Dense homogeneous fluoride films for DUV elements and method of preparing same

A fluoride, optical element technology, applied in optical elements, instruments, vacuum evaporation coating, etc., can solve the problems of surface/interface roughness and non-uniformity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

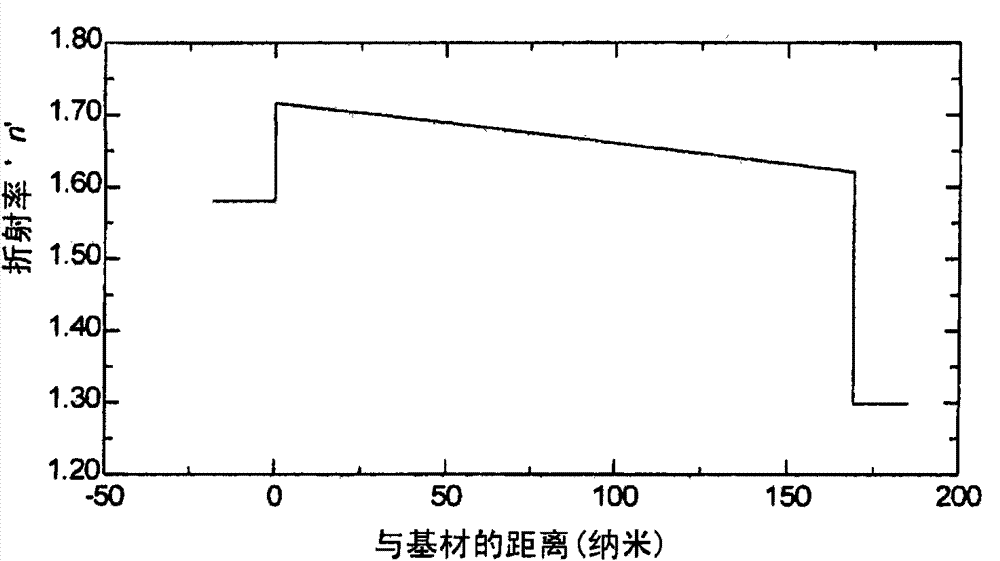

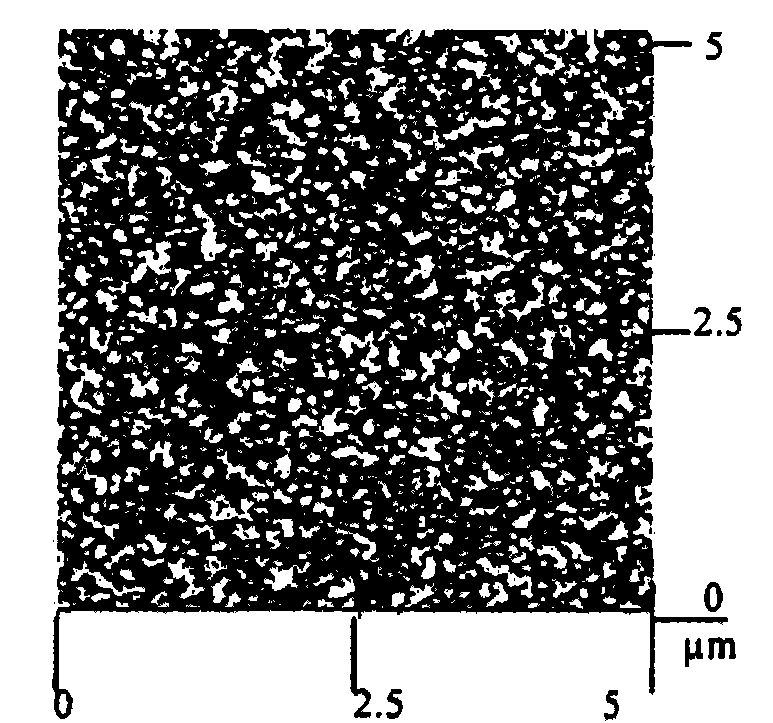

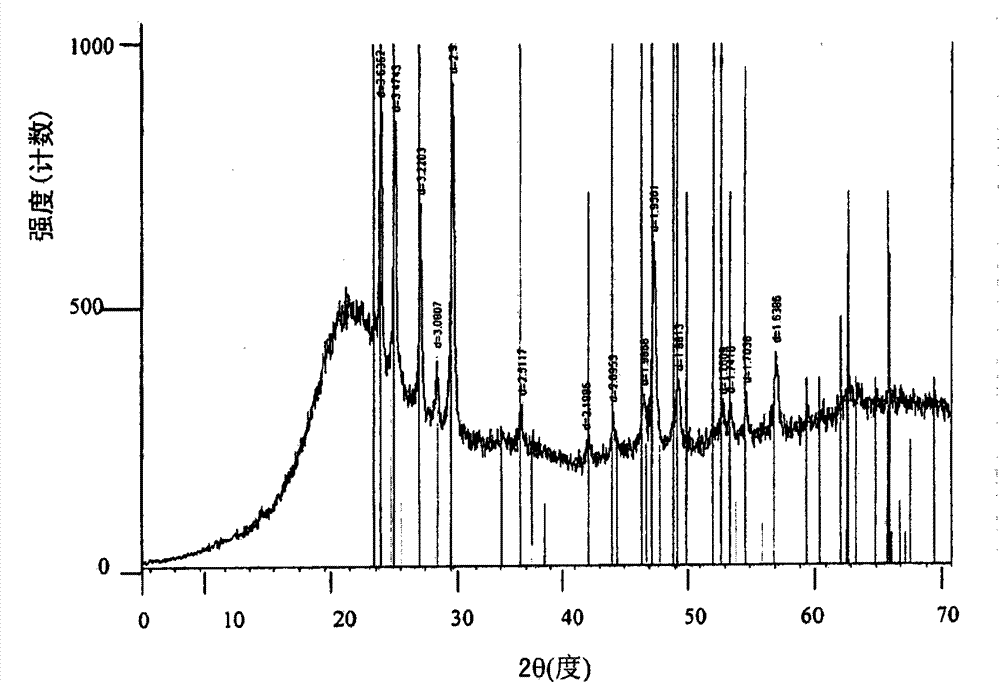

[0032] The present invention relates to optical elements (also referred to as substrates) coated with dense uniform fluoride films, and to methods of making such coated elements. The coating is a high ("H") index fluoride material and a low ("L") index material that co-evaporate to form a coating of L-H mixture (L-H layer, coating of co-deposited L and H materials). Fluorides of lanthanide metals (such as neodymium, lanthanum, dysprosium, yttrium, and gadolinium, and combinations thereof) are preferred metal fluorides for high refractive index materials, lanthanum fluoride (LaF 3 ) and gadolinium fluoride (GdF 3 ) is particularly preferred. Aluminum fluoride (AlF 3 ) and alkaline earth metal fluorides (calcium, magnesium, barium and strontium fluorides) are preferred low refractive index materials, magnesium fluoride (MgF 2 ) is the preferred alkaline earth metal fluoride. High refractive index materials have a refractive index of 1.55-1.75. The low refractive index mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com