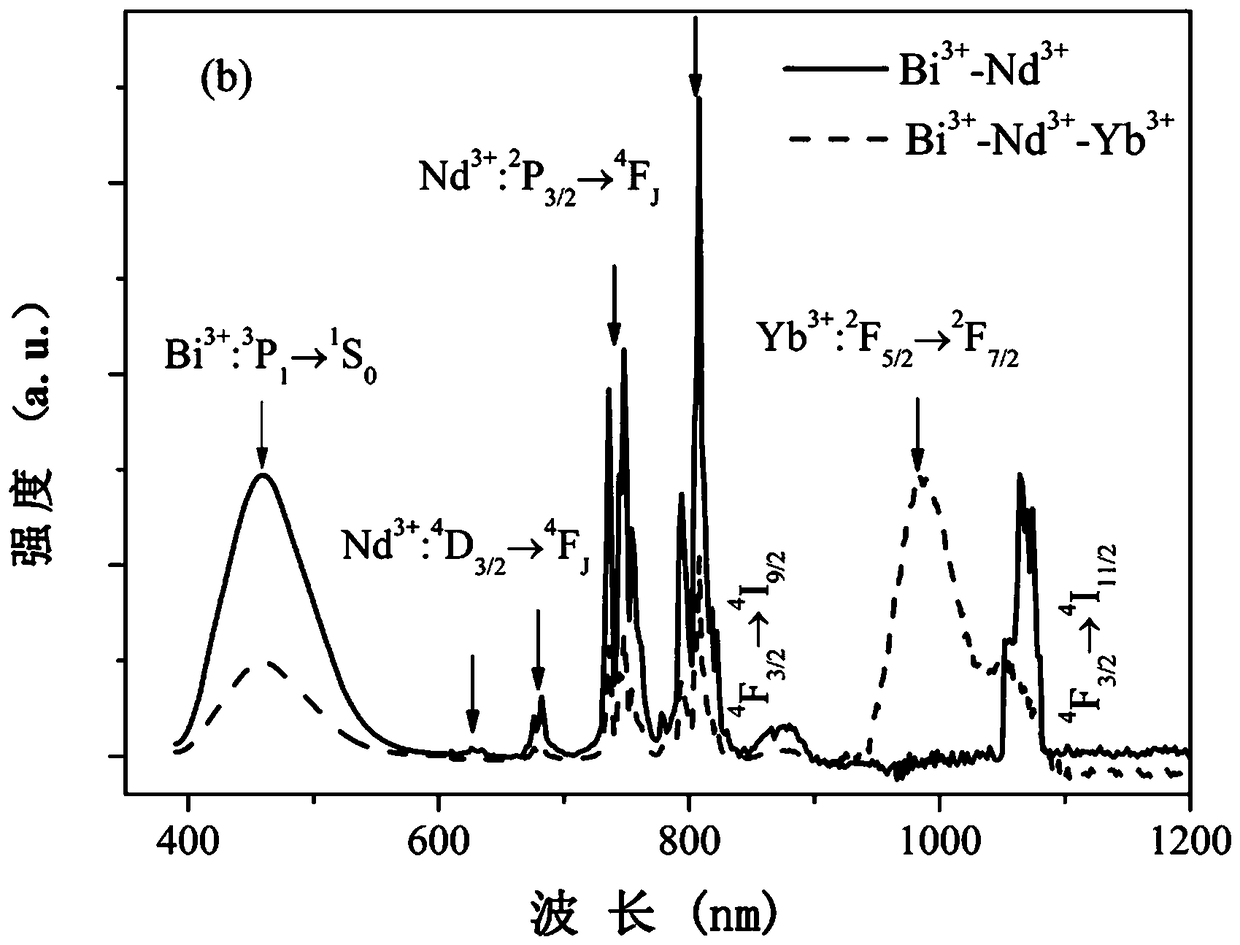

Bi-Nd-Yb co-doped YAG high-efficiency and wide-spectrum quantum cutting luminescent material

A technology of luminescent materials and quantum tailoring, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low utilization rate of solar spectrum, low conversion efficiency of sunlight, and low energy transfer efficiency, so as to improve photoelectric conversion efficiency, The effect of widening the absorption cross section and enhancing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the high-efficiency broad-spectrum quantum tailoring luminescent material of the Bi-Nd-Yb co-doped YAG comprises the following steps:

[0025] Step 1, weigh Y according to the molar percentage distribution ratio in the general formula 2 o 3 (A.R.), Al 2 o 3 (A.R.), Bi 2 o 3 (99.9%), Nd 2 o 3 (99.9%), Yb 2 o 3(99.9%), after that, put the weighed drug in an agate mortar and grind it for 1 to 3 hours to mix it evenly, and then put it in a corundum crucible to be sintered;

[0026] Step 2. Put the corundum crucible containing the sample into the tube furnace, evacuate for 1 to 3 times to reduce the pressure in the furnace chamber to below 0.01MPa, and inject argon gas until it is stable, so that the medicine is in the argon gas environment;

[0027] Step 3: Turn on the tube furnace and evenly raise the temperature to 100°C at a rate of 1°C to 5°C per minute and keep it warm for half an hour to remove the remaining moisture in the sample, t...

Embodiment 1

[0035] A kind of Bi-Nd-Yb co-doped YAG powder luminescent material, its composition general formula is Y 3 al 5 o 12 : 0.5mol% Bi 3+ , 0.5mol%Nd 3+ , 5.0mol% Yb 3+ .

[0036] Concrete preparation steps are as follows:

[0037] Step 1, using an electronic balance to accurately weigh yttrium oxide [Y 2 o 3 ] 5.5307g, alumina [Al 2 o 3 ] 4.2559g, bismuth oxide [Bi 2 o 3 ] 0.0388g, neodymium oxide [Nd 2 o 3 ] 0.0281 g, ytterbium oxide [Y 2 o 3 ] 0.3288 g, placed in an agate mortar and ground for 1.5 hours and mixed evenly, then the crude drug powder obtained by grinding was transferred to a corundum crucible for subsequent use; after the mixed drug was ground, the average particle diameter of the mixed drug powder was detected 2 μm; then put it into a 50 mL corundum crucible to be sintered;

[0038] Step 2. Put the corundum crucible containing the raw material powder in step 1 into the tube furnace, and evacuate to a pressure of 0.01MPa in the furnace. After that, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com