Two-phase stainless steel electrode

A technology of duplex stainless steel and welding rod, which is applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems that the low temperature impact toughness can not meet the needs, the performance of duplex stainless steel welding material is not stable enough, etc. Excellent performance, good resistance to intergranular corrosion, good weld forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

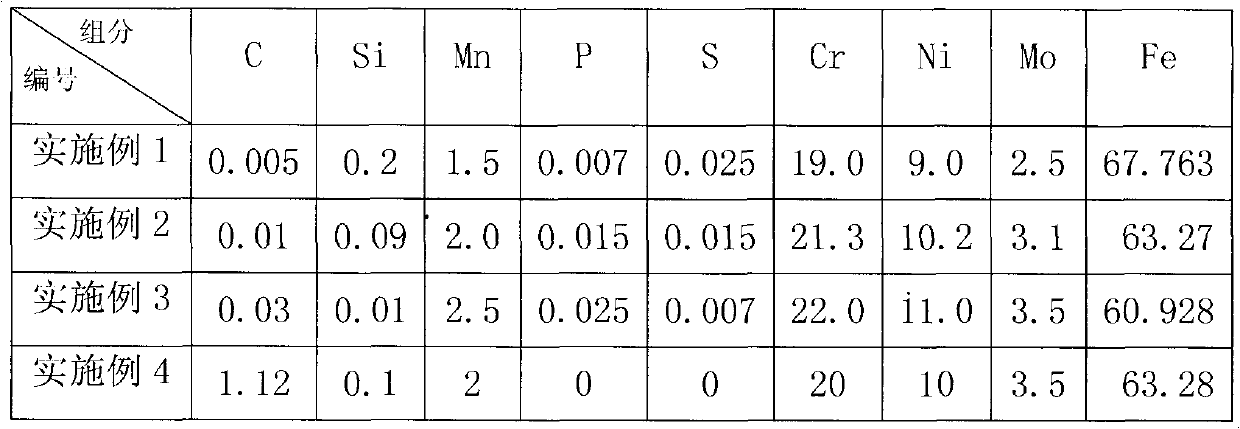

[0042] The present invention comprises welding core and coating, and its welding core composition is as follows table (% by weight):

[0043] C

Si

mn

P

S

0.005-0.03

0.01-0.2

1.5-2.5

0-0.025

0-0.025

Cr

Ni

Mo

Fe

19-22

9-11

2.5-3.5

margin

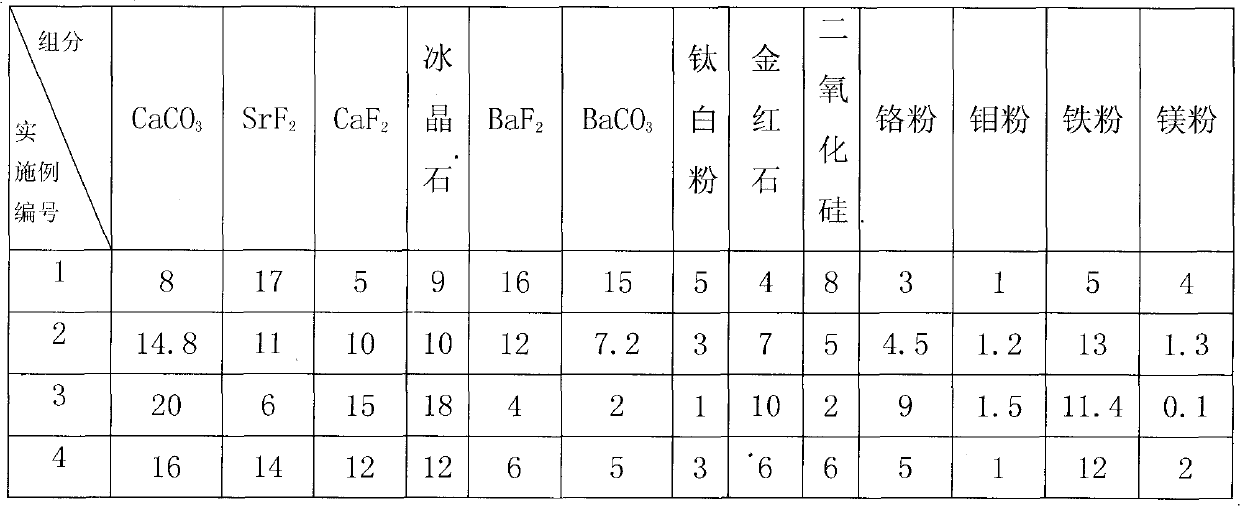

[0044] Its drug skin composition is as follows (% by weight):

[0045] CaCO 3

SrF 2

CaF 2

BaF 2

BaCO 3

Titanium dioxide

8-20

6-17

5-15

9-18

4-16

2-15

1-5

silica

Chrome powder

Molybdenum powder

Magnesium powder

4-10

2-8

3-9

1-1.5

5-13

0.1-4

[0046] The present invention adopts duplex stainless steel wire as the welding core, and is manufactured by using a general hand welding rod manufacturing process. Understand t...

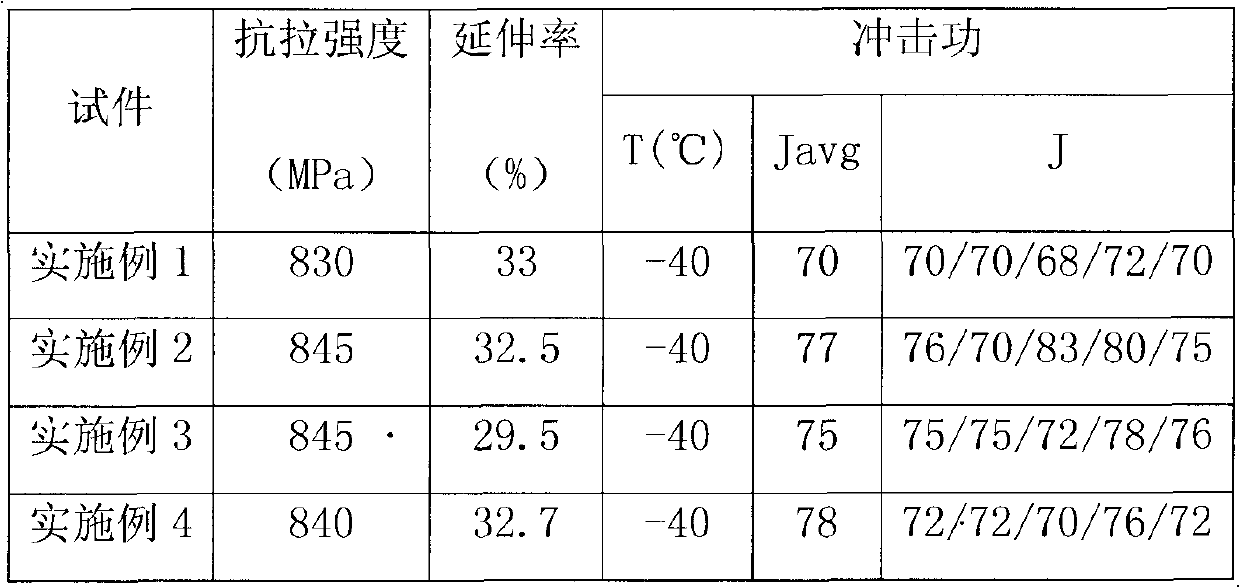

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com