Glass ceramic composition and its preparation method and application

A glass-ceramic and glass technology, applied in the field of glass-ceramic composition and its preparation, can solve the problems of high technical requirements, low yield, low mechanical strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of the glass-ceramic composition, comprising the steps of:

[0045] After the mixture of raw materials is ground evenly, the mixture is melted and kept warm to form a mixed solution, which is cooled and molded to obtain a precursor glass;

[0046] crushing the precursor glass to obtain precursor glass powder;

[0047] mixing the precursor glass powder and a toughening agent, and sintering in an atmosphere of protective gas to obtain the glass ceramic;

[0048] Among them, the raw materials are selected according to the following parts by weight: 25-35 parts of glass, 3-8 parts of zinc oxide, 5-20 parts of sodium fluoride, 10-15 parts of strontium fluoride, 15-25 parts of magnesium oxide, 15-25 parts of potassium carbonate 25 parts, shell powder 35-50 parts, mica powder 10-30 parts; and

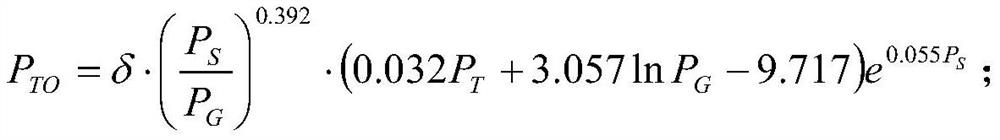

[0049] Wherein, the toughening agent parts by weight P TO Control is:

[0050]

[0051] In the formula, P S is the numbe...

Embodiment 1

[0071] The preparation method of the glass-ceramic composition provided by the invention comprises the following steps:

[0072] Step 1. Weigh raw materials according to the following parts by weight: 25 parts of glass, 3 parts of zinc oxide, 5 parts of sodium fluoride, 10 parts of strontium fluoride, 15 parts of magnesium oxide, 15 parts of potassium carbonate, 35 parts of shell powder, 10 parts of mica powder share;

[0073] Step 2, milling the weighed raw materials with a ball milling tank, the milling medium is absolute ethanol, drying and sieving after ball milling;

[0074] Step 3. Put the ball-milled raw materials into the flip mixer, then preheat the mixed raw materials at 350°C and melt for 2.5 hours, and quickly pour the evenly melted glass liquid into the metal mold preheated at 370°C , cooling to obtain a precursor glass, then ball milling the precursor glass, drying at 100°C for 24 hours, and passing through a 100-mesh sieve to obtain a precursor glass powder;

...

Embodiment 2

[0091] The preparation method of the glass-ceramic composition provided by the invention comprises the following steps:

[0092] Step 1. Weigh raw materials according to the following parts by weight: 35 parts of glass, 8 parts of zinc oxide, 20 parts of sodium fluoride, 15 parts of strontium fluoride, 25 parts of magnesium oxide, 25 parts of potassium carbonate, 50 parts of shell powder, 30 parts of mica powder share;

[0093] Step 2, milling the weighed raw materials with a ball milling tank, the milling medium is absolute ethanol, drying and sieving after ball milling;

[0094] Step 3. Put the ball-milled raw materials into the flip mixer, and then preheat the mixed raw materials at 550°C and melt them for 4 hours, and quickly pour the evenly melted glass liquid into the metal mold preheated at 550°C , cooling to obtain a precursor glass, then ball milling the precursor glass, drying at 100°C for 24 hours, and passing through a 100-mesh sieve to obtain a precursor glass po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com