Nanometer ball with strontium fluoride and production thereof

A micron-sphere and sub-micron technology, applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., to achieve the effect of short time-consuming, easy-to-obtain and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. SrF 2 Sub-micron preparation:

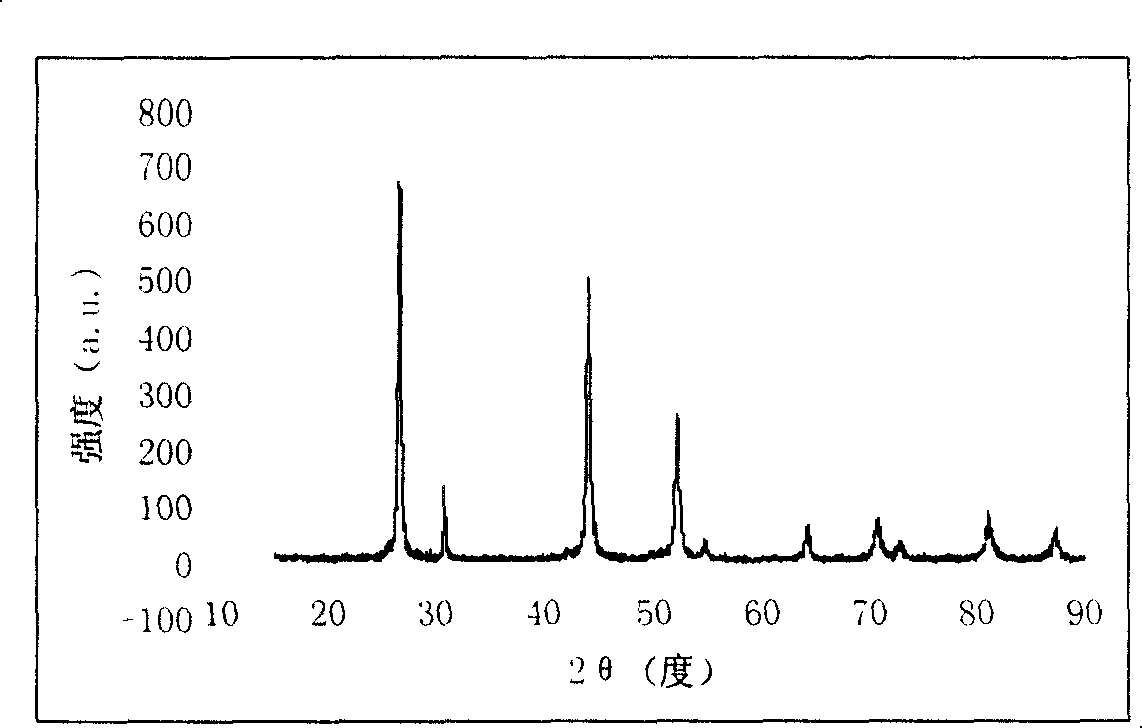

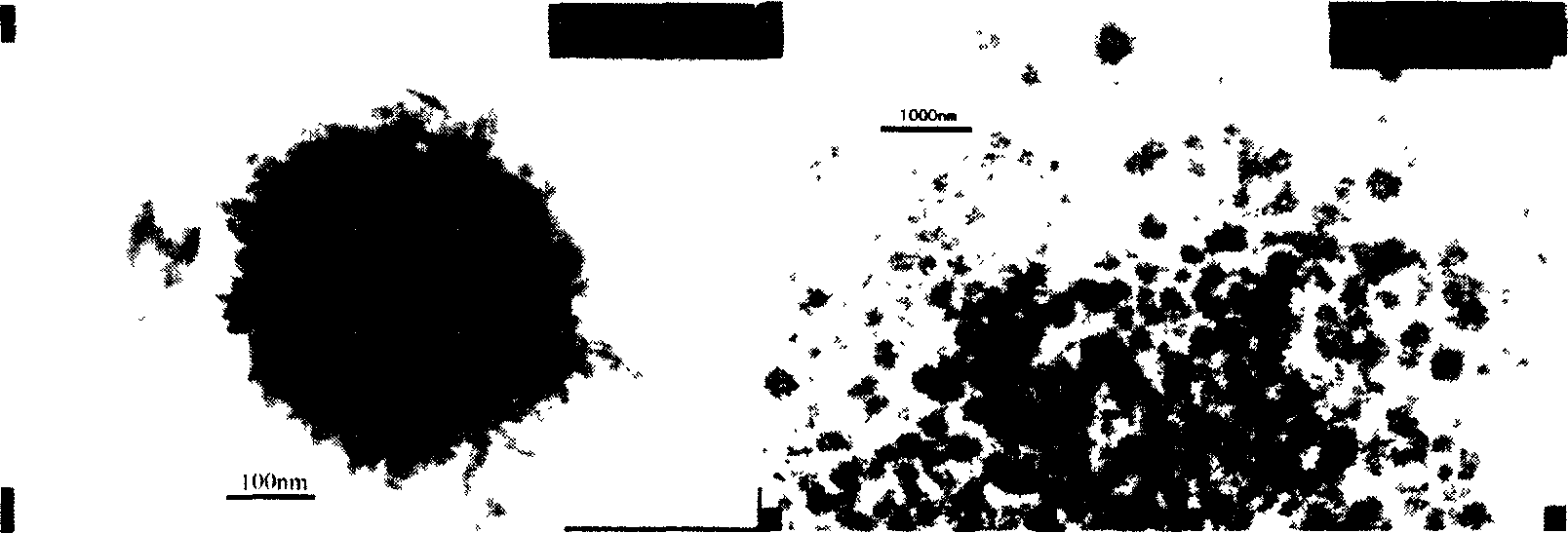

[0020] Add 60ml H to a 100ml round bottom flask 2 O and 1.06g Sr(NO 3 ) 2 Then, add 20ml of 0.40g ammonium fluoride aqueous solution, and place the system in a JY92-2D ultrasonic instrument (ultrasonic frequency 20kHz) produced by Ningbo Xinzhi Institute of Apparatus, and set the power at room temperature and normal pressure. It is 600W, ultrasonic for 30min. After the reaction, the product was centrifuged, the precipitate was washed successively with distilled water and ethanol, and the obtained precipitate was dried under vacuum and at room temperature to obtain a white powder, namely SrF 2 Submicron. Powder XRD results (see attached figure 1 ) Indicates that it is pure cubic SrF 2 . The position and intensity of the peaks match the literature values [see: Joint Committee on Powder Diffraction Standards, File No 06-0262.]. No impurity peak was found, indicating that the purity of the product is relatively high. Photo via TEM (...

Embodiment 2

[0021] Example 2. SrF 2 Preparation of submicron and microspheres

[0022] Add 60ml H to a 100ml round bottom flask 2 O and 0.27g Sr(NO 3 ) 2 Then, add 20 ml of an aqueous solution containing 0.10 g of ammonium fluoride. This system was placed in a JY92-2D ultrasonic instrument (ultrasonic frequency: 24-25kHz) produced by Ningbo Xinzhi Institute of Apparatus, and the power was set to 600W under normal pressure at room temperature and ultrasonic for 30 minutes. The product was centrifuged, the precipitate was washed sequentially with distilled water and ethanol, and the resulting precipitate was vacuum dried at room temperature to obtain a white powder, namely SrF 2 Sub-micron and micron spheres. The powder XRD results show that it is pure cubic SrF 2 . The position and intensity of the peak match the literature value [see: Joint Committee on Powder Diffraction Standards (JCPDS), File No 06-0262.]. No impurity peak was found, indicating that the purity of the product is relatively ...

Embodiment 3

[0023] Example 3. SrF 2 Sub-micron preparation

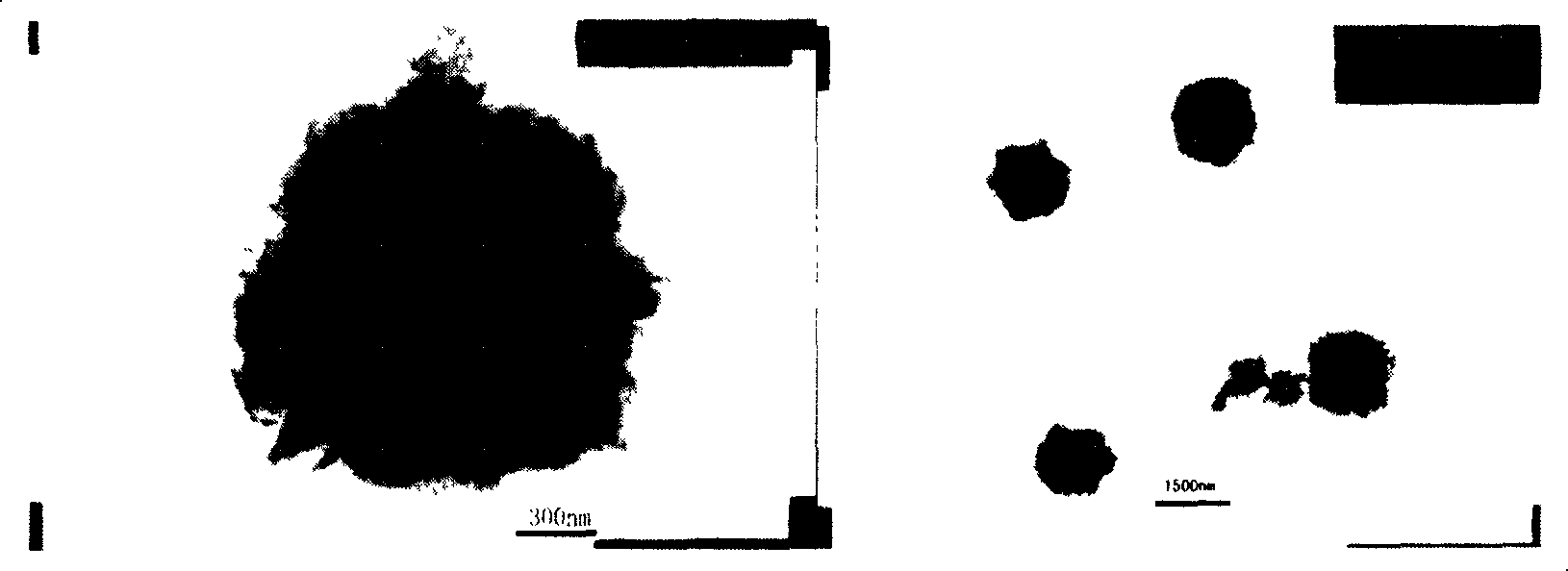

[0024] Add 60ml H to a 100ml round bottom flask 2 O and 2.11g Sr(NO 3 ) 2 Then, add 20ml containing 0.75g of ammonium fluoride aqueous solution. This system is placed in a JY92-2D ultrasonic instrument (ultrasonic frequency 20kHz) produced by Zhejiang Ningbo Xinzhi Institute of Apparatus, at room temperature and normal pressure, the power is set to 600W, and the ultrasonic is 30min. The product was centrifuged, the precipitate was washed sequentially with distilled water and ethanol, and the resulting precipitate was vacuum dried at room temperature to obtain a white powder, namely SrF 2 Submicron. The powder XRD results show that it is pure cubic SrF 2 . The position and intensity of the peaks match the literature values [see: Joint Committee on Powder Diffraction Standards (JCPDS), File No 06-0262.]. No impurity peak was found, indicating that the purity of the product is relatively high. Photo via TEM ( Figure 2-3 ), the SrF o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com