A kind of coarse grain strontium fluoride and its preparation method

A technology of coarse-grained, strontium fluoride, applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., can solve the problem of fine particles, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Add 21 liters of 10% strontium chloride solution in the synthesis reactor with stirring. 1.6 kg of 40% hydrofluoric acid solution was gradually added under stirring, and the addition was completed within 2 hours. After the feeding is completed, stop stirring, insert the air guide tube, and pass through the air guide tube into ammonia gas diluted 12 times with air. Pass ammonia until the pH value of the feed liquid reaches 7.8. The whole ventilation time is 4h. The consumption of ammonia is 0.8 kilogram. After the ammonia passing is completed, the material is moved to the suction filter tank for suction filtration, and washed with pure water until the chlorine radicals meet the requirements. Take out the wet product of strontium fluoride and dry it at 110~120℃ for 3h. Then heat up to 180-190°C and dry for 1 hour to obtain 1.85 kg of finished product. Content 99.9%.

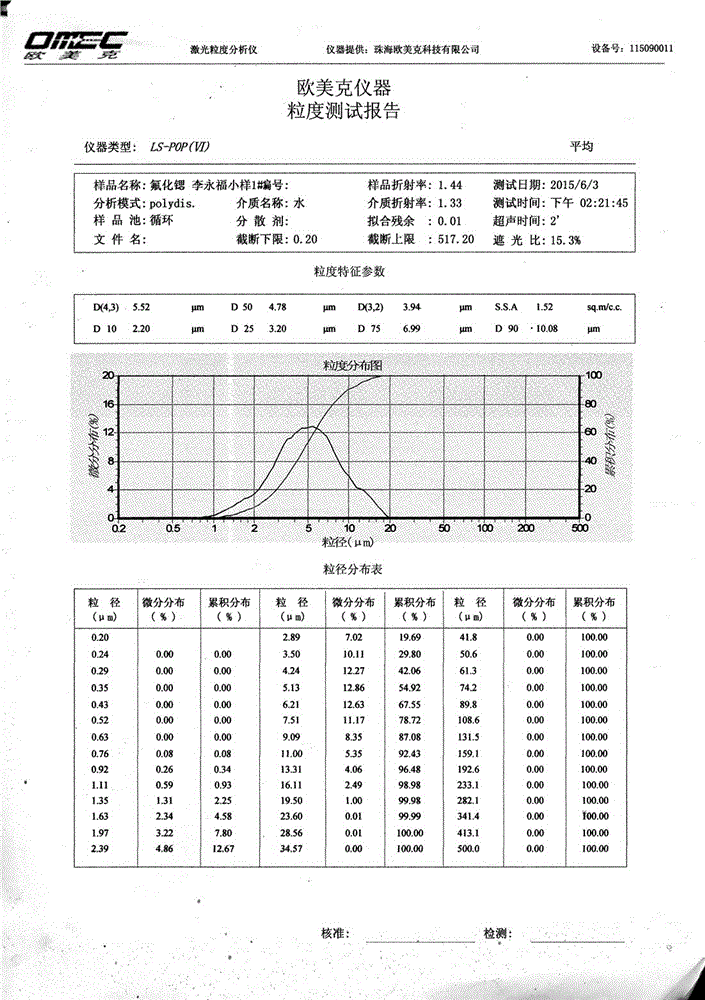

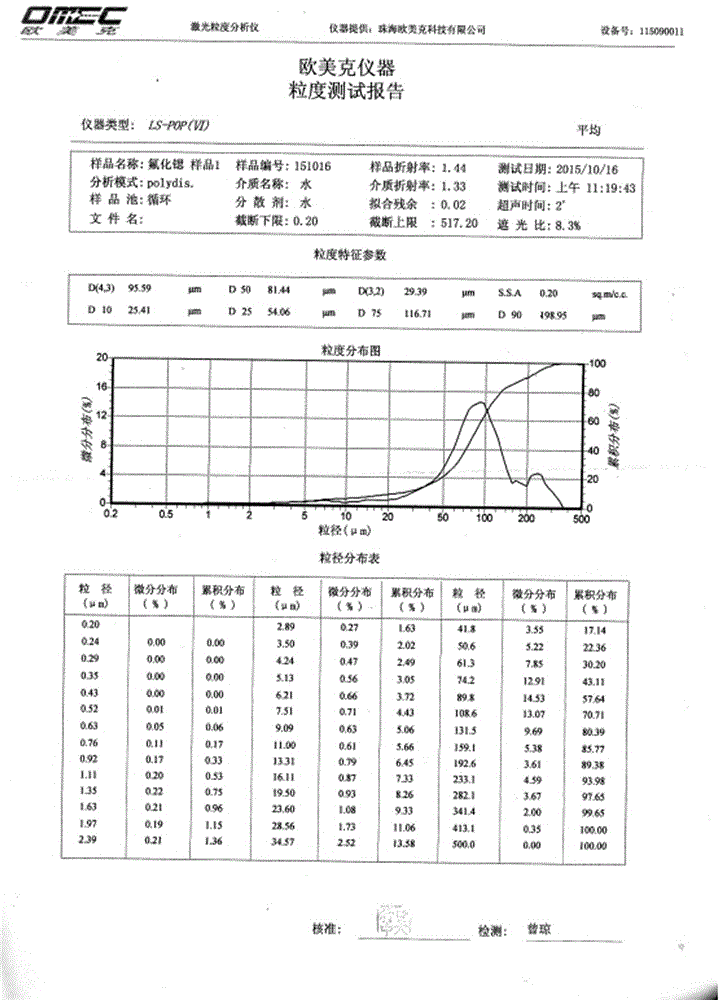

[0027] The above products were tested figure 2 ,Compared figure 2 and figure 1 I...

Embodiment 2

[0028] Embodiment 2: Add 21 liters of 10% strontium chloride solution in a synthetic reactor with stirring. 2.0 kg of 32% hydrofluoric acid solution was gradually added under stirring, and the addition was completed within 3 hours. After the feeding was completed, the stirring was stopped, an air guide tube was inserted, and ammonia gas diluted 8 times with air was introduced through the air guide tube. Pass ammonia until the pH value of the feed liquid reaches 7.6. The whole ventilation time is 3h. The consumption of ammonia is 0.86 kilograms. After the ammonia passing is completed, the material is moved to the suction filter tank for suction filtration, and washed with pure water until the chlorine radicals meet the requirements. Take out the wet product of strontium fluoride and dry it at 120~130℃ for 2.5h. Then heat up to 190-200°C and dry for 1 hour to obtain 1.80 kg of finished product. The content is 99.8%.

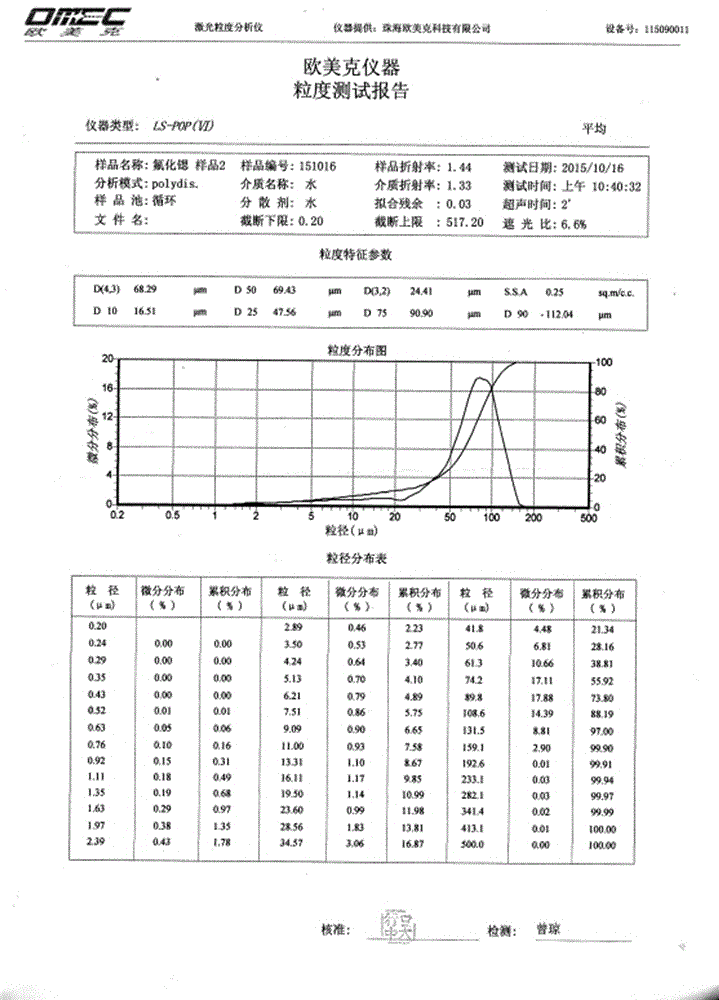

[0029] The above products were tested image 3 ,Compar...

Embodiment 3

[0030] Embodiment 3: Add 30 liters of 8% strontium chloride solution in the reaction synthesizer with stirring, gradually add 45% hydrofluoric acid solution under stirring, strontium in the strontium chloride solution and hydrofluoric acid in the hydrofluoric acid solution The ratio of the amount of acid to substance is 1:2.2-2.5, and the hydrofluoric acid solution is added in 1.5 hours. After the addition is completed, the diluted ammonia gas with a concentration of 20% ammonia is introduced until the pH is 8.0, and the aeration time is 2 hours. After the ammonia passing is completed, the material is transplanted into the suction filter tank for suction filtration and washed with pure water, and the wet product of strontium fluoride is taken out and dried at 130-140°C for 2 hours, and then heated to 200-220°C for 0.75 hours to obtain the product , The particle size inspection of the product shows that more than 70% of the products have a particle size between 50 and 150 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com