Aramid fiber-ultrahigh molecular weight polyethylene composite sheet material processing method

A technology of ultra-high molecular weight and composite boards, which is applied in the field of polymer composite boards. It can solve the problems of light resistance, poor water and chemical properties, large fracture extension, and high temperature resistance, so as to improve anti-aging performance, reduce stress and Surface tension, effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below, so that those skilled in the art can implement it with reference to the text of the description.

[0026] As an embodiment of this case, the processing method of aramid and ultra-high molecular weight polyethylene composite sheet includes the following steps:

[0027] Step 1) Dip the aramid filaments evenly spread into the glue tank containing the first adhesive, spread the dipped aramid filaments on the surface of the release material, and compound the aramid with the release material The filament is drawn by the feeding system into the drying equipment for drying, and then rewinded to obtain a roll of rubber-containing mono-aramid layer;

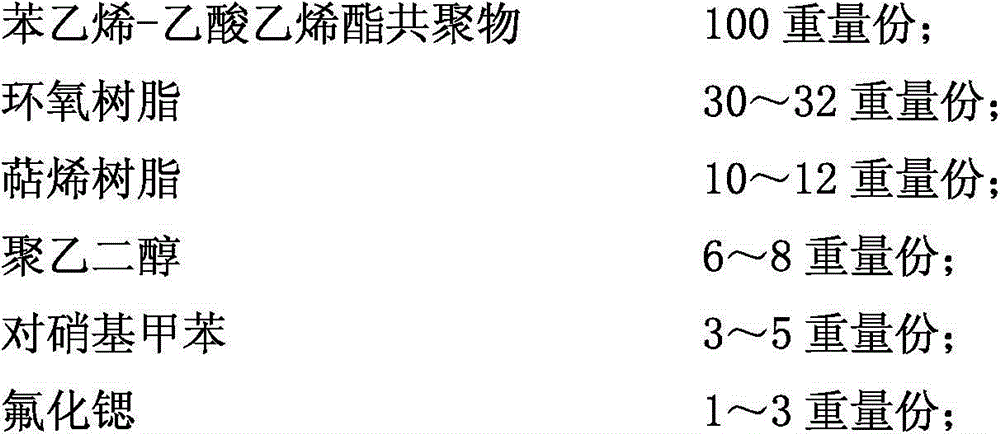

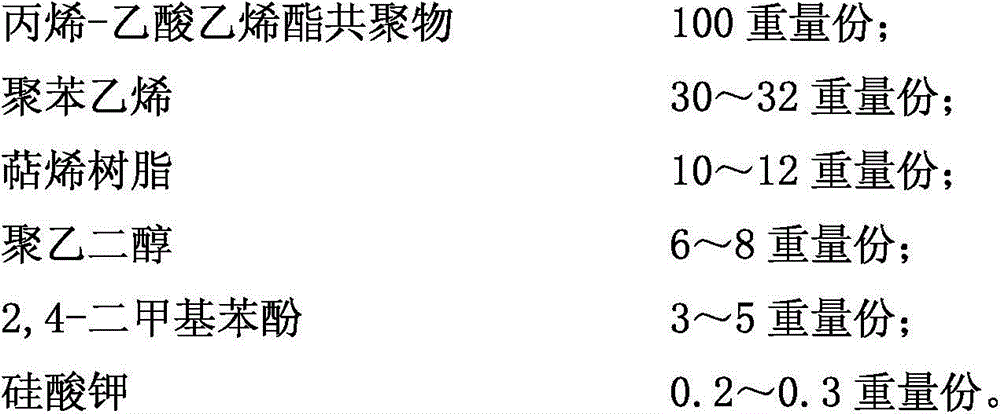

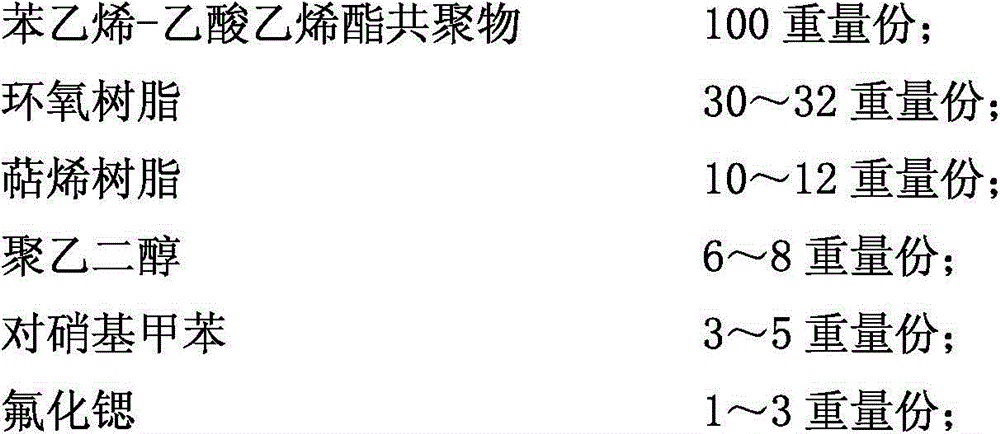

[0028] Step 2) Dip the ultra-high molecular weight polyethylene filaments uniformly spread into the glue tank containing the second adhesive, and lay the dipped polyethylene filaments on the surface of the release material to compound the release material The polyethylene fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com