A method of manufacturing impact-resistant soft non-weft fabric

A manufacturing method, the technology of non-woven fabrics, applied in the field of non-woven fabrics, can solve the problems of light resistance, poor water and chemical properties, large fracture extension, and high temperature resistance, so as to reduce stress and surface tension, improve toughness and Effects of impact resistance, high strength and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

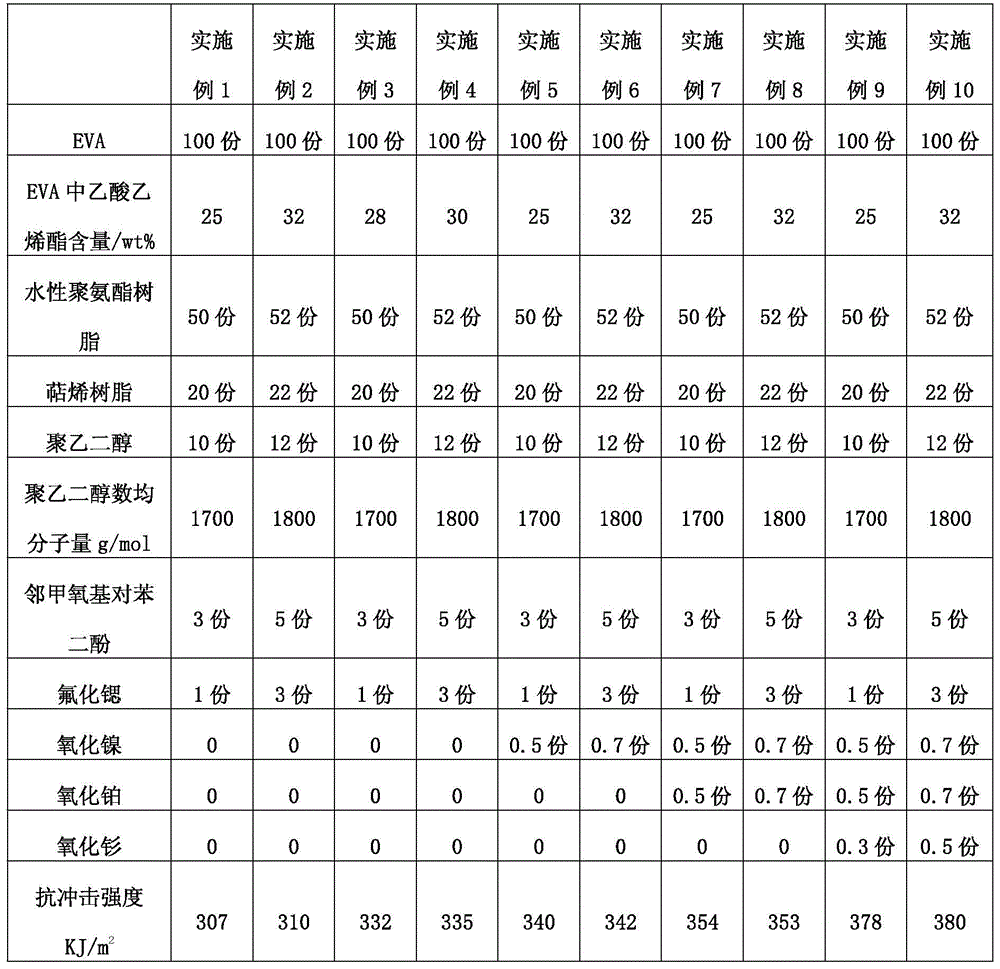

[0021] The present invention will be described in further detail below, so that those skilled in the art can implement it with reference to the description.

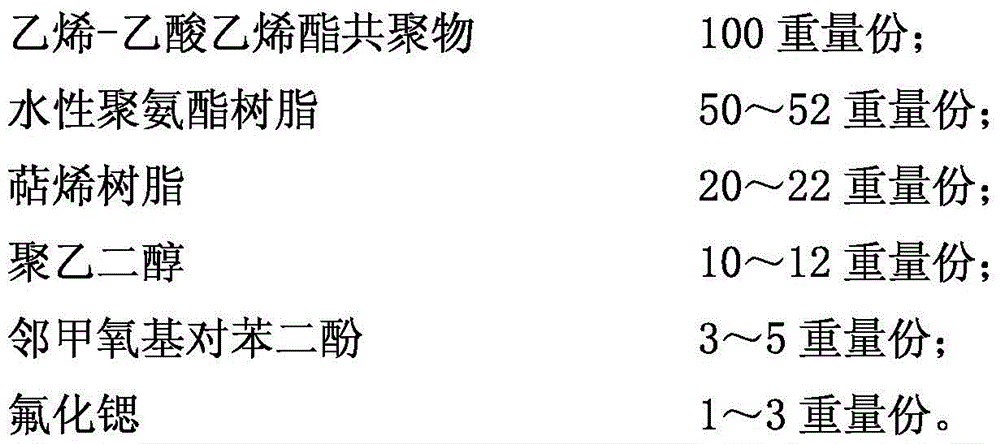

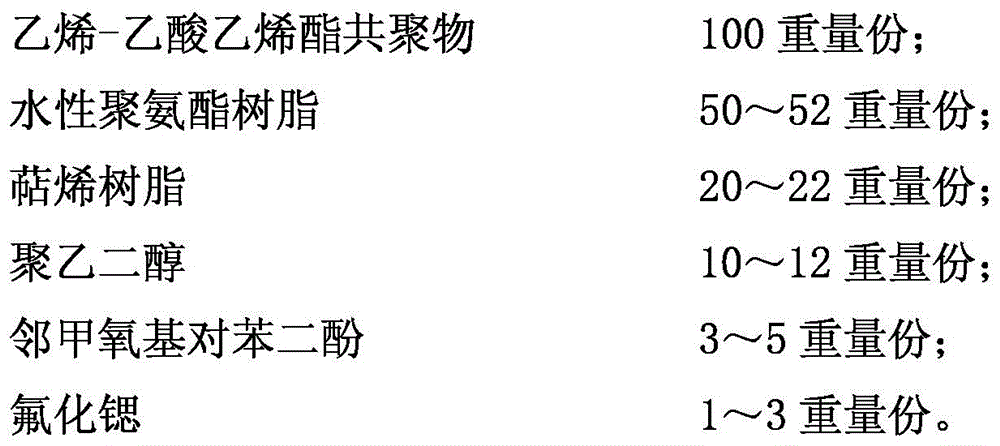

[0022] As the manufacturing method of the impact-resistant soft non-weft fabric of an embodiment of the present case, the method comprises the following steps:

[0023] Step 1) Dip the uniformly laid fiber filaments into the glue tank containing the adhesive, lay the dipped fiber filaments on the surface of the release material, and send the fiber filaments compounded with the release material to the coil The system is drawn into the drying equipment for drying, and then rolled to obtain a rolled single-fiber layer containing glue;

[0024] Step 2) Take two rolls of adhesive single-fiber layers, peel off the release material of the adhesive single-fiber layers, heat-compress the stripped two rolls of adhesive single-fiber layers at a relative angle of 45-90°, and collect Roll, obtain double-layer composite fiber layer; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com