Fluoroaluminate near-infrared quantum cutting material, and preparation method and application thereof

A technology of quantum tailoring and fluoroaluminate, applied in luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve problems such as damage to human health and pollution of the environment, and achieve the effect of easy operation and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

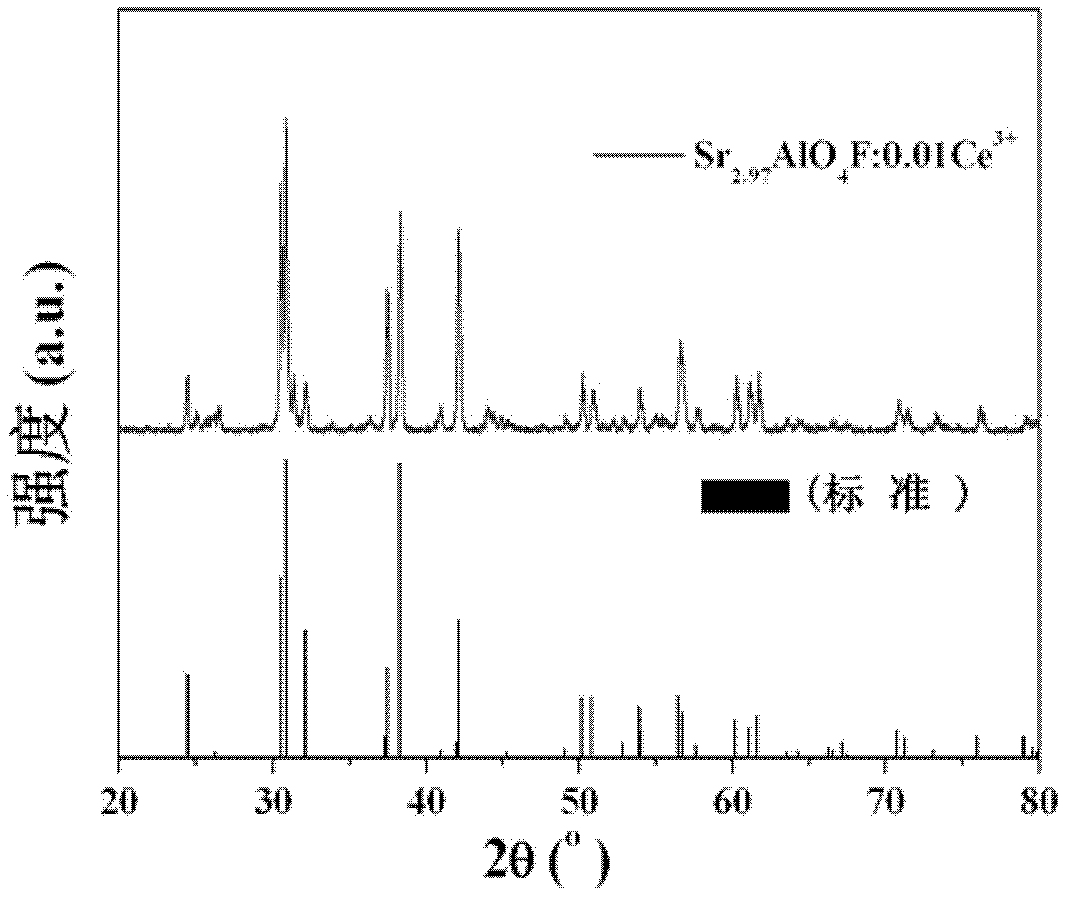

[0033] Example 1: Fluoroaluminate near-infrared quantum tailoring material Sr 2.97 AlO 4 F:0.01Ce 3+ preparation of

[0034] Strontium carbonate (SrCO 3 )0.7324g, strontium fluoride (SrF 2 ) 0.1256g, alumina (Al 2 o 3 )0.1019g, cerium oxide (CeO 2 ) 0.0034g. Grind and mix the above raw materials in an agate mortar, put them into a corundum crucible, put them into a high-temperature furnace, and raise the temperature to 1200°C at 600°C / h under a reducing atmosphere of CO, keep the temperature at 1200°C for 4 hours, cool, and take out The bulk material is ground to obtain a powder sample. The XRD diffraction pattern of this sample is shown in figure 1 , by combining with SrAlO 4 Compared with the standard card of F, it is found that the positions of the diffraction peaks are exactly the same, indicating that a small amount of Ce is doped 3+ Has no effect on the lattice structure of the matrix. The sample is excited at 401nm, and the room temperature excitation and em...

Embodiment 2

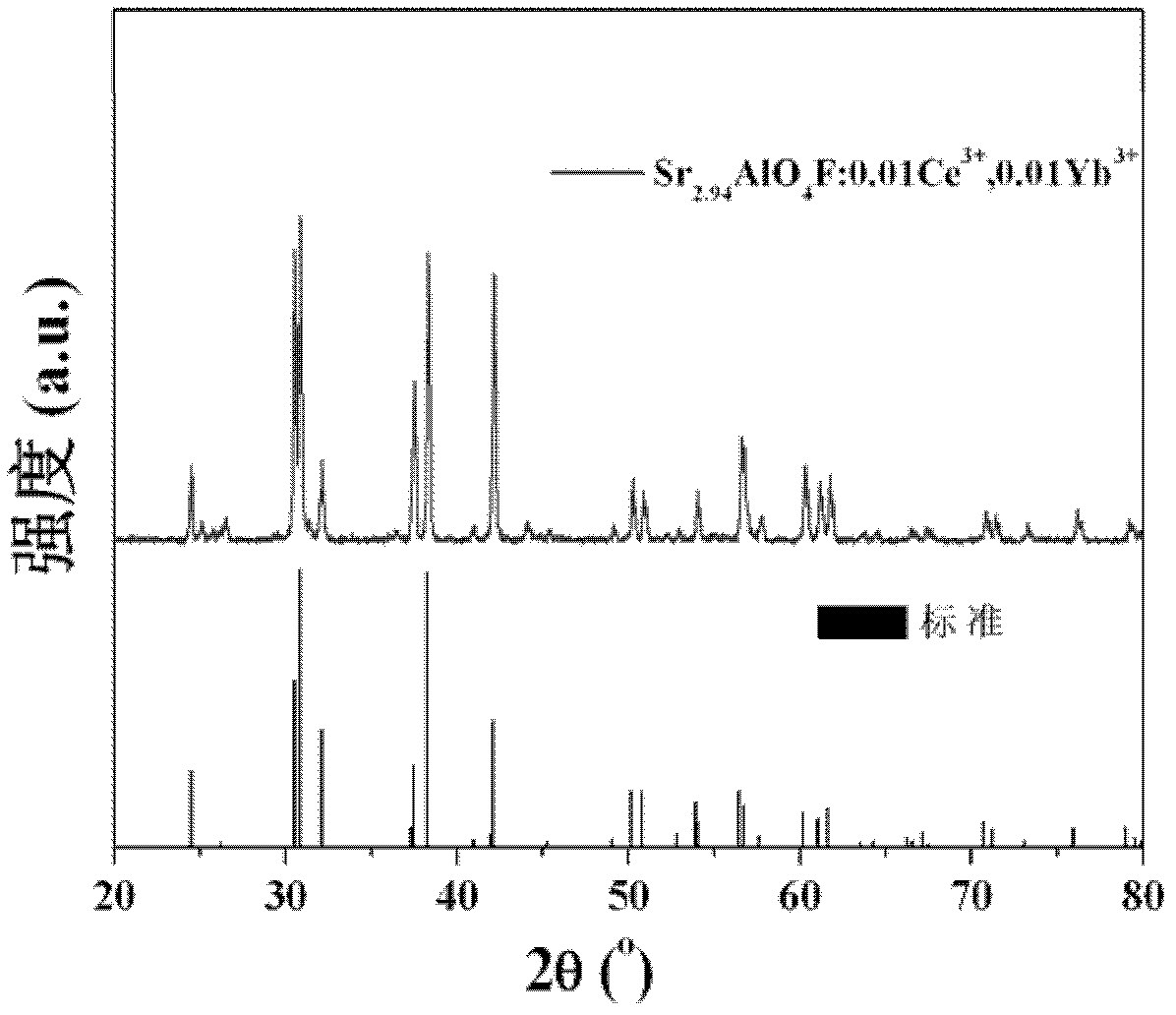

[0035] Example 2: Fluoroaluminate near-infrared quantum tailoring material Sr 2.94 AlO 4 F:0.01Ce 3+ , 0.01Yb 3+ preparation of

[0036] Strontium carbonate (SrCO 3 )0.7279g, strontium fluoride (SrF 2 ) 0.1256g, alumina (Al 2 o 3 )0.1019g, cerium oxide (CeO 2 )0.0034g and ytterbium oxide (Yb 2 o 3 ) 0.0039g. Grind and mix the above-mentioned raw materials in an agate mortar, put them into a corundum crucible, put them into a high-temperature furnace, and raise the temperature to 1200°C at 600°C / h under a reducing atmosphere of CO, keep the temperature at 1200°C for 4 hours, cool, and take out The bulk material is ground to obtain a powder sample. The XRD diffraction pattern of this sample is shown in figure 2 , by combining with SrAlO 4 Compared with the standard card of F, it is found that the positions of the diffraction peaks are exactly the same, indicating that a small amount of Ce is doped 3+ , Yb 3+ Has no effect on the lattice structure of the matrix. ...

Embodiment 3

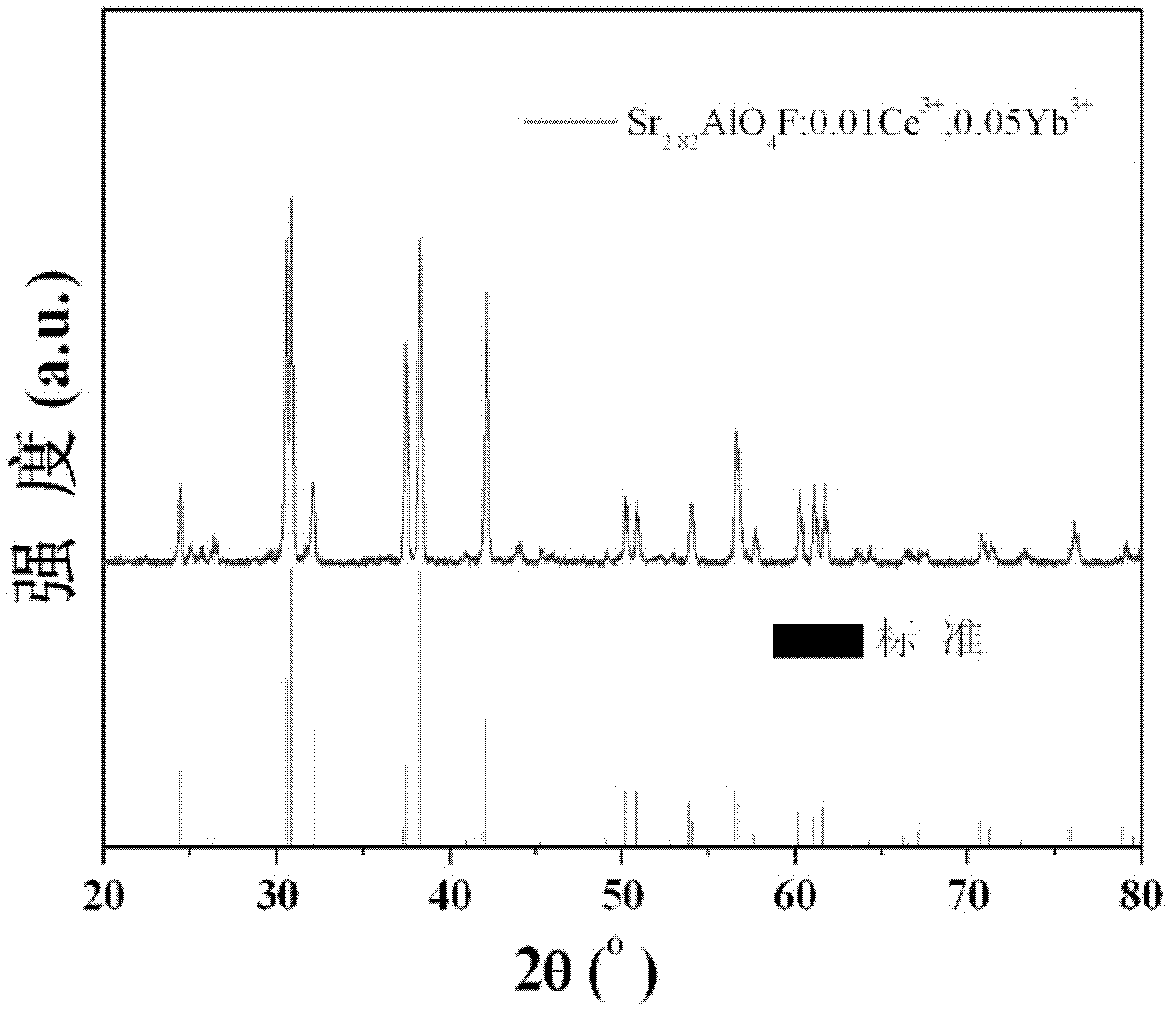

[0037] Example 3: Fluoroaluminate near-infrared quantum tailoring material Sr 2.82 AlO 4 F:0.01Ce 3+ , 0.05Yb 3+

[0038] Strontium carbonate (SrCO 3 )0.7103g, strontium fluoride (SrF 2 ) 0.1256g, alumina (Al 2 o 3 )0.1019g, cerium oxide (CeO 2 )0.0034g and ytterbium oxide (Yb 2 o 3 ) 0.0197g. Grind and mix the above-mentioned raw materials in an agate mortar, put them into a corundum crucible, put them into a high-temperature furnace, and raise the temperature to 1200°C at 600°C / h under a reducing atmosphere of CO, keep the temperature at 1200°C for 4 hours, cool, and take out The bulk material is ground to obtain a powder sample. The XRD diffraction pattern of this sample is shown in image 3 , by combining with SrAlO 4 Compared with the standard card of F, it is found that the positions of the diffraction peaks are exactly the same, indicating that a small amount of Ce is doped 3+ , Yb 3+ Has no effect on the lattice structure of the matrix. The sample is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com