Patents

Literature

37 results about "Strontium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium fluoride, SrF₂, also called strontium difluoride and strontium(II) fluoride, is a fluoride of strontium. It is a stable brittle white crystalline solid with melting point of 1477 °C and boiling point 2460 °C. It appears as the mineral strontiofluorite.

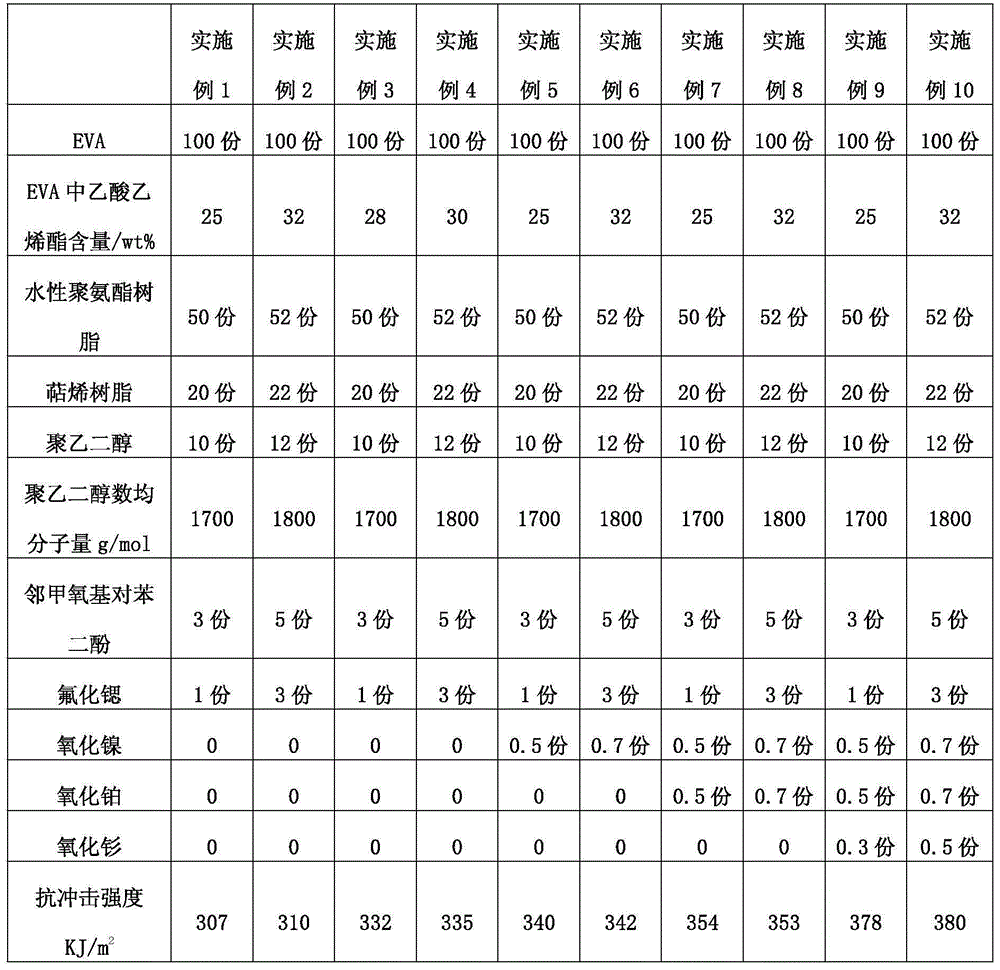

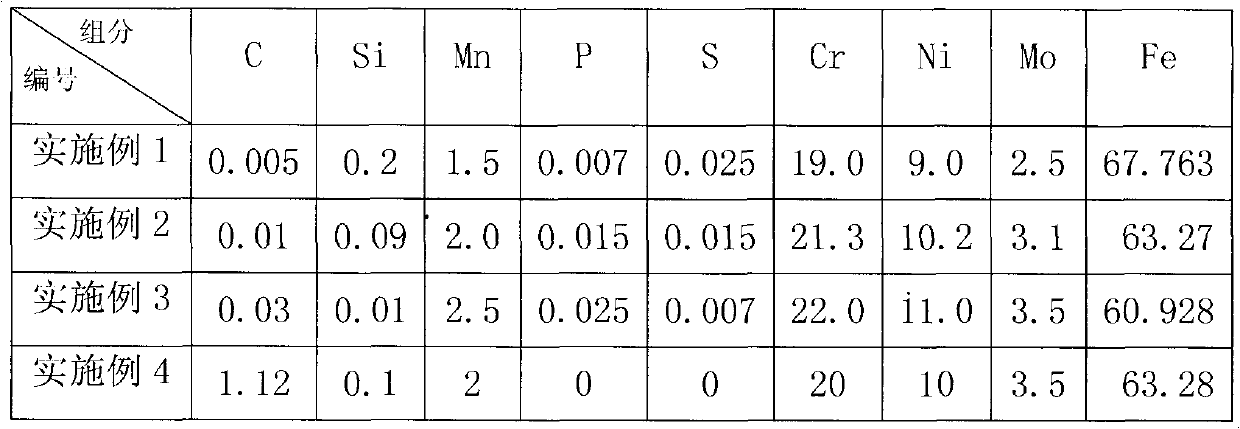

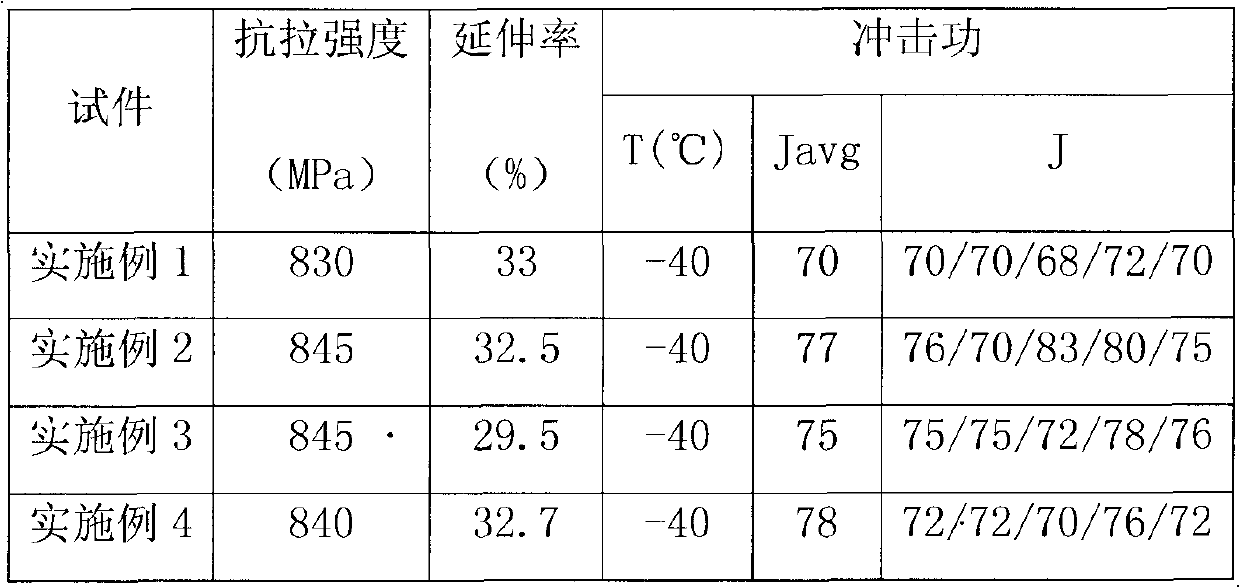

Two-phase stainless steel electrode

ActiveCN102233489AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaSlagWeld seam

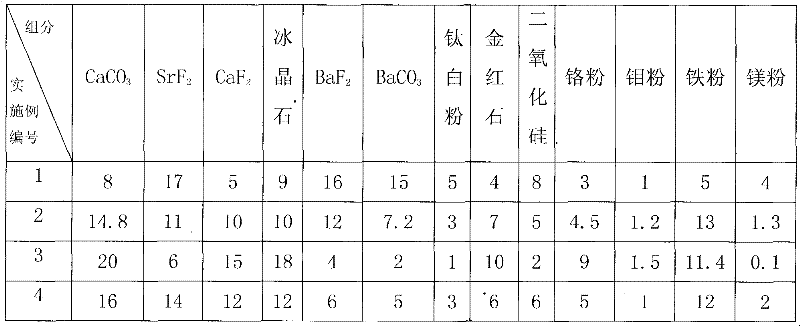

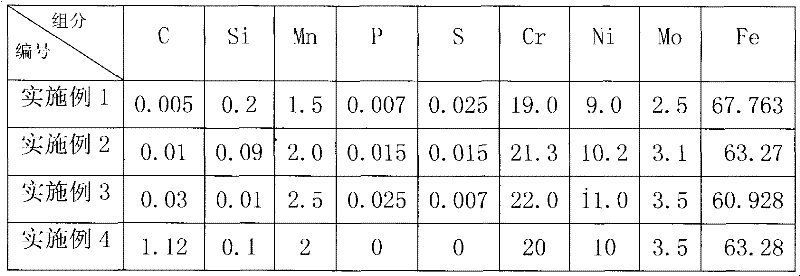

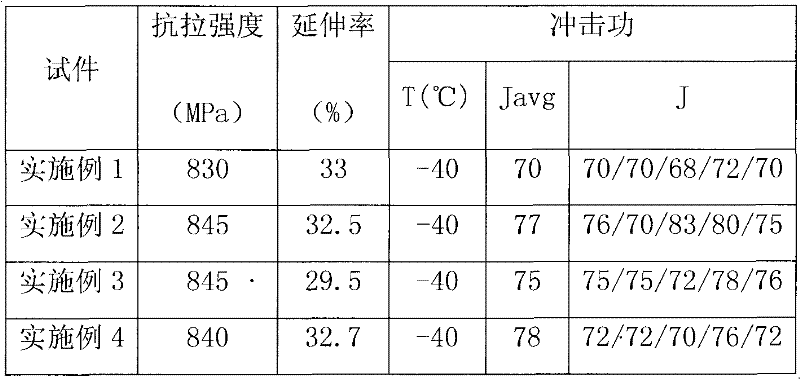

The invention discloses a two-phase stainless steel electrode, which comprises a core wire and a coating, wherein the coating is coated on the outer wall of the core wire and accounts for 0.4 to 0.5 percent of the total weight of the electrode. The core wire comprises the following components in percentage by weight: 0.005 to 0.030 percent of C, 0.01 to 0.20 percent of Si, 1.50 to 2.50 percent ofMn, 0 to 0.025 percent of P, 19.0 to 22.0 percent of Cr, 9.0 to 11.0 percent of Ni, 2.5 to 3.5 percent of Mo and the balance of Fe. The coating comprises the following components in percentage by weight: 8 to 20 percent of calcium carbonate, 2 to 15 percent of barium carbonate, 5 to 15 percent of calcium fluoride, 6 to 17 percent of strontium fluoride, 4 to 16 percent of barium fluoride, 9 to 18 percent of cryolite, 4 to 10 percent of rutile, 1 to 5 percent of titanium white, 2 to 8 percent of silicon dioxide, 3 to 9 percent of chromium powder, 1 to 1.5 percent of molybdenum powder, 0.1 to 4 percent of magnesium powder and 5 to 13 percent of iron powder. After the coating components are uniformly mixed, an adhesion agent is added into the mixture. The two-phase stainless steel electrode has high strength, high tenacity and intercrystalline corrosion resistance; and during welding, an electric arc is stable, splashing phenomena is reduced, a welding seam is well molded, slag is easy toremove, and the electrode has high operability.

Owner:KUSN GINTUNE WELDING

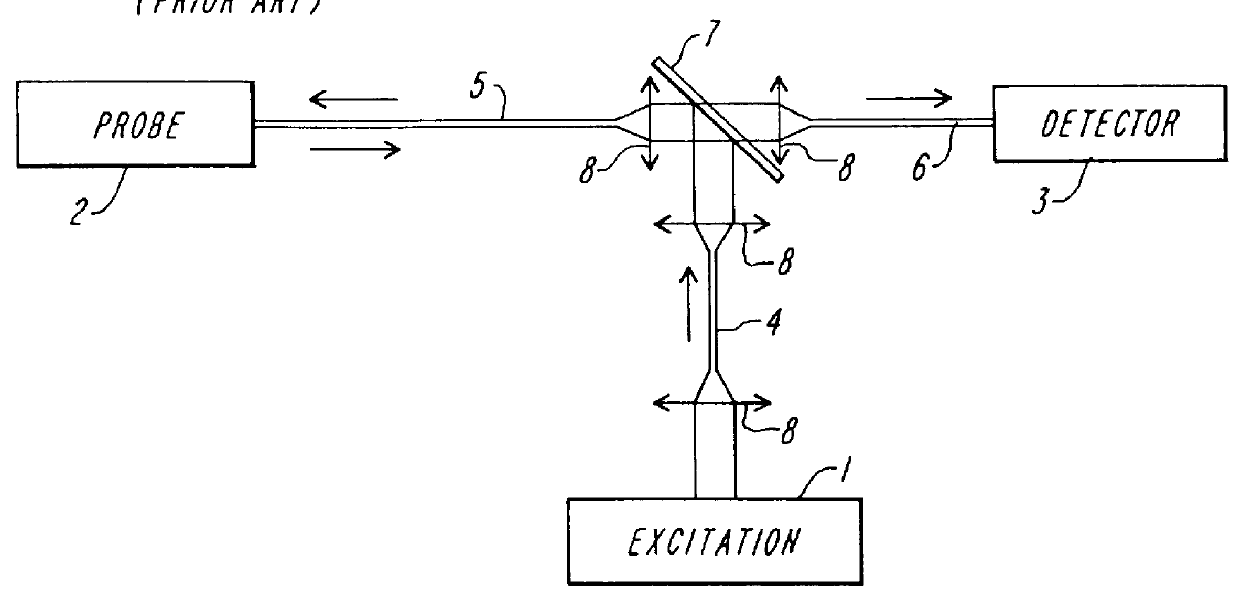

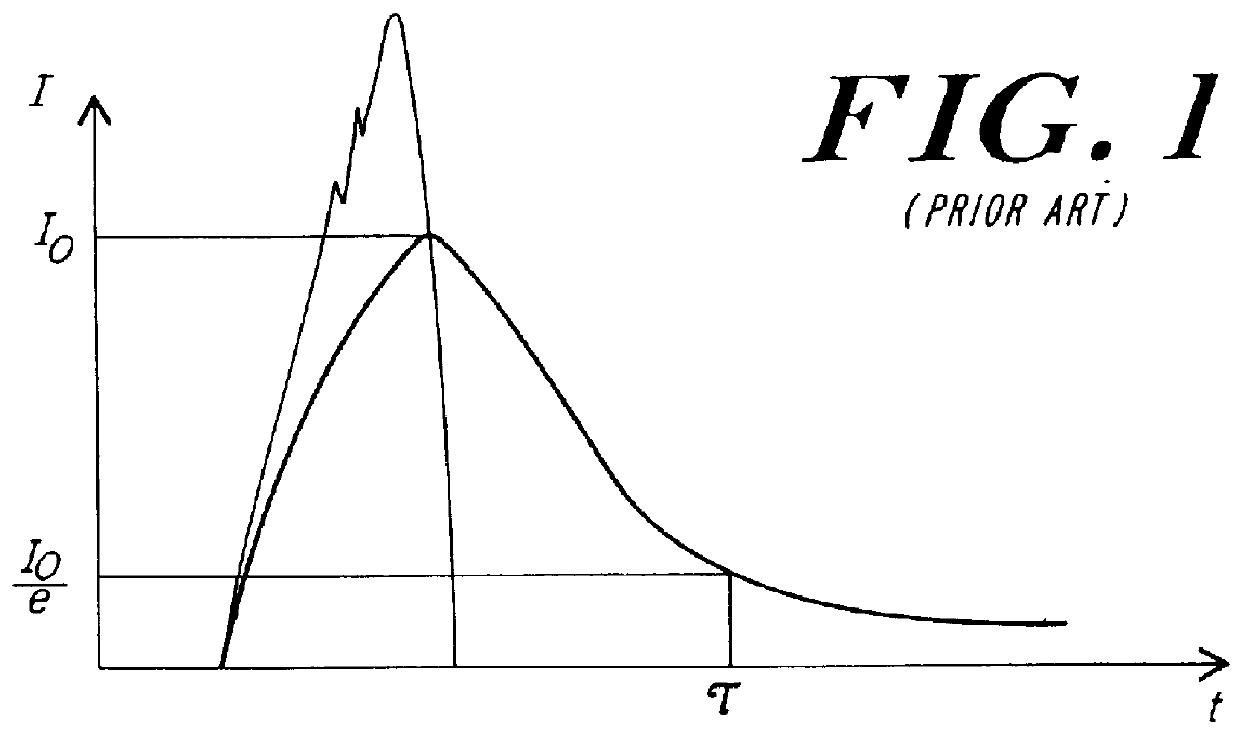

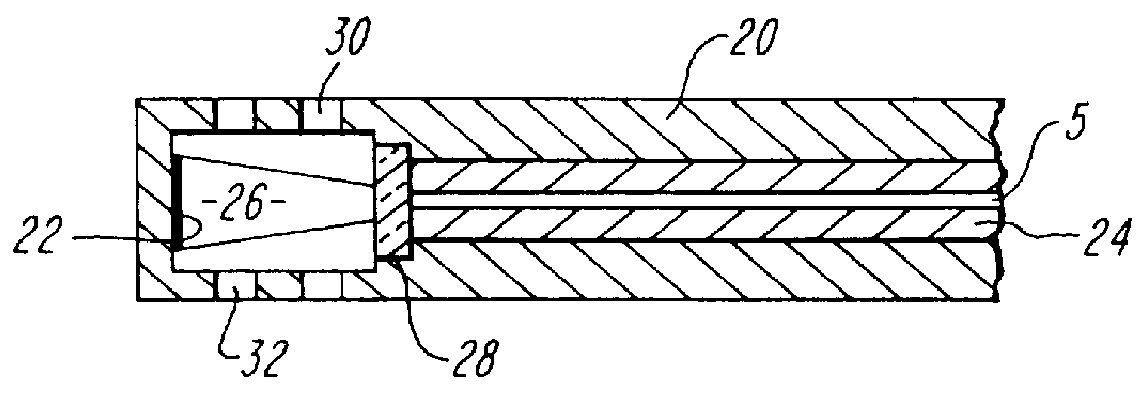

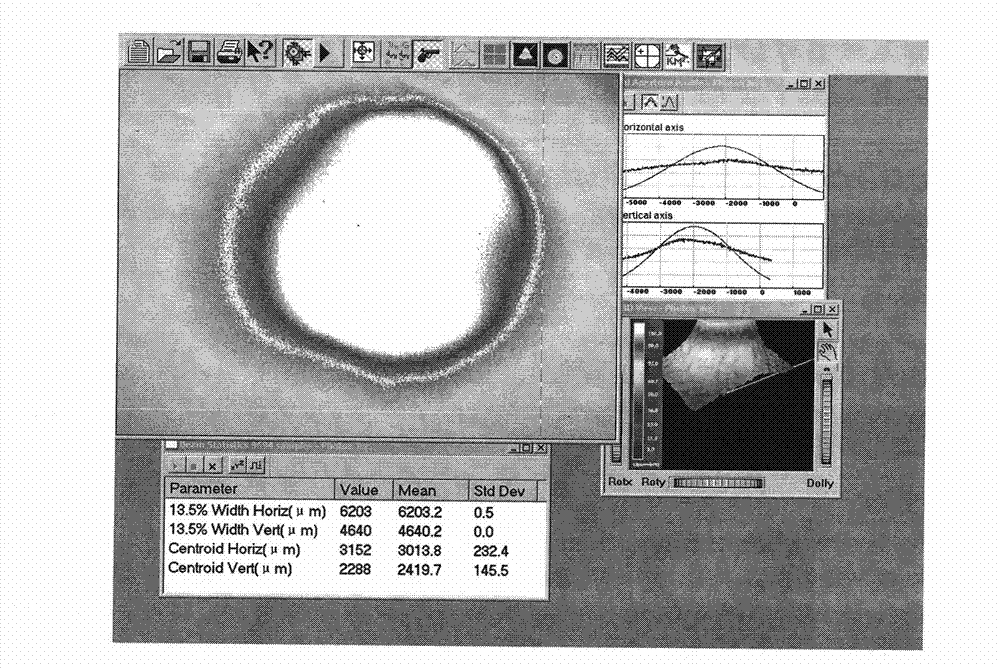

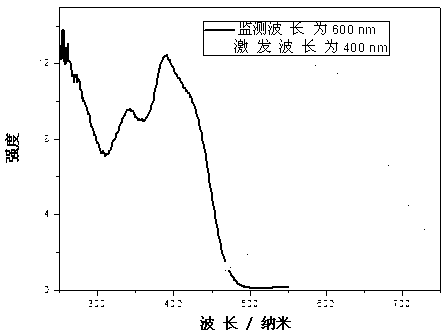

Device for optically measuring a cryogenic temperature

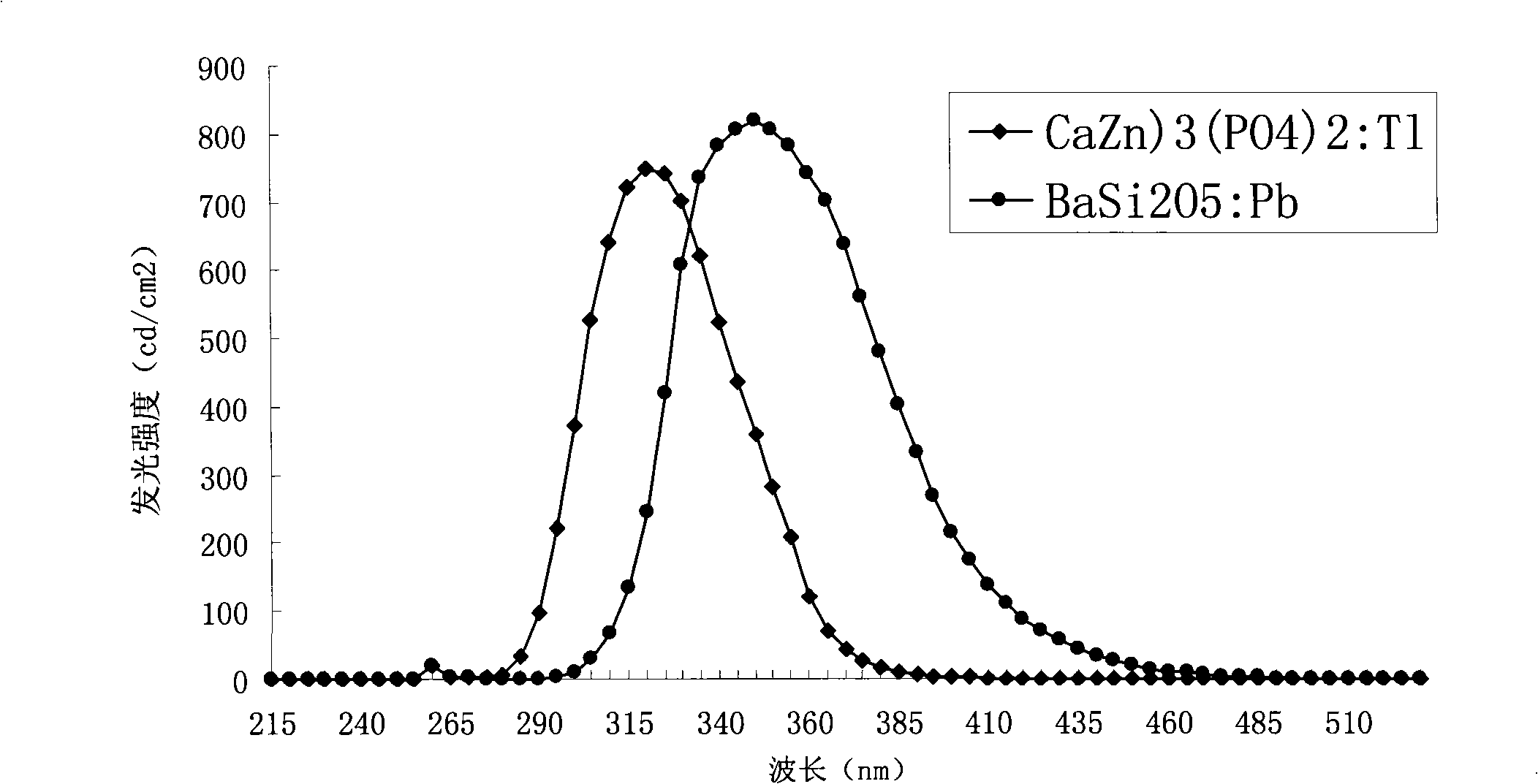

InactiveUS6086250AAccurate measurementQuick implementationPhotometryLuminescent dosimetersFiberLight flux

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

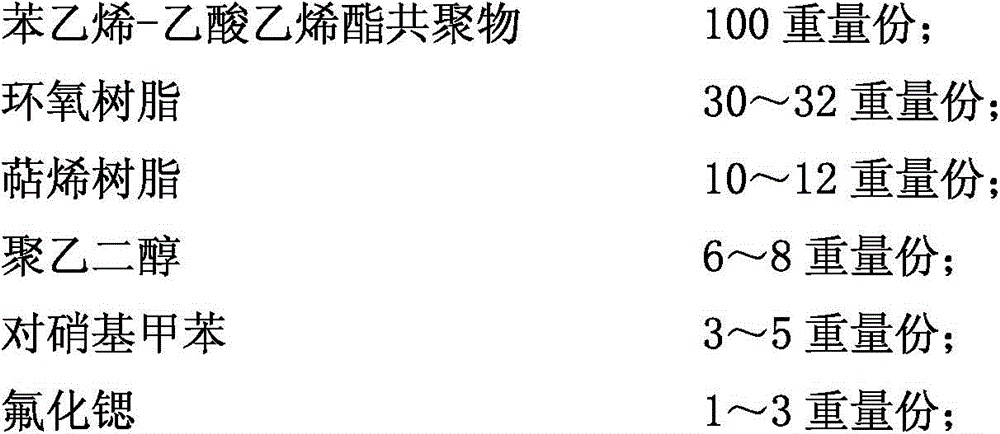

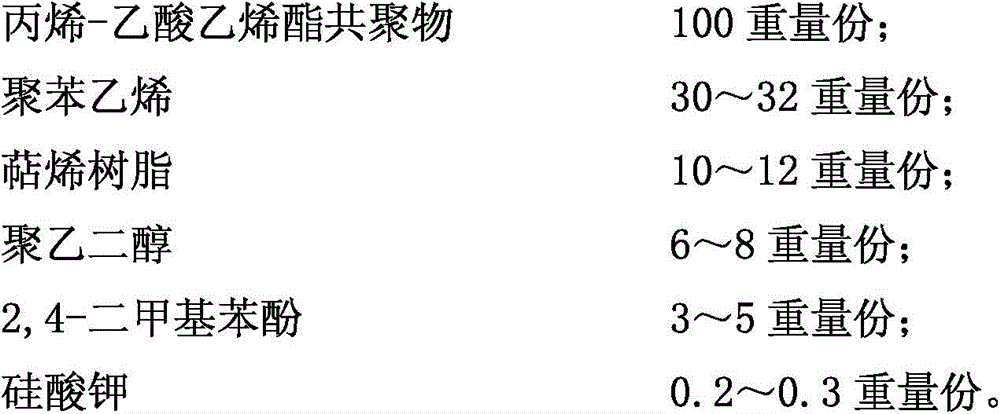

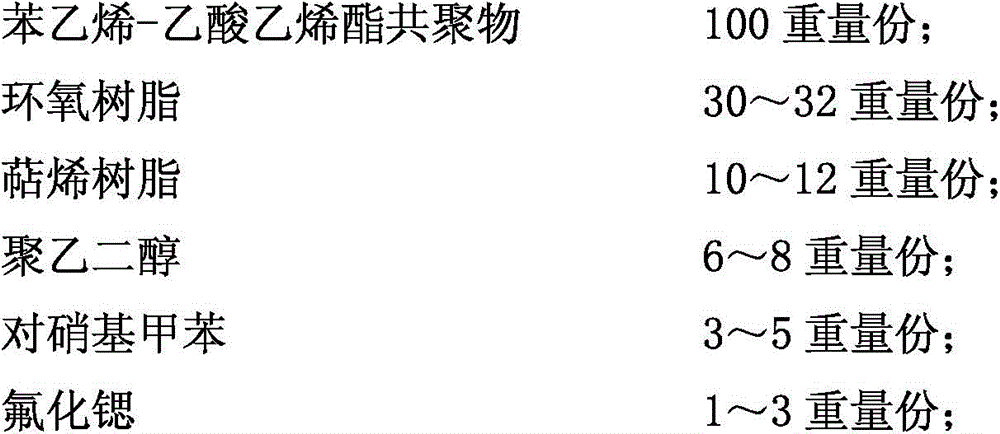

Aramid fiber-ultrahigh molecular weight polyethylene composite sheet material processing method

ActiveCN104960306AImprove anti-agingHigh bonding strengthLamination ancillary operationsNon-macromolecular adhesive additivesEpoxyMetasilicate

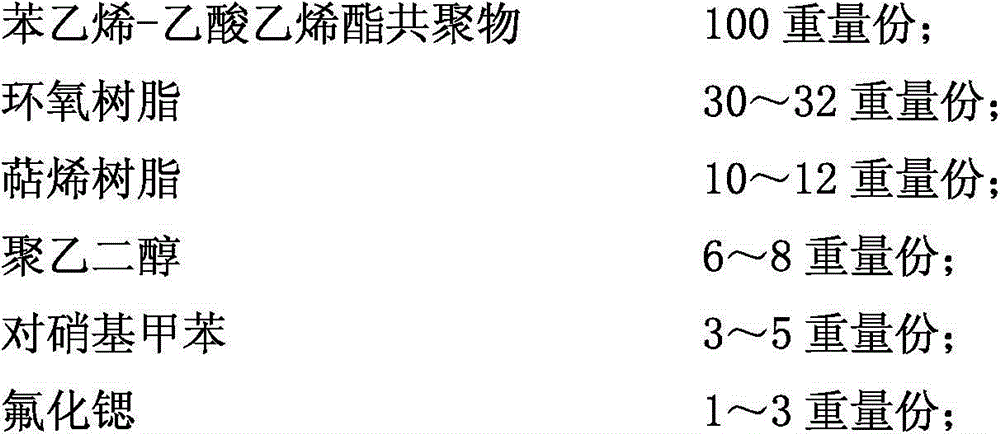

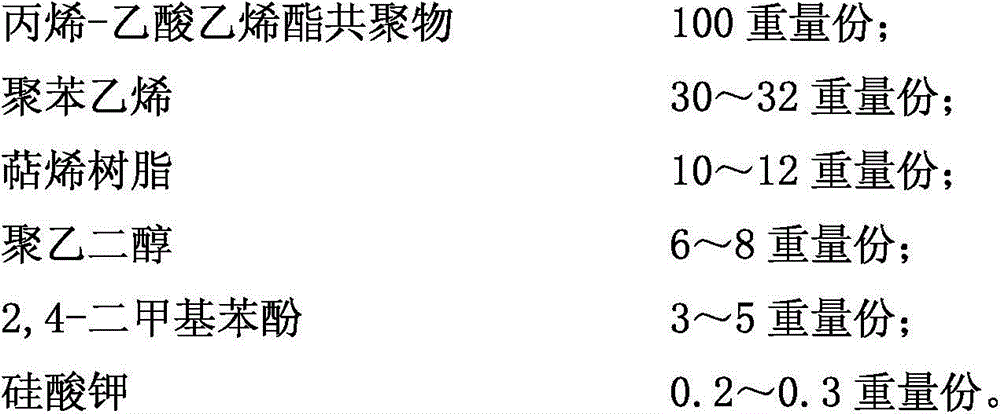

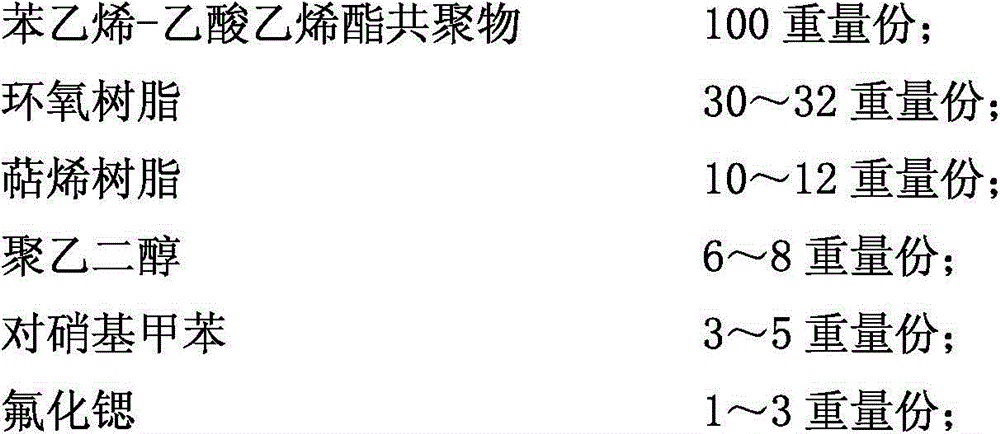

The invention discloses an aramid fiber-ultrahigh molecular weight polyethylene composite sheet material processing method. The method comprises fiber impregnation, single fiber layer hot pressing and multiple composite layer hot pressing. First glue comprises a styrene-vinyl acetate copolymer, epoxy resin, terpene resin, polyethylene glycol, p-nitrotoluene and strontium fluoride. Second glue comprises a propylene-vinyl acetate copolymer, polystyrene, terpene resin, polyethylene glycol, 2,4-dimethylphenol and potassium metasilicate. Through improvement of the glue and use of a multi-ingredient composite formula, bonding strength and density of the glue to aramid fibers and polyethylene fibers are effectively improved, and composite sheet material toughness and shock resistance are improved. Through freezing and unfreezing of the fibers subjected to impregnation, glue inner stress and surface tension are effectively reduced. Through UV treatment on the fibers subjected to impregnation, glue and fiber bonding strength is improved and a composite sheet material service life is prolonged.

Owner:CHANGSHU YONGLIJIAN NEW MATERIALS

Infrared colorful false proof material and preparation method thereof

InactiveCN101058707AWide spectral rangeHigh fluorescence brightnessOther chemical processesInorganic pigment treatmentFluorescenceLanthanum fluoride

The invention discloses an infrared colorful false proof material and making method, which comprises the following steps: selecting certain proportional alumina, lead fluoride, beryllium fluoride, calcium fluoride, strontium fluoride, lanthanum fluoride, europium trioxide, samarium trioxide, thulium trioxide and gadolinium trioxide as raw materal; blending these raw materials; grinding; heating; insulating; heating again; quenching; cooling; grinding; packing. The spectral scale is broad to form 3-6 different colorful fluorescences stimulated by laser at 960nm, which is fit for falseproof marking material.

Owner:龙彪

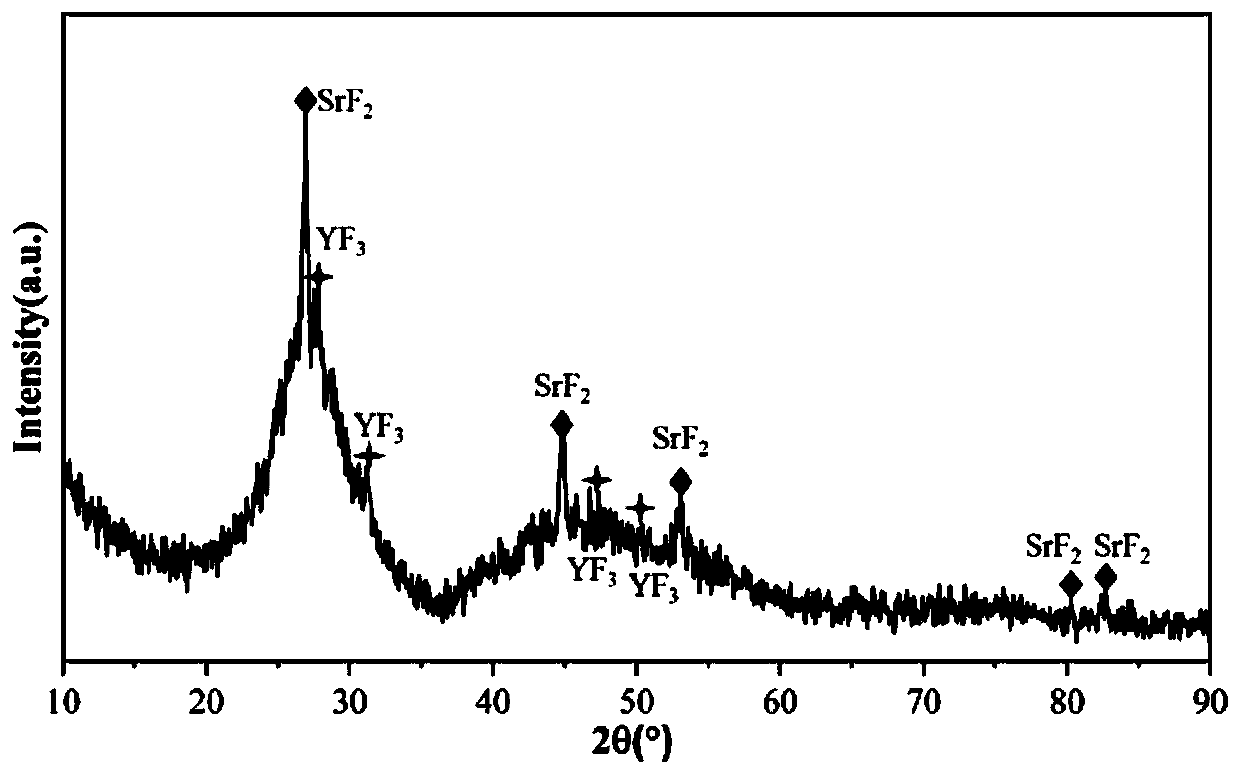

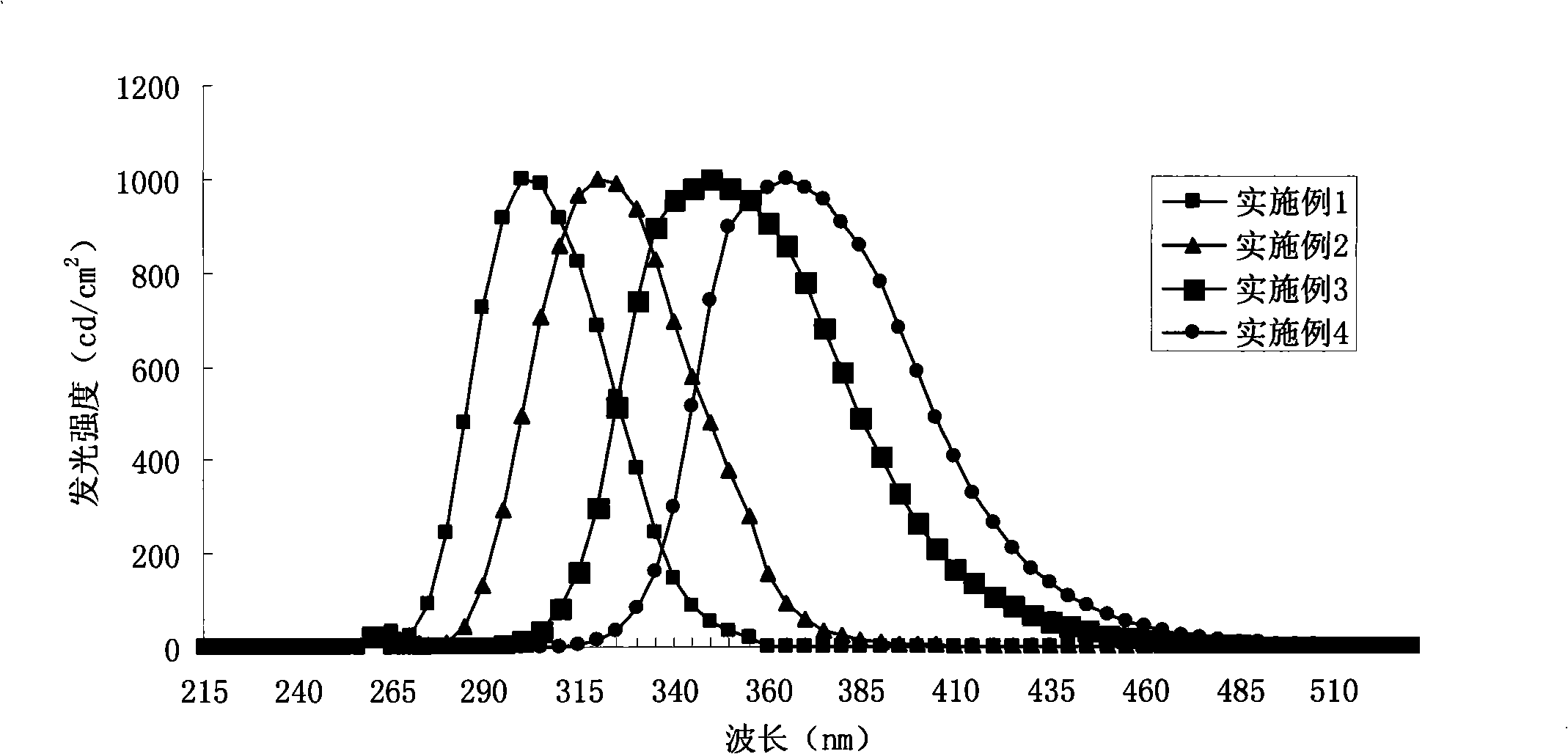

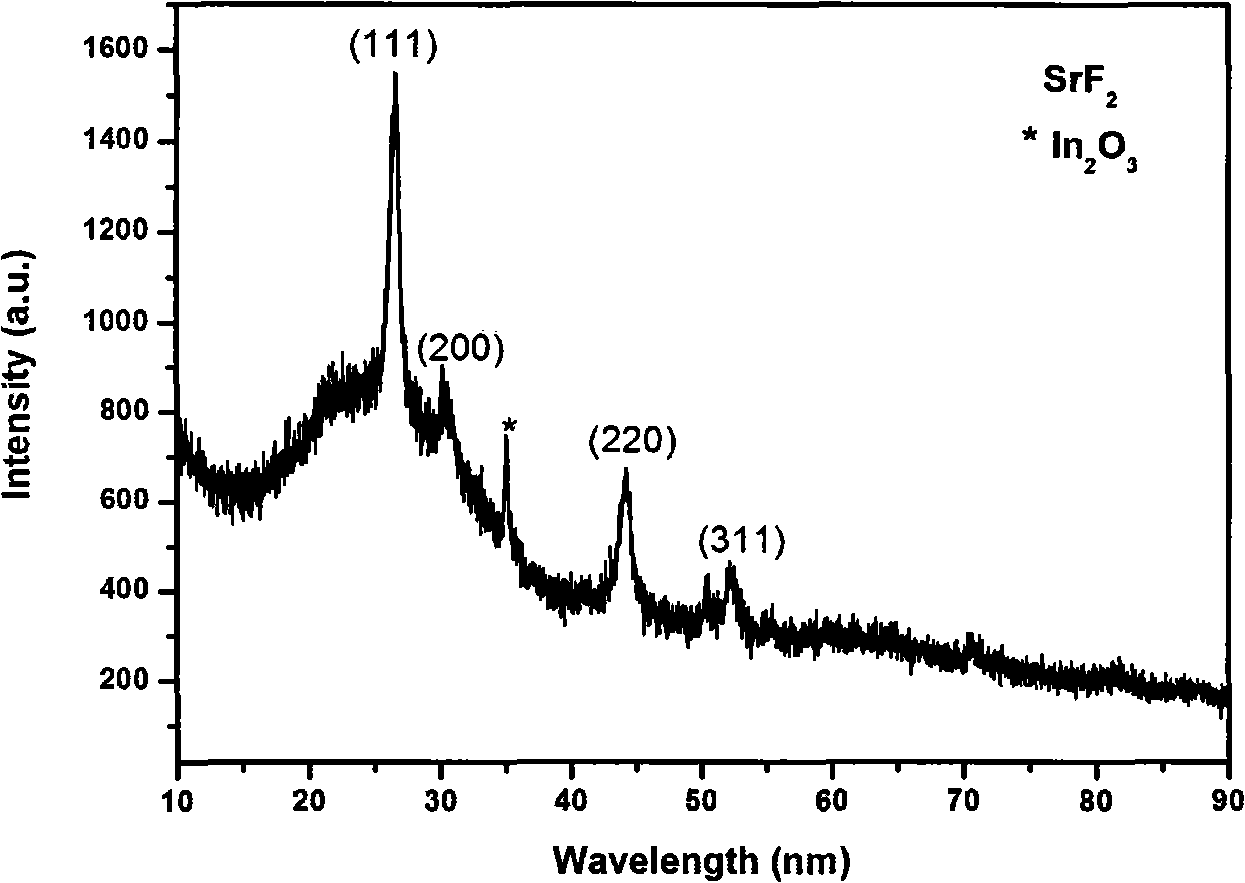

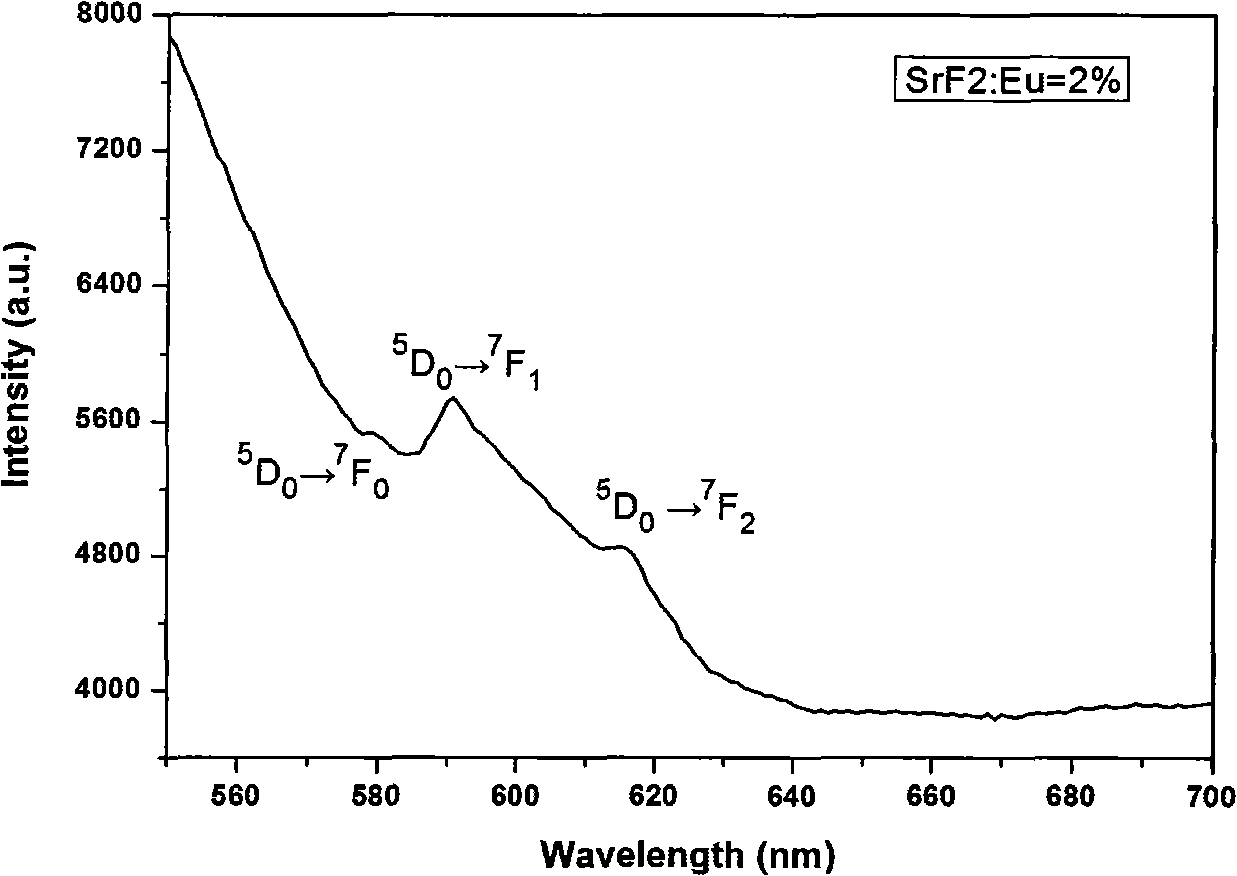

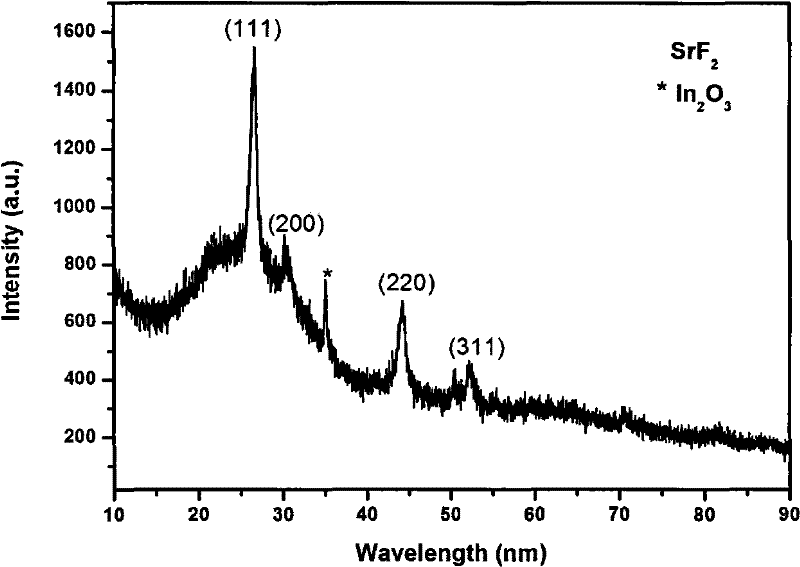

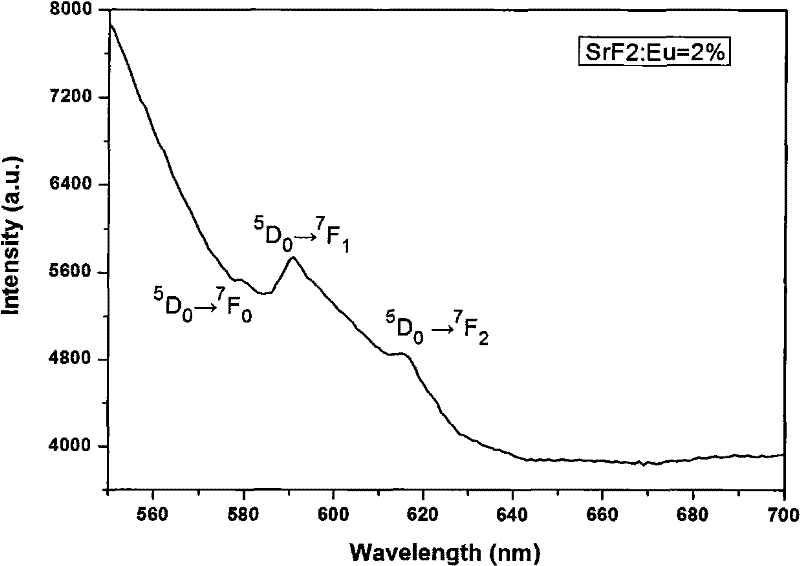

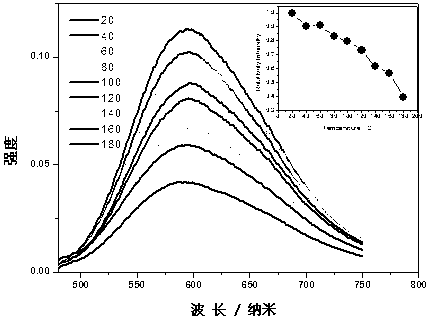

Fluorine indium glass ceramic containing erbium ion doped strontium fluoride and yttrium fluoride mixed crystals, and preparation method thereof

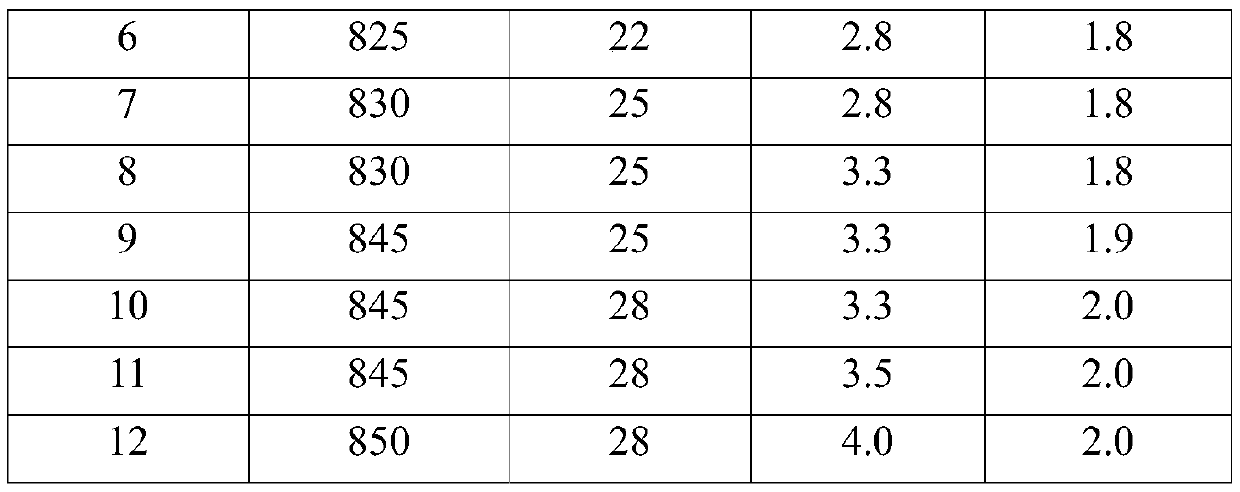

The invention discloses fluorine indium glass ceramic containing Er<3+>:SrF2-YF3 mixed crystals, and a preparation method thereof. According to the preparation method, the glass ceramic is composed ofuniform distribution of Er<3+>:SrF2-YF3 mixed crystals in a fluorine indium glass body. The fluorine indium glass ceramic containing Er<3+>:SrF2-YF3 mixed crystals is capable of realizing high efficiency 2.7<mu>m fluorescence emission. One-step moulding method is adopted, the preparation process is convenient and safe, and no expensive equipment is needed.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Synthetic method of luminescent material for sterilizing purifying energy conserving lamp

InactiveCN101348717AGood lookingImprove liquidityChemical industryLuminescent compositionsOxideStrontium fluoride

The invention discloses a method for synthesizing a luminescent material for a sterilizing and purifying energy-saving lamp. The method comprises the following steps: raw materials are weighed according to the mixture ratio of the chemical formula (N1-x-y My Cex)3Al12O19, and a fluxing additive is taken, and the materials are uniformly mixed and added into a corundum crucible which is then placed into an oxidizing atmosphere furnace for burning; a substance obtained is crushed and sieved and undergoes acid cleaning to neutrality through a dilute nitric acid solution, and the powder undergoes pumping filtration and drying; and the powder is placed into a reducing atmosphere for burning, and a finished product is obtained after final sieve classification. The method has the advantages that one or more than one among boric acid, barium fluoride, strontium fluoride, lithium chloride and lithium fluoride is taken as a fluxing agent and other certain rare earths and metal oxide are doped; and the luminescent material for the sterilizing and purifying energy-saving lamp synthesized by adoption of the method has good particle appearance and powder fluidity, high luminous brightness and uv intensity, and can sterilize, purify the air and distinguish counterfeit money.

Owner:常熟市江南荧光材料有限公司

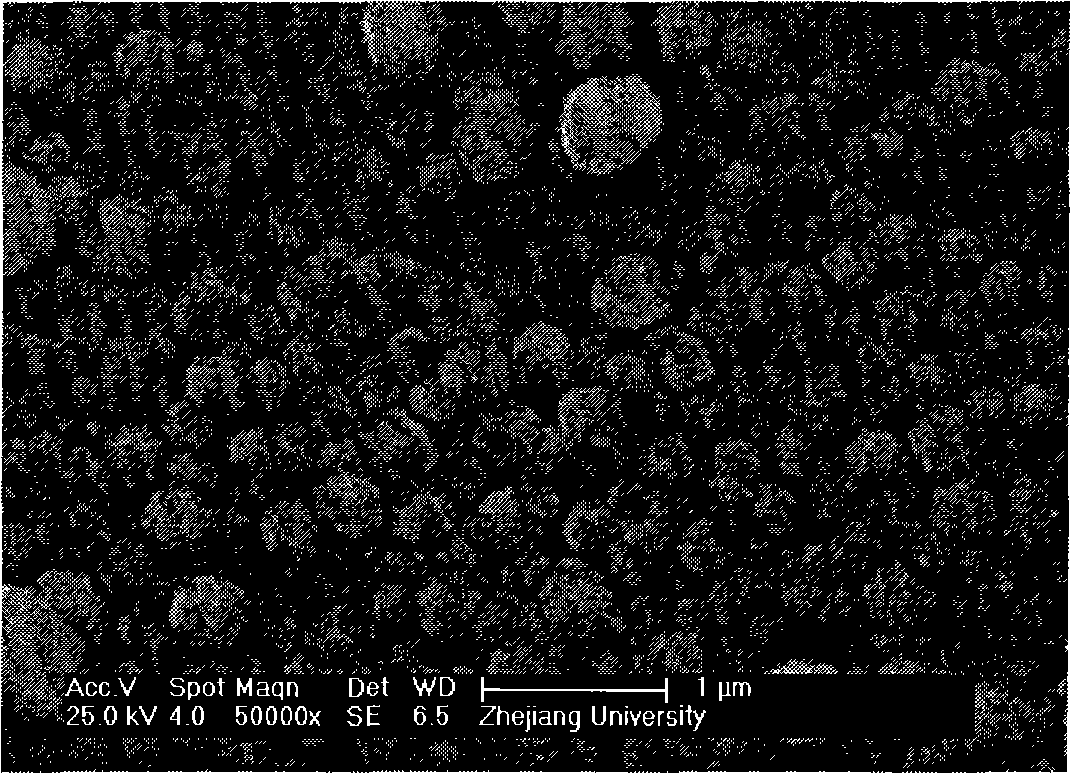

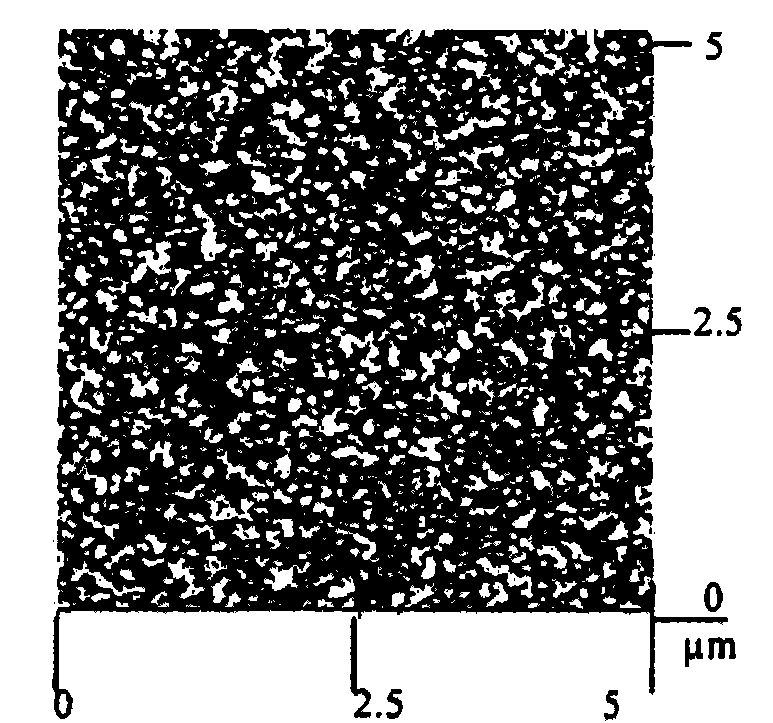

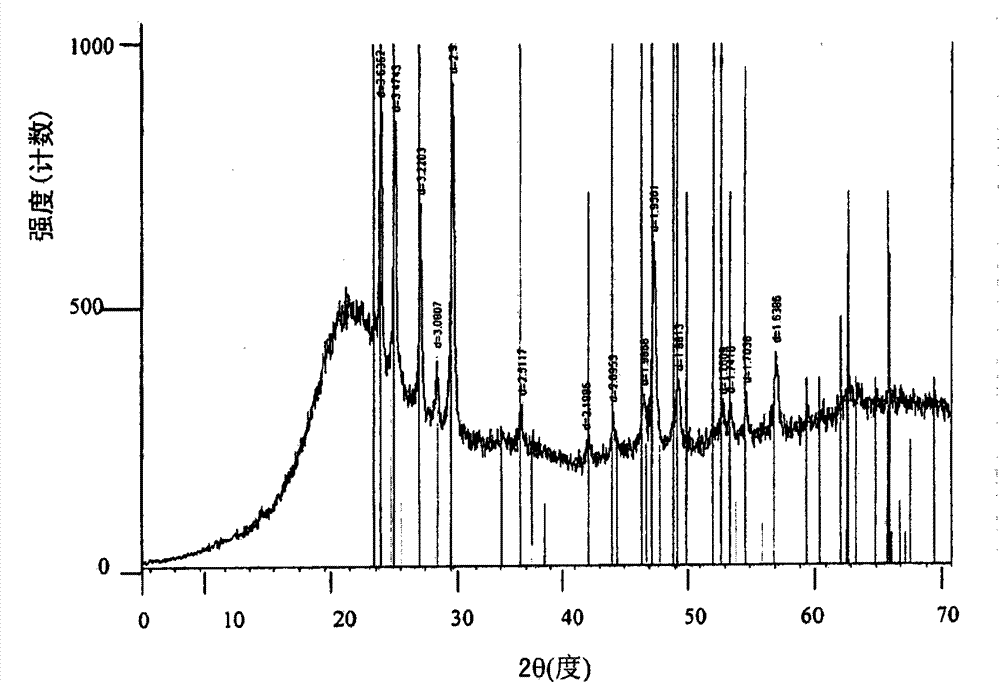

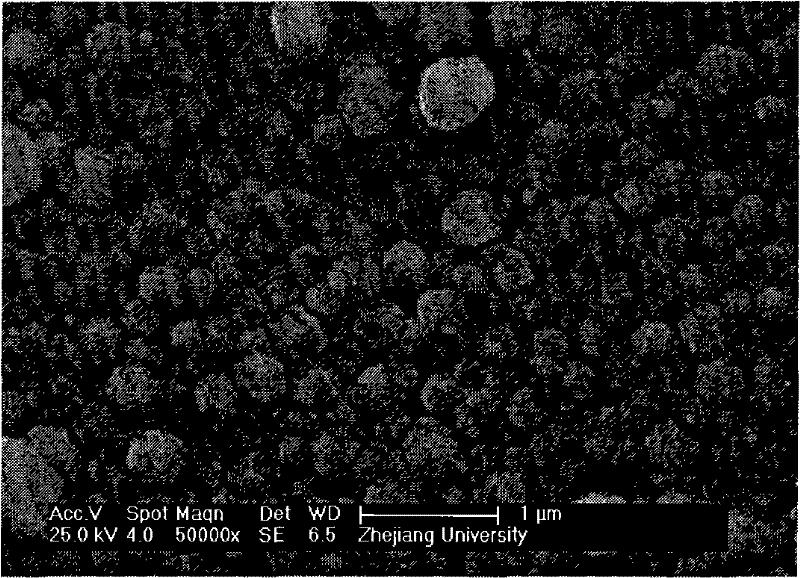

Method for preparing strontium fluoride or rare-earth doped strontium fluoride film by adopting electrolytic deposition

InactiveCN101892504ALow growth temperatureHigh crystallinityPolycrystalline material growthElectrolytic inorganic material coatingSodium ascorbateRare earth

The invention discloses a method for preparing a strontium fluoride or rare-earth doped strontium fluoride film by adopting electrolytic deposition. The method comprises the following steps of: 1) cleaning an ITO conductive glass twice or thrice by using acetone, then cleaning the ITO conductive glass in an ultrasonic cleaner for 10 to 30 minutes by using deionized water, activating the ITO conductive glass for 10 to 30 seconds in 10 percent nitric acid solution, and cleaning the ITO conductive glass by using the deionized water for later use; 2) adding sodium ascorbate and ammonium fluoride solution into compound solution of 0.01 to 0.5mol / L ethylene diamine tetraacetic acid and strontium ions, and adjusting the pH value to be between 6 and 9 to obtain electrolyte for later use; and 3) placing the ITO conductive glass serving as a working electrode, a platinum electrode serving as a counter electrode and a calomel electrode serving as a reference electrode into the electrolyte to perform electrolytic deposition so as to obtain the strontium fluoride film at an anode deposition potential of 0.8V to 1.4V relative to the calomel electrode. The method has the advantages of simple equipment, low cost and normal-pressure low temperature, is suitable for scientific research, and is expected to realize large-scale industrialized production.

Owner:ZHEJIANG UNIV

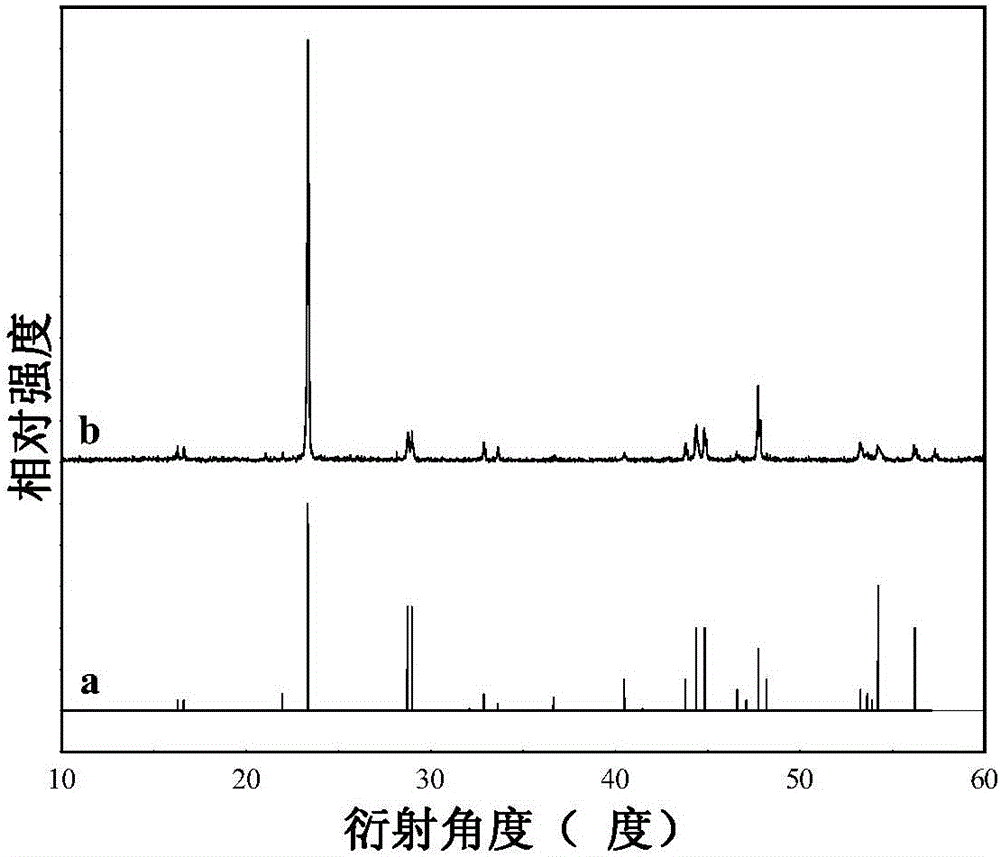

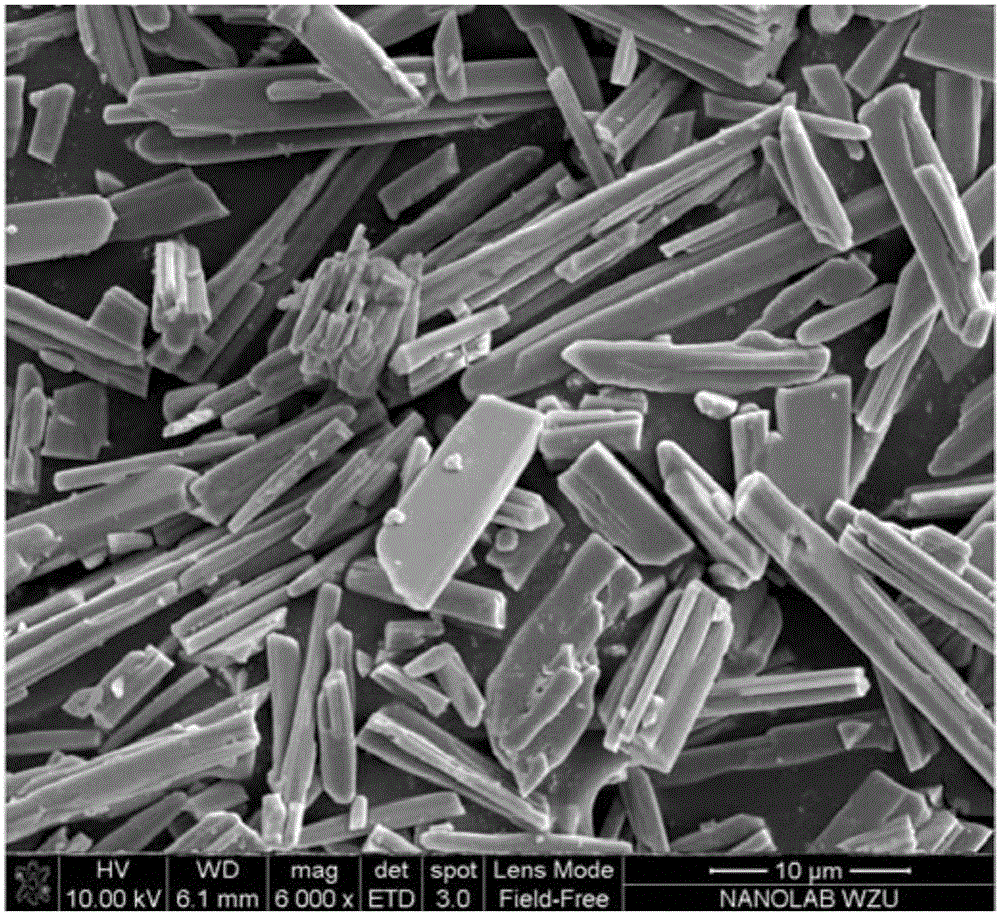

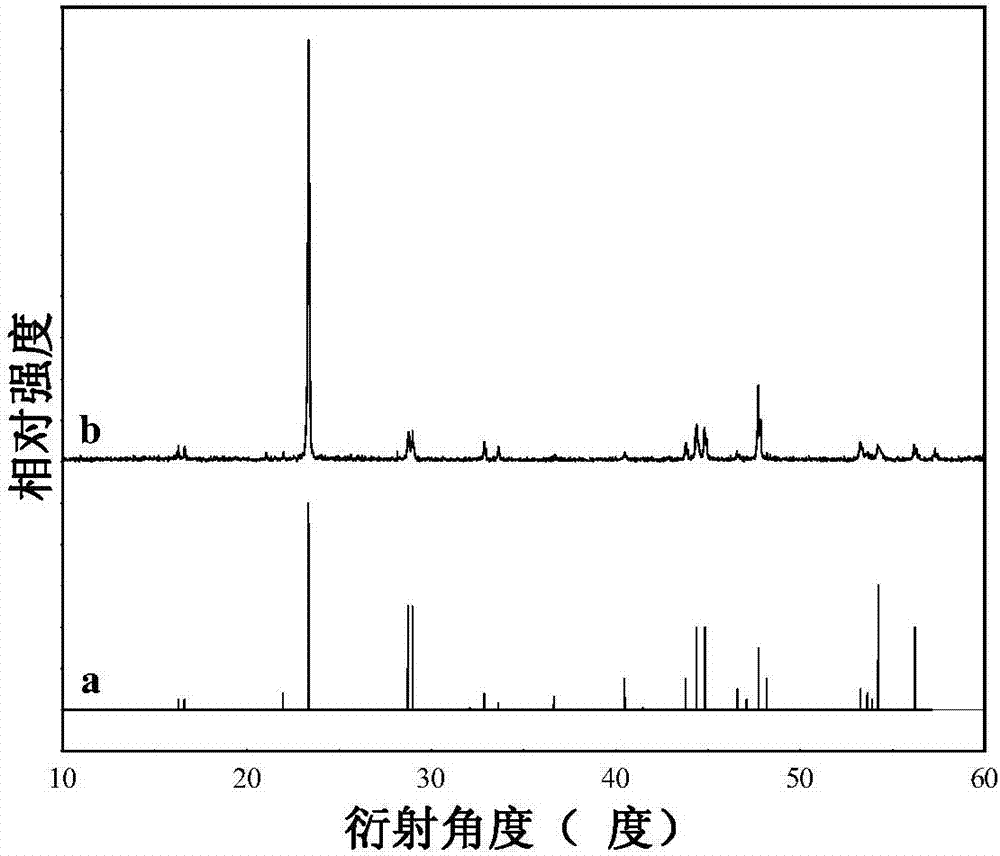

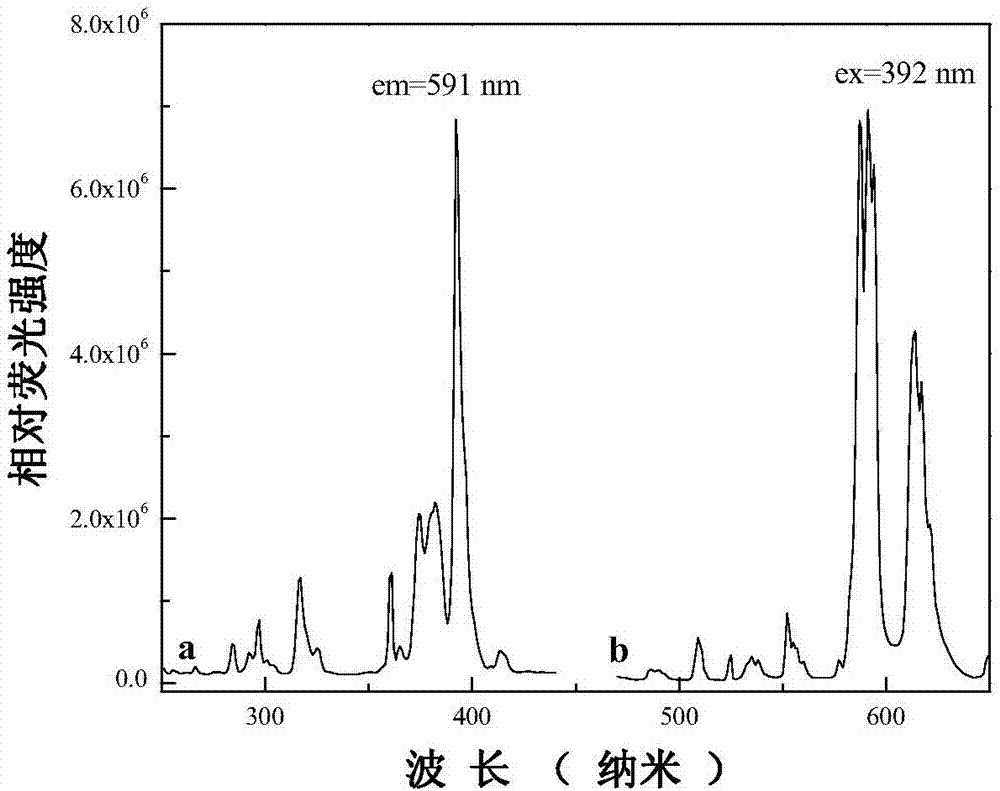

Rare earth doping fluozirconate luminescent material and preparing method thereof

ActiveCN105754596AHigh crystallinitySynthesis temperature is lowLuminescent compositionsRare earthHigh pressure

The invention discloses a rare earth doping fluozirconate luminescent material and a preparing method thereof.The chemical composition of the material is Sr(1-x)ZrF6: xRE3+, wherein RE can be Eu, Tb, Ce or Dy, and x is larger than or equal to 0.5% but smaller than or equal to 7.0%.The preparing method comprises the steps that solid strontium fluoride and rare earth oxide are accurately weighed according to a stoichiometric ratio and put into a reaction kettle liner, hexafluorozirconic acid and deionized water are added, stirring is conducted, the mixture is added into a reaction kettle, reaction is conducted at the temperature from 120 DEG C to 220 DEG C, and the micro-rodlike luminescent material crystallized in good condition is obtained.The material is low in phonon energy, the luminescent center is free of radiation and low in relaxation rate, and the luminescent efficiency is high.The material particles are disperse, do not unite and are beneficial to coated pipe application.The material is high in degree of crystallinity, the matrix is stable, and hydrolysis does not occur when the material is applied to a humid environment.The material can be applied to energy-saving lamps and high-pressure mercury lamps, the preparation technology is simple, and the requirement for equipment is low.

Owner:WENZHOU UNIVERSITY

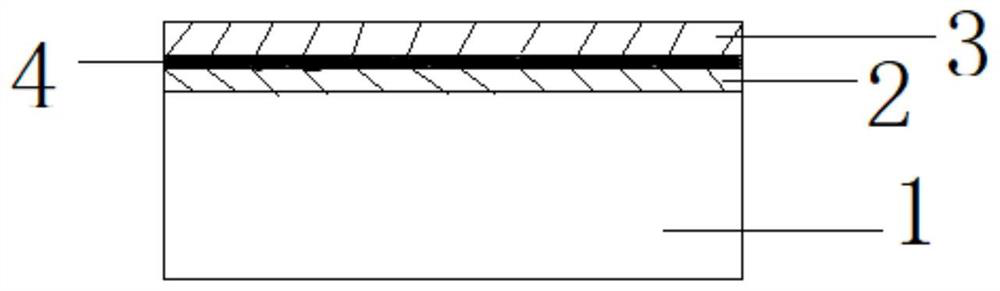

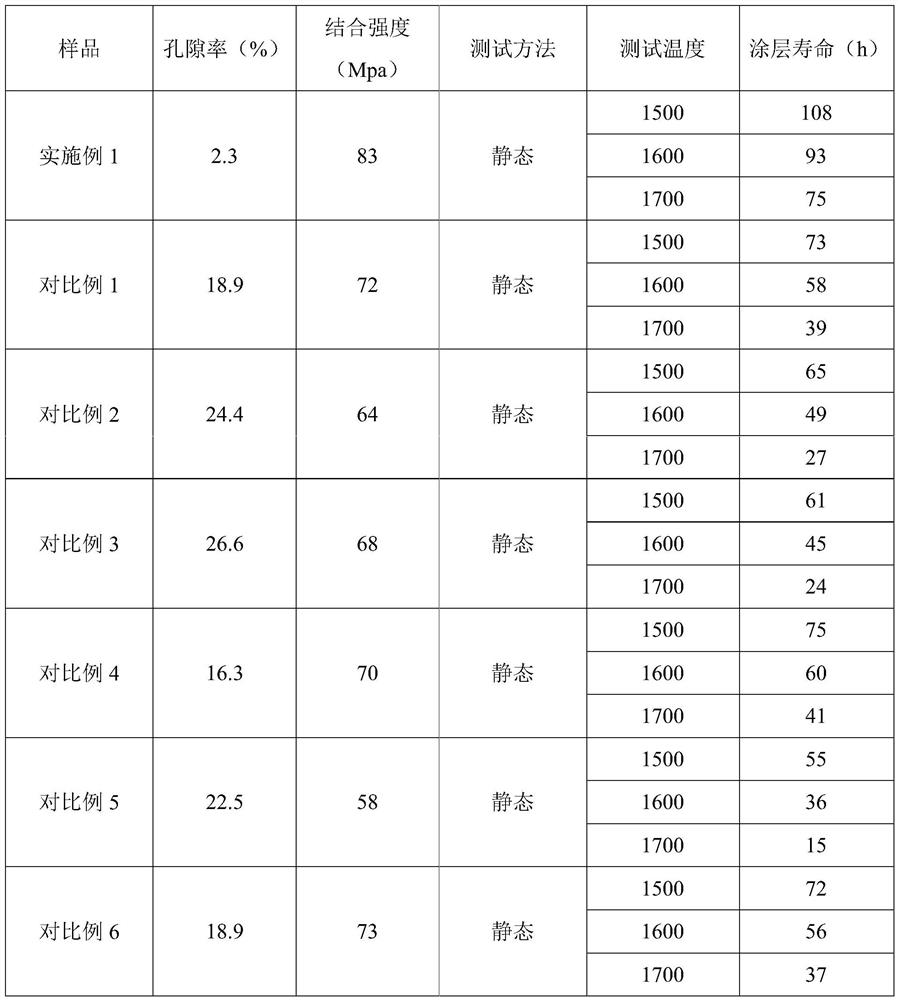

Coating for tungsten-copper alloy material and preparation method thereof

ActiveCN112662978AHigh bonding strengthImprove bindingMolten spray coatingPolyvinyl alcoholOxidation resistant

The invention discloses a coating for a tungsten-copper alloy material. The coating comprises a transition layer and an anti-oxidation layer formed on the surface of the alloy material in sequence, wherein the transition layer comprises the following raw materials in parts by weight: 15-20 parts of nano tin oxide, 10-15 parts of strontium fluoride, 0.1-0.5 part of tetrabutyl titanate and 1-5 parts of polyvinyl alcohol, and the anti-oxidation layer comprises the following raw materials in parts by weight: 10-20 parts of nano cerium oxide and 30-50 parts of silicon-barium-iron alloy powder. Two components of nano tin oxide and strontium fluoride are added into the transition layer so that the bonding strength of the transition layer is improved, and the porosity is reduced. The silicon-barium-iron alloy powder in the anti-oxidation layer reacts with oxygen in a high-temperature environment so that the alloy material is prevented from being oxidized at a high temperature, and the compactness of the anti-oxidation layer is improved through the nano cerium oxide. The invention further provides a preparation method of the coating for the tungsten-copper alloy material, the transition layer is prepared in a sintering mode, the anti-oxidation layer is sprayed to the surface of the transition layer through hypersonic flame, and it is guaranteed that the coating is uniformly distributed on the surface of the alloy material and does not easily crack or fall off.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

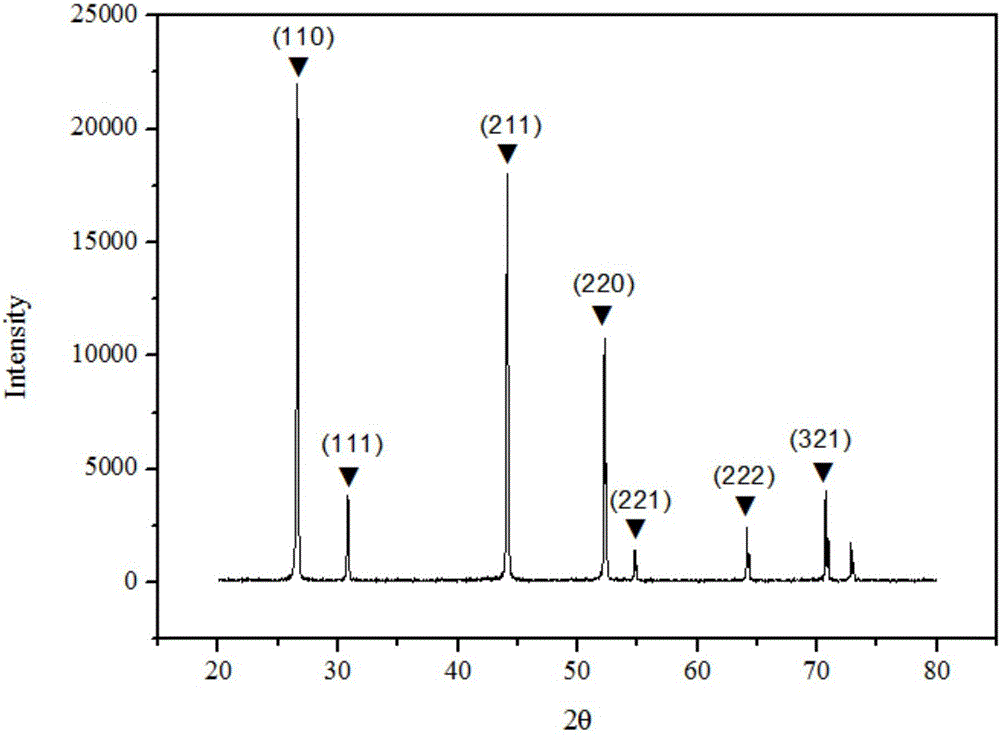

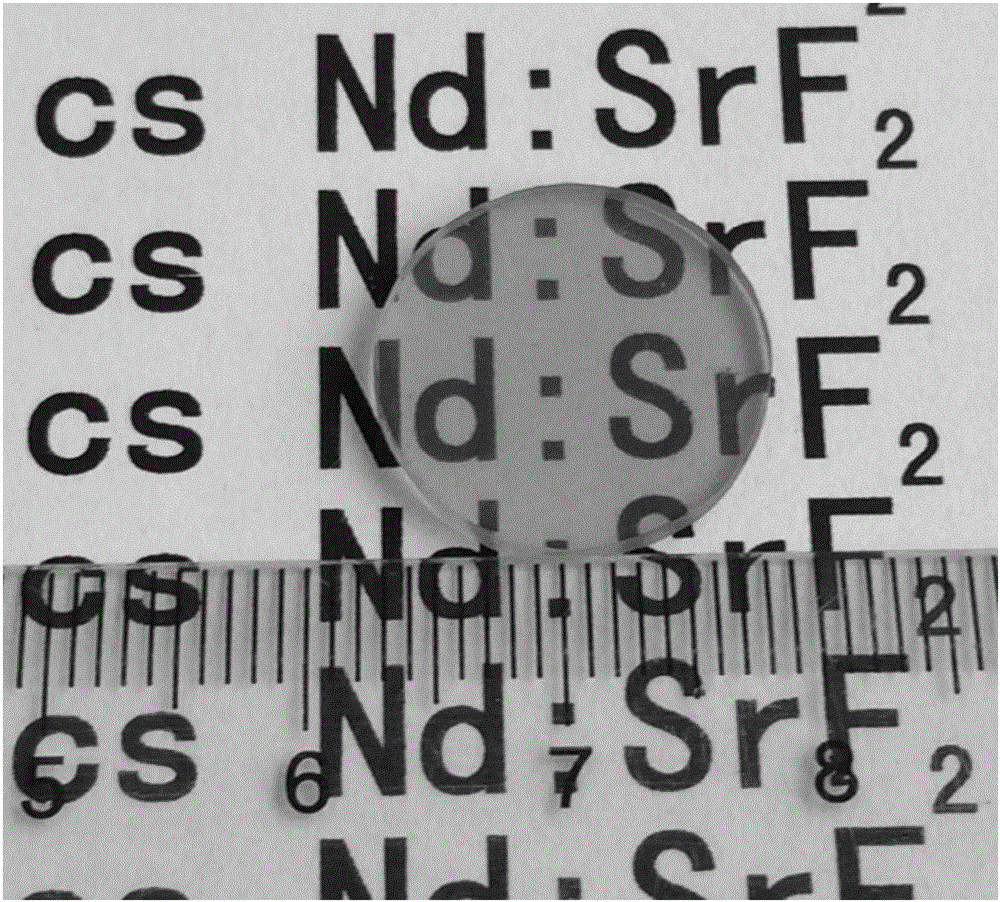

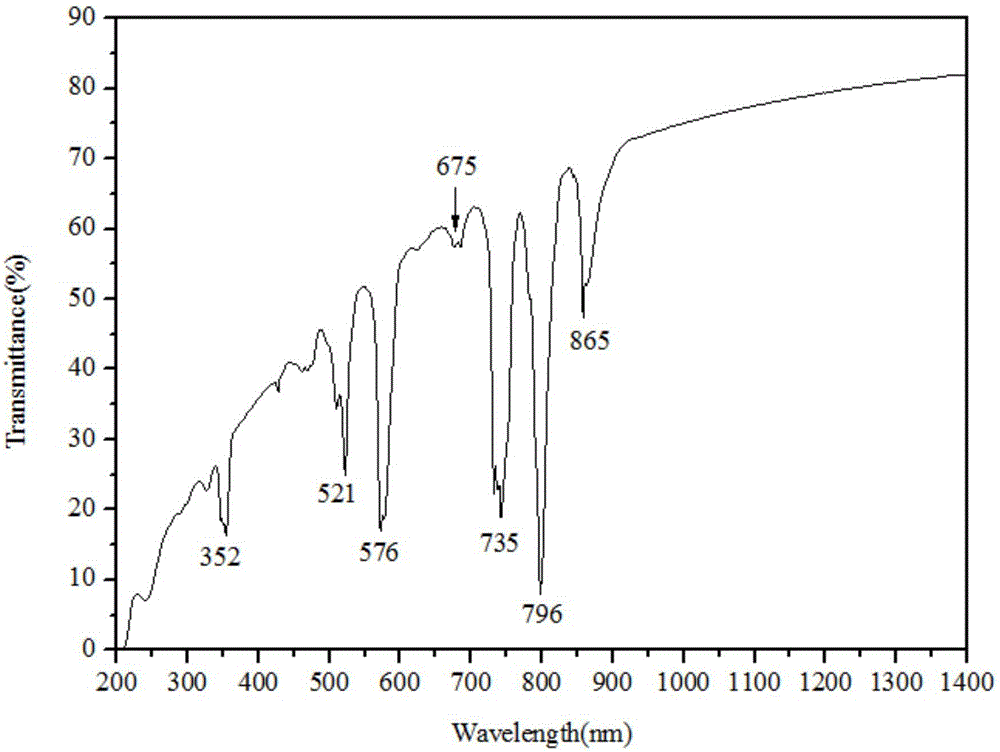

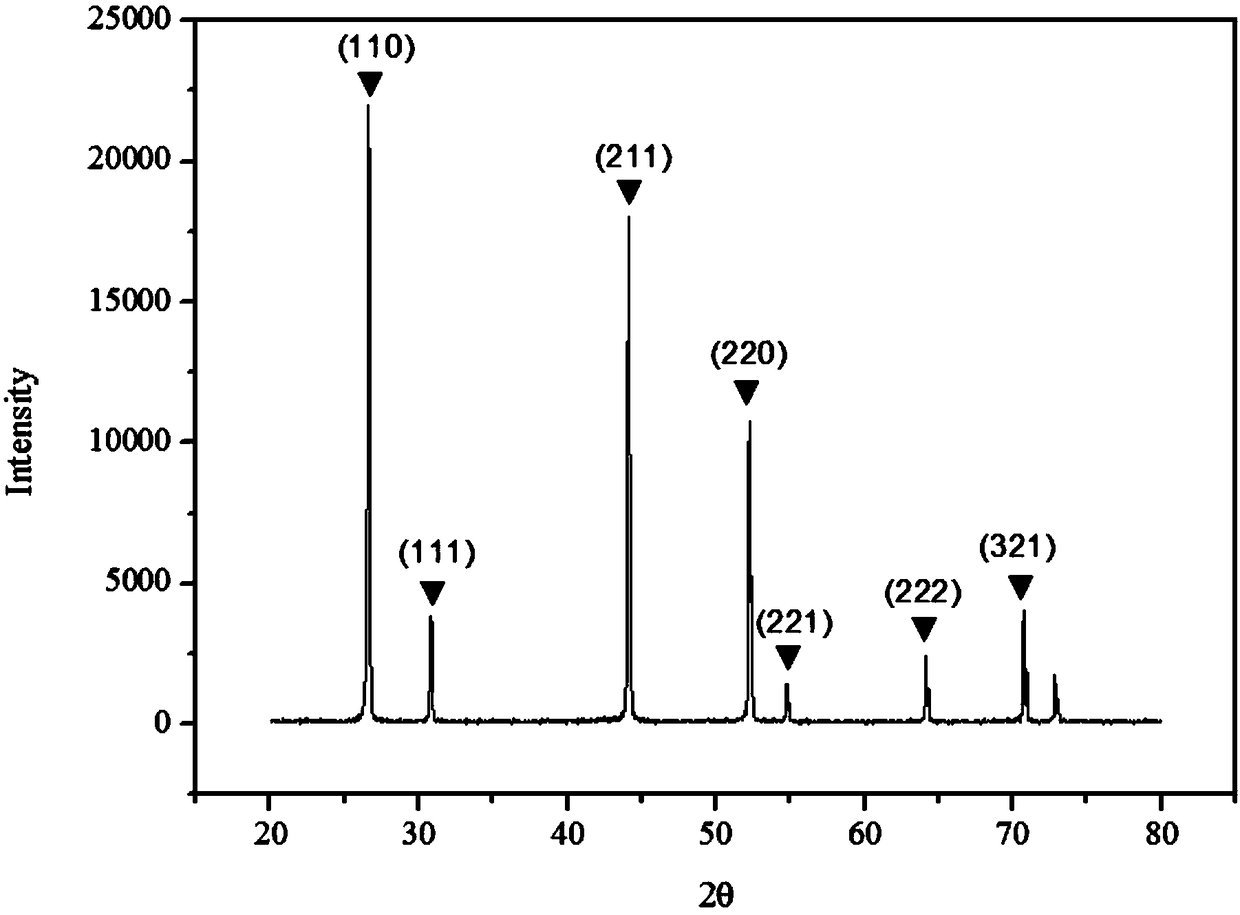

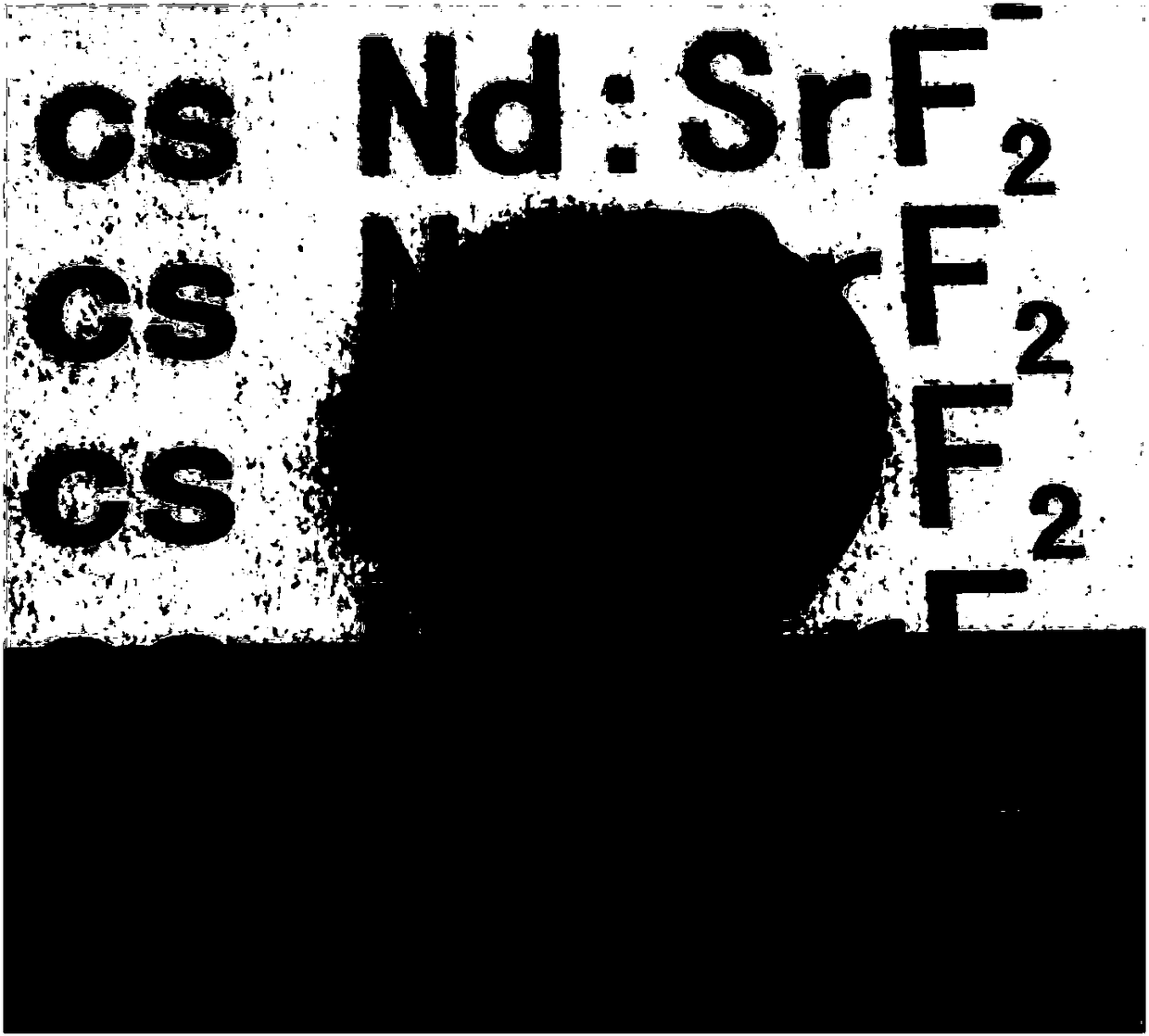

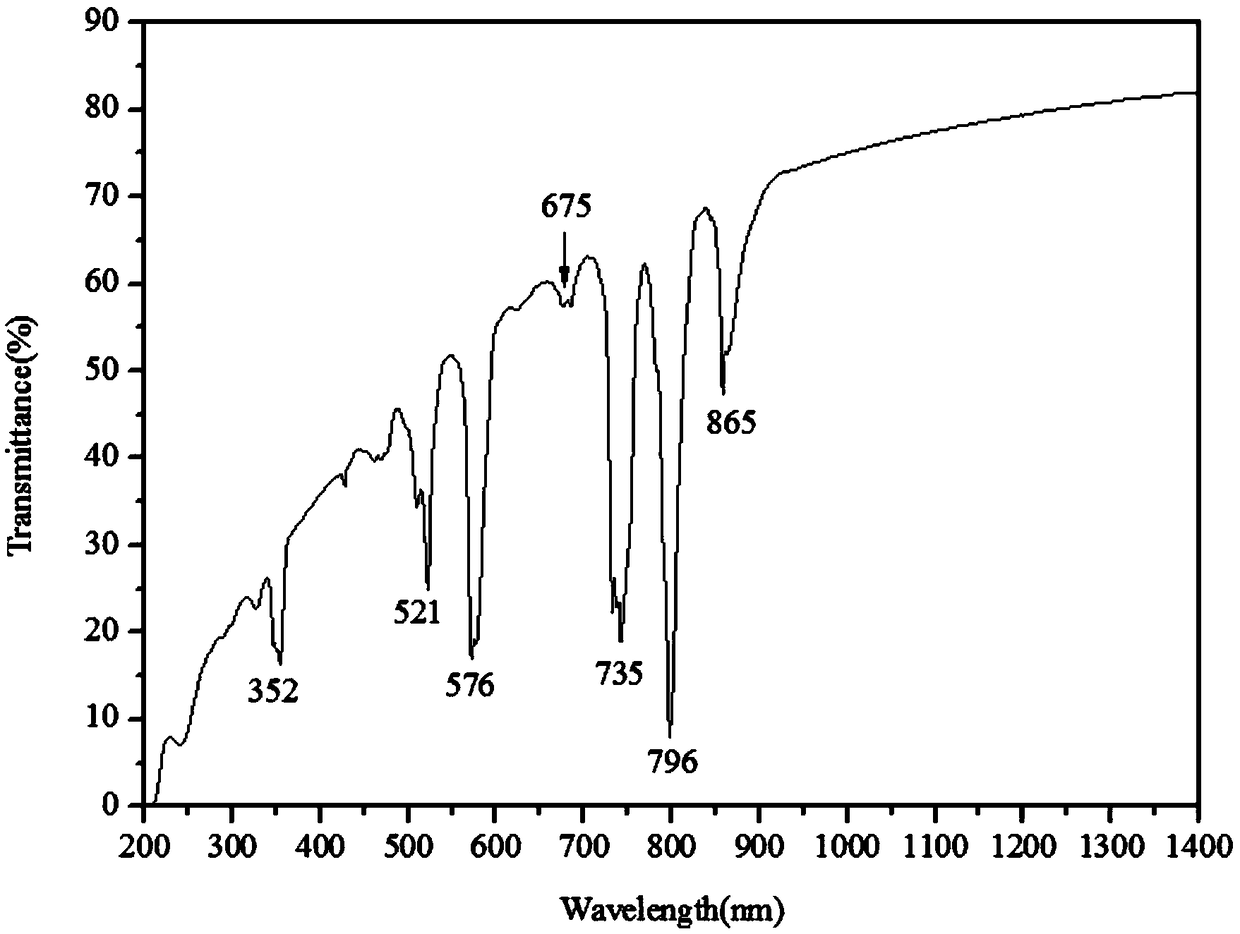

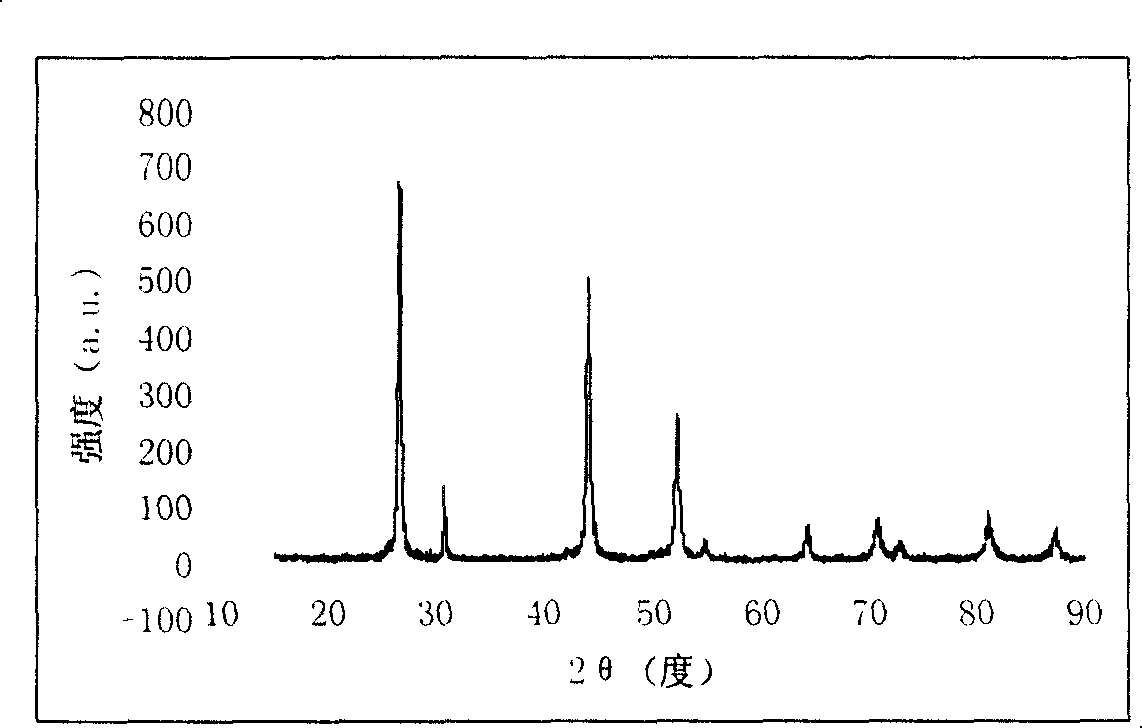

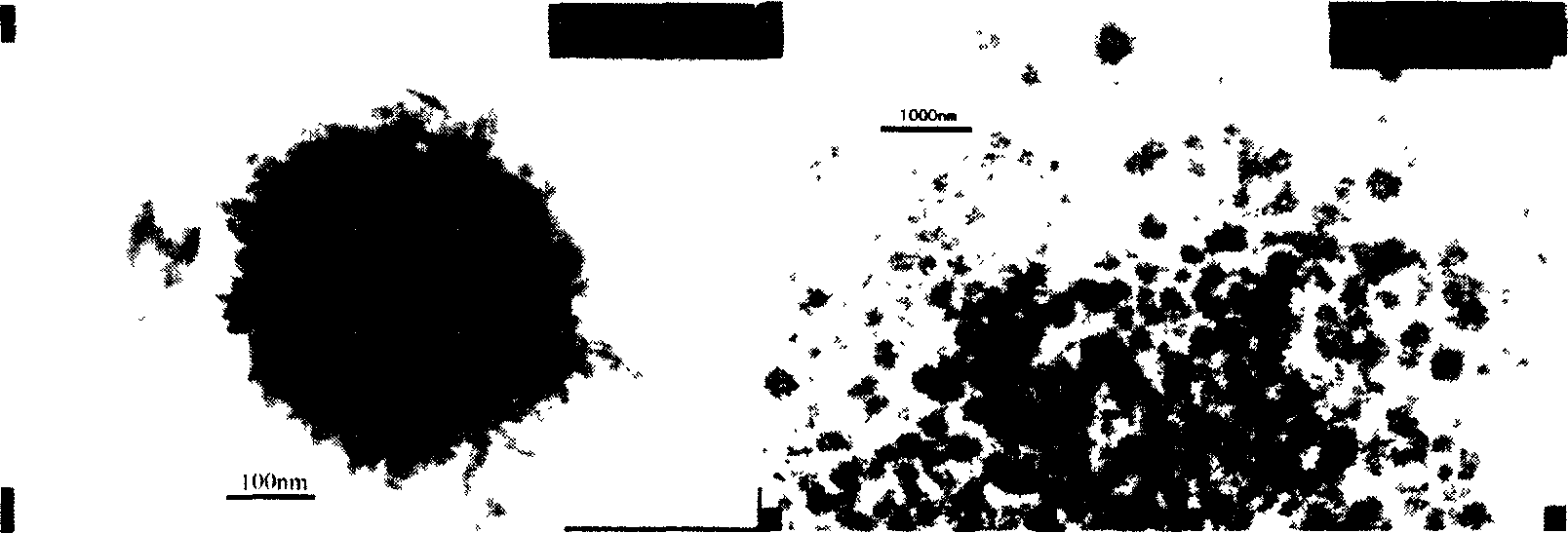

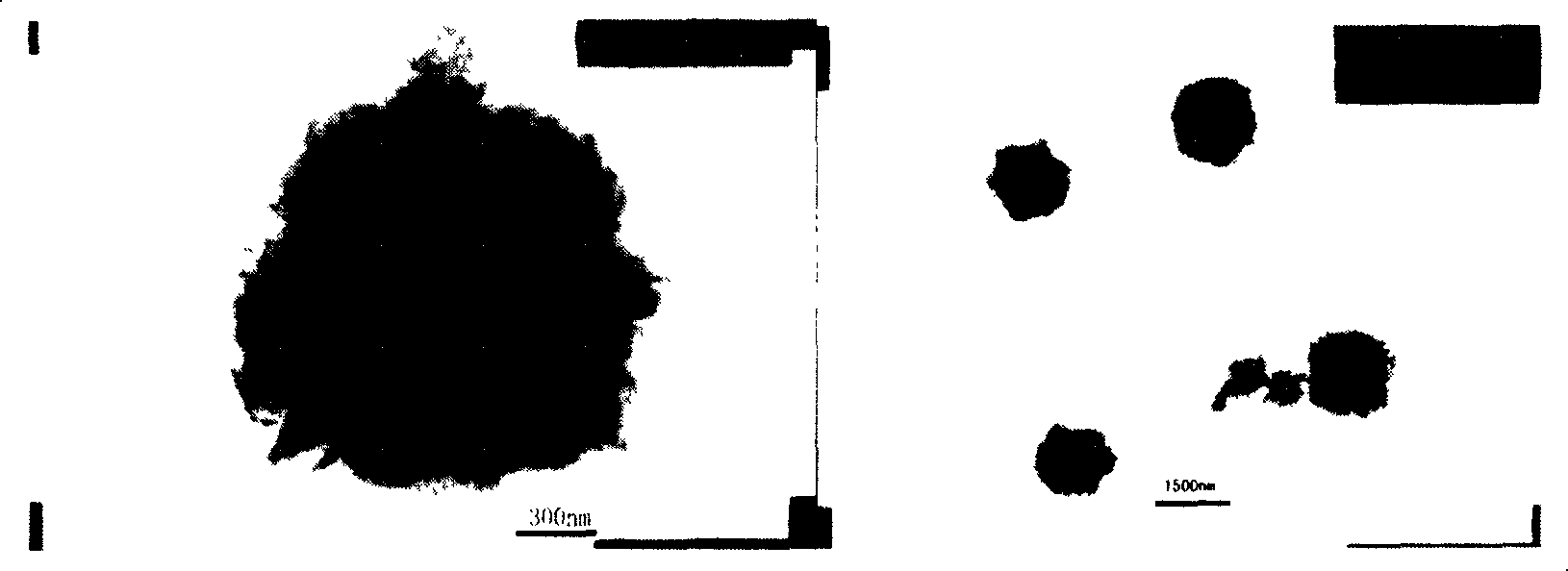

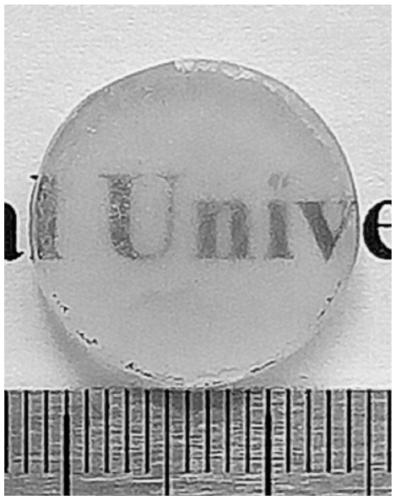

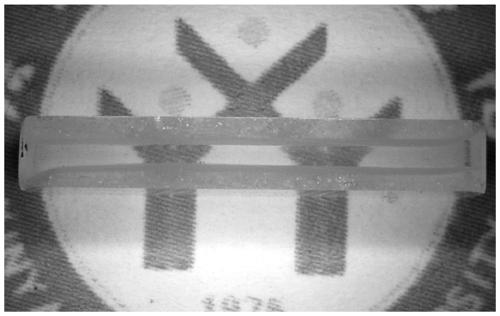

Neodymium-doped strontium fluoride laser transparent ceramic and preparation method thereof

The invention relates to a neodymium-doped strontium fluoride laser transparent ceramic. According to the invention, neodymium ions and a strontium fluoride matrix undergo a chemical reaction to form a displacement solid solution, and hot-pressing sintering, post-treatment and other operations are carried out so as to obtain the laser transparent ceramic with a density approximate to 99.8%. A preparation method for the laser transparent ceramic comprises the following steps: preparing Nd<3+>: SrF2 nanometer powder by using an azeotropic distillation process and then carrying out azeotropic distillation with n-butanol as an entrainer to maximally remove moisture in gel, wherein obtained powder is not prone to agglomeration, has uniform particle size distribution, and has a grain size of 15 to 30 nm; and preparing the laser transparent ceramic by using vacuum hot-pressing sintering technology with LiF as a sintering aid. The prepared laser transparent ceramic has maximum transmittance of 85.83% in visible and near-infrared wave bands and has strong absorption peaks at 576 nm, 735 nm and 796 nm. The preparation method is simple, suitable for large-scale production and low in cost; and the prepared laser transparent ceramic has good optical homogeneity.

Owner:WUHAN UNIV OF TECH

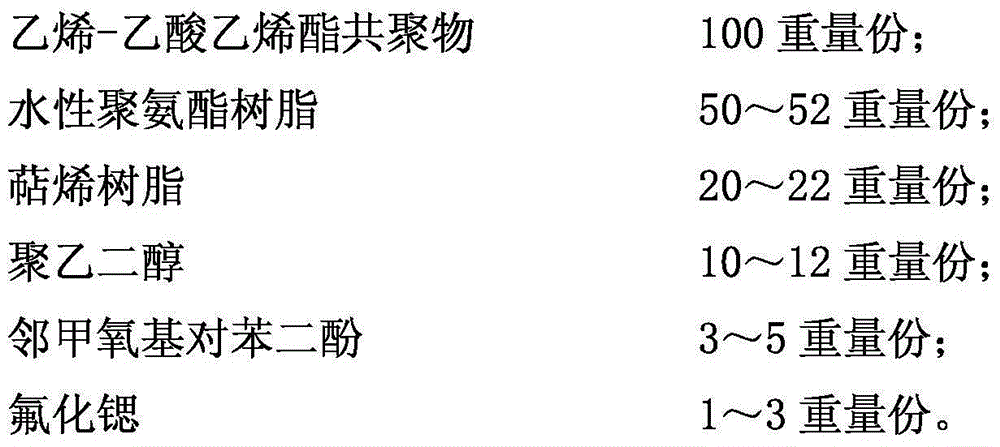

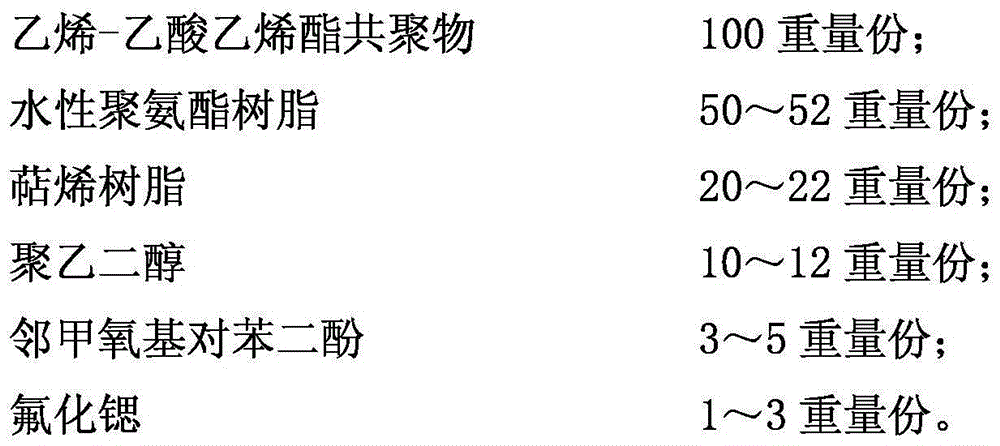

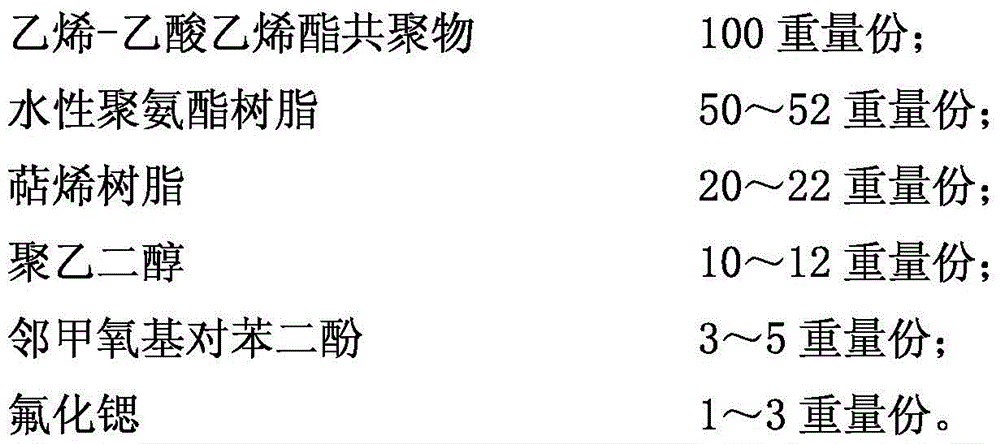

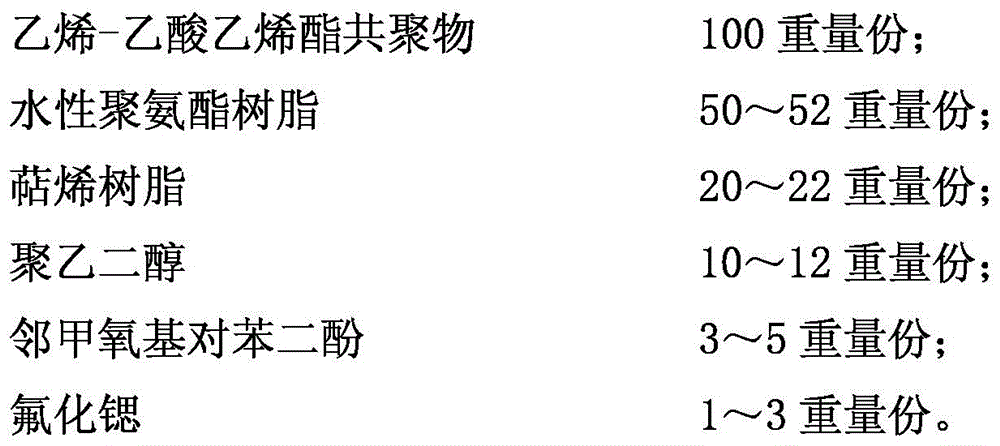

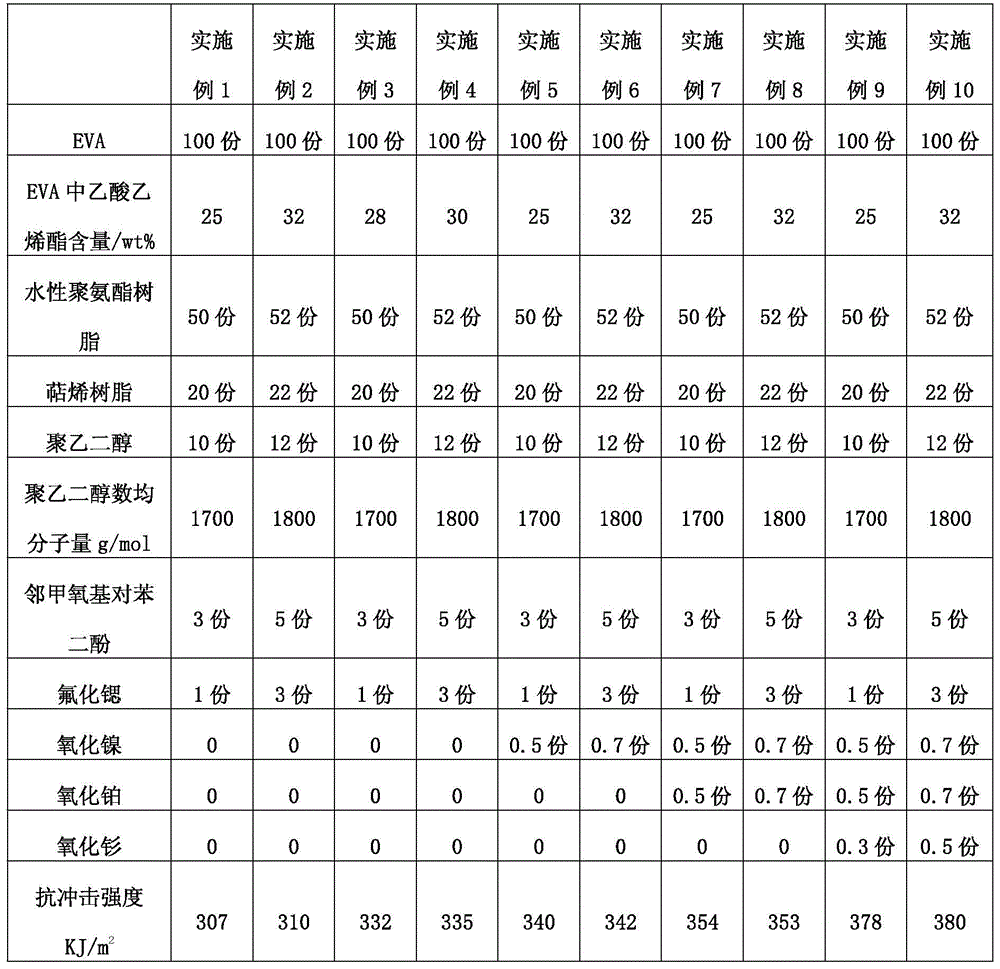

Manufacturing method of anti-impact soft no-woven cloth

ActiveCN104999748AHigh bonding strengthHigh densitySynthetic resin layered productsLaminationBond densityAdhesive

The invention discloses a manufacturing method of anti-impact soft no-woven cloth. The method comprises the steps that 1, fiber adhesive dipping is conducted, and hot-pressing is conducted on single-fiber layers; 2, hot-pressing is conducted on two-layer composite fiber layers; 3, hot-pressing is conducted on two-layer composite fiber layers with two to four rolls to prepare the anti-impact soft no-woven cloth with four to eight composite fiber layers, wherein adhesives used in the method comprises ethylene vinyl acetate copolymers, waterborne polyurethane resin, terpene resin, polyethylene glycol, o-methoxyhydroquinone and strontium fluoride. According to the manufacturing method of the anti-impact soft no-woven cloth, the adhesives are improved, a multi-component composite formula is adopted, the bonding strength and the bonding density of the adhesives on fibers are effectively improved, and the tenacity and the anti-impact property of the no-woven cloth are improved; freezing and unfreezing are conducted on the fibers which are dipped in the adhesives, the internal stress and the surface tension of the adhesives are effectively decreased, and hot-pressed composite fiber layers have higher strength and anti-impact capacity.

Owner:CHANGSHU YONGLIJIAN NEW MATERIALS

Two-phase stainless steel electrode

ActiveCN102233489BArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaSS - Stainless steelSilicon dioxide

The invention discloses a two-phase stainless steel electrode, which comprises a core wire and a coating, wherein the coating is coated on the outer wall of the core wire and accounts for 0.4 to 0.5 percent of the total weight of the electrode. The core wire comprises the following components in percentage by weight: 0.005 to 0.030 percent of C, 0.01 to 0.20 percent of Si, 1.50 to 2.50 percent ofMn, 0 to 0.025 percent of P, 19.0 to 22.0 percent of Cr, 9.0 to 11.0 percent of Ni, 2.5 to 3.5 percent of Mo and the balance of Fe. The coating comprises the following components in percentage by weight: 8 to 20 percent of calcium carbonate, 2 to 15 percent of barium carbonate, 5 to 15 percent of calcium fluoride, 6 to 17 percent of strontium fluoride, 4 to 16 percent of barium fluoride, 9 to 18 percent of cryolite, 4 to 10 percent of rutile, 1 to 5 percent of titanium white, 2 to 8 percent of silicon dioxide, 3 to 9 percent of chromium powder, 1 to 1.5 percent of molybdenum powder, 0.1 to 4 percent of magnesium powder and 5 to 13 percent of iron powder. After the coating components are uniformly mixed, an adhesion agent is added into the mixture. The two-phase stainless steel electrode has high strength, high tenacity and intercrystalline corrosion resistance; and during welding, an electric arc is stable, splashing phenomena is reduced, a welding seam is well molded, slag is easy toremove, and the electrode has high operability.

Owner:KUSN GINTUNE WELDING

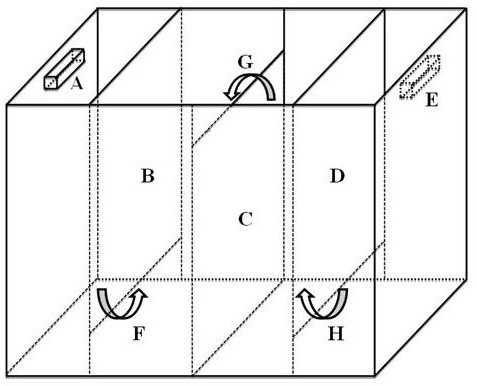

Method for preparing strontium fluoride crystal

InactiveCN113104879AHigh yieldHigh purityCalcium/strontium/barium fluoridesStrontium fluorideGlycine solution

The invention provides a method for preparing a strontium fluoride crystal. Strontium chloride is used as a strontium source reactant, ammonium fluoride or sodium fluoride is used as a fluorine source reactant, glycine is used as a biological regulating agent, and the strontium fluoride crystal is prepared. Strontium chloride, ammonium fluoride or sodium fluoride and a glycine solution are sequentially added into a communicated reaction container provided with a left ear groove, a right ear groove, a left barrier plate, a middle barrier plate and a right barrier plate, and after the reaction is finished, the product is filtered, washed and dried to obtain the strontium fluoride crystal. The purity of the prepared strontium fluoride crystal reaches 99.0%-99.9%, the yield reaches 99.0%-99.9%, and the purity and crystallinity are high. The method has the characteristics of simple process, mild reaction conditions, low energy consumption, low cost and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

A rare earth-doped fluorozirconate luminescent material and its preparation method

ActiveCN105754596BHigh crystallinitySynthesis temperature is lowLuminescent compositionsStrontium fluorideChemical composition

The invention discloses a rare earth-doped fluorozirconate luminescent material and a preparation method thereof. The chemical composition of the material is Sr(1‐x)ZrF6:xRE3+, where RE=Eu, Tb, Ce or Dy, 0.5%≤x≤7.0%; its preparation method is as follows: solid strontium fluoride and rare earth oxide The stoichiometric ratio is accurately weighed and put into the lining of the reaction kettle, then the fluozirconic acid and deionized water are added, stirred, the mixture is put into the reaction kettle, and reacted at 120-220°C to obtain a well-crystallized micron rod-shaped luminescent material. The phonon energy of the material is low, the non-radiative relaxation rate of the luminescence center is low, and the luminescence efficiency is high. The material particles are dispersed and not agglomerated, which is conducive to the application of coated pipes. The material has a high degree of crystallinity, a stable matrix, and can be applied in a humid environment without hydrolysis. The material can be used in energy-saving lamps and high-pressure mercury lamps, and has simple preparation process and low equipment requirements.

Owner:WENZHOU UNIVERSITY

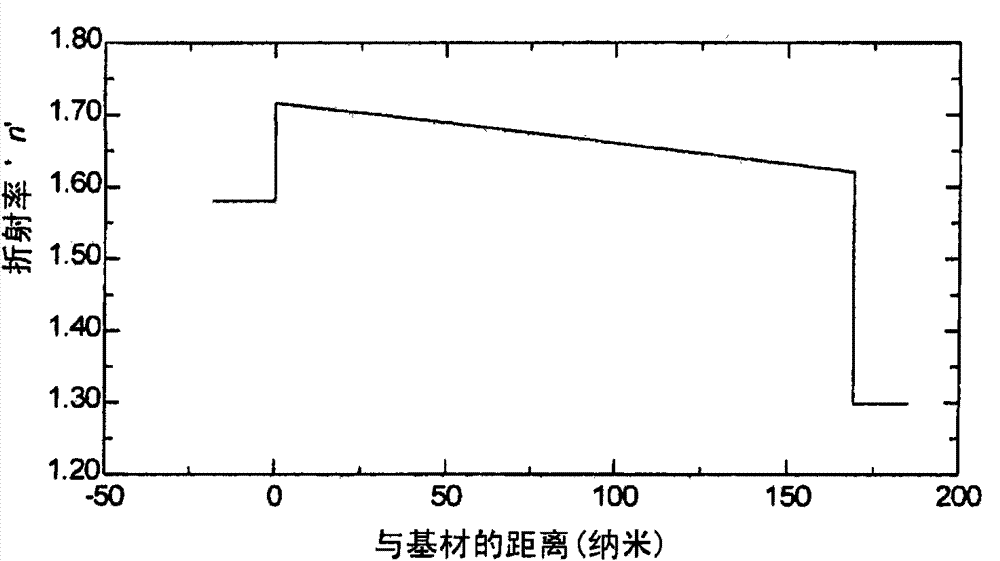

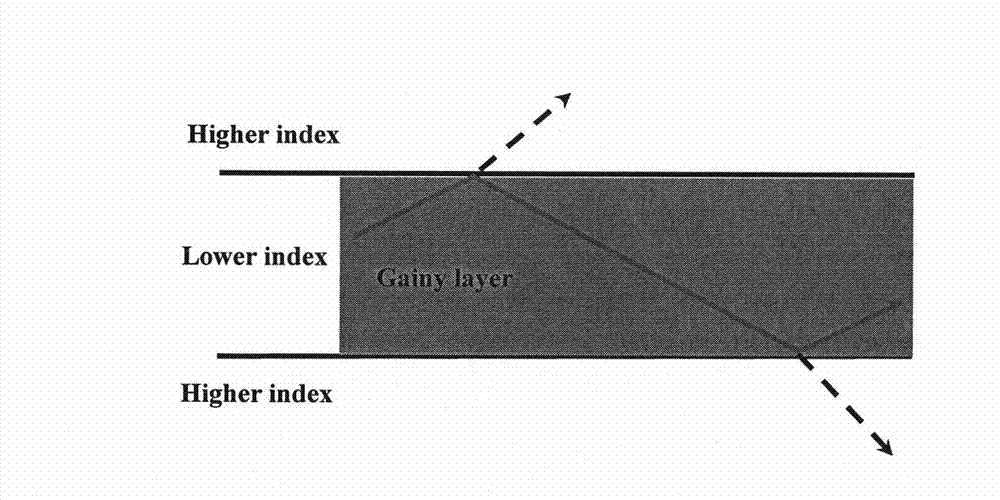

Composition of oversized mode area fluorphosphate optical fiber and preparation method thereof

InactiveCN101995587BGood thermal propertiesGood optical performanceCladded optical fibreOptical waveguide light guideLanthanum fluorideRefractive index

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

A processing method of aramid fiber and ultra-high molecular weight polyethylene composite sheet

ActiveCN104960306BImprove anti-agingHigh bonding strengthLamination ancillary operationsNon-macromolecular adhesive additivesEpoxyPolymer science

The invention discloses an aramid fiber-ultrahigh molecular weight polyethylene composite sheet material processing method. The method comprises fiber impregnation, single fiber layer hot pressing and multiple composite layer hot pressing. First glue comprises a styrene-vinyl acetate copolymer, epoxy resin, terpene resin, polyethylene glycol, p-nitrotoluene and strontium fluoride. Second glue comprises a propylene-vinyl acetate copolymer, polystyrene, terpene resin, polyethylene glycol, 2,4-dimethylphenol and potassium metasilicate. Through improvement of the glue and use of a multi-ingredient composite formula, bonding strength and density of the glue to aramid fibers and polyethylene fibers are effectively improved, and composite sheet material toughness and shock resistance are improved. Through freezing and unfreezing of the fibers subjected to impregnation, glue inner stress and surface tension are effectively reduced. Through UV treatment on the fibers subjected to impregnation, glue and fiber bonding strength is improved and a composite sheet material service life is prolonged.

Owner:CHANGSHU YONGLIJIAN NEW MATERIALS

Preparing method and application of catalyst

InactiveCN105797761AHigh activityImprove thermal stabilityPhysical/chemical process catalystsRare-earth elementCerium

The invention relates to a preparing method and application of a catalyst. The catalyst comprises, by weight, 50-60 parts of raw light-rare-earth mineral powder containing lanthanum and cerium, 30-40 parts of raw heavy-rare-earth mineral powder containing yttrium, 32-38 parts of micro silicon powder, 17-19 parts of zirconium oxide, 20-24 parts of sodium borate, 1-3 parts of boron nitride, 0.2-0.3 part of titanium carbide, 0.4-0.5 part of tantalum carbide and 1-1.5 parts of addition agent; the addition agent is one or several of boric acid, strontium fluoride, calcium fluoride and aluminum fluoride. The preparing method includes the following steps that 1, the addition agent is subjected to dry ball grinding for 2 h-10 h; 2, the addition agent subjected to dry ball grinding and other materials are put into a bi-conical mixing machine to be fully mixed, and the mixing time is 20 h-40 h; 3, the mixture is screened through a 200-mesh screen and packaged, and the catalyst is obtained. Compared with the prior art, the catalyst is unique in component and simple in production technology; as rare earth elements are adulterated, the activity of the catalyst can be enhanced, the heat stability of the finished product can be improved, and the service life of the finished product can be prolonged.

Owner:张平

Method for preparing strontium fluoride or rare-earth doped strontium fluoride film by adopting electrolytic deposition

InactiveCN101892504BLow growth temperatureHigh crystallinityPolycrystalline material growthElectrolytic inorganic material coatingSodium ascorbateRare earth

The invention discloses a method for preparing a strontium fluoride or rare-earth doped strontium fluoride film by adopting electrolytic deposition. The method comprises the following steps of: 1) cleaning an ITO conductive glass twice or thrice by using acetone, then cleaning the ITO conductive glass in an ultrasonic cleaner for 10 to 30 minutes by using deionized water, activating the ITO conductive glass for 10 to 30 seconds in 10 percent nitric acid solution, and cleaning the ITO conductive glass by using the deionized water for later use; 2) adding sodium ascorbate and ammonium fluoride solution into compound solution of 0.01 to 0.5mol / L ethylene diamine tetraacetic acid and strontium ions, and adjusting the pH value to be between 6 and 9 to obtain electrolyte for later use; and 3) placing the ITO conductive glass serving as a working electrode, a platinum electrode serving as a counter electrode and a calomel electrode serving as a reference electrode into the electrolyte to perform electrolytic deposition so as to obtain the strontium fluoride film at an anode deposition potential of 0.8V to 1.4V relative to the calomel electrode. The method has the advantages of simple equipment, low cost and normal-pressure low temperature, is suitable for scientific research, and is expected to realize large-scale industrialized production.

Owner:ZHEJIANG UNIV

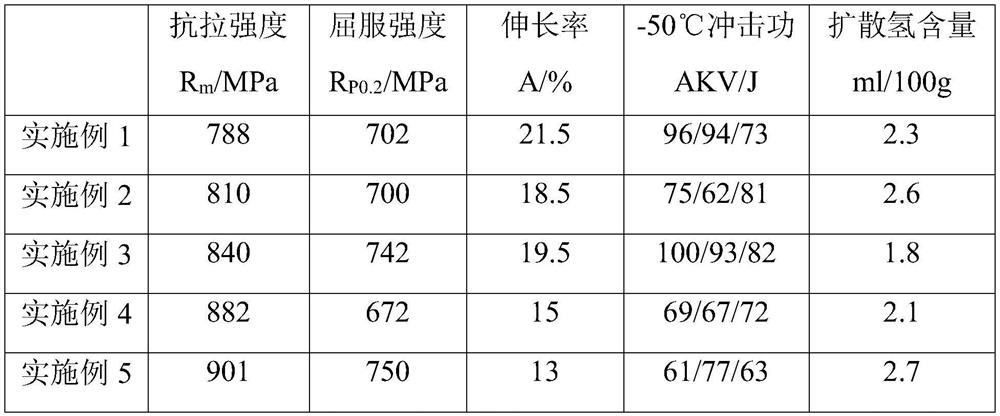

High-strength anti-cracking metal powder core type flux-cored wire for engineering machinery

ActiveCN114248040AImprove toughnessImprove mechanical propertiesWelding/cutting media/materialsProcess efficiency improvementFerrochromeZirconium alloy

The high-strength anti-cracking metal powder core type flux-cored wire for the engineering machinery comprises a steel belt and powder filled in the steel belt, and the powder comprises the following components in percentage by mass: 1.5-2.0% of silicon carbide, 10-14% of ferromanganese, 0.4-0.8% of silicon-barium alloy, 8-14% of nickel powder, 0-3% of ferrochromium, 1-4% of molybdenum powder, 0.3-0.4% of niobium-zirconium alloy, 0.2-0.5% of strontium fluoride, 0.2-0.5% of arc stabilizer and the balance of iron powder. And the balance of iron powder. The metal powder core type flux-cored wire has the excellent comprehensive mechanical properties of high strength, high toughness and the like, the tensile strength of the metal powder core type flux-cored wire is larger than or equal to 780 MPa, the yield strength of the metal powder core type flux-cored wire is larger than or equal to 670 MPa, and the impact energy at-50 DEG C is larger than or equal

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

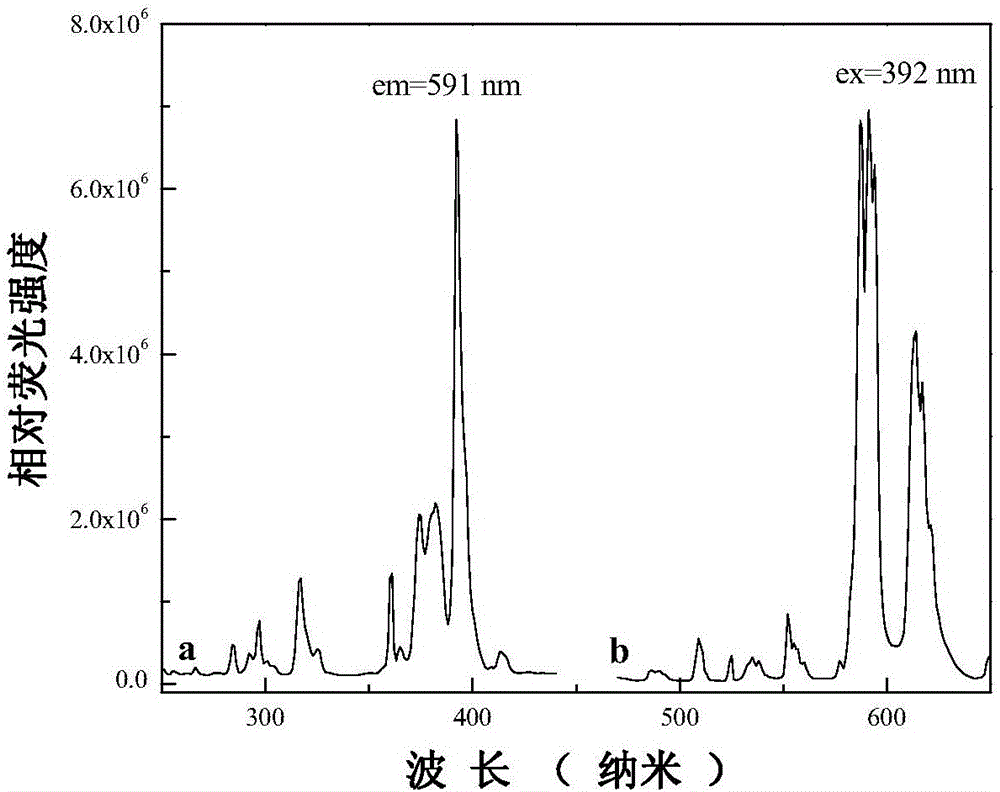

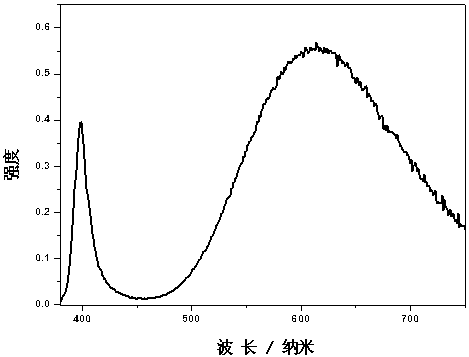

Orange-red rear-earth phosphors and preparation method thereof

InactiveCN103059843AStrong excitationStrong orange-red emissionLuminescent compositionsStrontium chloride hexahydrateStrontium bromide

The invention relates to orange-red rear-earth phosphors and a preparation method thereof. The orange-red rear-earth phosphors are prepared from strontium carbonate, calcium chloride, strontium chloride hexahydrate, strontium fluoride, strontium bromide, aluminum hydroxide, boric acid and europium oxide serving as raw materials by adopting a high-temperature solid state method. The preparation method comprises the following steps of: uniformly mixing the raw materials according to proportions, pre-sintering for 3-6 hours at 400-500 DEG C, cooling to a room temperature, taking out the raw materials and uniformly grinding again, reducing and sintering at a CO atmosphere for 4-10 hours at 1000-1200 DEG C, and grinding fine obtained sinters to obtain final products. The orange-red rear-earth phosphors have high luminous efficiency, good stability and very high quenching temperature and are suitable for InGaN chips giving out ultraviolet lights with about 400nm wavelength.

Owner:YUNNAN MINZU UNIV

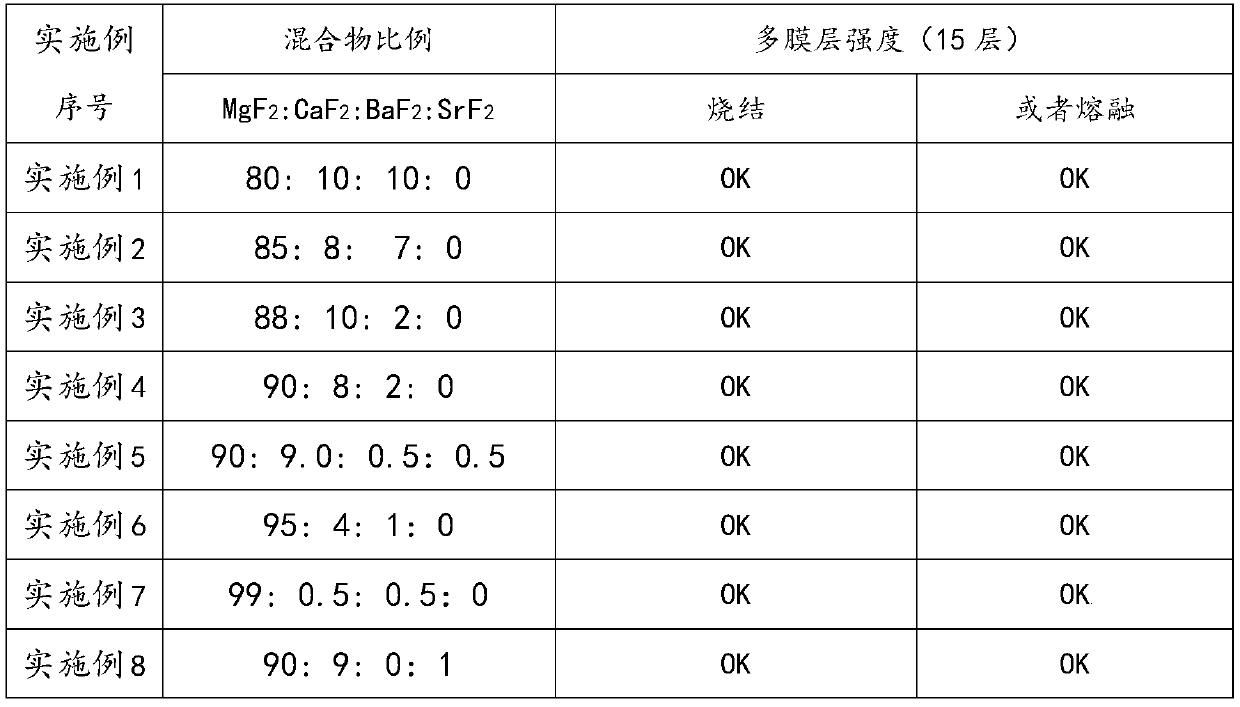

A low refractive index optical coating material with uniform film formation and preparation method thereof

ActiveCN107219567BReduce stressEnsure stabilityMirrorsVacuum evaporation coatingRefractive indexMaterials science

The invention provides a low-refractive-index optical film coating material of uniform film forming and a preparation method thereof, and belongs to the technical field of optical film coating material. The low-refractive-index optical film coating material is composed of magnesium fluoride and additive calcium fluoride, barium fluoride or strontium fluoride. The components of the low-refractive-index optical film coating material are prepared and mixed according to the weight ratio through granulation. The weight preparation of the low-refractive-index optical film coating material is listed as follows: 80-99.5 of magnesium fluoride and 0.5-20 of the total additive fluoride, and 3-6h sintering is performed under the temperature of over 800 DEG C. According to the film coating material, the magnesium fluoride and the calcium fluoride, the barium fluoride and the strontium fluoride are simultaneously evaporated and deposited on the optical surface in the process of depositing on the optical element, and the situation of oriented growth in the conventional deposition process of single magnesium fluoride is prevented because of the effect of the calcium fluoride, barium fluoride and strontium fluoride molecules so as to form optical film layers of low uniform stress, stability of multilayer films can be guaranteed in coating the multilayer films because of reduction of stress and the problem of film cracking of the multilayer films can be solved.

Owner:北京富兴凯永兴光电技术有限公司 +1

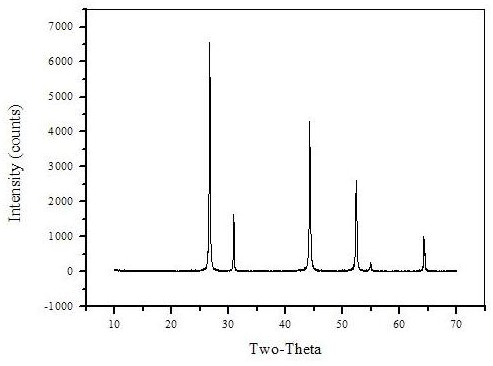

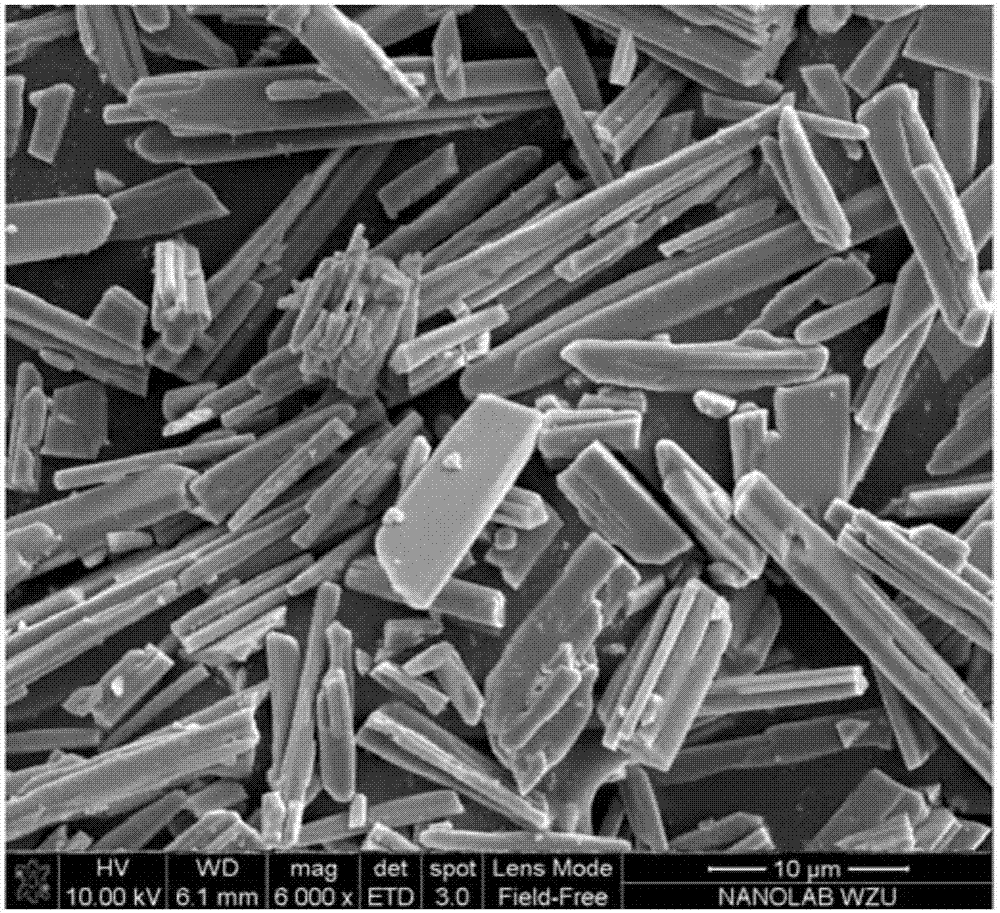

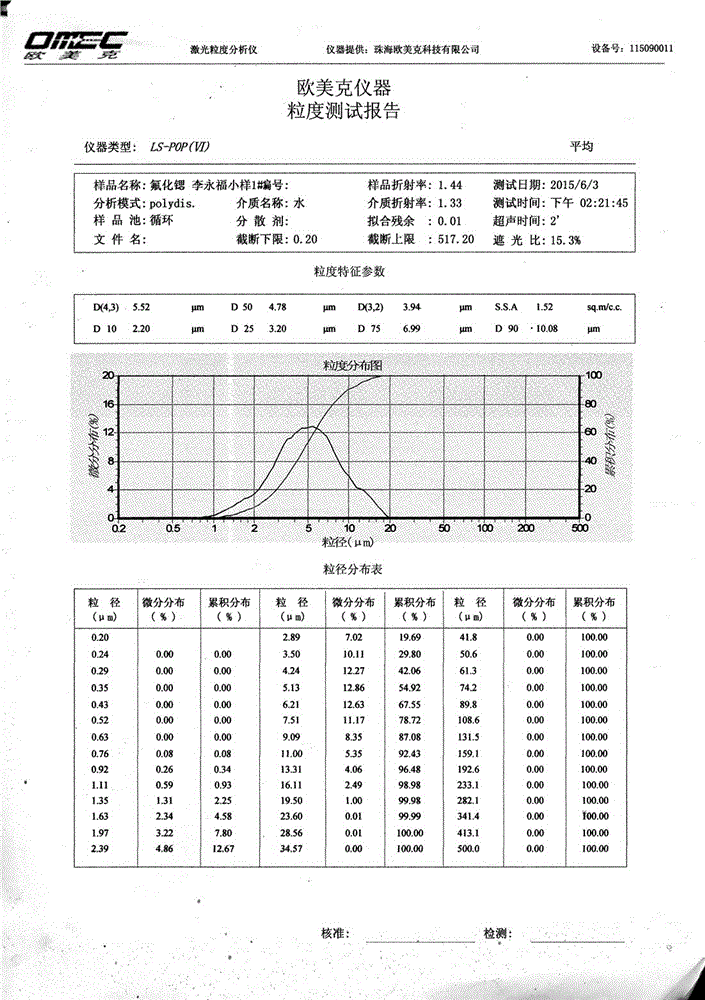

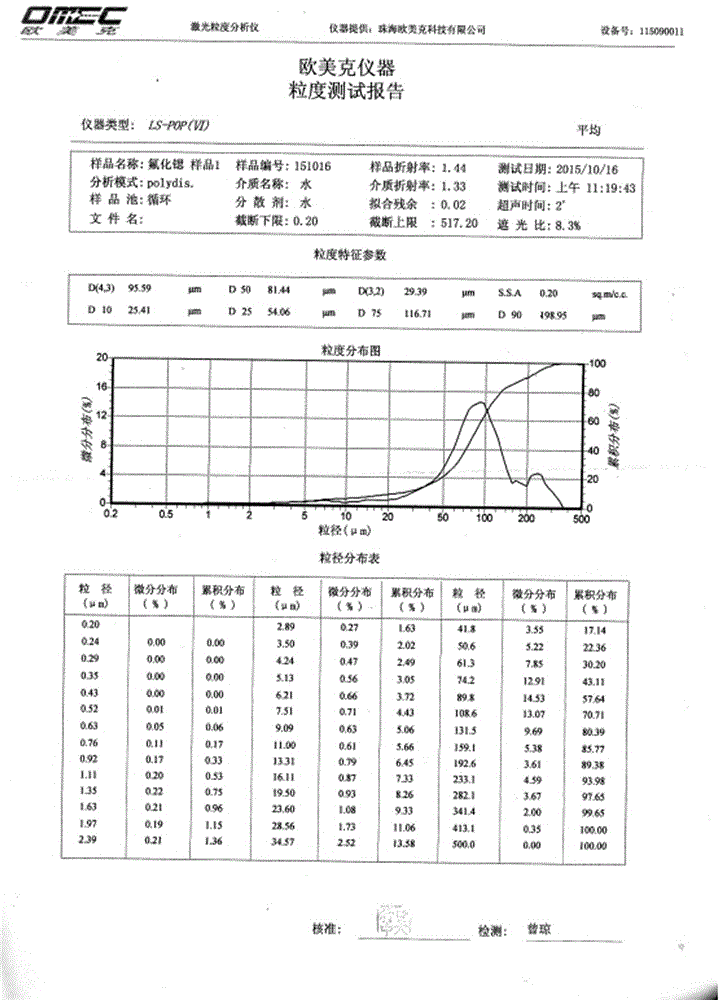

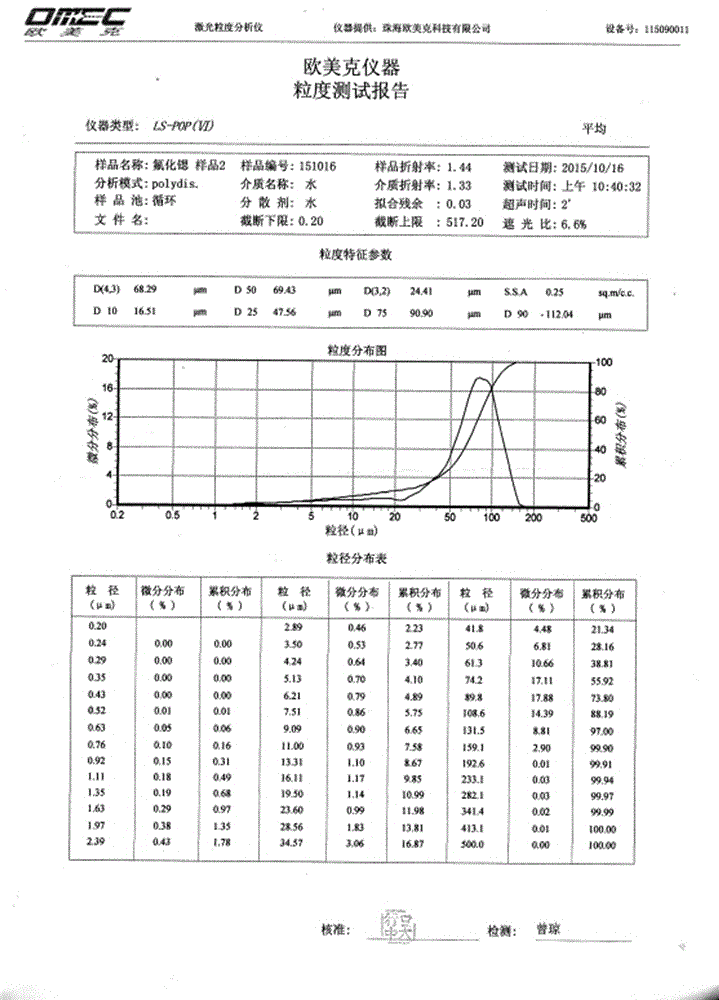

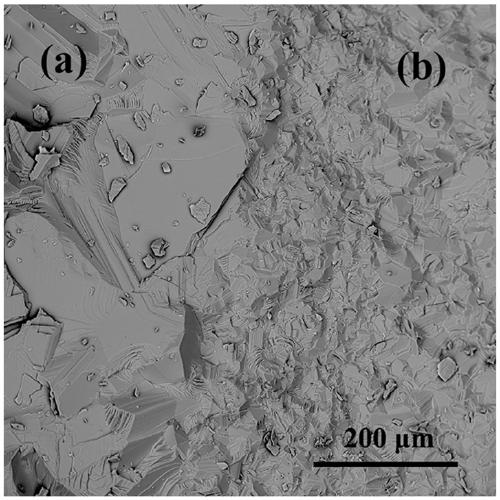

A kind of coarse grain strontium fluoride and its preparation method

ActiveCN105366704BThe preparation method is simple and easyEasy to operateCalcium/strontium/barium fluoridesHydrofluoric acidStrontium fluoride

The invention relates to the field of chemical industry, particularly a coarse grain strontium fluoride and a preparation method therefor. The preparation method comprises the steps of: performing a reaction on a strontium chloride solution and a hydrofluoric acid solution to obtain strontium fluoride; then using ammonia gas as a precipitator to slowly precipitate the strontium fluoride; utilizing a property that strontium fluoride dissolves in hydrochloric acid in an initial stage of synthesizing strontium fluoride, dissolving the strontium fluoride in hydrochloric acid rather than arising precipitation immediately; and then stepwise neutralizing acid therein by diluted ammonia to precipitate strontium fluoride stepwise and uniformly, thus growing the grains to obtain a large-grain crystal product, and the grain size of over 70% of prepared strontium fluoride particles can reach 50-150[mu]m,. The preparation method is simple, easy to operate, short in production period and high in production efficiency.

Owner:SICHUAN HUANAN INORGANIC SALTS CO LTD

Neodymium-doped strontium fluoride laser transparent ceramic and preparation method thereof

Owner:WUHAN UNIV OF TECH

Nanometer ball with strontium fluoride and production thereof

InactiveCN100393622CRaw materials are easy to obtainMild conditionsCalcium/strontium/barium fluoridesStrontium fluorideAlcohol

A strontium fluoride ball and its production are disclosed. The procedure includes preparing ammonium fluoride solution with concentration 5.0-38g / L, preparing strontium nitrate solution with concentration 4.5-105g / L, adding ammonium fluoride solution into strontium nitrate solution in proportion=2:1, precipitating out deposits with ultrasonic 6-30mins, centrifugal separating out deposits, washing by water and alcohol, and vacuum drying at room temperature to obtain white powdery SrF2 nanometer ball.

Owner:NANJING UNIV +1

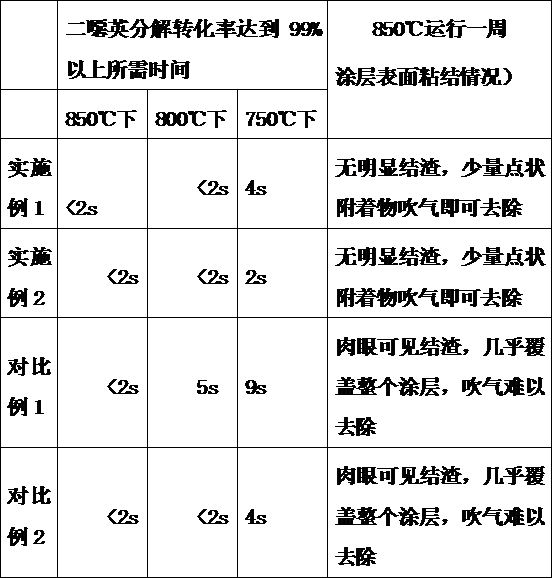

High-temperature anti-sticking coating capable of catalytically decomposing dioxins

ActiveCN113969071AExcellent anti-adhesion performanceRealize purple light emissionFireproof paintsAnti-corrosive paintsOptical radiationUltraviolet lights

The invention relates to a high-temperature anti-sticking coating capable of catalytically decomposing dioxins. The high-temperature anti-sticking coating is prepared from the following components in percentage by weight: 35 to 70 percent of a ceramic filler, 15 to 55 percent of a binder and 0.5 to 5 percent of Yb / Tm co-doped fluoride nanocrystal. In the Yb / Tm co-doped fluoride nanocrystal, in terms of 100 mol% of fluoride, the doping amount of Tm is 0.1 to 2 mol%, and the doping amount of Yb is 0.5 to 5 mol%; the average particle size of the nanocrystal is 20-100 nm, and the nanocrystal can absorb visible light or infrared light and convert the visible light or infrared light into ultraviolet light. The characteristic that Yb / Tm co-doped fluoride nanocrystals absorb visible light / infrared light to generate up-conversion luminescence is utilized, purple light emission is achieved, then the photolysis reaction of dioxins is caused, and visible light and infrared light radiation generated by incineration of the incinerator is also recycled to a certain extent. Fluoride is selected from calcium fluoride, barium fluoride and strontium fluoride, is not only a good luminescent material matrix, but also a good lubricating material, and has a remarkable effect on the anti-bonding performance of the coating.

Owner:深圳优易材料科技有限公司

A method of manufacturing impact-resistant soft non-weft fabric

ActiveCN104999748BHigh bonding strengthHigh densitySynthetic resin layered productsLaminationBond densityAdhesive

The invention discloses a manufacturing method of anti-impact soft no-woven cloth. The method comprises the steps that 1, fiber adhesive dipping is conducted, and hot-pressing is conducted on single-fiber layers; 2, hot-pressing is conducted on two-layer composite fiber layers; 3, hot-pressing is conducted on two-layer composite fiber layers with two to four rolls to prepare the anti-impact soft no-woven cloth with four to eight composite fiber layers, wherein adhesives used in the method comprises ethylene vinyl acetate copolymers, waterborne polyurethane resin, terpene resin, polyethylene glycol, o-methoxyhydroquinone and strontium fluoride. According to the manufacturing method of the anti-impact soft no-woven cloth, the adhesives are improved, a multi-component composite formula is adopted, the bonding strength and the bonding density of the adhesives on fibers are effectively improved, and the tenacity and the anti-impact property of the no-woven cloth are improved; freezing and unfreezing are conducted on the fibers which are dipped in the adhesives, the internal stress and the surface tension of the adhesives are effectively decreased, and hot-pressed composite fiber layers have higher strength and anti-impact capacity.

Owner:CHANGSHU YONGLIJIAN NEW MATERIALS

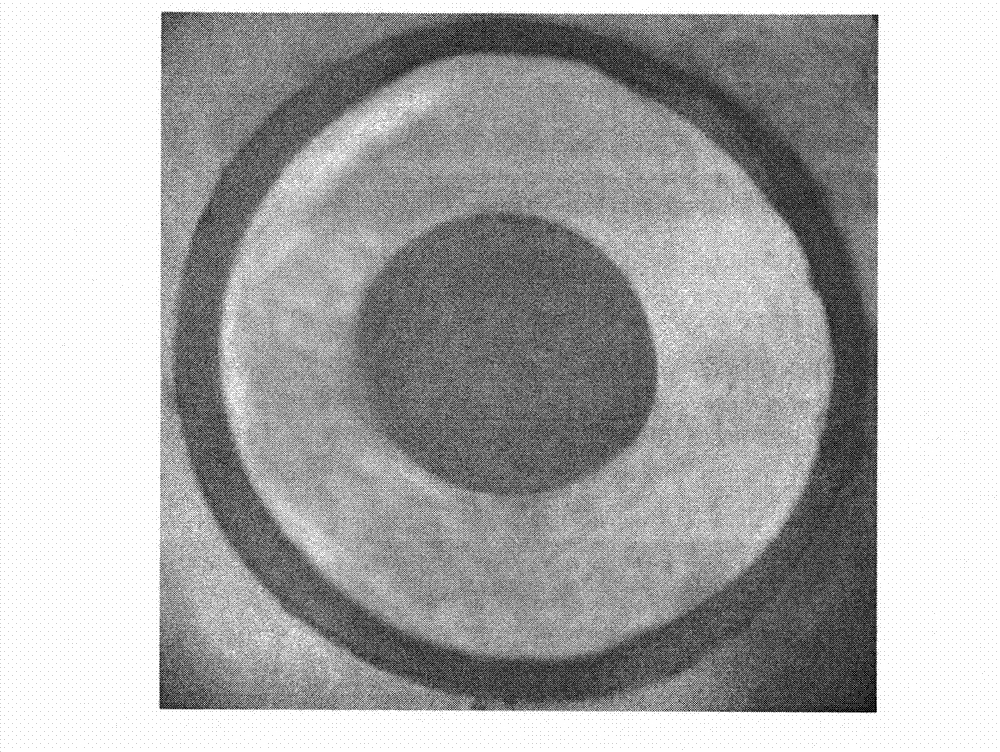

Preparation method for strontium fluoride optical material with composite structure

PendingCN111362699AImprove thermal conductivityReduce thermal effectsActive medium materialLaser technologyStrontium fluoride

The invention discloses a preparation method for a strontium fluoride optical material with a composite structure. The preparation method comprises the following specific steps: 1) synthesizing pure strontium fluoride (SrF2) powder by adopting a chemical precipitation method, and mixing the SrF2 powder with rare earth fluoride ReF3 powder; 2) carrying out primary molding on obtained mixed powder,and carrying out isostatic cool pressing treatment so as to obtain a green body with a composite structure; 3) putting the green body into a mold, and putting the mold into a vacuum furnace for pressurization sintering; and 4) after sintering is finished, taking a sample out of the vacuum furnace, and carrying out polishing treatment so as to obtain the strontium fluoride optical material with thecomposite structure. Compared with a conventional single-structure strontium fluoride optical material in which components including strontium fluoride crystals and ceramics are uniformly distributed, the strontium fluoride optical material with the composite structure provided by the invention has the following advantages: through the design of the composite structure, the thermal conductivity of the optical material can be improved; generated heat can be conducted out of the body more quickly in laser application; the thermal effect of the optical material is relieved; and the strontium fluoride optical material is more competitive in application in the fields of high-power laser technology and the like.

Owner:XINYANG NORMAL UNIVERSITY

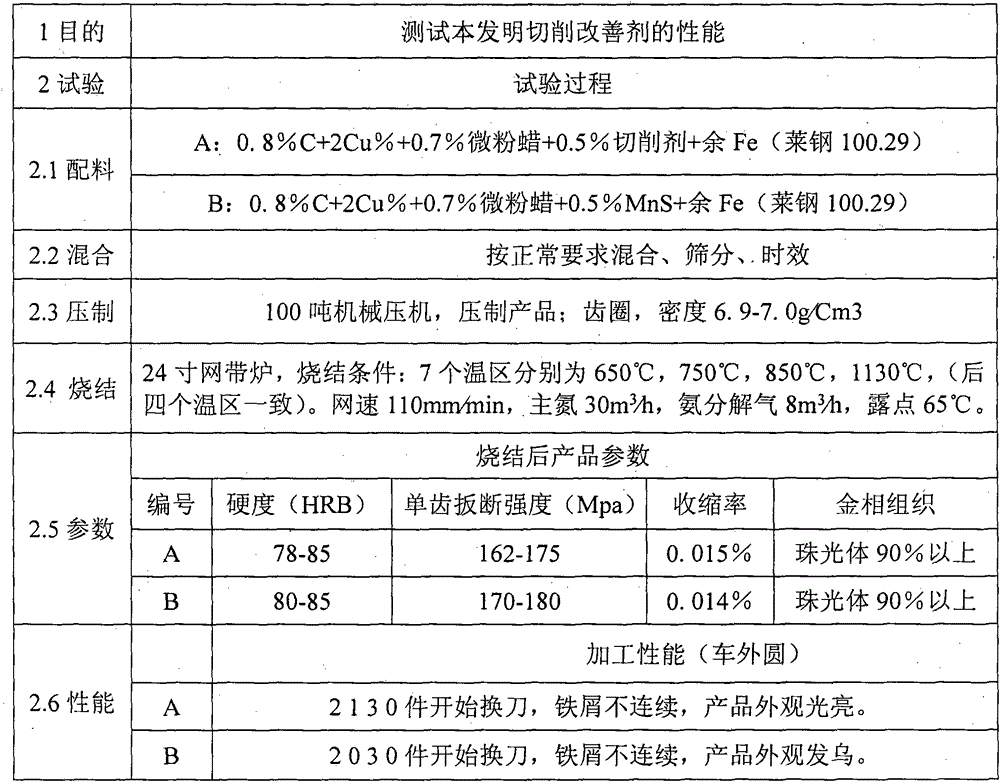

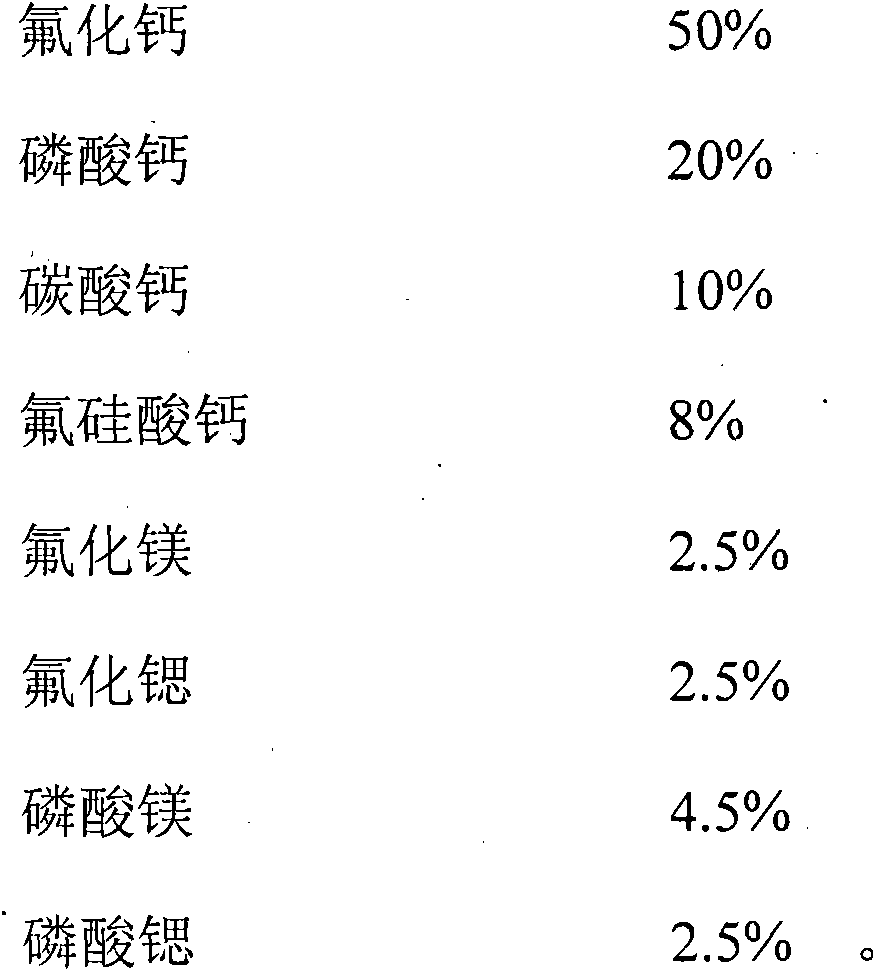

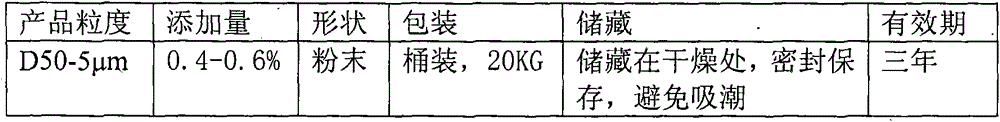

Cutting improver and preparation method thereof

InactiveCN104625042AReduce intermittent impactExtended service lifeMagnesium phosphateMagnesium orthophosphate

The invention discloses a cutting improver and a preparation method of the cutting improver. The cutting improver solves the problem that the strength and toughness of materials are reduced when existing improvers are added. The cutting improver comprises, by weight, 50% of calcium fluoride, 20% of calcium phosphate, 10% of calcium carbonate, 8% of calcium fluosilicate, 2.5% of magnesium fluoride, 2.5% of strontium fluoride, 2.5% of magnesium phosphate and 2.5% of strontium phosphate. The cutting improver solves the problem that the strength and toughness of materials are reduced when existing improvers are added. The cutting improver is applied to the field of various products such as iron-based products, copper-based products, stainless steel-based products and powder metallurgy products formed in common molding, injection molding, hot press molding and other modes.

Owner:莱芜市冠隆纳米科技有限公司

Glass ceramic composition and its preparation method and application

ActiveCN109020200BHigh densityImprove flexural strengthGlass shaping apparatusStrontium fluorideSodium fluoride

The invention discloses a glass ceramic composition, comprising: 25-35 parts of glass, 3-8 parts of zinc oxide, 5-20 parts of sodium fluoride, 10-15 parts of strontium fluoride, 15-25 parts of magnesium oxide, 15 parts of potassium carbonate ~25 parts, shell powder 35~50 parts, mica powder 10~30 parts. The invention discloses a method for preparing a glass-ceramic composition, which comprises the following steps: after the mixture of raw materials is ground uniformly, the mixture is melted and kept warm to form a mixed solution, and cooled and molded to obtain a precursor glass; the precursor glass is crushed, A precursor glass powder is obtained; the precursor glass powder is mixed with a toughening agent, and sintered in an atmosphere of protective gas to obtain the glass ceramics.

Owner:JILIN TEACHERS INST OF ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com