High-temperature anti-sticking coating capable of catalytically decomposing dioxins

A technology of catalytic decomposition and anti-stick coating, applied in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problem of insufficient utilization of energy, and achieve the effect of reducing energy consumption, improving decomposition efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

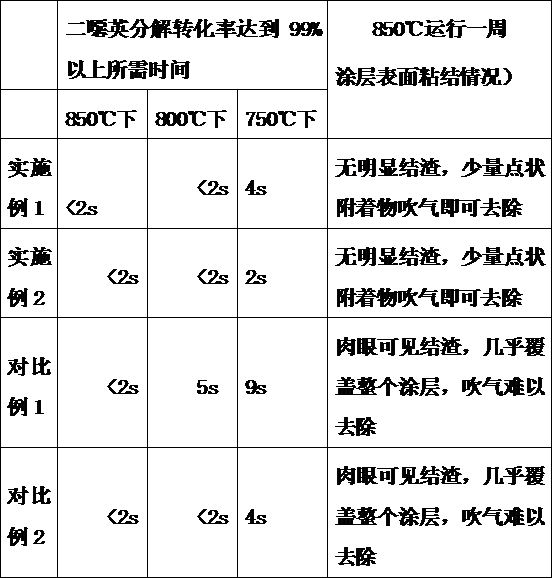

Examples

Embodiment 1

[0033] A high-temperature anti-sticking coating that can catalyze and decompose dioxins, comprising the following components: 55wt% ceramic filler, 35wt% binder, 1.2wt% Yb / Tm co-doped fluoride nanocrystals, and the balance is water; In the Yb / Tm co-doped fluoride nanocrystal, based on 100mol% of fluoride, the doping amount of Tm is 0.5mol%, and the doping amount of Yb is 2mol%; the average particle size of the nanocrystal is 70nm.

[0034] The filler composition is: 50% alumina, 2% zirconium silicate, 3% zirconia; 1% mica powder; 2% carbon nanotubes; 0.8% graphene; 0.3% yttrium oxide; 0.4% cerium oxide; 2% oxide Palladium; 2% V 2 o 5 ;1%TiO 2 , wherein the particle size of zirconium silicate is 45nm, and the particle size of zirconia is 20 microns.

[0035] The coating preparation method comprises the following steps:

[0036] (1) Mix and stir the ceramic filler, binder, and water to obtain a mixture; (2) Add fluoride nanocrystals to the mixture and mix evenly to obtain a ...

Embodiment 2

[0038] Compared with Example 1, 1wt% Er-doped fluoride nanocrystals were also added. In the Er-doped fluoride nanocrystal, the Er doping amount is 0.3mol% based on 100mol% of fluoride; the average particle size of the nanocrystal is 55nm. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com