Preparation method for strontium fluoride optical material with composite structure

A technology of optical materials and composite structures, applied in active medium materials, lasers, laser parts, etc., can solve problems such as the research results and literature reports of strontium fluoride optical materials with unseen composite structures, so as to alleviate thermal effects and improve thermal conductivity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation process of powder raw materials: Using strontium nitrate and potassium fluoride reagents as raw materials, chemical precipitation method is used to synthesize SrF in aqueous solution 2 The suspension is centrifuged-washed-dried-grinded to obtain SrF 2 Powder. Then, weigh 10 gSrF 2 Powder, 0.5 g neodymium fluoride (NdF 3 ) Powder, mix the two powders in an alcohol solution, put the suspension in an ultrasonic cleaner for 30 minutes, and then dry-grind again to obtain SrF 2 -NdF 3 (5wt.%) Mixed powder.

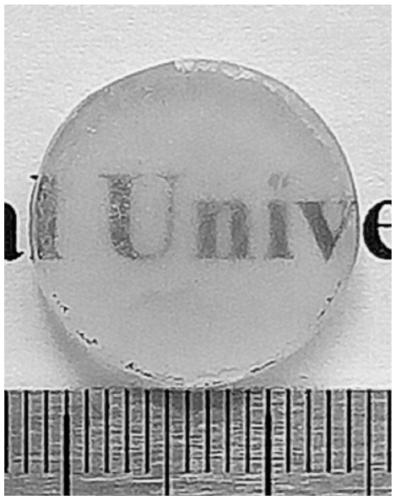

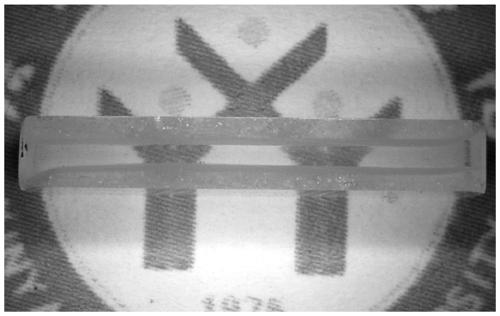

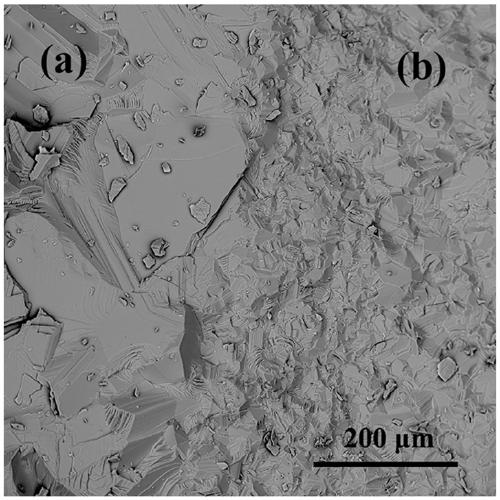

[0026] 2) The forming process of the composite structure blank: load 1.0 g SrF into the stainless steel mold 2 Powder, apply a pressure of 20 MPa to the steel mold and hold the pressure for 5 minutes; fill the mold with 1.0 g SrF 2 -NdF 3 (5wt.%) Mix powder, apply 20 MPa pressure to the steel mold, and hold the pressure for 5 min; load 1.0 g SrF into the mold 2 For powder, apply a pressure of 20 MPa to the steel mold and hold the pressure for 5 min; put the pr...

Embodiment 2

[0031] 1) Preparation process of powder raw materials: Using strontium nitrate and potassium fluoride reagents as raw materials, chemical precipitation method is used to synthesize SrF in aqueous solution 2 The suspension is centrifuged-washed-dried-grinded to obtain SrF 2 Powder. Then, weigh 10 gSrF 2 Powder, 1.0 g of ytterbium fluoride (YbF 3 ) Powder, mix the two powders in an alcohol solution, put the suspension in an ultrasonic cleaner for 30 minutes, and then dry-grind again to obtain SrF 2 -YbF 3 (10 wt.%) mixed powder; use the same method to get SrF 2 -YbF 3 (5 wt.%) Mixed powder.

[0032] 2) The forming process of the composite structure blank: Put 0.8 g SrF into the stainless steel mold 2 Powder, apply a pressure of 10 MPa to the steel mold, hold the pressure for 1 min; put 0.8 g SrF into the mold 2 -YbF 3 (5 wt.%) Mixed powder, apply a pressure of 10 MPa to the steel mold, hold the pressure for 1 min; put 0.8 g SrF into the mold 2 -YbF 3 (10wt.%) Mix powder, apply a p...

Embodiment 3

[0036] 1) Preparation process of powder raw materials: Using strontium nitrate and potassium fluoride reagents as raw materials, chemical precipitation method is used to synthesize SrF in aqueous solution 2 The suspension is centrifuged-washed-dried-grinded to obtain SrF 2 Powder. Then, weigh 10 gSrF 2 Powder, 0.2 g of erbium fluoride (ErF 3 ) Powder, mix the two powders in an alcohol solution, and place the suspension in an ultrasonic cleaner for 30 minutes, then dry and grind again to obtain SrF 2 -ErF 3 (2 wt.%) mixed powder; use the same method to get SrF 2 -ErF 3 (5 wt.%), SrF 2 -ErF 3 (10 wt.%) Mixed powder.

[0037] 2) The forming process of the composite structure blank: 0.5 g SrF is loaded into the stainless steel mold 2 Powder, apply a pressure of 5MPa to the steel mold, hold the pressure for 10 minutes; put 0.5 g of SrF into the mold 2 -ErF 3 (2 wt.%) Mix the powder, apply a pressure of 5MPa to the steel mold, and hold the pressure for 10 minutes; put 0.5 g of SrF in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com